FMT Swiss AG mobiSERVE Instruction Manual

81 231 932 A801 GB

OPERATING INSTRUCTIONS

AND SAFETY NOTES

mobiSERVE

Mobile with battery

2

GB Operating instructions - mobiSERVE

FMT Swiss AG

This documentation is exclusively intended for the operating company and their sta.

Without our written consent, the content of this documentation (textes, gures, drawings,

charts, diagrams etc. ), must not be duplicated or distributed, neither in full or in part, utilized

for the purpose of competition or passed on/made availabe to third parties.

FMT Swiss AG

Fluid Management Technologies Swiss AG

Gewerbestraße 6

6330 Cham / Schweiz

Tel. +41 41 712 05 37

Fax +41 41 720 26 21

Email: info@fmtag.com

Internet: www.fmtag.com

Operating instructions translation

Date of issue: 05/2017

We reserve the right to make design and product modications, which serve to improve the

product.

3

Operating instructions - mobiSERVE

GB

Table of Contents

1. Introduction ________________________________________________________________________4

1.1 Preface ____________________________________________________________________________4

1.2 Obligations of the personnel ___________________________________________________________4

1.3 Symbols in this manual _______________________________________________________________4

1.3.1. Structure of the warning notes _________________________________________________________4

1.3.2. Hazard symbols _____________________________________________________________________5

1.3.3. General symbols _____________________________________________________________________5

2. Safety instructions ___________________________________________________________________5

2.1 Authorized personnel_________________________________________________________________6

2.2 Notes on cleaning and repair___________________________________________________________6

2.3 Intended conditions of use ____________________________________________________________6

2.4 Risks when handling the mobiSERVE ____________________________________________________7

3. Transport and in-house transport _______________________________________________________7

4. Design and functional description ______________________________________________________8

5. Commissioning and operation _________________________________________________________9

5.1 Filling operation ____________________________________________________________________11

5.2 Adjusting the ow rate_______________________________________________________________11

6. Technical data______________________________________________________________________11

7. Assembly__________________________________________________________________________12

8. Daily use __________________________________________________________________________12

8.1 Discharge in normal mode____________________________________________________________13

8.1.1. Resetting the partial amount__________________________________________________________13

8.1.2. Resetting the resettable total amount RESET TOTAL _______________________________________14

8.1.3. Discharge with display of the current ow rate (Flow Rate Mode) ____________________________14

8.1.4. Resetting the partial amount__________________________________________________________15

9. Calibration ________________________________________________________________________15

9.1 Denition _________________________________________________________________________15

9.2 Why to calibrate ____________________________________________________________________15

9.3 Calibration mode ___________________________________________________________________16

9.4 Display of the current calibration factor and, if required, resetting the manufacturer's factor ______16

9.4.1. Calibration during operation _________________________________________________________17

9.4.2. Calibration procedure during operation ________________________________________________18

9.4.3. Direct change of the K FACTOR ________________________________________________________20

10. Conguration of the mobiServe counter ________________________________________________22

11. Preventive maintenance _____________________________________________________________23

12. Troubleshooting ____________________________________________________________________23

13. Maintenance ______________________________________________________________________24

14. Repair/Service______________________________________________________________________24

15. Disposal___________________________________________________________________________24

16. EC Declaration of Conformity _________________________________________________________25

17. Exploded view of the mobiSERVE 200 l__________________________________________________26

18. Exploded view of the mobiSERVE 60 l ___________________________________________________28

4

GB Operating instructions - mobiSERVE

1. Introduction

1.1 Preface

Please carefully read these operating instructions and observe in particular all safety notes!

Our sta will be pleased to provide support if you have any questions about the product.

Yours sincerely, FMT Swiss AG

1.2 Obligations of the personnel

Before they start to work, all persons who are entrusted with work with the mobiSERVE are obliged:

– to follow all applicable regulations on occupational safety and accident prevention.

– to read and to comply with all safety instructions and warning notes contained in these operating

instructions.

Please observe the following instructions in the interest of all concerned:

Refrain from any unsafe working methods!

Adhere to all hazard and warning notes contained in this manual!

In addition to this documentation, keep to all generally accepted safety rules, legal provisions as

well as all other binding rules regarding occupational safety, accident prevention and environmental

protection!

Wear appropriate protective clothing in accordance with the work to be done!

Perform only work for which you have been suciently trained and instructed!

Only genuine spare parts as well as original tools and auxiliaries of the manufacturer are allowed to be

used in order to ensure the functional safety and maintain the warranty coverage.

