PLUMBING

There is 20 ft. (6.1 m) of 1/4 in. (6.35 mm) O.D. polyethylene tubing supplied with the FLOJET Bottled Water Dispensing

System. Carefully measure the distance between the pump module outlet and the appliance water inlet or optional

faucet, and cut the tubing clean and square to prevent tting leaks. If the refrigerator and faucet are being connected,

use 1/4 in. (6.35 mm) tube “T” tting and place it in an accessible location. Push the cleanly cut tubing end into the pump

module outlet port, past the o-ring to tube stop. Route tubing to the refrigerator water valve and connect it to the water

inlet valve in the back of the refrigerator by using the tube connector tting. First slip nut over the tube, then place the

ferrule over the tube, then install onto the refrigerator water valve tting and tighten.

For installation and use with commercial coffee and tea brewing equipment:

Many commercial coffee and tea brewing machines can be connected to a water supply line. Ensure that you have a 1/4

in. (6.35 mm) I.D. connection tting at the water inlet that can accept the supplied 1/4 in. (6.35 mm) O.D. tubing. These

brewing machines have a factory installed device that restricts incoming water to a safe pressure that won’t damage the

brewing machine. This device is usually referred to as an inlet pressure regulator or ow restrictor. If you intend to use the

Flojet BW system with one of these brewing machines, you should remove the brewing machine’s inlet restrictor device.

Consult the brewing machine manufacturer for details. Failure to remove the brewing machine’s restrictor may cause

the Flojet BW series pump to cycle itself off and on repeatedly, leading to premature motor failure of the Flojet BW unit.

This type of failure is not covered under warranty. Use of lter devices with your commercial brewer is unnecessary; see

below

For installation on refrigerators with ice making and/or water dispensing functions:

Do not use any external ltration devices. These will cause the pump to over-cycle, possibly causing premature pump

failure, not covered under warranty. If your refrigerator has factory installed internal ltration that must remain in place

as part of the water line, this too may cause over-cycling resulting in pump failure. Contact the refrigerator maker

and inquire about obtaining an empty or dummy lter housing for use instead of the standard lter model. If none is

available, the use of a small accumulator tank will be necessary. You may order Flojet P/N 30573002B, tank, and P/N

20381-064, tting kit. Please contact Flojet for more information.

