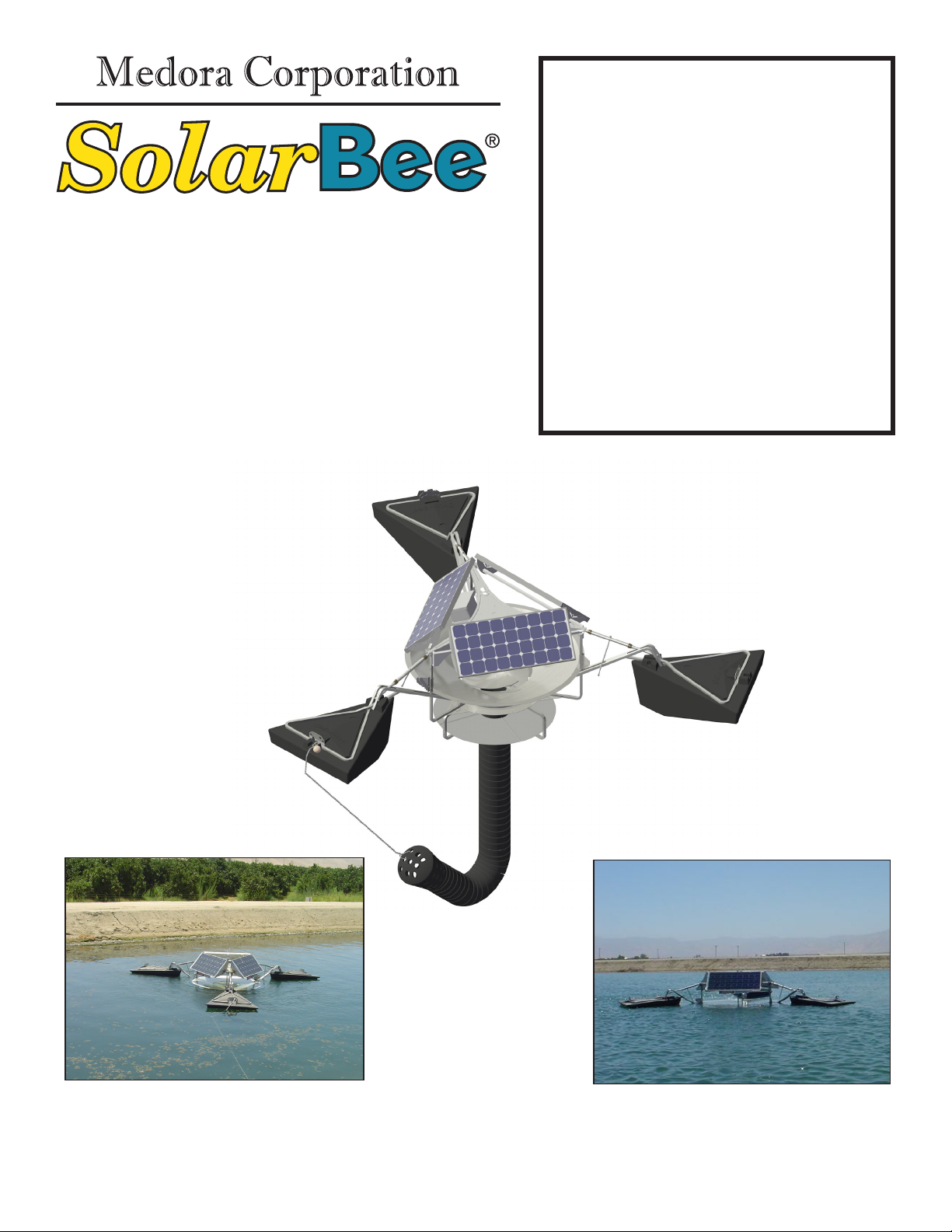

Medora SolarBee SB10000DM User manual

SB10000DM OWNER’S MANUAL

Contents

Safety Instructions ...............................

Introduction ..........................................

Operation and Features .......................

Maintenance and Field Adjustment ......

General Electrical Schematic ...............

Troubleshooting ...................................

Specications .......................................

Model Drawing .....................................

Overall Machine Dimensions ................

Parts Identication ...............................

Warranty Statement .............................

Removal Instructions ...........................

Storage Instructions .............................

Installation Instructions ........................