1.3 Symbols in this manual

1.3.1 Structure of the warning notes

The warning notes have the following structure:

SIGNAL WORD

Type and source of the hazard

Consquences of non-compliance with the notes

Measures to avoid that risk

Depending on the danger level, dierent signal words are used:

Signal word Danger level Consequences of non-compliance

DANGER Imminent threat

of danger

Death or serious bodily injury

WARNING Possible threat

of danger

Death or serious bodily injury

CAUTION Possibly dangerous

situation

Minor bodily injury

ATTENTION Possibly dangerous

situation

Damage to material property

5

Operating instructions - mobiSERVE

GB

NOTE

Indicates further information or tips which facilitate work.

1.3.2 Hazard symbols

Symbol Meaning

General hazard symbol. The warning note marked in this way contains sup-

plementary information on the type of hazard.

This symbol warns of dangerous electrical voltages.

This symbol warns of a hazardous explosive atmosphere.

1.3.3 General symbols

Symbol Meaning

A small black square indicates the work you have to perform.

–The dash denotes lists.

aThe arrow identies cross-references.

If cross-references to other chapters are required within the text, the expres-

sion is shortened for reasons of clarity.

Example: aChapter 2 Safety instructions

This means: please refer to chapter 2 for the safety instructions.

2. Safety instructions

Various dangers may occur if the mobiSERVE is improperly handled during installation, commissioning

and daily operation.

WARNING

Risk of injury and damage to material property because of improper

handling

Hold the manual at the disposal of the operating sta at the usage site of the

unit. Country-specic safety measures and accident prevention regulations

must be observed.

6

GB Operating instructions - mobiSERVE

2.1 Authorized personnel

Only qualied and authorized persons are allowed to operate and to work on the mobiSERVE.

Persons are qualied if they are, due to their training, experience, instruction and knowledge of the

relevant standards, able to assess assigned tasks and to identify potentially hazardous situations.

These persons must have been authorized by the person responsible for the safety of the unit and must

be able to identify and to avoid potential dangers.

All persons charged with installation, operation, maintenance and repair work, must have read and

understood this operation manual.

A copy of this operating manual must be stored permanently and ready at hand at the place of usage

of the unit.

2.2 Notes on cleaning and repair

WARNING

Wear suitable gloves as a protection against long-term skin contact with

urea solution.

The mobiSERVE is allowed to be cleaned by instructed personnel only.

When handling urea solutions, adhere to the information provided on the

material data safety sheet.

2.3 Intended conditions of use

The mobiSERVE urea conveying system has been designed for conveying urea solutions (urea, AdBlue®)

or water from mobile tanks into containers provided for this purpose, for example vehicle tanks.

The urea conveying system is operated independently of the mains power.

The mobiSERVE is suitable for use in workshops.

WARNING

Never use it to deliver explosive uids such as gasoline or other u-

ids with similar ashpoints!

The mobiSERVE is only allowed to be connected to an appropriate voltage source (see type plate).

Conveying caustic or other hazardous chemical or biological substances is forbidden.

The use in the food industry is forbidden.

Any departure from the usage stipulations (other uid media, use of force) or user modications

(changes, use of non-original parts) can be dangerous and is considered as non-intended usage.

The user is liable for any damage resulting from non-intended use.

During repairs to any electrical components, the appropriate safety and test requirements are to be

observed.

Only genuine replacement parts are to be used for any repairs, because otherwise the warranty will be

invalidated.

2.4 Risks when handling the mobiSERVE

Any application beyond the intended use can lead to hazardous situations and shall be regarded as non-

intended use.

7

Operating instructions - mobiSERVE

GB

DANGER

Risk of injury and material damage because of improper installation, elec-

tric current or contaminated media

Risk of injury from stumbling or falling because of improperly laid

power lines.

Moving the device with defective castors and/or defective accessories

is forbidden!

If the power cable is not used, this one must be disconnected from the

mobiSERVE and kept in a safe place.

Never work on a pump that is running

Mount or remove attachments and accessories only when the pump is

switched o.

For your own safety, disconnect the pump in addition from the power supply.

Do not pump contaminated uids

Take special care to ensure that there are no contaminants in the uid to

be pumped.

Damaged attachments and accessories can lead to personal injury and

material damage

Attachments and accessories must be checked for wear, splits or other

damage throughout its period of use.

Damaged accessories and attachments must be replaced immediately.

With reference to the period of use, please note the details in ZH 1A45.4.2

or DIN 20066 Part 5.3.2.

Escaping liquids can cause environmental harm

Comply with the stipulations of the German Water Resources Act (WHG) and

of the Plant Regulations of the German federal states.

3. Transport and in-house transport

All lifting and transport work may only be done by qualied and suitably instructed personnel. Only use

the provided attachment points as well as approved lifting gear and slings to lift the mobiSERVE.

Use appropriate means to secure the mobiSERVE and the related individual parts on a means of

transport / transport pallet.

It is not allowed to transport the urea conveying system with tted urea dispensing container!

Urea dispensing containers / urea cans must be transported separately. The manufacturer's transport

provisions must be observed.

