Flo-tech DK345-000 Setup guide

1

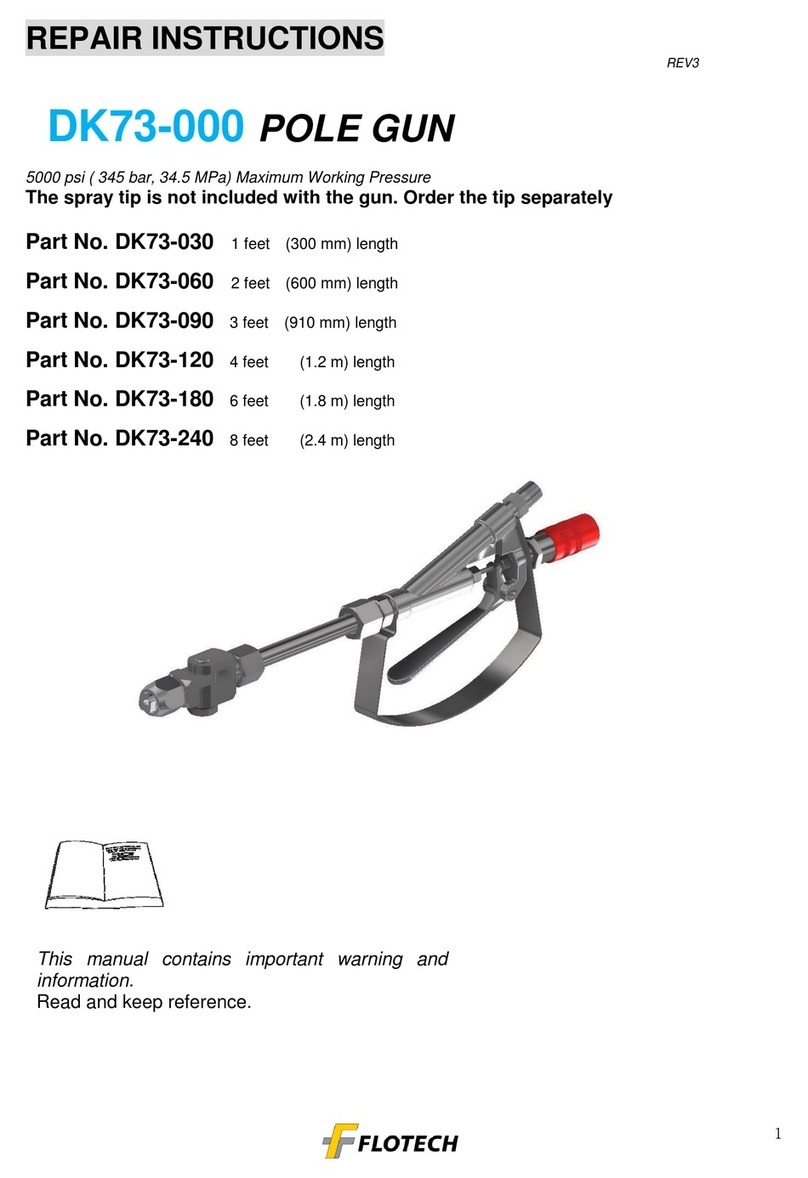

REPAIR INSTRUCTIONS

REV7

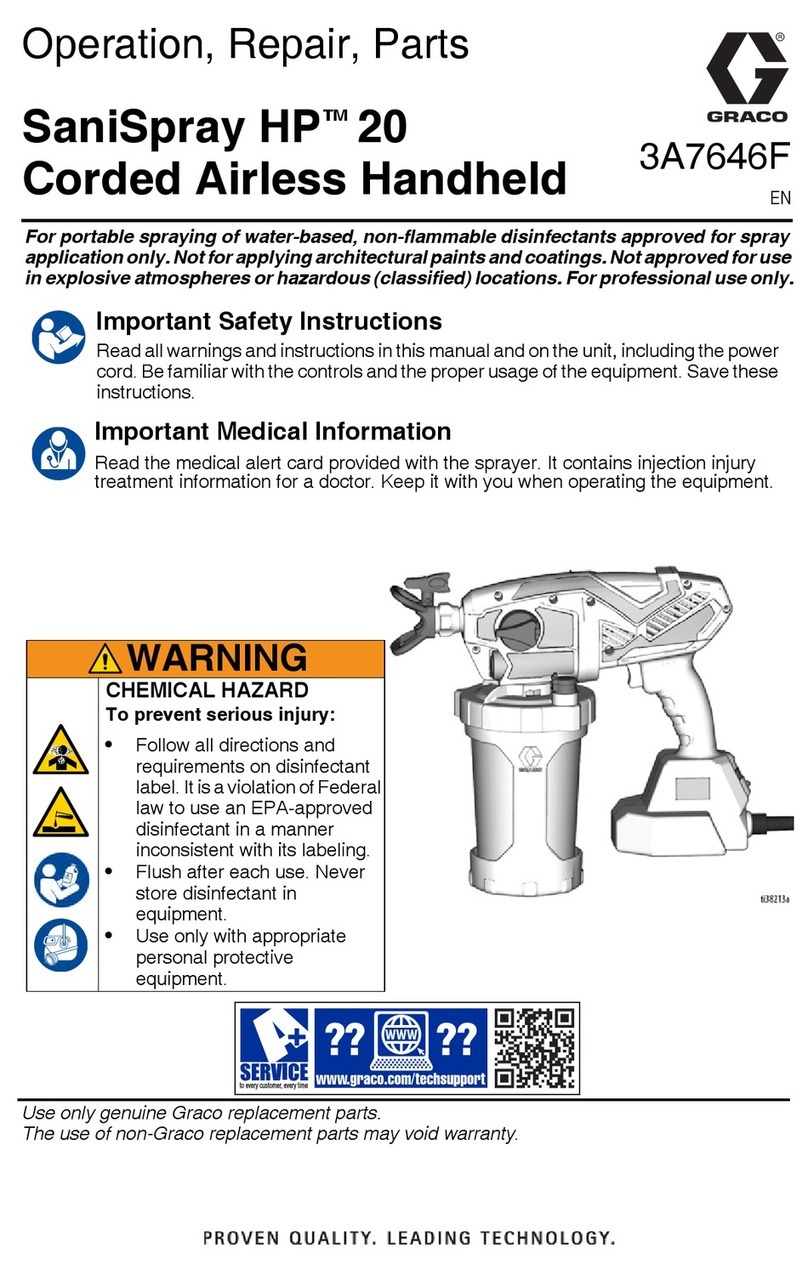

DK345-000 Airless Spray Gun

5000 psi ( 345 bar, 34.5 MPa) Maximum Working Pressure

This manual contains important warning and

information.

Read and keep reference.

2

WARNING

INJECTION HAZARD

Spray from the spray gun, hose leaks or ruptured

components can inject fluid into your body and

cause extremely serious injury, including the need for

amputation. Splashing fluid in the eyes or on the

skin can also cause can also cause serious injury.

_ Fluid injected into the skin is a serious injury. The

injury may look like just a cut, but it is a serious

injury. Get immediate medical attention.

_ Do not point the gun at anyone or any part of the

body.

_ Do not put hand or fingers over the spray tip.

_ Do not stop or deflect leaks with your hand, body,

glove or rag.

_ Do not “blow back” fluid; this is not an air spray

system.

_ Always have the tip guard on the spray gun when

spraying

_ Check the spray gun diffuser (if so equipped)

operation weekly. Refer to the gun manual.

_ Be sure the spray gun safety knob operates before

operating the gun.

_ Lock the spray gun safety knob when you stop

spraying.

_ Follow the Pressure Relief Procedure on page 3

when you are instructed to relieve pressure, stop

spraying, check, clean or service any system

equipment, or install or change spray tips.

_ Tighten all fluid connections before each use.

_ Check the hoses, tubes and couplings daily.

Replace worn or damaged parts immediately.

Permanently coupled hoses cannot be repaired.

_ Handle and route hoses and tubes carefully. Keep

hoses and tubes away from moving parts and

hot surfaces. Do not use the hoses to pull

equipment. Do not expose FLOTECH hoses to

temperatures

above 150_F (66_C) or below –40_F (–40_C).

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment

to rupture, malfunction, or start

unexpectedly and result in serious injury.

_ This equipment is for professional use only.

_ Read all instruction manuals, tags, and

labels before operating the equipment.