1

4

5

16

29

32

35

36

37

38

39

42

48

50

506_20161129

Medora Corp. • 3225 Hwy 22 • Dickinson, ND 58601

Ph +1 701 225 4495 • +1 866 437 8076 • Fax +1 701 225 0002 • www.medoraco.com

© 2017 Medora Corp. • Dickinson, ND

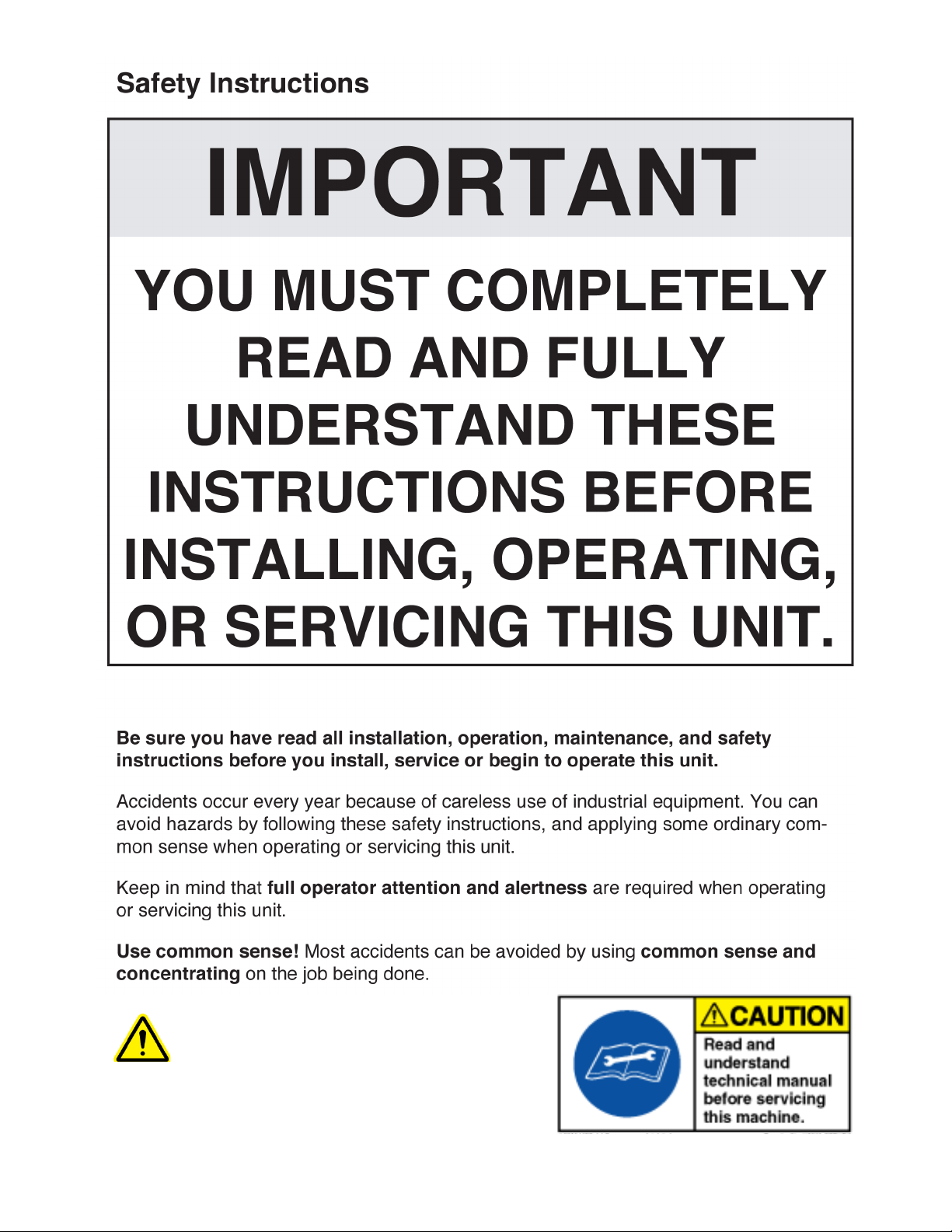

1

Carefully read safety information when you see

any safety symbols:

2

Safety

Rotating Equipment

CAUTION: KEEP BODY APPENDAGES

OR LOOSE CLOTHING AWAY FROM

THE IMPELLER ASSEMBLY WHILE THE

MACHINE IS OPERATING! IF MAINTENANCE

IS REQUIRED, BE SURE TO TURN THE

SOLARBEE OFF FIRST! WEAR PROTECTIVE

GLOVES AND BE CAUTIOUS OF SHARP

LEADING EDGES ON IMPELLER BLADES

WHILE CLEANING! FAILURE TO FOLLOW

THESE WARNINGS COULD LEAD TO INJURY!

---------------------------------------------------------------------------------------------------------------------------------------