CAUTION

It is forbidden to transport the mobiSERVE with plugged-in power cord.

For a transport of the battery, the poles must be protected by caps and

insulating tape.

WARNING!

Castors/tyres are provided for in-house transports. When moving the

device, check to ensure that all aps and doors are properly closed and that

the urea container is safely placed on the mobiSERVE and is secured against

falling!

8

GB Operating instructions - mobiSERVE

4. Design and functional description

The mobiSERVE is a mobile relling vehicle featuring an electronic counter with digital display.

The built-in pump is operated by an on-board lead accumulator. An integrated charger is provided to

recharge the battery. The battery charge level is indicated on the control panel. The quantity delivered

is measured by means of an electronic system featuring an oval gear meter.

A rotary knob allows to continuously adjust the ow rate in a dened range.

The LCD (liquid cristal display) of the mobiSERVEs is equipped with two numerical registers and various

screens which only appear if needed by the current function.

Legend:

1. Register of the partial amount ( 5 digits with oating point: 0.000+99999), indicating the quantity

issued since the last actuation of the RESET key

2. Display of the calibration modality

3. Register of the total amount (6 digits with oating point 0.0 - 999999x10/x100) that can show two

types of total amounts:

3.1 Total amount not resettable to zero (TOTAL)

3.2 Total amount resettable to zero (RESET TOTAL)

4. Display of the multiplication factor of the total amount (x10/x100)

5. Display of the total amount type (TOTAL/RESET TOTAL)

Flow control Battery charge level

On / O

Flow rate / discharge amoun

Display LCD

9

Operating instructions - mobiSERVE

GB

6. Display of the total amount measuring unit; L = Liters; GAL = Gallons

7. Flow rate display

8. Display of the partial amount measuring unit:

QTS = Quarters; PTS = Pints; L = Liters; GAL = Gallons;

The mobiSERVE is equipped with two push buttons (RESET and TOTAL) whereby each of them carries

out two main functions. In combination, these two buttons perform other auxiliary functions.

Main functions:

1. RESET-Taste:

to reset the partial amount register and the resettable total amount register

RESET TOTAL.

2. TOTAL key:

to call up the calibration mode of the unit. In combination, both keys allow to call up the

conguration mode, where the measuring unit desired can be entered.

Main switch On/O

Upon actuation of the main switch, the pump starts to work. The battery charge indicator shows the-

battery status, and in the LCD display, the daily amount is indicated.

The pump's maximum duty cycle is 5 minutes. This prevents an uncontrolled pump operation, if acci-

dentally the main switch has not been switched o.

When the unit is turned o and on again, the pump restarts to work. The LCD display remains active for

30 minutes after the main switch has been turned o.

Measuring chamber

The measuring chamber is located in the middle part of the unit.

The measuring chamber is equipped with oval gears. When rotating, these oval gears produce electri-

cal impulses which are processed by the microprocessor on the electronic card.

The microprocessor works with a calibration factor (i. e. with a "weight" allocated to each impulse). The

impulses produced during rotation are converted in uid volumes expressed in the previously determi-

ned measuring unit and are displayed in the partial and total amount registers on the LCD screen.

All mobiSERVEs leave the factory with a calibration factor, called FACTORY K FACTOR, which amounts

to approx. 1,000. The unit can be calibrated in order to optimally adjust the counter to the uid to be

measured.

It is possible at any time to return to the calibration set by the manufacturer.

Battery

The mobiSERVE is powered by a maintenance-free 12 V lead accumulator.

The battery compartment is located in the housing.

To replace the battery, the housing cover must be removed.

5. Commissioning and operation

Check the mobiSERVE and the assembled attachments for completeness and damage. Replace any

damaged parts immediately and never use a damaged pump.

CAUTION

Before working on the device, apply the locking brake of the castors.

10

GB Operating instructions - mobiSERVE

CAUTION

Never operate the mobiSERVE without a uid for more than 2 minutes.

Your urea pump may be damaged by dry running.

It is forbidden to operate the unit with defective equipment.

Press the nozzle valve lever up according to the delivery rate desired or actuate the lock.

Operate the rocker switch to turn the mobiSERVE on.

Placing and lling the barrel:

Suitable devices are to be used to lift the urea container onto the space provided for it on the mobi-

SERVE. Check to ensure that the whole surface is used, because otherwise there is the risk that the urea

container may fall backwards out of the trolley. In addition, the urea container must be secured against

falling out.

200 liter mobiSERVE 25 352

Place the 200 l barrel on the load area of the trolley. Actuate the parking brakes

of the two castors in order to ensure a secure and safe standing position.

Insert the suction line into the barrel and connect the screw coupling and the

barrel thread.

Tighten the union nut in order to connect the preassembled hose and the

suction line in the barrel. Check to ensure that the O-rings are not damaged at

the connection.

