Foley Engines ZF 45 C - Walter Operating instructions

R E P A I R M A N U A L A N D S P A R E P A R T S L I S T

R E P A I R M A N U A L A N D S P A R E P A R T S L I S T

R

E

P

A

I

R

M

A

N

U

A

L

ZF 45 C version 10; 001

ZF 45 C - Walter version 002

ZF 45 C - Toyota version 11; 003

ZF 63 C version 07; 001

ZF 88 C version 001

Cod.

310.01.0056d

FOLEY ENGINES

1-800-233-6539

1

Repair Manual and Spare Parts List ZF 45C / 63C / 88C

TABLE OF CONTENTS

Introduction ........................................................... 2

SECTION I: GENERAL DATA .................................... 2

1. Transmission Set-up ....................................... 2

2. Consumable goods ......................................... 3

3. Measuring Tools .............................................. 3

4. Standard Tools and Fixture ............................. 3

SECTION II: SPECIAL TOOLS ................................. 4

SECTION III: DISASSEMBLY PREPARATION......... 5

Introduction ........................................................... 5

1. Preliminary operation ...................................... 5

2. Housing disassembly ...................................... 5

3. Input shaft ....................................................... 8

4. Forward clutch housing disassembly .............. 9

SECTION IV: ASSEMBLY .......................................... 12

Introduction ........................................................... 12

1. Input shaft ....................................................... 12

2. Housing assembly........................................... 15

3. Complementary operations............................. 18

4. Oil pump.......................................................... 21

SECTION V: PLAYADJUSTMENT ........................... 22

1. Reverse clutch clearance................................ 22

2. Forward clutch clearance................................ 23

3. Input shaft play................................................. 24

4. Output shaft bearing play................................. 25

SECTION VI: TIGHTENING TORQUES ................... 26

SECTION VII: FUNCTION TEST .............................. 26

1. Filling up with transmission fluid ..................... 26

2. Check fluid level.............................................. 26

3. Function test ................................................... 27

4. Shifting pressure ZF 45C / 63C / 88C............. 28

5. Lube oil delivery ZF 45C / 63C / 88C.............. 29

SECTION VIII: TROUBLESHOOTING...................... 30

SECTION IX: AUTOMATIC TRANSMISSION

FLUID.................................................. 33

SECTION X: SPARE PARTS LISTAND

EXPLOSION DRAWINGS.................... 35

Repair Manual and Spare Parts List ZF 45C / 63C / 88C

2

INTRODUCTION

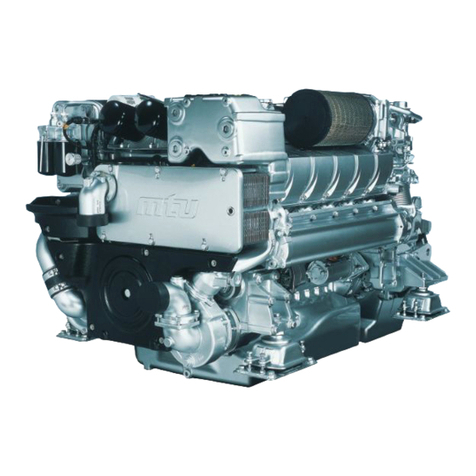

Thismanualgivesspecificinstructionsfortheproperrepair

on ZF 45C / 63C / 88C model transmissions.

Please follow the procedures carefully to insure quality

service.

ZF HURTH MARINE recommends to read the manual

completely before starting with repairs, as some of the

procedures described are rather complex.

Along with standard tools, ZF HURTH MARINE

recommendstheuseofspecialtools,necessarytoperform

repairs correctly. The special tools are available trough

your local ZF HURTH MARINE dealer.

This manual is based on the technical information at the

timeof printing.The manualhas beenchecked carefullyin

order to avoid errors. However ZF HURTH MARINE is not

liable, for any misrepresentations, errors of description or

omissions.

Modificationsonfuturemanualsmaybeintroducedwithout

prior notice.

Thefollowinginternationalsymbolsareusedinthisservice

manual.