_ Use the equipment only for its intended

purpose. If you are uncertain about the

usage, call your distributor.

_ Do not alter or modify this equipment. Use

only genuine FLOTECH parts and

accessories.

_ Check the equipment daily. Repair or

replace worn or damaged parts

immediately.

_ Do not exceed the maximum working

pressure of the lowest rated system

component. This equipment as a 5000 psi

(345bar) maximum working pressure.

_ Do not lift pressurized equipment.

_ Route the hoses away from the traffic

areas, sharp edges, moving parts, and hot

surfaces. Do not expose FLOTECH hoses

to temperatures above 150_F (66_C) or

below –40_F (–40_C).

_ Do not use the hoses to pull the equipment.

_ Use fluids or solvents that are compatible

with the equipment wetted parts. See the

Technical Data section of all the

equipment manuals. Read the fluid and

solvent manufacturer’s warnings.

_ Fluid hoses must have spring guards on

both ends to protect them from rupture

caused by kinks or bends near the

couplings.

_ Comply with all applicable local, state and

national fire, electrical and other safety

regulations.

TOXIC FLUID HAZARD

Hazardous fluids or toxic fumes can cause a serious

injury or death if splashed in the eyes or on the

skin, inhaled, or swallowed.

_ Know the specific hazards of the fluid you are using.

_ Store hazardous fluid in an approved container.

Dispose hazardous fluid according to all local, state

and national guidelines.

_ Always wear protective eyewear, gloves, clothing

and recommended by the fluid and solvent

manufacturer.

FIRE AND EXPLOSION HAZARD

Improper grounding, poor air ventilation,

open flames, or sparks can cause a

hazardous condition and result in fire or

explosion and serious injury.

_ Ground the equipment and the object being

sprayed.

_ Provide fresh air ventilation to avoid the

buildup of flammable fumes from solvent

or the fluid being sprayed.

_ Extinguish all the open flames or pilot lights

in the spray area.

_ Electrically disconnect all the equipment in

the spray area.

_ Keep the spray area free of debris,

including solvent, rags, and gasoline.

_ Do not turn on or off any light switch in the

spray area while operating or if fumes are

present.

_ Do not smoke in the spray area.

_ Do not operate a gasoline engine in the

spray area.

_ If there is any static sparking while using

the equipment, stop spraying

immediately. Identify and correct the

problem.

MOVING PARTS HAZARD

Moving parts, such as the air motor piston and the

secondary pump lever and connecting rod area,

can pinch or amputate fingers.

_ Do not operate the equipment with the air motor

plates removed.

_ Keep your body and tools clear of any moving parts

when starting or operating the equipment.