For an exchange of barrels, proceed in reverse order.

60 liter mobiSERVE 25 353

The 60 l trolley is equipped with a plastic container. The suction hose and the

connecting hose are already preassembled in the barrel.

You have the possibility to ll the container by an external lling operation. The

suction hose is equipped with a SEC adapter, so that the container can be lled

by means of the pump in the trolley.

To do this, connect the SEC adapter to the existing IBC container.

Open the red screw cap at the trolley container and insert the nozzle into this

opening.

Turn the rotary knob for ow control to 100 %.

Switch the main switch on. The pump starts to work now.

Open the nozzle valve and actuate the lock. The nozzle valve will automatically

close when the container is full.

Then, shut o the main switch and reconnect the SEC adapter to the suction

line of the trolley container.

NOTE

In case of a relling or after an exchange of a barrel, completely bleed the air

from the system, in order to avoid measuring errors in the electronic counter

system.

To do this, open the second opening of the trolley container and insert

the nozzle valve. Perform a lling operation as described under paragraph

5.1 until the medium is delivered without air.

The mobiSERVE is now ready for use.

11

Operating instructions - mobiSERVE

GB

5.1 Filling operation

Approach the mobiSERVE to the vehicle to be relled.

During lling, the parking brake should be always applied at the rear castors in order to prevent an

uncontrolled movement of the trolley.

Insert the nozzle valve into the tank opening and turn the main switch on.

The pump starts to work.

The following information is indicated on the control panel: battery charge level, counted daily amount

and total amount.

Open the nozzle valve. As soon as the lling operation is completed, turn the main switch o again.

NOTE

The mobiSERVE is optionally delivered with a nozzle valve which allows to

carry out a lling operation according to ISO 22241-5. Please refer to the

operating instructions supplied with unit for information on the operation of

the nozzle valve according to ISO 22241-5.

5.2 Adjusting the ow rate

The mobiSERVE is equipped with a ow rate control unit.

The innitely variable ow rate can be adapted to the vehicle to be lled.

To do this, turn the rotary knob "Flow Rate" in the range from min to max. The current ow rate can be

indicated in the display.

Refer to aParagraph 8.1.3. Discharge and display of the current ow rate (ow rate mode).

6. Technical data

Designation mobiSERVE 200 l

25 352; 25 352 836

mobiSERVE 60 l

25 353; 25 353 836

Pump design Diaphragm pump, self-priming

Delivery rate under free discharge l/min 10-20, innitely variable 6-12, innitely variable

Discharge pressure up to bar 1,7

Pumping media Urea (AdBlue®) or water

Motor data

Power consumption A 18

Voltage V 12 V DC

Fuse A 25

Protection class IP 54

Charger

Operating voltage V 230 V AC

Frequency Hz 50-60

Power consumption A 0,6

Charging current A 5

Accu

Voltage V 12 V DC

Capacity Ah 24

Charging time when battery

completely empty

h 5

Connecting cable, length m 1,2

Weight kg 85 62

Dimensions LxWxH mm 1000 x 800 x 1080 780 x 550 x 1080

Hose length m 4 2

Nominal width hose mm 19 13,5

Tab. 6-1: Technical data

12

GB Operating instructions - mobiSERVE

7. Assembly

The mobiSERVE is supplied with assembly included.

Depending on the version, the attachments can or must be tted.

NOTE

During assembly, pay attention to cleanliness and to an exact connection

and precise sealing.

WARNING

Before connecting the unit to the power supply system, the correct

insulation of the power cord must be checked.

8. Daily use

The mobiSERVE is supplied ready for use.

The trolley is immediately ready for use, even after long periods of storage.

The only operation required for daily use is to reset the registers of the partial and/or resettable total

amount to zero.

