Fondis Ulys Series User manual

INDICATIONS PLACED ON THE NAMEPLATE FOUND ON THE APPLIANCE

oModel : ………………………………..

oSeries number : …………………………..

o

Date of purchase : ………………………...

Installation guide & User guide

(please keep)

Réf :

01/2012

Ulys

®

IMPORTANT :

IT IS RECOMMENDED TO NOTE THE SERIAL NUMBER AND

TO WRITE IT DOWN IN THE BOX ABOVE. IT WILL BE

NECESSARY FOR ORDERING SPARE PARTS.

ARTICLE ULYS600

QTE

ULYS700

QTE

ULYS800V

QTE

ULYS900

QTE

ULYS1100

QTE

ULYS XXL

QTE

1.1 BF58200

1 BF55200

1 BF56200 1 BF53200

1 BF57200 1 BF518200

1

1.2 BF56299

1 BF55299

1 BF56299 1 BF53299

1 BF57299 1 BF518299

1

1.3 BF53324

2 BF53324

2 BF53324 2 BF53324

2 BF53324 2 BF53324 2

1.4 BF40125

2 BF40125

2 BF40125 2 BF40125

2 BF40125 2 BF52608 2

1.5 BF58316

4 BF55316

4 BF56316 4 BF53316

4 BF55316 4 BF53316 4

1.6 BF58305

2 BF55305

2 BF56305 2 BF53305

2 BF57305 2 BF518305

2

1.7 BF53007

1 BF53007

1 BF53007 1 BF53007

1 BF53007 1 BF53007 1

1.8 BF53008

1 BF53008

1 BF53008 1 BF53008

1 BF53008 1 BF53008 1

1.9 BF56285

1 BF55285