SECTION I: GENERAL DATA

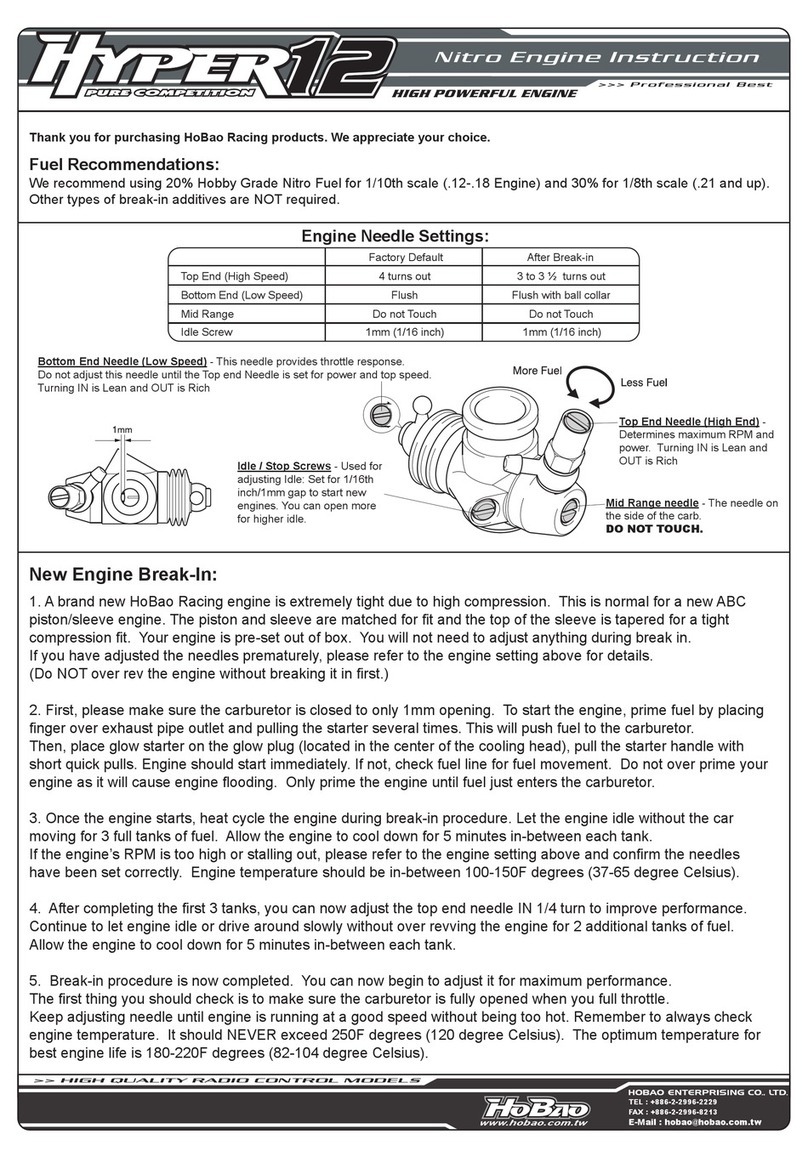

1. TRANSMISSIONS SET-UP

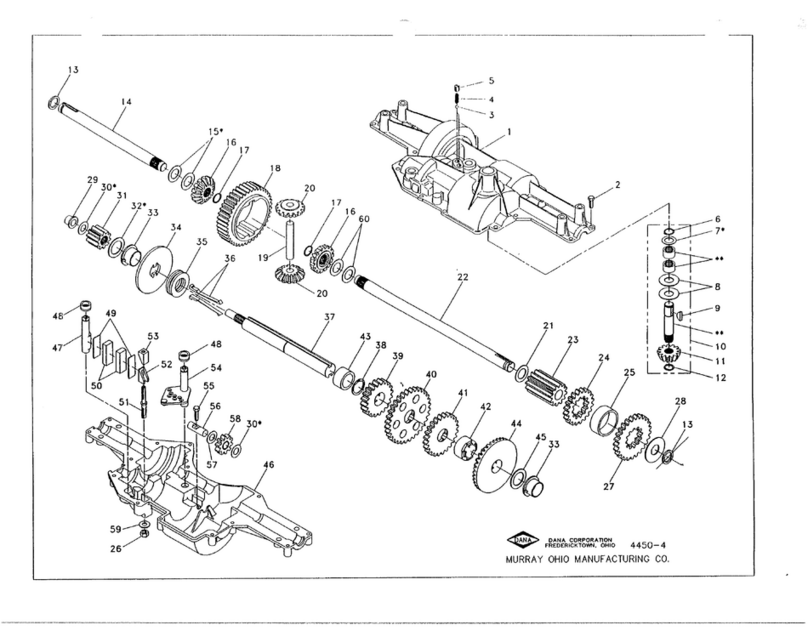

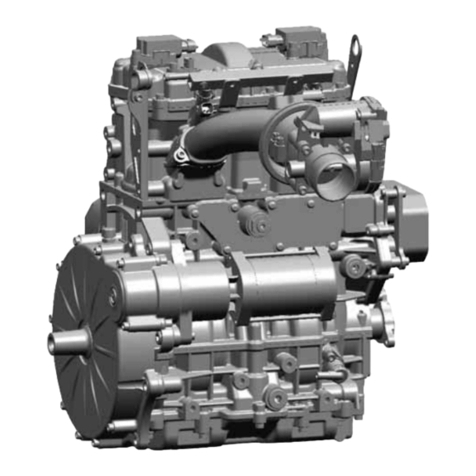

The main components of the HSW Marine Transmissions

are:

Item 1two-piece aluminum die cast

1.1 oil filter

1.2 oil dipstick

1.3 pump

Item 2gears

2.1 input shaft with forward clutch

pack assembly

2.2 planet gear carrier assembly

Item 3control valve

1.2

2.2

2.1

WARNING:THISSYMBOLWARNSOFPOSSIBLE

PERSONAL INJURY.

CAUTION:Thissymbolwarnsofpossibledamage

to transmission.

1.3

3

1

1.1

3

Repair Manual and Spare Parts List ZF 45C / 63C / 88C

2. CONSUMABLE GOODS

For cleaning:

Cold cleaner such as benzine, trichloroethane or Loctite

fast cleaner No. 7063.

WARNING

Keepdetergentsawayfromyourskin,donotdrinkand

do not inhale their vapors! Always wear protective

gloves and safety glasses!

Note accident prevention rules!

For assembly:

•Loctite 245 for securing output flange on spline

•Loctite 574 on the outside diameter of the seals and on

mating surfaces

•Grease: Klüber STABURAGS NBU 30, for radial shaft

seals

•ATF Fluid - 1.75 Liters (1.85 US qts)

[see ATF fluid list chap. IX]