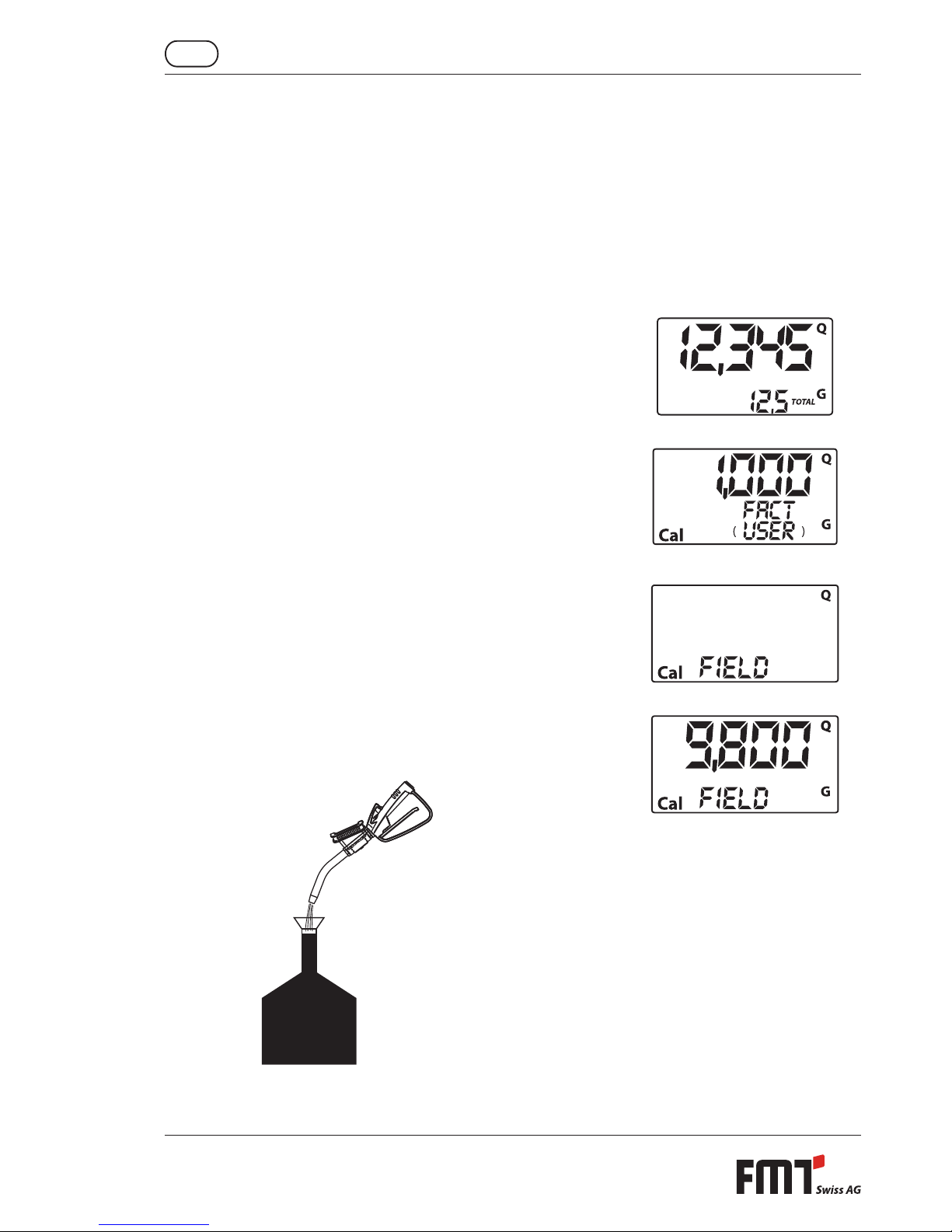

Then, the two screens for normal operation are called up. The rst screen indicates the partial amount

and the resettable total amount RESET TOTAL. The other screen shows the partial amount and the ab-

solute total amount TOTAL. The transition from the resettable total amount to the absolute quantity is

done automatically and is performed within a period of time dened during manufacturing. It cannot

be changed by the user.

Register of

RESETTABLE

TOTAL VOLUME

Register of

ABSOLUTE

TOTAL VOLUME

Register of partial volume

The register of the absolute total amount TOTAL cannot be reset to zero by the user. It will continuously

increase over its whole lifetime. The registers of the two total amounts RESET TOTAL and TOTAL take the

same space and the same digits on the display. This is the reason why the two total amounts will never

appear together, but are always shown alternately.

The mobiSERVE is programmed in a way that the one or the other total amount is displayed at certain

moments:

The absolute total amount TOTAL is shown in the standby mode of the counter.

The resettable total amount RESET TOTAL is displayed at the following moments:

- For a short time (some seconds) after the partial amount has been reset to zero.

- During discharge of uid.

Some seconds after uid discharge, this short time time span has elapsed and the counter changes to the

standby mode. The display of the lower register shows the absolute total amount.

13

Operating instructions - mobiSERVE

GB

NOTE

6 digits are available to indicate the total amounts, plus two icons x10/x100.

The increase is done with the following sequence:

0,0 ---> 99999,9 ---> 999999 ---> 100000 x10 --->

999999 x10 ---> 100000 x100 ---> 999999 x100.

8.1 Discharge in normal mode

During standard discharge, the counter simultaneously displays the partial amount issued and the

resettable total amount RESET TOTAL.

An unintended pressing of the RESET or TOTAL key during counting has no eect.

Some seconds after uid discharge, the display of the lower register changes from the resettable total

amount to the absolute total amount: The message RESET over the word TOTAL goes out and the value

of the resettable total amount is replaced by the absolute total amount.

This state is called pause (or standby) and remains unchanged as long as the user does not carry out any

operations at the counter.