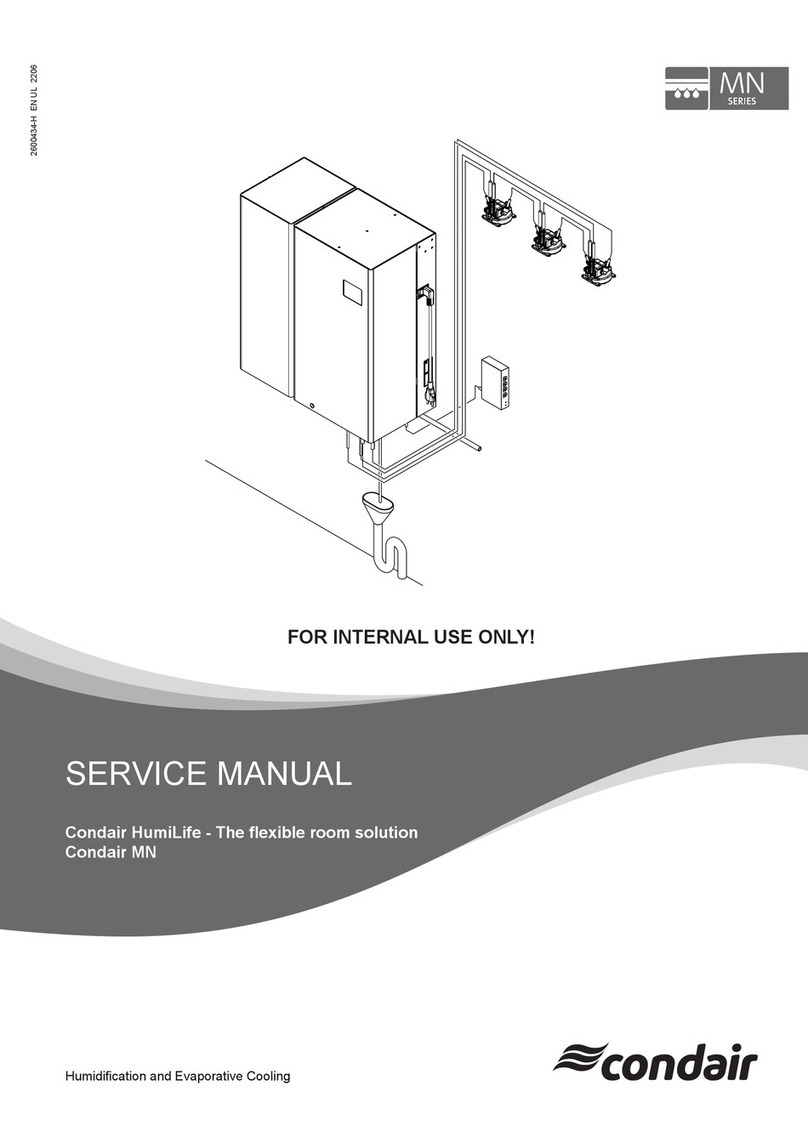

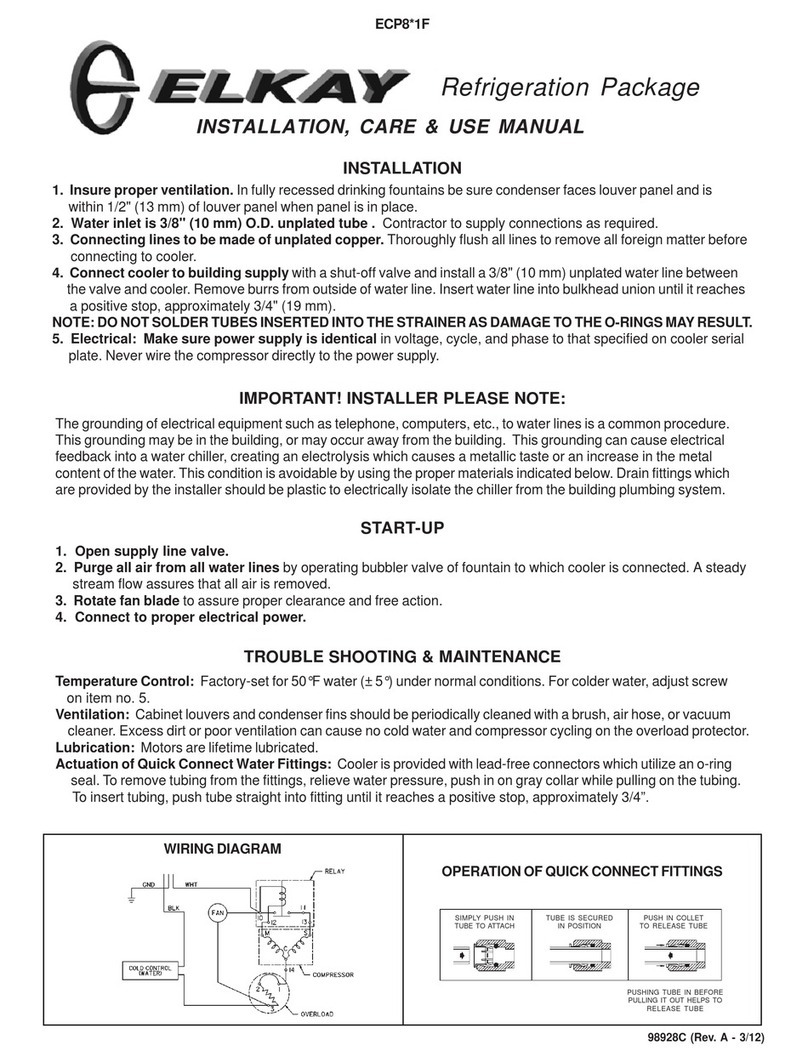

ELECTRICAL

WARNING: Risk of Electrical Shock!

Follow all local electrical and safety codes.

Make sure power source conforms to the voltage on the power adapter provided with the Bottled Water System.

CAUTION: DO NOT USE COPPER TUBING WITH ANY MODEL OF FLOJET BOTTLED WATER DISPENSING

SYSTEMS

WARNING:

• Observe accident prevention regulations in force.

• Use suitable equipment and protection.

• Always refer to the local and/or national regulations,legislation, and codes in force regarding

the selection of the installation site, plumbing, and power connections.