3. MEASURING TOOLS

Dial indicator gauge with arm-type support

Range 0 - 1" (0 - 25 mm) in 0.0005" (0.01 mm) increments

Caliper

Range0-6"(0-150mm)in0.0005"(0.01mm)increments

1/2" tool bar

working edge within 0.0002" per 12"

4. STANDARD TOOLS AND FIXTURE

Wrench

for hexagon bolts (8 mm, 13 mm, 14 mm, 17 mm, 19 mm,

22 mm)

Allen wrench

(5 mm, 6 mm, 8 mm)

Hexagon drive socket wrench

(13 mm, 17 mm, 19 mm)

Torque wrenches

Ranges:

-20 lb in -200 lb in (5 Nm - 65Nm)

-15 lb ft - 100 lb ft (30 Nm - 150 Nm)

Plastic hammer (1000 g) (24 oz)

sturdy screwdriver

- Pullers

blindholebushing (planetarygearassembly)range1/4" to

1 3/4" 4 lb slide hammer

output flange range 3 1/2" to 5 1/2" 5 ton; 3 - jaw

No. 2 Pry bars

1/2" stock

Snap ring pliers

sizes: 9" (shaft diameter 1 1/2" to 3 1/2")

10" (bore diameter 1 1/2" to 4")

Repair Manual and Spare Parts List ZF 45C / 63C / 88C

4

SECTION II: SPECIAL TOOLS

It is assumed that all standard tools, such as, torque

wrenches,open-endwrenches,AllenKeysandextractors,

are available.

All fixtures for pressing in and out should be used in

conjunctionwithahydraulicormanualpress.Identnumbers

are also stock reference numbers.