8.1.1 Resetting the partial amount

The register of the partial amount can be reset to zero by pressing the

RESET key, when the counter is in the standby mode, i. e. when TOTAL

is shown in the display.

After pressing the RESET key, i. e. when zero reset is executed, the

display shows successively all digits switched on and o.

Following this operation, at rst the partial amount reset to zero and

then RESET TOTAL is indicated.

And after a few seconds, RESET TOTAL is replaced by TOTAL, the total

amount NOT resettable.

14

GB Operating instructions - mobiSERVE

8.1.2 Resetting the resettable total amount RESET TOTAL

The resettable total amount can only be reset to zero after previously

having reset the partial amount register to zero. The total amount

is reset by pressing on the RESET key for a longer time, while the

message RESET TOTAL is shown on the display, as on the following

screen:

The following steps are to be carried out schematically:

Wait until the normal standby screen appears (only the total

amount TOTAL is displayed).

Press shortly the RESET key. After this operation, the partial amount

reset to zero and RESET TOTAL are shown at rst.

The counter begins the resetting operation of the partial amount.

While RESET TOTAL is shown on the display, press the RESET key

once again for at least one second.

The display will show all segments again, then comes the phase,

during which all segments are switched o, followed by the display

of the reset total amount RESET TOTAL.

8.1.3 Discharge with display of the current ow rate (Flow Rate Mode)

During discharge operations, the following displays may simultaneously appear:

- Partial amounts discharged

- Current ow rate in (measuring unit of the partial amount/min) as shown in the following.

Procedure to get into this mode:

Wait until the counter is in the standby mode, i.e. until the display only shows the total amount.

Shortly press on the TOTAL key.

Discharge begins.

The current ow rate is updated every 0.7 seconds. For this reason, the display may be relatively unstable

for low ow rates. The higher the ow rate, the higher the stability of the value indicated.

NOTE

The ow rate is measured in the measuring unit of the partial amount. If,

as in the following example, the partial amount and the total amount have

dierent measuring units, note that the ow rate shown is indicated in the

measuring unit of the partial amount. In the example below, the ow rate is

indicated in QTS./Min.

15

Operating instructions - mobiSERVE

GB

The message GAL next to the ow rate refers to the register of the (resettable or NOT resettable) total

amount, which is shown again, when the display mode of the ow rate is left again.

In order to return to the normal mode, press the TOTAL key once again.

An unintended pressing of the RESET or TOTAL key has no eect during counting.

NOTE

Even though the resettable (RESET TOTAL) and the absoute (TOTAL) amounts

are not shown, the values nevertheless increase. These values, however, can

be checked after the discharge, when the TOTAL key is shortly pressed in the

"normal mode".

8.1.4 Resetting the partial amount

In order to reset the partial amount register to zero, nish discharge and wait until the counter indicates a

ow rate of 0,0 (refer to illustration) and then shortly press the RESET key.

In contrast to resetting in the normal mode, the counter will, in this case, not go through the phase during

which all display segments are successively switched on and o, but will immediately show the register of

the partial amount reset to zero.

9. Calibration

9.1 Denition

Calibration factor or "K FACTOR":

This is the multiplication factor the system allocates to the electric impulses received in order to convert

them into the unit of the measured uid.

FACTORY K FACTOR: Default calibration factor preset during fabrication. It is set to 1000.

The preset calibration factor can be reloaded by means of a simple procedure if the user has made

changes.

USER K FACTOR: calibration factor which has been adapted to the user's requirements, i. e. which has

been changed by a calibration.

9.2 Why to calibrate?

The mobiSERVE is delivered with a setting made by the manufacturer. In most operating conditions, this

setting will ensure a precise measurement.

Nevertheless, a calibration made under operating conditions may be advisable, e. g. if the counter is

operated under extreme conditions.

16

GB Operating instructions - mobiSERVE

9.3 Calibration mode

The mobiSERVE oers the possibility to carry out a quick and precise electronic calibration by changing

the calibration factor ( K FACTOR).

Two procedures are possible to calibrate the unit:

Calibration during simulated operation, when uid is discharged.

Direct calibration, whereby the calibration factor is changed.

When the TOTAL key is pressed for a longer time, the user gets access to the calibration process:

Display of the calibration factor currently being used.

Resetting the calibration factor of the manufacturer (FACTORY K FACTOR) after a calibration by the user.

Change of the calibration factor by means of one of the procedures mentioned above.

In the dierent phases of the calibration mode, the meanings of the messages on the display vary

regarding the partial and total amount issued.

In the calibrating mode, the counter cannot show normal data.

NOTE

The mobiSERVE is equipped with a non-volatile memory ensuring that the

saved calibration and total discharge amount data are retained even without

power supply. After the battery has been replaced, a new calibration is not

necessary.

