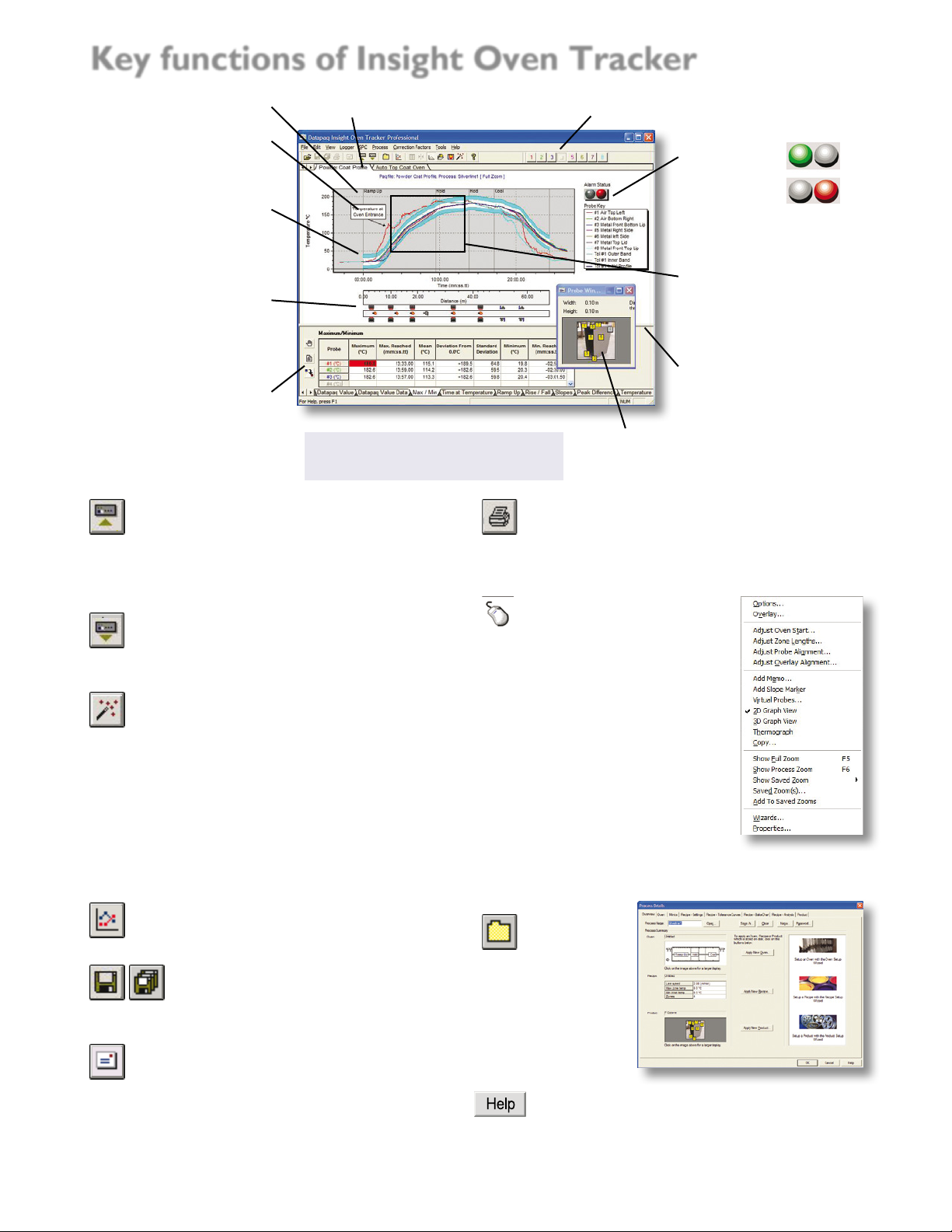

Rise/Fall and Slopes

*

Calculates and analyses the rates

of heating and cooling for each

probe.

Peak Difference

Data for the two probes which

recorded temperatures with the

biggest difference at any single point

in the profile.

Ramp Up

Calculates the profile slope over a given

time range, and gives the time taken to

reach a given cure temperature.

Maximum/Minimum

Analyse the maximum

and minimum

temperatures

achieved by each probe.

Time at Temperature

Calculate the time at which a

specified temperature is reached,

and the time for which the

product was at, or above, that

temperature.

View Data

Display the raw temperature data for

any point in the profile.

•Click on the probe-trace of interest.

•Drag the vertical bar to the appropriate position

and read time and temperature information.

Alarms

See when and why an alarm condition

is triggered, caused by out-of-tolerance

analysis results or by (e.g.) logger going

over temperature, low battery or invalid

measurements.

Datapaq Value

Insight compares the coating manufacturer’s recommended

curing time/temperature with the actual time/temperature

values experienced by the product and generates an

index of cure which indicates the degree of compliance.

•Input cure-schedule information from your coating supplier: click the

Options button , or use the Wizard .

Assess the Datapaq Value obtained during a profile run:

•Generally, near 100 indicates cure OK

•Significantly less than 100 indicates under-cure

•Significantly greater than 100 indicates over-cure

From quality-assurance tests, find the range of Datapaq Values (e.g. 80–140)

which gives you acceptable coating cure-quality. Datapaq Value then becomes

a rapid means of ensuring that the process is in control.

Area Under Curve

Calculates the area which lies below

the temperature profile curve

but above a threshold temperature.

Temperature Difference Data

*

Display the difference in

temperature between

any two probes throughout

the temperature profile.

The analysis options

Temperature

above which

coating damage

is possible.

Three coating cure schedules (low, mid and

high Time at Temperature settings).

Temperature

at which curing

(cross-linking)

starts.

See Insight’s Help system for full

details of using the analysis modes.

For each analysis mode, click

on the Options button in the

Analysis Window to select

parameters for that analysis.

Click button to edit the

probes’ names.

Bakechart

*

A graphical

alternative to

Datapaq Value,

comparing the cure results with

an envelope of acceptable time/

temperature values (Oven Tracker

Professional only).

The Bake Chart Data tab shows

the data as a table.

The Datapaq Value Data * tab shows the Datapaq Value for every data

point in the profile run, in both in numerical and graphical form.

*Feature available in Oven Tracker Professional only.