3

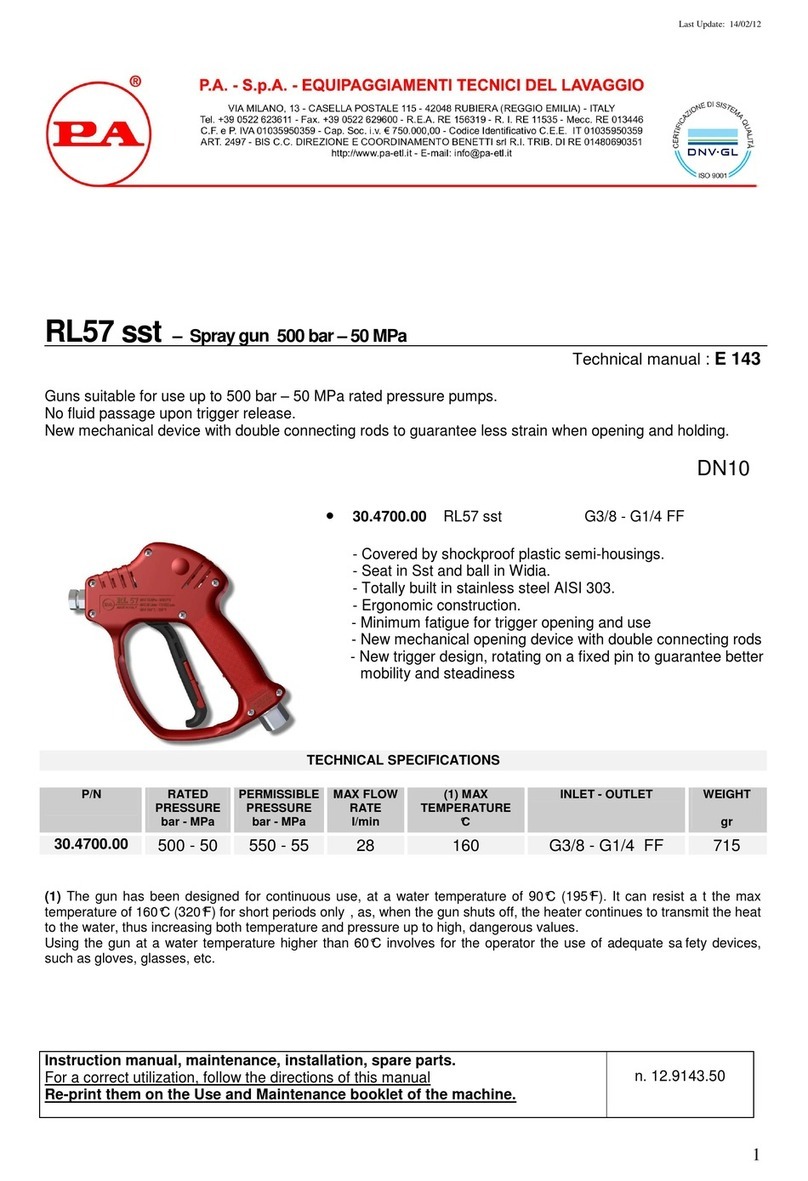

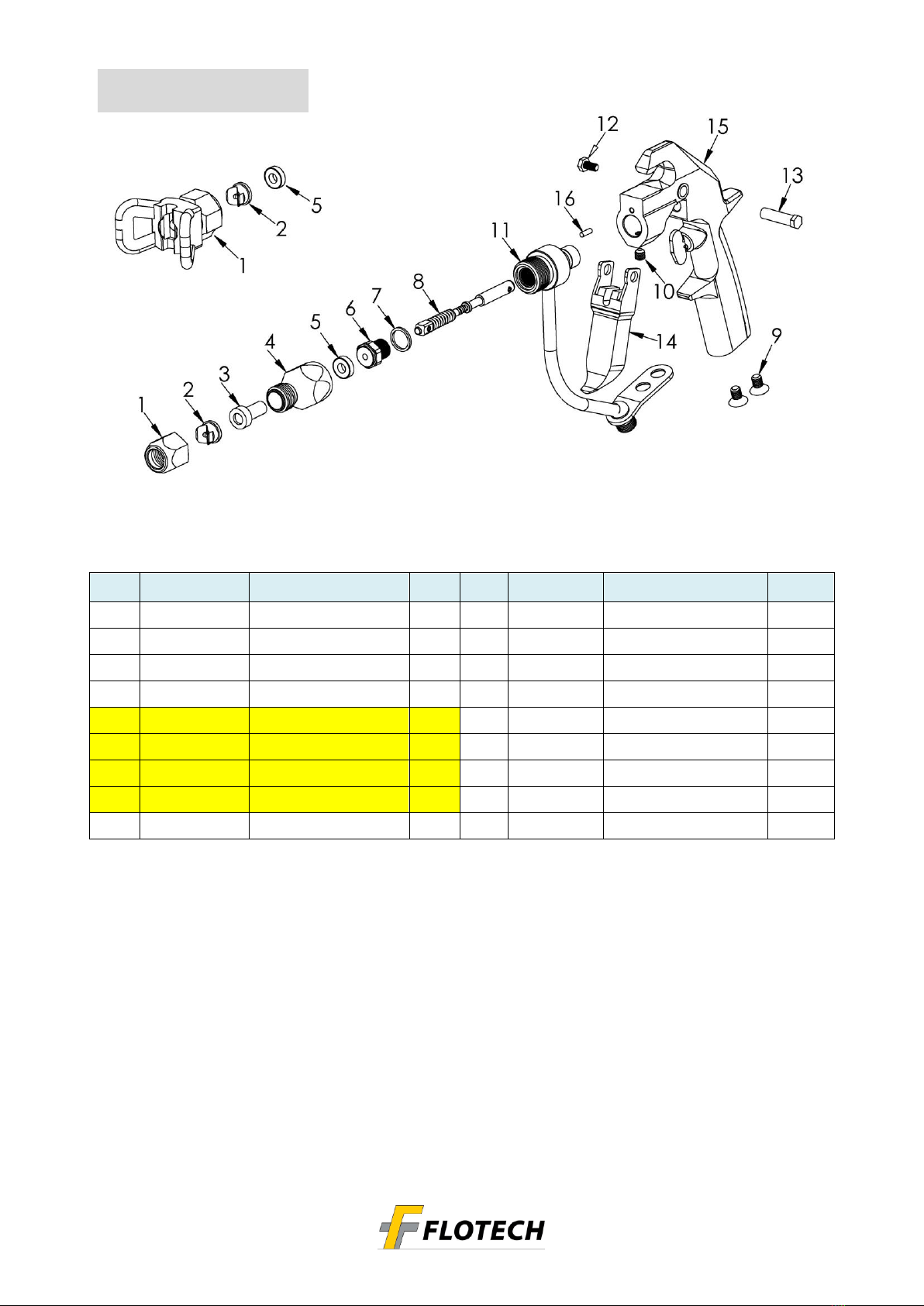

Parts draws

NO

Code

Description

Qty

No

Code

Description

Qty

1

DK345-01

TIP, Guard

1

10

DK345-10

Set Screw

1

*2

G269xxx

TIP

1

11

DK345-11

Fluid Housing

1

*3

DK-KS1060

TIP Filter

1

12

DK345-12

Screw

1

4

DK345-04

TIP Filter Housing

1

13

DK345-13

Pivot Pin

1

5

DK345-05

Gasket

1

14

DK345-14

Trigger 2 Finger

1

6

DK345-06

Seat

1

15

DK345-15

Handle

1

7

DK345-07

Gasket, copper

1

16

DK345-16

Spring Pin

1

8

DK345-08

Needle ass’y

1

9

DK345-09

Screw

2

Note : part marked * are the option parts

Replacement Danger and Warning labels, tags and cards

are available at no cost.

These parts are included in repair kit which may be purchased separately.

DK345-RK include item no 5,6,7,8

Always use genuine FLOTECH parts.

4

FLOTECH Standard Warranty

FLOTECH warrants all equipment referenced in this document which is manufactured by FLOTECH and bearing its name to be free from

defects in material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended,

or limited warranty published by FLOTECH, FLOTECH will, for a period of twelve months from the date of sale, repair or replace any part

of the

equipment determined by FLOTECH to be defective. This warranty applies only when the equipment is installed, operated and

maintained

in accordance with FLOTECH written recommendations.

This warranty does not cover, and FLOTECH shall not be liable for general wear and tear, or any malfunction, damage or wear caused by

faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or

substitution

of non–FLOTECH component parts. Nor shall FLOTECH be liable for malfunction, damage or wear caused by the incompatibility of