9.4 Display of the current calibration factor and, if required, resetting the manufacturer's factor

When the TOTAL key is pressed in the standby mode, the calibration factor currently being used is

indicated.

Two cases may occur:

a) If a calibration has never been carried out yet, or if the manufacturer's value has been set after a

calibration, the following display will appear:

The message FACT (abbreviation for FACTORY) indicates that the calibration factor of the manufacturer

is used.

b) If calibrations have been eected by the user, the calibration value currently being used is shown

(0.998 in our example).

The message USER appears on the screen to indicate that the calibration factor used has been

entered by the user.

The ow chart opposite informs on the logical relationships between the various screens.

In this mode, the RESET key allows to change from the USER to the FACTORY FACTOR.

To conrm the calibration factor selection, shortly press the TOTAL key while USER or FACT is displayed.

After restart, the counter will use the calibration factor just conrmed.

17

Operating instructions - mobiSERVE

GB

Standby

Standby

Standby

RESET long

RESET short

TOTAL long

TOTAL short

Time OL 1

LEGEND

NOTE

At the moment when the factor of the manufacturer is conrmed, the

previous user factor is deleted from the memory.

9.4.1 Calibration during operation

During this procedure, a uid is delivered in a measuring container under realistic operation conditions

(ow rate, viscosity), which must be strictly adhered to.

The following points must be observed for a correct calibration of the counter:

Completely bleed the air from the system before the calibration is carried out.

Use a calibrated container which has a capacity of at least 5 liters and features exact measuring marks.

For calibration, carry out the discharge procedure at a constant ow rate corresponding to the rate

issued during normal operation. Fill the container until it is full.

18

GB Operating instructions - mobiSERVE

Do not reduce the ow rate when the measuring scale of the container is almost reached during the

nal period of discharge. At the end of the lling operation, the right procedure is to carry out short

relling cycles at the normal operating ow rate.

After the discharge operation, wait a few minutes in order to ensure that all air bubbles have been

removed from the container. The correct value can be read only upon completion of this phase,

because at an earlier stage, the level may still drop in the container.

Carry out the procedure correctly as described in the folowing.