1 BF56285 1 BF53285

1 BF57285 1 BF57285 1

1.10A BF40204

4 BF40204

4 BF40204 4 BF40204

4 BF40204 4 BF40204 4

1.10B BF59501

4 BF59501

4 BF59501 4 BF59501

4 BF59501 4 BF59501 4

1.11 BF58282

1 BF55282

1 BF56282 1 BF53282

1 BF55282 1 BF53282 1

1.12 BF58281

1 BF55281

1 BF56281 1 BF53281

1 BF55281 1 BF53281 1

1.13 BF58300

1 BF55300

1 BF56300 1 BF53300

1 BF57300 1 BF57300 1

1.14 BF56334

1 BF55334

1 BF56334 1 BF53334

1 BF57334 1 BF518334

1

1.15 BF53336

1 BF53336

1 BF53336 1 BF53336

1 BF53336 1 BF53336 1

1.16 BF53335

1 BF53335

1 BF53335 1 BF53335

1 BF53335 1 BF53335 1

1.17 BI11854

4 BI11854

4 BI11854 4 BI11854

4 BI11854 4 BI11854 4

1.18 BF53352

1 BF53352

1 BF53352 1 BF53352

1 BF53352 1 BF53352 1

1.19 BF53337

1 BF53337

1 BF53337 1 BF53337

1 BF53337 1 BF53337 1

1.20 BF56009

1 BF40114

1 BF56009 1 BF40114

1 BF40114 1 BF40114 1

1.22 BUTSIL 2 BUTSIL 2 BUTSIL 2 BUTSIL 2 BUTSIL 2 BUTSIL 2

2 BF56288

1 BF55288

1 BF56288 1 BF53288

2 BF57288 2 BF57288 2

3 BF58287

1 BF55287

1 BF56287 1 BF53287

1 BF57287 1 BF53287 1

1 BF518287

1

4 BF58286