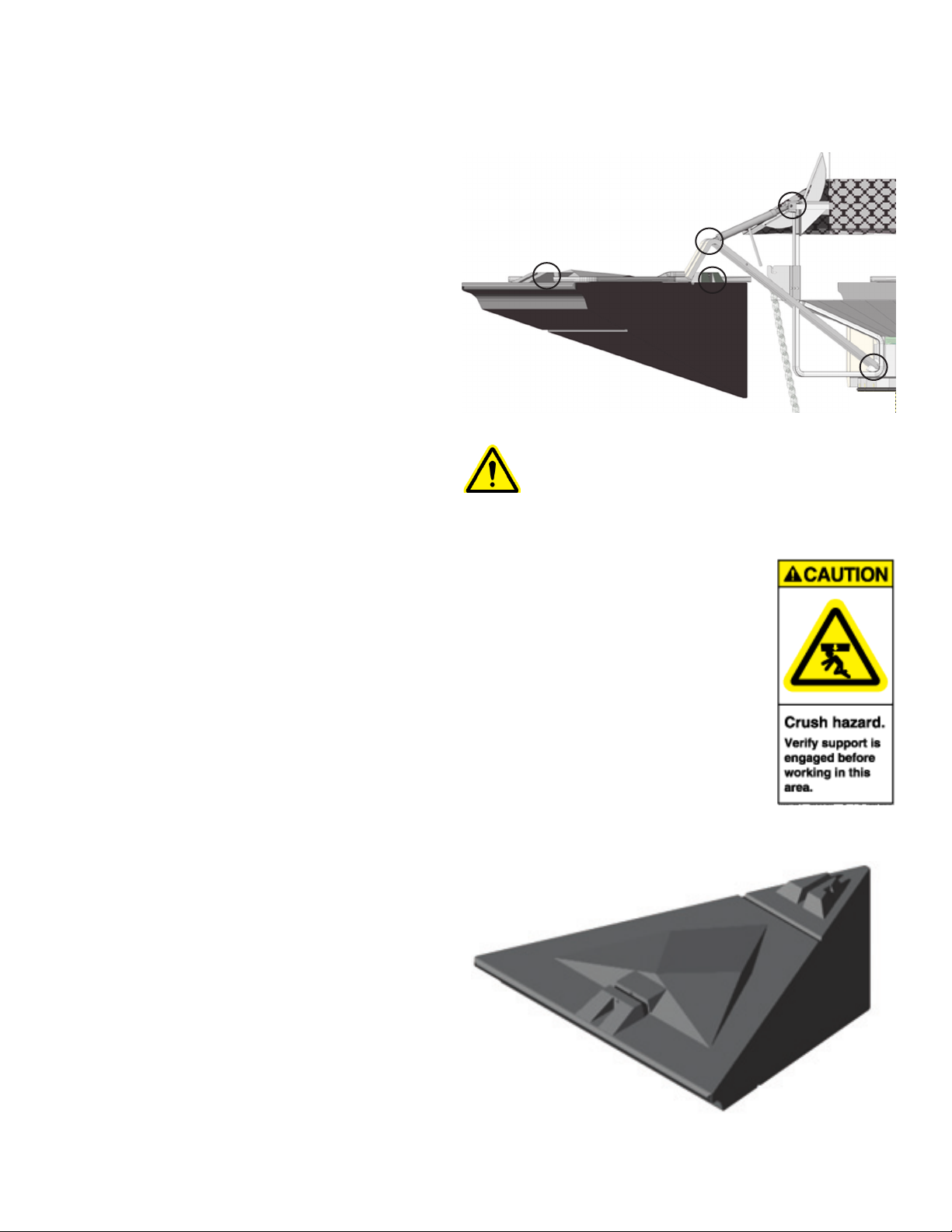

Crush Hazard

CAUTION: DO NOT REMOVE ANY FLOAT ARM OR TURNBUCKLE PINS

OR BOLTS WHILE THE SOLARBEE IS FLOATING IN THE WATER! THE

SOLARBEE MUST BE RESTING ON THE GROUND OR SAFELY SUPPORTED

TO RELIEVE THE FORCES ON THE FLOAT ARM AND TURNBUCKLE

STRUCTURES PRIOR TO DISASSEMBLY! FAILURE TO FOLLOW THIS

WARNING COULD LEAD TO SINKING THE SOLARBEE, OR CAUSE SERIOUS

INJURY!

Entanglement Hazard

WARNING: IF MOVING OR DEPLOYING

MOORING BLOCKS CONNECTED TO THE

ANCHOR CHAIN, BE SURE THAT YOU AND

OTHERS ARE CLEAR OF THE ANCHOR

CHAIN BEFORE SINKING THE MOORING

BLOCKS! LOWER THE MOORING BLOCKS

INTO THE WATER SLOWLY. FAILURE TO

DO SO COULD CAUSE SERIOUS INJURY OR

DEATH BY DROWNING!

---------------------------------------------------------------------------------------------------------------------------------------

THIN ICE HAZARD

WARNING: DURING WINTER CONDITIONS WHEN THE

SOLARBEE IS FROZEN IN OR PARTIALLY FROZEN IN,

THE MACHINE SHOULD NOT BE APPROACHED. THE

ICE AND SNOW AROUND THE SOLARBEE SHOULD NOT

BE ASSUMED TO SUPPORT WEIGHT. FAILURE TO DO

SO CAN RESULT IN SERIOUS INJURY OR DEATH BY

DROWNING OR HYPOTHERMIA!!!

3

Safety

Signage and Instuctions - The SolarBee is supplied with warning signage and instructions written

in the english language. It is very important that all operators and the public having access to the

SolarBee equipment be informed of the associated safety hazards. If English is not the dominant

language in the region, Medora Corporation strongly recommends that all warning signage and

instructions be translated to the dominant language.

For SolarBee machines installed into a public reservoir where there is open access to the machine, it

is strongly encouraged to properly notify the public of its presence. To avoid an injury or damage to

the equipment, the public should remain at least 5 meters away from the machine at all times.

Below is a sample public notication sign:

PUBLIC INFORMATION NOTICE

The _______ has installed SolarBee solar-powered high-flow long-distance circulation

equipment to improve the water quality and to enhance the recreational value of the lake.

Some facts about SolarBee SB10000DM / 10000 gpm Circulators:

• SolarBees come in various sizes, the largest unit

circulates 14 million gallons per day. The machine in

this lake circulates 14.0 million gallons per day.

• The machine runs during daylight & night hours entirely

powered by solar energy.

• SolarBee long distance water circulation helps:

o prevent lake water stagnation,

o control blue-green algae blooms,

o improve the lake ecosystem,

o provide a healthy environment for fish, frogs,

crayfish, and other aquatic organisms.

• SolarBee units have an expected life of 25+ years.

• More information on this technology is available at

www.medoraco.com

.

Help Us Keep the SolarBee Working.

Report vandalism, by calling:

______________

For your safety, and to help achieve the water quality goals for this lake, please do not go near the machines.