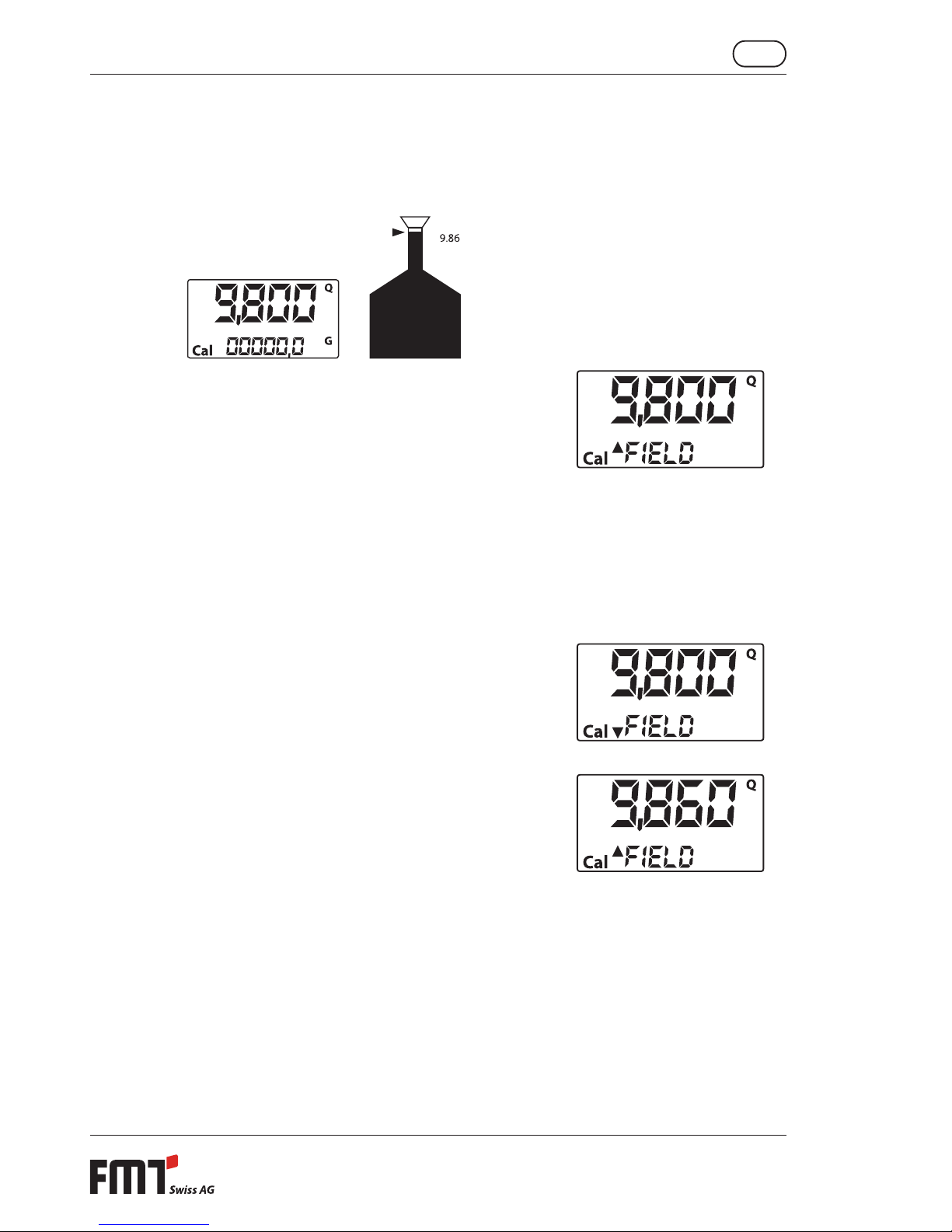

9.4.2 Calibration procedure during operation

Operation Display-Conguration

1 NONE

Counter in normal mode, not counting

2 LONG PRESS ON THE TOTAL KEY

The mobiSERVE enters into the calibration mode, shows

the message TOTAL and the calibration factor used instead

of the total amount. The messages FACT and USER indicate

which one of the two factors (manufacturer or user ) is

currently being used.

3 LONG PRESS ON THE RESET KEY

The mobiSERVE indicates the TOTAL screen and the

resettable total amount indicator is zero. The counter is

ready to carry out a calibration during operation.

4 DISCHARGE IN THE CALIBRATED CONTAINER

Start the dispense in the calibrated container without

pressing a key.

19

Operating instructions - mobiSERVE

GB

The discharge procedure can be interrupted and started

at any time. Carry out the discharge until the uid has

achieved the measuring scale of the calibrated container. It

is not necessary to achieve a certain amount.

Set value Actual value

5

SHORT PRESS ON THE RESET KEY

The mobiSERVE is informed that the calibration discharge is

nished. Check to ensure that the discharge is completely

nished before this happens.

To calibrate the mobiSERVE, the value indicated by the

partial amount counter (example 9.800) must be brought

to the actual value indicated by the calibrated container.

On the lower left corner of the display, an arrow appears,

pointing upwards or downwards, thus indicating the

direction in which the USER K FACTOR value is changed.

Increase or reduce when the operations 6 or 7 are carried

out.

6 SHORT PRESS ON THE RESET KEY

Change of arrow direction. This procedure can be repeated

as often as required.

7 SHORT/LONG PRESS ON THE TOTAL KEY

The value indicated is changed in the direction dened by

the arrow:

One unit for each short press on the TOTAL key

Continuously, when the TOTAL key is kept depressed -

the rst 5 units change slowly, then quickly.

If the value desired is exceeded, repeat the operation

from point 6 (6).

20

GB Operating instructions - mobiSERVE

8 LONG PRESS ON THE RESET KEY

The mobiSERVE is informed that the calibration procedure

is nished.

Before this operation is carried out, check to ensure

that the STANDARD VALUE corresponds to the ACTUAL

VALUE.

Actual value

The mobiSERVE calculates the new USER K FACTOR. This

calculation may take some seconds, according to the

correction to be made. During this procedure, the arrow

disappears, but TOTAL remains on the screen.

If this procedure is carried out after point 5 without

changing the value indicated, the USER K FACTOR is equal

to the FACTORY K FACTOR and is thus ignored.

9 NO OPERATION

After the calculation, the new USER K FACTOR is indicated

for some seconds, then, the restart procedure is repeated in

order to nally get into the standby mode.

ATTENTION: From that moment, the value indicated is the

new calibration factor used by the counter, and it remains

so, also after a battery replacement!

10 NO OPERATION

The mobiSERVE stores the new operating calibration factor

and is prepared for discharge with the USER K FACTOR just

calculated.

9.4.3 Direct change of the K FACTOR

This procedure is especially helpful in order to correct an average error, which may occur because of the

multitude of tasks carried out. If, during normal counter operation, an average percent error occurs, this

one may be corrected by altering the calibration factor currently being used by the same percent value. In

this case, the percentage of the correction of the USER K FACTOR can be calculated by the user as follows:

new calibration factor = old calibration factor x

Table of contents

Popular Pressure Washer manuals by other brands

Pulsar

Pulsar PWG3000H owner's manual

North Star

North Star 157596 owner's manual

Villager

Villager VHW 100 Operator's manual

Generac Portable Products

Generac Portable Products 1675-0 owner's manual

North Star

North Star M157304G Installation, operation and maintenance manual

Simoniz

Simoniz SPD-220 Operator's manual