FLOTECH equipment with structures, accessories, equipment or materials not supplied by FLOTECH, or the improper design,

manufacture,

installation, operation or maintenance of structures, accessories, equipment or materials not supplied by FLOTECH.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized FLOTECH distributor for

verification of the claimed defect. If the claimed defect is verified, FLOTECH will repair or replace free of charge any defective parts. The

equipment will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect

in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor, and

transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING BUT

NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR

PURPOSE.

FLOTECH sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other

remedy (including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any

other incidental or consequential loss) shall be available. Any action for breach of warranty must be brought within six months of the

date of sale.

FLOTECH MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR

COMPONENTS SOLD

BUT NOT MANUFACTURED BY FLOTECH.These items sold, but not manufactured by FLOTECH (such as electric motors,

switches,

hose, etc.), are subject to the warranty, if any, of their manufacturer. FLOTECH will provide purchaser with reasonable assistance in

making

any claim for breach of these warranties.

In no event will FLOTECH be liable for indirect, incidental, special or consequential damages resulting from FLOTECH supplying

equipment

hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract,

breach of warranty, the negligence of FLOTECH or otherwise.

FLOTECH Information

TO PLACE AN ORDER OR FOR SERVICE, contact your FLOTECH distributor, or call these numbers to identify the nearest

distributor.

Other Flo-tech Paint Sprayer manuals