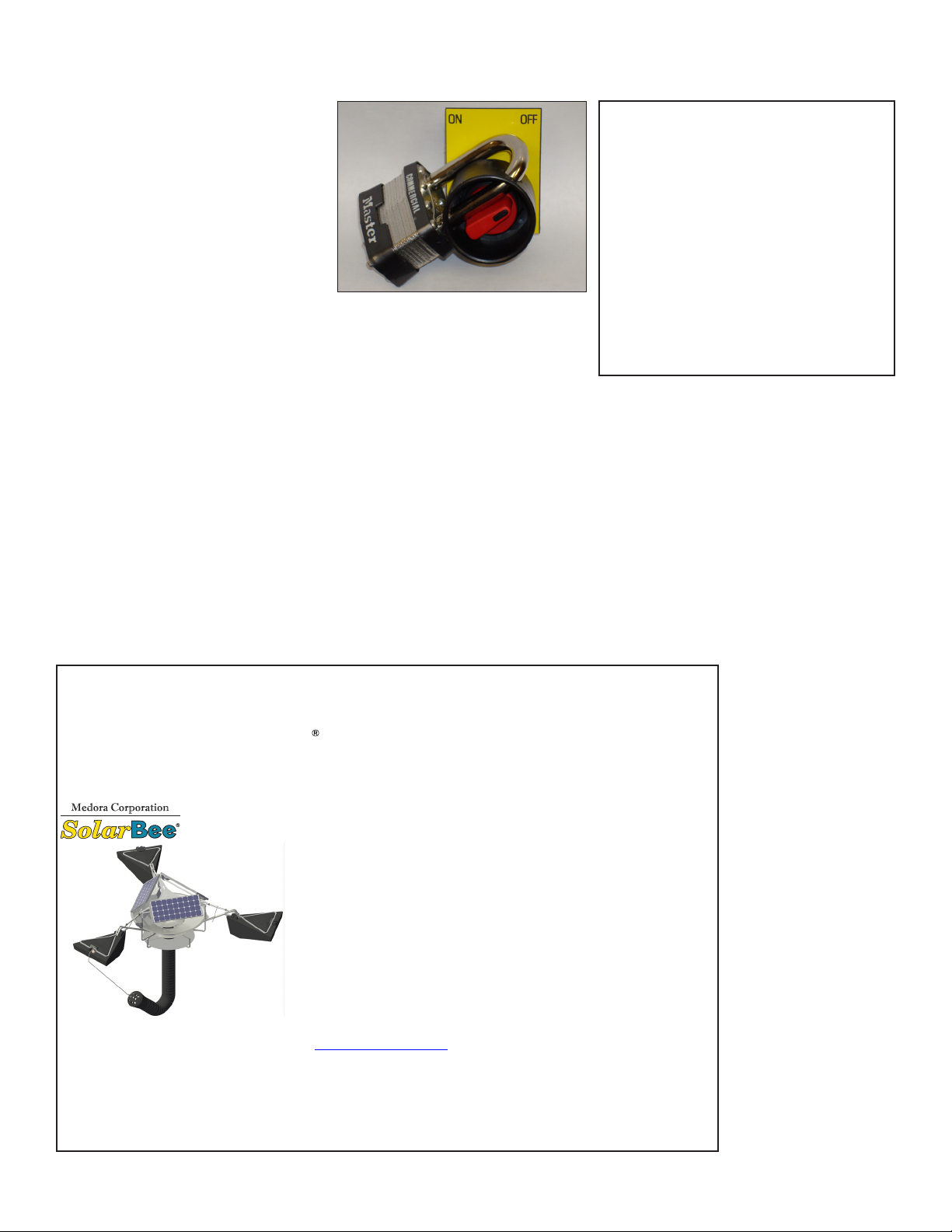

Lock Out - When the On/Off

switch is in the On position,

the SolarBee may start up at

any time. The SolarBee On/

Off switch can be locked out

by placing a pad lock through

the shroud of the switch while it

is in the Off position. The On/

Off switch is to be used as the

emergency stop.

EU Declaration of Conformity

Trade Name: SolarBee

Responsible Party: Medora Corporation

Address: 3225 Hwy 22

Dickinson, ND 58601 USA

Telephone: 1-866-437-8076

This equipment complies with:

• Machinery Directive 98/37/EC

• Noise Emissions of Outdoor

Equipment Directive 2004/14/EC

• Electromagnetic Compatibility Directive

(EMC) 89/336/EEC

4

Thank you for purchasing this SolarBee.

We trust that you’ll nd the SolarBee to be

very effective in treating your water. Every

SolarBee is tested and inspected at our

manufacturing facility before being delivered

to you. An experienced and trained Medora

Corp. eld team will deliver and install

your SolarBee. During the installation, the

eld team will present to you a summary

of the background, operation, and routine

maintenance of your SolarBee. They are

very helpful and willing to answer any eld

questions you may have.

The SolarBee has proven to be effective in a

variety of applications including wastewater,

stormwater, freshwater, potable water, salt

water, and many more. Research and

development continue to be a high priority

in order to provide you with the up-to-date

knowledge and best technology available for

your application. Extensive design efforts

have been made to make the SolarBee easy to

maintain with high quality, long life parts.

If at any time you feel that your SolarBee is not

operating at its full potential, feel free to contact

the main ofce where a knowledgeable Medora

Corp. service team is available to offer help.

There are methods of eld adjustment that may

be benecial following the installation. Our

service team will gather the latest information

on your application and combine it with their

experience to optimize the performance of your

SolarBee.

Technology Features

• Solar power achieving day/night operation

• Durable brushless motor

• Advanced controls system

- Scheduled-reverse, and anti-jam routine

- SCADA outputs, machine monitoring

- SD Card reprogrammable

- Seasonal RPM

• Robust frame and oat arm structures

• Swinging PV module gates

• PV modules with angle adjustment

• Quick detachable impeller

• Lower oating prole, improved aesthetics

• Smooth, quiet operation

Medora Corporation Factory And Delivery Fleet

5

The SolarBee is designed to circulate water

by bringing water from below and sending it

out across the top in a thin layer causing a

mixing effect. The laminar layer ows outward

radially, in diverging “stream lines” from the

distribution dish. As it does, vertical ow is

induced in between the water being drawn

below and the water above. At the level of the

ow intake, water is drawn from all corners of

the pond. As this lower layer of uid makes

its way inward with converging streamlines

to the SolarBee, the water is forced upward,

toward the surface, providing gentle mixing,

de-stratication, and surface renewal.

The SolarBee obtains all the energy it needs

from the sun. Its solar panels provide power

to the onboard battery which energizes the

drive system’s controls and motor. The new

Technology allows excess solar energy to be

stored during the day and used during the

night allowing the SolarBee to operate during

the night without being connected to the grid.

During operation, a visible ow can be

observed coming off the distributor dish

and spreading outward. The impeller of the

SolarBee is designed to operate at full speed

when there is sufcient sunlight and battery

charge. The rpms may drop down some

during the later night and early morning when

the battery uses up its charge after a longer

period of overcast days. In severe sunlight

limited conditions, the machine may slow

down or stop temporarily to protect the battery

from damage.

SB10000DM Flow Pattern

Operation

Flow Coming Off Distributor Dish

6

Features

The SolarBee with technology includes new

features which enhance its performance

through more efcient and durable

components, improved operation monitoring

capablilities, easy component access, and a

robust frame structure.

Solar / Electronics

Photovoltaic (PV) Modules -The PV modules

are often referred to as the solar panels. The

SolarBee uses 100% solar energy to provide

day/night operation. The PV modules collect

solar power to operate the machine with

excess left over to charge an onboard 12-volt,

deep cycle battery. The SolarBee has 3 80-

watt PV modules which individually connect to

the digital controller. A bird deterrent is located

directly above the PV modules to prevent bird

fouling.