Mandrel

Oil pump seal, (Id. No. 500493)

P/N 978.45.0022.0

Mandrel

Bushing, (Id. No. 500494)

P/N 978.45.0023.0

Mandrel

Control valve oil seal, (Id. No. 500495)

P/N 978.45.0024.0

Mandrel

Input shaft rollers bearing, (Id. No. 500496)

P/N 978.45.0025.0

Mandrel

Forward clutch circlip, (Id. No. 500497)

P/N 978.45.0026.0

Mandrel

Input shaft ball bearing (Id. No. 500498)

P/N 978.45.0027.0

Mandrel

Output shaft ball bearing, (Id. No. 500499)

P/N 978.45.0028.0

Plate

Housing support, (Id. No. 500500)

P/N 978.45.0029.0

Plug

Forward clutch, (Id. No. 500501)

P/N 978.45.0030.0

Wrench

Output flange, (Id. No. 500446)

P/N 978.40.0002.0

Antirotation bracket

Output flange, (Id. No. 500502)

P/N 978.45.0031.0

Clamp ring

Input shaft play, (Id. No. 618582)

P/N 219.354.3

5

Repair Manual and Spare Parts List ZF 45C / 63C / 88C

2. HOUSING DISASSEMBLY

2.1 Position the marine gearbox on the housing support

(P.N. 500500).

2.2 Screw off bolts (6) and washers (10). Remove the

pumpcoverassembly(34).Inspectsealingring(1)and

O-Ring(33);inspectforwearandreplaceifnecessary.

2.3 Removetherotorpumpfromtheshaft.Ifitneedstobe

replaced, the complete cover assembly (34) has to be

replaced.

NOTE:Pumpgearshould beinstalledthesamesidedown

as removed.

SECTION III: DISASSEMBLY

PREPARATION

INTRODUCTION

Clean the transmission thoroughly on the outside before

disassembly.

The repair area should be clean and well lighted.

ZF HURTH MARINE recommends using a stand (P.N.

500500) for aiding in assembly and disassembly.

1. PRELIMINARY OPERATION

1.1 Remove the breather valve (22) and oil dipstick (26).

Clean the breather with suitable cleaner, allow to dry

and coat with oil.

1.2 Screw off bolts (6) and washers (10), remove the filter

cover(5),seal(4)andfilterelement(3).Inspectsealfor

wearandreplaceifnecessary.Cleanthefilterelement

with suitable cleaner.

WARNING

Position a container to pick up the oil flow.

Repair Manual and Spare Parts List ZF 45C / 63C / 88C

6

2.7 Remove the cover (35).

2.8 Remove reverse clutch first outer disc (63).

2.9 Remove springs (58).

2.4 Using pliers remove the key (28) from shaft.

NOTE: Take note of the position of the key.

2.5 Screw off bolts (7), (8) and washers (10).

2.6 Bytappingwithasofthammerseparatethecover(35)

from the housing (36).

7

Repair Manual and Spare Parts List ZF 45C / 63C / 88C

2.13 Turn the housing upside down. Using the tool

P.N.500446 loosen nut (72); stop the output flange

(66) from turning using tool P.N.500502. Discard O-

Ring (71) and replace with a new one.

2.14 Remove flange using appropriate puller.

WARNING

[see type page 3].

2.15 With a soft hammer disassemble the output shaft.

Driving it out from the housing.

2.10 Remove inner disc (62), outer disc (63), inner disc

(62), the last outer disc (63) and if present shims

(64),(65).

2.11 Pull out the shaft and forward clutch assembly.

2.12 Removethrust washer(45)which isremainedon the

planetgearcarrierassemblyand(withstandardpuller)

bushing (46).

Repair Manual and Spare Parts List ZF 45C / 63C / 88C

8

3.3 With pliers remove the circlip (44).

NOTE: Take note of the position of the circlip (44).

3.4 Supportthe ringgear allowingroomfor theinput shaft

with gears to come out bottom side.

NOTE: Pressing on splined end of shaft disassemble it

from the clutch housing.

This operation will damage the bearing.

