4

|

nVent.com/ERICO

Installation and Operating Instructions

• Transient protection devices are usually rated to protect

against non-repetitive pulses from sources such as direct or

induced lightning energy.

• They are not designed to provide protection against repeated

cyclic anomalies such as those caused by motor speed

control notching (variable speed controls, etc).

• SRFs are not designed to provide protection against

sustained over-voltage conditions where the supply voltage

exceeds, for an extended period of time, the nominal rating of

the protection equipment. i.e continuous over-voltages from

poorly regulated generators or distribution systems.

• Smaller power generation equipment does not always

conform to the same standards of voltage regulation that

is in place for mains power reticulation. A large number of

smaller or cheaper generators have a voltage waveform that

approximates 240Vrms (often poorly regulated), but more

importantly, which often contains significant higher order

harmonics and may exhibit a peak voltage on each half cycle

far in excess of the normal 340V (peak). Such machines

are usually capacitive excitation induction generators, as

opposed to synchronous generators. The problem is usually

increased when the generator is lightly loaded.

• Harmonic voltages may also be present in distribution

systems that do not feature generators. This is normally

where non-linear loads are used, such as UPSs, rectifiers,

switch-mode power supplies and motor speed controls. The

harmonic voltages may have peak voltages in excess of the

protective clamping voltages, causing problems such as

excessive heat build up. Because the harmonic waveforms

contain higher order frequencies, capacitive leakage currents

may increase to above prescribed limits and shorten the

life of the SRF. It should be noted that in sites with large

harmonic voltage distortion, the SRF capacitance may

dramatically affect the power factor.

• Seek the manufacturers ' advice before installing any SRF

into a circuit which features a total harmonic voltage ratio

above 5%.

• With large transients, significant energy may be passed by

the SRF diverters back to the source or to earth. This may,

under some circumstances, cause upstream earth leakage

circuit breakers or residual current devices (ELCBs & RCDs)

to nuisance trip. Where possible, these devices should be

installed after the SRF in order to reduce this possibility.

• Transient protection devices often have minimum

requirements for upstream fusing to ensure proper operation.

See section 6.1 for fusing requirements.

• By-pass switches are not recommended to be used with

SRFs as they compromise the protection offered. The

connection of the by-pass switch compromises the input to

output separation requirement by bringing the SRF input

and output wiring into close proximity at the switch.

3 INSTALLATION CAUTIONS

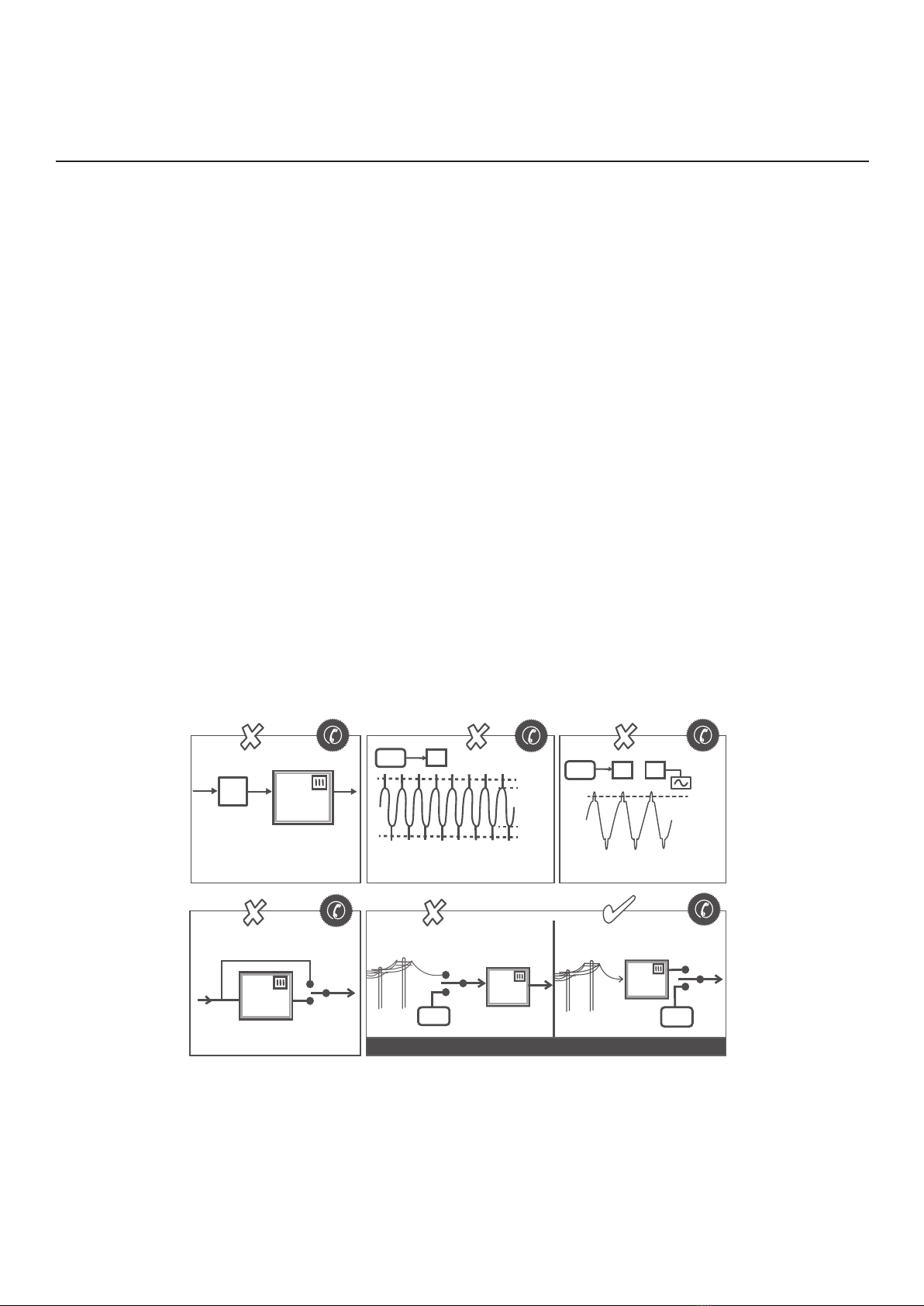

Figure 1. Seek specialist advice with the above installations.

SRF

SRF

SRF

SRF SRF

ELCB

or

RCD

NON PREFERRED NON PREFERRED PREFERRED

AVOID UPSTREAM EARTH LEAKAGE CIRCUIT BREAKERS

(ELCB’S) OR RESIDUAL CURRENT DEVICES (RCD’S)

BYPASS SWITCHES

BYPASS SWITCHES COMPROMISE PROTECTION

AVOID REPETITIVE VOLTAGES IN EXCESS OF SRF RATING AVOID HIGH HARMONIC VOLTAGES

276 Vrms

Or

276 Vrms

276 Vrms

240 Vrms

240 Vrms

GENERATOR

GENERATOR

GENERATOR GENERATOR

SRF SRF

MAINS / GENERATOR CHANGE OVER SWITCH CONNECTION