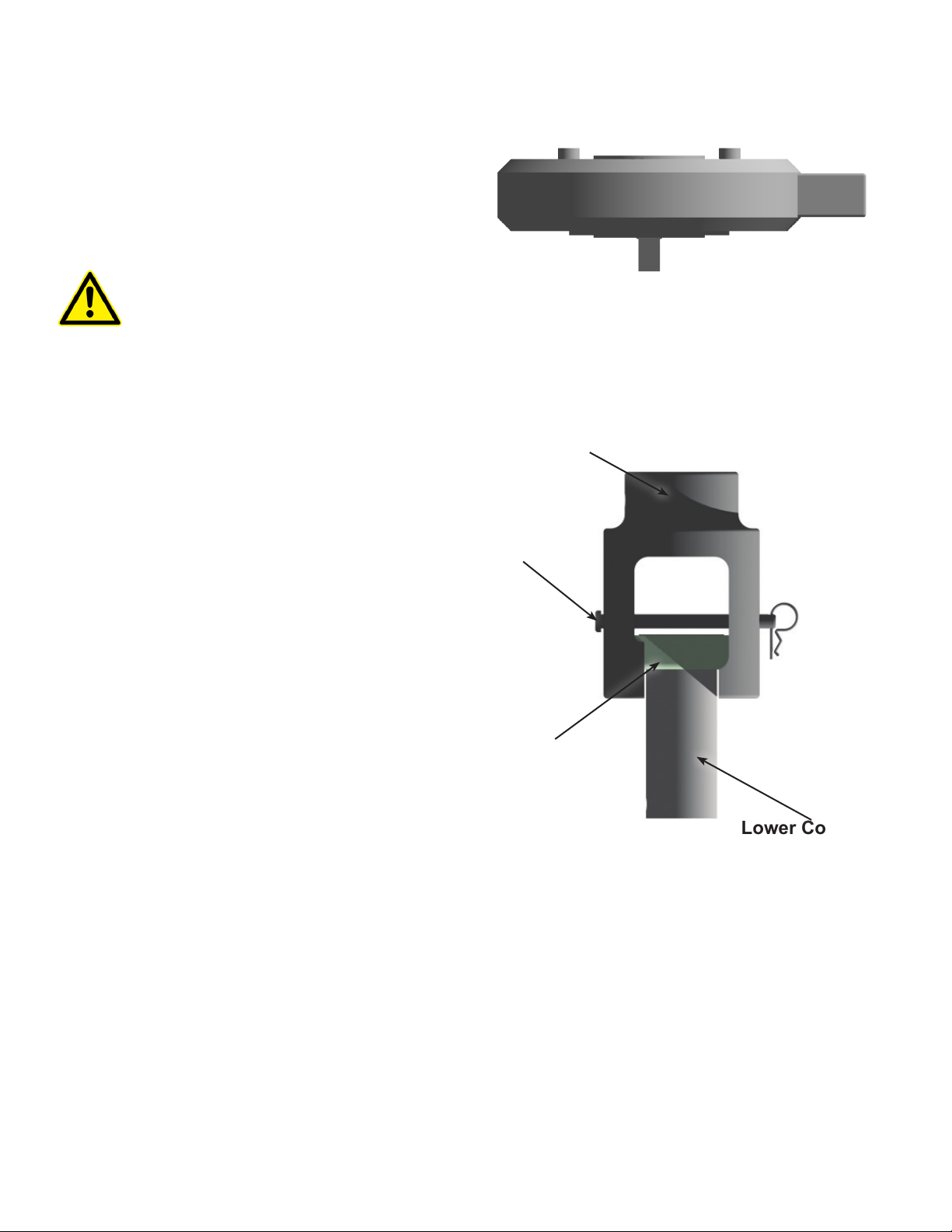

The PV modules have 3 angle settings

that are set at the factory based on solar

energy availability unique to the customer's

geographic location. The attest position is a

35 degree angle for customers located where

solar power availability is greatest. The mid-

range setting position is a 45 degree angle for

customers where solar power availability is

moderately available. The steepest position

is a 55 degree angle intended for winter

conditions to prevent snow and ice buildup

from lasting a long time period on the PV

modules (following winter conditions, the PV

modules should be returned to their original

position to maximize solar energy collection).

55 Degree

45 Degree

35 Degree

7

For cable tethered anchoring, the north facing

panel may be ipped to face the south using

a special panel gate. A tethered machine is

xed and will not rotate, so the north facing

panel will receive the least sunlight, unless

ipped using the special gate. For mooring

block anchoring, this is not an option due

to the machine rotating about the mooring

blocks.

Each PV module is xed to a gate that opens

up allowing quick access to the interior

components of the machine. Each gate opens

by simply removing a pin on the latch end.

Onboard Battery - The onboard battery is

located directly below the dish in a stainless

steel compartment. During operation,

the battery is submerged in the water to

maintain a stable-temperature environment

that increases its performance and life. The

battery is double-walled to isolate its contents

from the water it is submerged in.

The onboard battery stores excess power from

the solar panels during the day and operates

the machine using the stored power during the

night and extremely overcast days.

PV Module Gate

Hinge End

Latch End

Features

Battery

Compartment

Onboard Battery

8

Features

Digital Controller

PV Module

Gate Open

Front Face Of Digital Controller

Left Side Face Of Digital Controller

Digital Controller - The digital controller is

located near the top center of the SolarBee.

The digital controller can be easily accessed

by opening the PV module gate directly

above and in front of it. The digital controller

is constructed with a NEMA 4X (IP 66)

Enclosure.

All solar energy collection and motor operation

are managed by the digital controller. This

component has two primary functions: (1) To

direct and divide the power being collected by

the PV modules between the brushless motor

and battery. (2) To serve as the main control

center that operates the brushless motor.

There are 3 PV module connections located

on the front face of the digital controller. If

the onshore power accessory was purchase,

a connection will be located on the right side

face. The onshore connection is used only

in applications where onshore grid power is

desired.

The left side face of the digital controller

contains the brushless motor connection,

battery connection, and On/Off switch. The

On/Off switch activates power to the motor.

When the switch is turned to the Off position,

the motor will not operate. The charging

function of the controller will continue to

charge the battery even when the switch is

turned off.

9

Features

SCADA outputs offering machine operation

parameters reside within the digital controller.

Please contact Medora Corp. if you are

interested in receiving these parameters.

Motor Controller - The motor controller is

located near the motor just below the top plate

of the SolarBee. The motor controller is sealed

in line with the electrical cord that runs to the

brushless motor.

The motor controller on the SolarBee receives

power and signals from the main control center

located inside the external enlosure. These

signals are used to operate the brushless

motor at the commanded speed. The motor

controller also sends feedback signals back up

to the main control center.

Due to the high frequency of communication

between the motor controller and brushless

motor, the two components need to be located

close to one another. This is the primary

reason for having the motor controller located

directly on the SolarBee.

All electronic connections on the SolarBee

equipment should only be used for the inputs

or outputs that they are labeled and designed

for. If any of the leads going into the electronic

controller are disconnected, be sure when re-

connecting to place them in the proper position.

Wiring - All electric wiring includes corrosion-

resistant, industrial cords with molded, weather

and watertight connectors. The connectors are

indexed to prevent improper wiring. A general

electrical schematic can be found in the

Maintenance and Field Adjustment section.