Use a press with:

distance: 200 mm (8 inches)

min. force: 2000 kg (4400 lbs)

3.5 Remove piston rings (40) from the input shaft (37).

3. INPUT SHAFT

3.1 Remove piston rings (39) from the input shaft (37).

3.2 Remove spacer (42b), needle bearing (42a), other

spacer (42b) and shims (75-76).

2.16 Don't disassemble the output shaft.

If it's necessary to replace it, ask for complete gear

carrier assembly (38).

9

Repair Manual and Spare Parts List ZF 45C / 63C / 88C

4.4 Remove forward clutch inner (60), outer (61) shims

(73) (74) and end disc (59).

WARNING

4.5 Remove circlip (55), cup springs (54).

Remove only if defective.

4.6 WithatoolP.N.500498driveoutballbearing(43)which

has to be discarded and replaced with a new one.

4.7 Introduce air with tool P.N. 500501 to push out the

piston (51).

The piston can also be removed by gently tapping on

the outer diameter of the housing with a soft hammer.

4. FORWARD CLUTCH HOUSING

DISASSEMBLY

4.1 Remove circlip (48).

WARNING

4.2 With a screwdriver remove the circlip (50).

4.3 Support clutch housing flat on to a work bench. Sepa-

rate ring gear support (47) from the ring gear (49).

51

500501 47

Repair Manual and Spare Parts List ZF 45C / 63C / 88C

10

4.8 Remove O-Rings (52), (53) from the piston (51).

WARNING

4.9 Inject air through the indicated hole, to remove the

piston (56). The hole is located on the upper circular

surface of the housing cover (clutch piston side) just

under the piston screw (18).

4.10 Remove the O-Ring (33) from cover (35).

4.11 Remove O-Rings (57) from piston (56).

NOTE: Replace O-Rings (33, 57) if disassembled.

4.12 Removethe stopscrew(17) andpositionscrew (18),

thetwowashers(13),thespring(20)andtheball(21).

4.13 Removethe neutralsafetyswitch (15),theplugs (12,

14), spacer (16), ball (21) and washer (19).

4.14 Using two screwdrivers pull out the distributor shaft

(24), the distributor shaft seal (23) will come out

together.

Remove seal ring (23) from the spool valve (24).

NOTE: 1 - Take note of the position of the seal ring.

2 - Replaced the seal ring if disassembled.

CAUTION

Don't disassemble the distributor shaft (24), if it's

necessary to replace it use the complete group.

13

17

13

18

11

Repair Manual and Spare Parts List ZF 45C / 63C / 88C

4.17 Remove baffle (29).

With a screwdriver take out an end of the baffle from

the groove on the housing.

Bygrippingandrollingupthebaffletakeitoutfromthe

housing.

NOTE: ZF 45C VERS. TOYOTA 11 ONLY

Twoadditionalbaffles(30)and(31)andpinspacer(32)are

present.

4.18 Remove output sealing ring (2).

NOTE: This operation will damage the oil seal.

4.19 Remove circlip (70).

4.15 Bystrikingwithasofthammerremoveneedlebearing(41).

Only if bearing is defective.

To do it properly support the cover allowing room for the

needle bearing to come out bottom side. Stick a screw

driver/punch into the internal edge of the cage and tap

gently with a soft hammer in a criss cross pattern.

NOTE: This operation will damage the bearing.

WARNING

The improper useof screwdriver/punchcandamage

the cover. After having removed the bearing check for

scratches on the cover.

4.16 Remove sealing ring (1) and O-Ring (33) from pump

cover (34).

NOTE: This operation will damage the sealing ring.

Take note of the position of the seal ring.

Repair Manual and Spare Parts List ZF 45C / 63C / 88C

12

1. INPUT SHAFT

1.1 InstallO-Rings (52)(53) on thepiston (51).Insertthe

piston into the input bell (47).

NOTE: Wet the O-Rings with ATF.

Wet the mating surfaces with ATF.

Complete the assembly with a soft hammer.

WARNING

1.2 Position cup springs (54) as shown in figure.

First cup spring has to be installed with the bigger

diameter against the piston.

Second and third cup springs have to be installed in

succession with their bigger diameters against each

other.

SECTION IV: ASSEMBLY

INTRODUCTION

Awell-lightedworkareathat isfreefromdirtandchips,will

facilitate the work considerably.