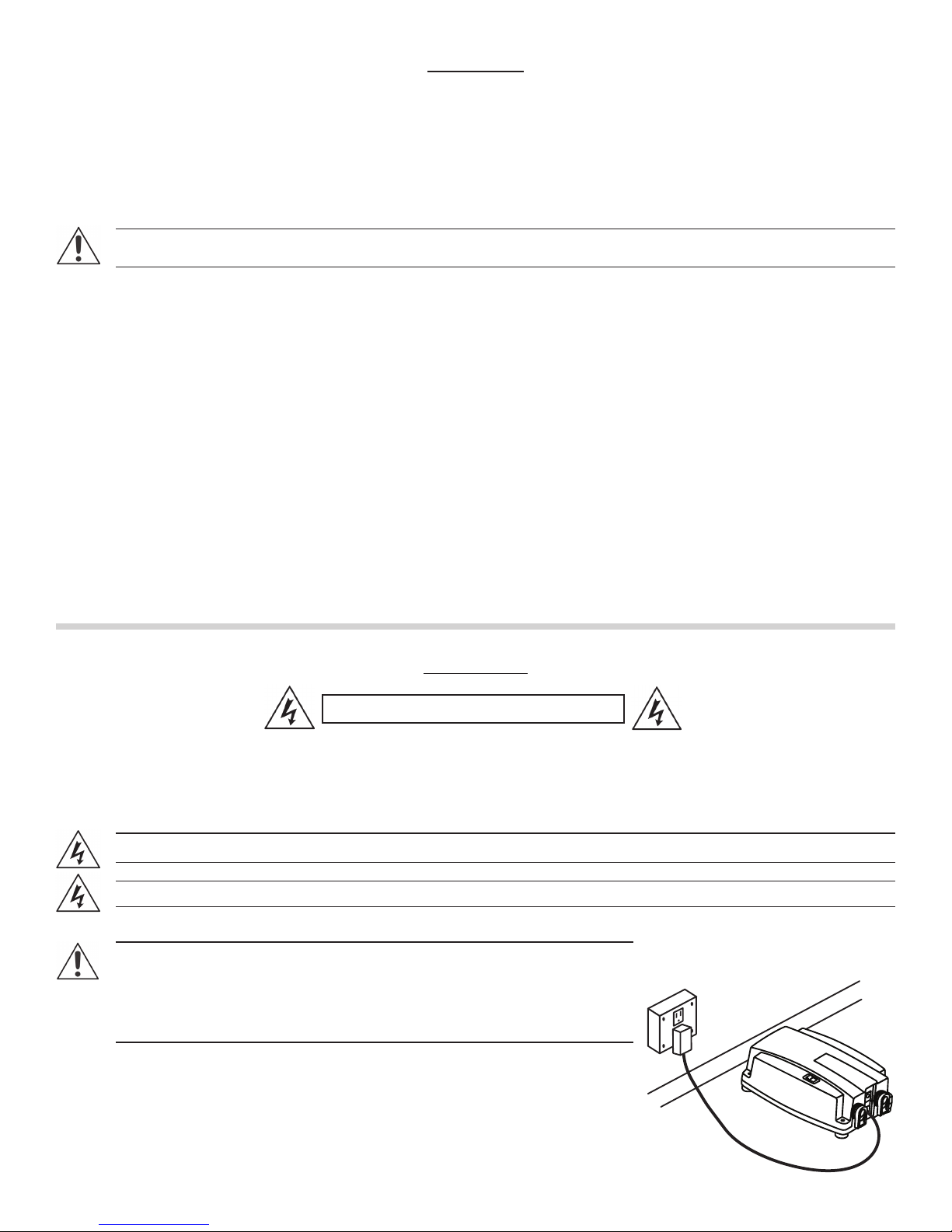

Electrical installation

Electrical Hazard:

Installation:

Electrical requirements:

WARNING: Make sure that all connections are performed by qualied installation technicians and in compliance with the regulations in force.

The local regulations in force overrule specied requirements listed below.

Electrical connection checklist

Check that the following requirements are met:

• The electrical leads are protected from high temperature, vibrations, and collisions.

• The current type and voltage of mains connection must correspond to the specications on the data plate on the pump.

WARNING: Before startingworkon the unit,makesurethat the unit andthe control panelare isolated fromthe power supplyand cannot be energized.

4