SCADA Signal From SolarBee Unit

Durable Wiring And Connectors

10

Features

Upper Coupling

Lower Coupling

Coupling Sleeve

Clevis Pin

Brushless Motor / Impeller

Brushless Motor - The brushless motor is

located directly below the Top Deck. 4 bolts

run down through the Top Deck and into the

housing of the brushless motor fastening it

onto the machine.

CAUTION: THE BRUSHLESS MOTOR

WEIGHS APPROXIMATELY 80 LBS (36KG).

DO NOT REMOVE WITHOUT DISCUSSING

THE PROCEDURES AND EQUIPMENT

NECESSARY WITH A SOLARBEE SERVICE

TEAM MEMBER.

The brushless motor is built to be very

durable. The housing is constructed of casted

aluminum. The brushless motor runs very

quietly and smoothly. It does not require any

maintenance. A drive shaft extends through

the bottom center of the housing.

Shaft Coupling - The shaft coupling connects

the brushless motor drive shaft to the impeller

shaft. The shaft coupling is located directly

below the brushless motor and is made up

of 3 main components. These components

are called the upper coupling, lower coupling,

and coupling sleeve. The shaft coupling is

designed to allow quick disconnect for removal

of the impeller assembly. Disconnecting the

impeller shaft from the brushless motor shaft

is simply accomplished by pulling out a pin

and requires no tools. The upper coupling

remains attached to the brushless motor while

the lower coupling and coupling sleeve remain

on the impeller shaft.

Brushless Motor

11

Features

Impeller Assembly - The impeller assembly is

made up of the stainless steel impeller shaft,

stainless steel ag indicator, freeze sleeve,

stainless steel impeller blades, and plastic

impeller bushing. The impeller assembly is

easily removed by pulling a pin on the shaft

coupling.

CAUTION: KEEP BODY APPENDAGES

OR LOOSE CLOTHING AWAY FROM

THE IMPELLER ASSEMBLY WHILE

THE MACHINE IS OPERATING! IF

MAINTENANCE IS REQUIRED, BE SURE

TO TURN THE SOLARBEE OFF FIRST!

The ag indicator is xed to the shaft and used

as a visual indicator of the impeller shaft's

rotational speed.

A food grade oil-lled, Teon freeze sleeve

secured with o-rings surronds the impeller

shaft. The freeze sleeve is free to rotate on

the shaft. If the water should freeze around

the machine, the freeze sleeve will stand still,

frozen in by the ice, but inside the plastic

sleeve, the impeller shaft will be turning.

The impeller blades are welded to a hub that

is securely fastened to the impeller shaft. The

impeller is designed to gently pump water from

below and can handle up to 4-inch (10cm)

spherical solids.

The impeller bushing is a smooth collar that

the impeller shaft tip ts into. The impeller

bushing aligns and centers the impeller shaft

within the machine.

Turn SolarBee Off Before Performing Maintenance

Flag Indicator

Freeze Sleeve

Impeller Bushing Block

Impeller Blades

Impeller Hub

12

Features

Distributor Dish / Hose / Intake Plate

The distributor dish, structural members,

structural fasteners, and mounting brackets are

constructed of stainless steel.

Distributor Dish - Near-laminar ow is

achieved by the SolarBee due to its uniquely

designed distributor dish. The impeller

rotates while sitting within the lower half of the

distributor dish. There are also small water

passages located below the dish to strengthen

the induced ow effect (water movement

occuring between the lower water layer

entering the machine and the upper water layer

leaving the dish).

The top lip of the distributor dish is set

approximately 2- inch to 2.5-inch (5.1cm to

6.4cm) below the surface of the water to

achieve best ow results. The distributor dish

depth is set by rotating the turnbuckles located

on the oat arms.

Hose / Intake Plate - On the SB10000DM ,

the intake plate is directly below the distributor

dish and the hose extends down through the

intake plate. The Dual Mix design allows the

SolarBee to draw water from different depths.

Most of the water drawn into the SolarBee

enters above the intake plate. A small amount

of water is also drawn into the hose through the

strainer. The majority ow through the intake

plate circulates the top water column while the

smaller amount of ow through the hose slowly

processes the lower water column.

SB10000DM Intake And Hose Conguration

Distributor Dish

Strainer

Hose

Intake Plate

13

Float Arms / Floats

The SolarBee contains 3 oat arms and 3

oats. The oat arms allow vertical positioning

of the machine and the oats provide

buoyancy.

Float Arms - The oat arms are constructed

of stainless steel components. They connect

the oats to the central machine structure.

Each oat arm has a sturdy turnbuckle.

The turnbuckles can easily be rotated to

adjust the vertical height of the distributor

dish. Lengthening the turnbuckle (rotating

clockwise) will raise the lip of the distributor

dish, whereas shortening the turnbuckle

(rotating counter-clockwise) will cause the lip

of the distributor dish to lower.

The turnbuckle and oat arm structure

components are constructed with robust

stainless steel materials allowing the SolarBee

to operate in severe environments without

being damaged. The turnbuckle is self

locking. Simply rotate the handle to expand

or collapse the turnbuckle for dish depth

adjustment.

It is important to check the distributor dish

depth routinely. The SolarBee naturally

drops into the water over time due to biomass

buildup and trapped air escaping from the

hose. If the distributor dish lip is too high, the

water coming off the lip may become turbulent

and the ow rate of the machine may be

reduced.

Features

Turnbuckle

Float Arm

2-in to 2.5- in (5.1-cm to 6.4-cm)

Distance Between Distributor Dish And Water Level

Handle

14

If the distributor dish lip is too low, the water

coming off the lip will ow just underneath the

surface of the pond and the surface will not be

renewed.

Each oat arm is connected to the central

machine structure with 1 bolt and 1 pin. Each

oat is connected to the oat arm by 2 pins.

The turnbuckle can be removed from the oat

arm by pulling a pin, but should only be done

when the unit is resting on the shore.

If re-attaching the turnbuckle to the oat

arm, be sure that each threaded end of the

turnbuckle together are screwed all the way

in or all the way out before re-attaching. If

threaded ends are not equally expanded or

collapsed before xing the ends, the turnbuckle

will have limited adjustment.