ZF HURTH MARINE recommends to use a swivelling

stand, described in the disassembly section to aid in the

assembly.

Thoroughly clean all mating surfaces from any loctite or

gasket material.

WARNING

Cleanersandsolventscanbetoxicandharmfulwithout

proper ventilation.

Use caution when using such cleaners.

Always wear protective gloves and glasses!

The next assembly procedure requires the following:

•A hydraulic or mechanical press.

4.20 Supporthousing(36)flatonapress,pressoutbearing

(67), then remove shims (68) (69).

NOTE: This operation will damage the bearing.

51 54

35

Tool

36

67

13

Repair Manual and Spare Parts List ZF 45C / 63C / 88C

1.6 Insertenddisc(finishedsideup)(59), shims(73 -74)

and alternatively outer clutch disc (61) and inner

clutch disc (60).

NOTE: To set correct play see item 2 page 23.

Clutch discs have to be coated with ATF.

1.7 Withtoolp.n.500498andasuitablesupportpressthe

ball bearing (43) into the ring gear support (47).

1.8 Insert the circlip (48).

WARNING

Besurethatsnapringhasbeenproperlyseated(check

circlipopeningtobenotclosetoslotsinclutchhousing).

1.3 Position the circlip (55).

1.4 With tool P.N. 500497 compress the cup springs.

Be sure of their aligment.

1.5 Install the piston rings (40).

NOTE: Coat sealing rings with grease or Petroleum Jally.

Repair Manual and Spare Parts List ZF 45C / 63C / 88C

14

1.12 Install the circlip (50).

WARNING

Be sure that snap ring has been properly seated (check

circlip opening to be not close to slots in clutch housing).

1.13 Install onto input shaft (37) the seal rings (39).

NOTE: Install seal rings (39) with openings in opposite

positions.

1.14 Insert shims (75, 76) between circlip (48) and thrust

washer (42).

NOTE: To set correct play see item 3 pag. 24.

1.9

Presstheforwardclutchhousing(47)on the inputshaft

(37).

1.10 Install the circlip (44).

NOTE: Check carefully correct position of the circlip (44).

1.11 Turn up side down the ring gear (49) and place it on

a suitable support, allowing the shaft go down

completely.

Insert the input shaft (37) into the ring gear (49)

allowingtheinnerclutchdiscstobedrivenbythedisc

carrier.

15

Repair Manual and Spare Parts List ZF 45C / 63C / 88C

2.2 Insert the baffle (29) as shown in the picture. The fold

of the baffle must correspond with the groove on the

housingoppositetothebreatherpositiononthesecond

foldintothesame slot.Thebafflemustbestraightand

tight up against the under side of the housing.

NOTE: ZF 45C vers. TOYOTA 11 only

Install additional baffles (30, 31) and pin spacer (32).

2.3 With special tool P.N. 500496 install needle bearing

(41) into the cover (35).

2.4 Install O-Rings (33) into the cover (35).

1.15 WithtollP.N.500499andasuitablesupportpressball

bearing (67).

Add shims (68, 69) max bearing play:

0,1 mm (0.0039 in)

NOTE: To set correct play see item 4 page 25.

1.16 Install snap ring (70).

2. HOUSING ASSEMBLY

2.1 With tool P.N. 500499 install sealing ring (2).

NOTE:

- Use Loctite P.N. 574 between housing and sealing ring.

- Fillinternallipsofsealingringwithhighqualitygrease(for

ex. Klüber STABURAGS NBU 30).

Repair Manual and Spare Parts List ZF 45C / 63C / 88C

16

2.8 Assemble the cover (5).

Tightsbolts(6)withwasher(10).Tighteningtorque:18

Nm (13.3 lb ft.).

2.9 Installspoolvalve(24)ontofrontcover(35)chekingfor

the correct alignement of groove.

2.10 Install stop screw (17) with washer (13) Tightening

torque: 12 Nm (8.9 lb ft.).

Installontocover(35)ball(21),spring(20)andguide

spring (18) together with sealing washer (13).

Guidespring(18)tighteningtorque:12Nm(8.9lbft.).