Floats - The SolarBee has 3 oats, made from

high density Polyethylene. The oats are lled

with a Polystyrene closed-cell foam for long

term buoyancy. The oats have a uniquely

designed shape to:

• Minimize the interference with the water

ow on the surface coming off the

distributor dish.

• Have a low prole above the water for

minimizing wind resistance and

offering less exposure to vandalism.

• Avoid being crushed by ice pressure.

• Provide extra buoyancy when needed

without going much deeper into the

water.

Features

Float Arm Connection Points

Pin

Pin

Pin

Bolt

Pin

Float

CAUTION: DO NOT REMOVE ANY

FLOAT ARM OR TURNBUCKLE

PINS OR BOLTS WHILE THE

SOLARBEE IS FLOATING IN THE

WATER! THE SOLARBEE MUST

BE RESTING ON THE GROUND OR

SAFELY SUPPORTED TO RELIEVE

THE FORCES ON THE FLOAT ARM

AND TURNBUCKLE STRUCTURES

PRIOR TO DISASSEMBLY!

FAILURE TO FOLLOW THIS

WARNING COULD LEAD TO

SINKING THE SOLARBEE, OR

CAUSE SERIOUS INJURY!

15

Features

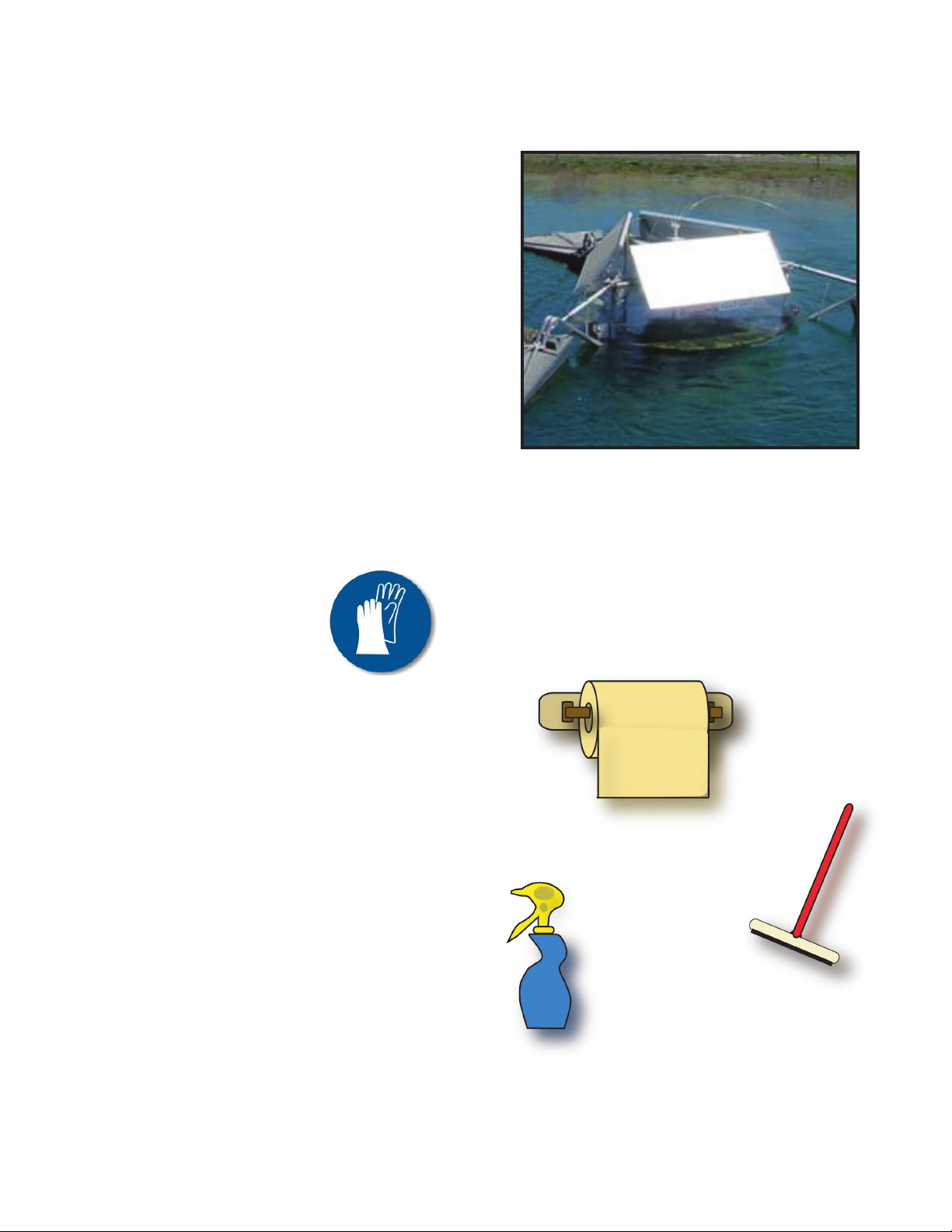

Mooring Blocks

Mooring Block System (7:1 Scope)

Anchoring Systems

The SolarBee uses one of the following

anchoring systems. The mooring block

system consists of submerged anchors

and doesn't require lines running from the

shoreline. The tethering system uses cable

that spans across the pond or reservoir

connecting to tethering posts on the shorline.

Mooring Block System - The mooring block

system consists of two mooring blocks made

of high density Polyethylene with smooth,

rounded bottoms. The smooth bottoms

prevent any damage being done to a pond

liner or reservoir bottom. The mooring blocks

are concrete lled and weigh approximately

70-lbs. (31.75 kg).

Stainless steel anchor chain is used to

connect the mooring blocks to the SolarBee at

the oat plate on one of the oats. The anchor

chain contains swivels approximately every

15-ft (4.5m) to prevent the chain from twisting

and tangling.

A 7:1 scope is generally preferred for the

length of anchor chain. For example, if the

pond is approximatley 10-ft (3m) deep, the

anchor chain will go from the rst mooring

block out 70-ft (21m) to the machine. The 7:1

scope prevents the machine from moving

during high wind and wave conditions. The

two mooring blocks are generally spaced

apart along the anchor chain by a distance

approximately the depth of the water. From

time to time, as determined by specic

circumstances, the scope can be reduced to

5:1.

Movement of machine - For a SolarBee anchored

by a mooring block system, the machine may

rotate 360 degrees around the mooring blocks on a

radius of approximately 5X to 7X the water depth.

For example, a machine that is in 10 ft (3m) of

water may travel on a 70 ft (21 m) radius from the

location of the mooring blocks

16

Features

Tethering System

Following severe weather conditions (greater

than 80-mph (129 km/hr) wind, higher than 4-ft

(1.2m) waves, or ice thaw), it is possible for

the SolarBee to drag the anchors and move

out of position. If this should happen, the pond

or reservoir operator will need to re-locate the

machine to its original position.

WARNING: IF MOVING OR DEPLOYING

MOORING BLOCKS CONNECTED TO THE

ANCHOR CHAIN, BE SURE THAT YOU AND

OTHERS ARE CLEAR OF THE ANCHOR

CHAIN BEFORE SINKING THE MOORING

BLOCKS! LOWER THE MOORING BLOCKS

INTO THE WATER SLOWLY. FAILURE TO

DO SO COULD CAUSE SERIOUS INJURY

OR DEATH BY DROWNING!

Tethering System - The tethering system

constists of 2 tether posts or duckbill anchors

set into the shoreline across from one another.

A stainless steel cable is strung across the

pond or reservoir and tied to both tether posts.

The SolarBee has 2 short chains running from

two of the oat plates on the machine out to the

cable line running across the pond or reservoir.

The tethering system is used in applications

where the body of water is very narrow or

the Mooring Block System is not applicable.

Following severe weather conditions (greater

than 80-mph (129 km/hr) wind, higher than 4-ft

(1.2m) waves, or ice thaw), it is possible for

the tether posts to pull partly or completely out

of the ground. If this should happen, the pond

or reservoir operator will need to re-locate the

machine to its original position.

Movement of machine - For a SolarBee anchored

by a tether system, the machine will have limited

movement, however slack will be left to allow for

water uctuation. The tether line slack will be

eld determined based on tether line span and

expected water uctuation. The SolarBee will not

rotate when it is anchored using the tether system.

17

Maintenance and Field Adjustment

SolarBee Orientation During Install

The performance of the SolarBee has

proven to increase tremendously when its

operator understands the operation of the

machine and knows how to carry out eld

adjustment procedures. During installation,

an experienced Medora Corp. eld team

thoroughly trains the operator on how to keep

the SolarBee performing at its best.

In most applications, it is strongly encouraged

that the operator have a boat to perform

routine checkups and eld adjustment

procedures on the SolarBee. A large,

expensive boat isn't necessary. Our Medora

Corp. eld teams use 12 ft (3.65m) Jon boats

that work ne for almost all applications.

It is extremely important that safety comes

rst every time the SolarBee is inspected or

having maintenance procedures performed. It

is strongly encouraged that anyone working on

or near the machine follow these rules:

Wear a personal oatation device

Stay focused and alert

Turn the SolarBee off before working on it

Stay clear of parts while they are moving

To turn the SolarBee motor off, turn the On /

Off switch to the off position. To completely

power down the digital controller, remove all

power sources in the proper sequence.

DIGITAL

CONTROLLER

ON / OFF

SWITCH

18

Maintenance and Field Adjustment

PV Module Cleaning

The solar panels are the SolarBee's primary

source of energy, so it is important that they

be kept clean. Over time, dust collects on the

PV modules or birds are not kept completely

off by the bird deterrent resulting in the panel's

effective surface area decreasing.

PV Module Cleaning

TOOLS RECOMMENDED:

Squeegee

Glass Cleaner

Paper Towel or Wash Cloth

STEP 1: Rinse panel face off with water.

STEP 2: Use squeegee, towel, or wash cloth to

clean surface of panel.

STEP 3: Remove any streaks or lms using

glass cleaner and paper towel/wash cloth.

STEP 4: Repeat Steps 1 through 3 for each

solar panel.

19

Maintenance and Field Adjustment

Solar Panel Angle Adjustment

The SolarBee technology includes tilting PV

modules to allow for optimal solar collection for

different geographical regions and changing

sun position during the seasons.

Use 35 Degree (Flattest Position):

Where - Locations south of 40 degree latitude.

When - During fall, summer, and spring or year

round if no adjustment is preferred.

OR

Where - Locations north of 40 degree latitude.

When - During summer only.

Use 45 Degree (Middle Position):

Where - Locations north of 40 degree latitude

(Especially Great Lakes Region and Canada).

When - During spring and fall or year round if

no adjustment is preferred.

OR

Where - Locations south of 40 degree latitude.

When - During winter

Use 55 Degree (Steepest Position):

Where - Locations north of 40 degree latitude.

When - During winter season or periods of

abundant snow (The steep angle will help

prevent snow from building up on the panels).

TOOLS RECOMMENDED:

Two 1/2" or 13mm wrenches

STEP 1: Loosen 2 bolts on each end of the PV

module using 1/2" or 13mm wrenches as shown in

the gure below.

Bolts

STEP 2: Firmly grip the PV module and slide it up

or down the tracks until it is in the desired position.

For each of the three recommended angle settings

listed, there is a slot in the top tracks at both ends

that the top bolt will drop into.

STEP 3: Once the PV module is in the desired

position, tighten all four bolts.

STEP 4: Repeat steps 1 through 3 for other two

solar panels

Bolts

Other Medora Water System manuals

Popular Water System manuals by other brands

Everpure

Everpure Opaque Housing A-20 20 Specification sheet

salmson

salmson Siriux Series Installation and starting instructions

Nikken

Nikken Aqua Pour operating manual

Everpure

Everpure Replacement Cartridge 7TO Specification sheet

oventrop

oventrop Regumaq X-25 operating instructions

Wayne

Wayne Jet Pump Water Systems Shallow Well Operating instructions and parts manual

Elkay

Elkay MFWSF100 Mounting instructions

Naked

Naked NKD-R Installation & start?up guide

HYDRO GUARD

HYDRO GUARD LongNeck Standard HG-31 User's operation manual

Addie Water Systems

Addie Water Systems OXIDIZER PLUS owner's manual

J.E. Adams

J.E. Adams 9730 manual

ABANTERA

ABANTERA Neo GreenWashing user manual