Turn slowly spool valve (24) to centre groove to ball

(21).

NOTE:Theplugshowninthefigurewiththearrow,willonly

be tighten if the distributor is correctly oriented.

2.5 Install O-Ring (57) into the piston (56).

Wet O-Ring with ATF oil and using a plastic hammer,

install the assembled piston (56) into cover (35).

2.6 Install the filter (3).

2.7 Install the rubber oil plate (4).

17

Repair Manual and Spare Parts List ZF 45C / 63C / 88C

2.14 Install plug (14) and washer (19).

NOTE: Tighten to 25 Nm (18.5 lb ft.) torque.

2.15 Install sealing ring (23) using the special tool P.N.

500495 and a plastic hammer.

NOTE: Check the correct position of sealing ring (23).

2.16 Install the lever (25) with bolt (11) washer (10) and

nut (9).

NOTE: Tigthen bolt (11) to 22.5 Nm. (16.5 lb ft.) torque.

2.11 Installbushing(16)inthewaythatitsbiggerdiameter

is up.

2.12 Install the ball (21).

2.13 Install the microswitch (15).

Repair Manual and Spare Parts List ZF 45C / 63C / 88C

18

3.3 Install the thrust washer (45).

CAUTION

Be sure the bend correspond with the hole.

3.4 Assemble the input shaft assembly into the housing.

NOTE: To set correct play see item 3 page 23.

3. COMPLEMENTARY OPERATIONS

3.1 Install the friction bearing (46) with tool P.N. 500494.

3.2 Assemble the output shaft by pressing the shaft into

the housing.

NOTE: Coat output shaft with grease prior to assembly.

As a precaution support the inner race of the bearing.

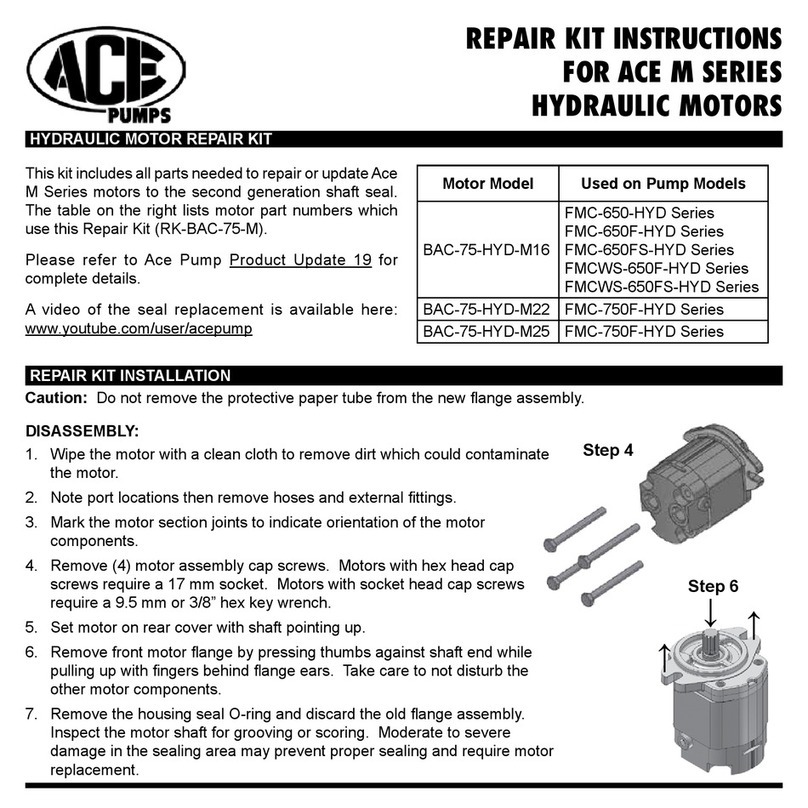

Neutral Safety Switch Function check

Connect neutral safety switch with a lamp in series to a

battery. The neutral safety switch operates when the lamp

is lighted.

NOTE: The lamp must be extinguised when the pin is

pushed in.

45

Battery 14 V DC

Battery 14 V DC

Lamp 8.4 A

Lamp 8.4 A

Neutral

position

A or B

position

This manual suits for next models

3

Table of contents