2 BF55286

2 BF56286 2 BF53286

2 BF55286 2 BF53286 2

5 BF53296

2 BF53296

2 BF53296 2 BF53296

2 BF53296 2 BF53296 2

6 BF58344

2 BF55344

2 BF56344 2 BF53344

2 BF57344 2 BF53344 2

7 BF40178

2 BF40178

2 BF40178 2 BF40178

2 BF40178 2 BF40178 2

9 BF56345

1 BF55345

1 BF56345 1 BF53345

1 BF57345 1 BF57345 1

10.1 BF58308

1 BF57308

1 BF56308 1 BF53308

1 BF57308 1 BF518308

1

10.2 BF56309

1 BF57309

1 BF56309 1 BF53309

1 BF57309 1 BF57309 1

10.3 BF58310

1 BF57310

1 BF56310 1 BF53310

1 BF57310 1 BF518310

1

10.4 BF56346

1 BF57346

1 BF56346 1 BF53346

1 BF57346 1 BF57346 1

11 BF58391

1 BF57391

1 BF56391 1 BF53391

1 BF57391 1 BF518391

1

12 BF58295

1 BF53295

1 BF53295 1 BF53295

1 BF53295 1 BF53295 3

13.2 BF56284

1 BF55284

1 BF56284 1 BF53284

1 BF57284 1 BF57284 1

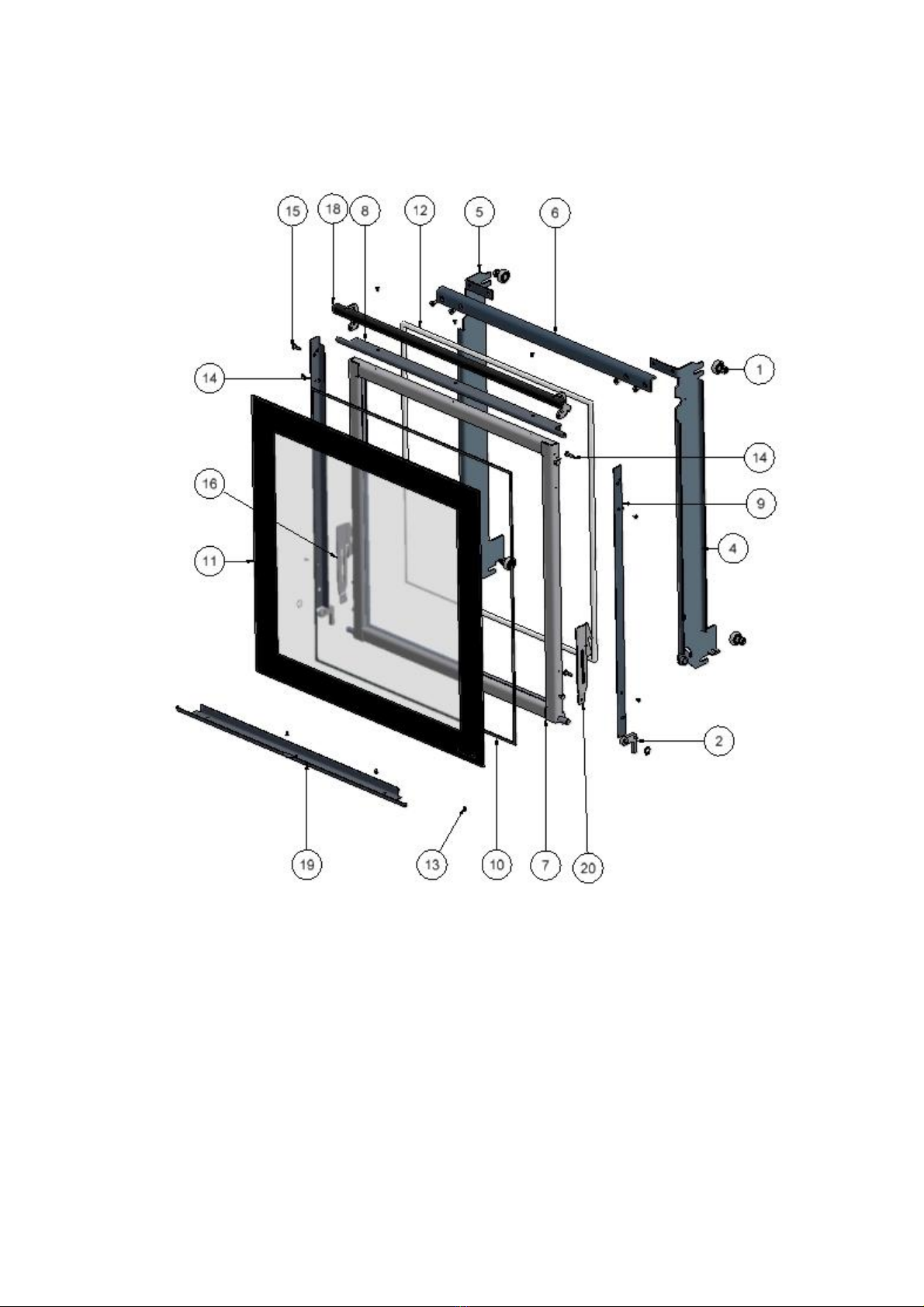

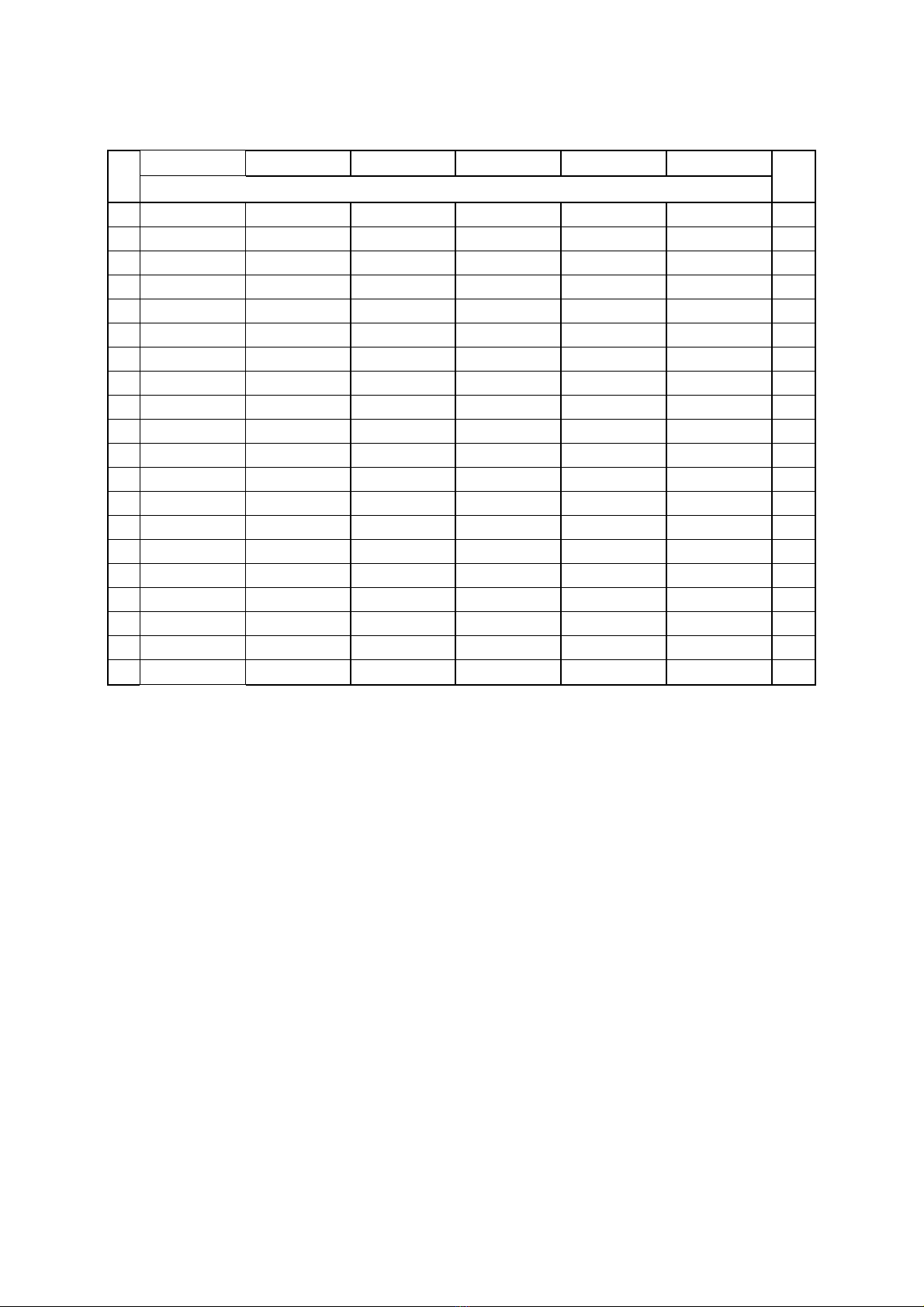

N°

ULYS 600 ULYS 700 ULYS 800 ULYS 900 ULYS 1100 ULYS XXl QTE

CODART

1 BF52535 BF52535 BF52535 BF52535 BF52535 BF52535 4

2 BF53260 BF53260 BF53260 BF53260 BF53260 BF53260 1

3 BF53261 BF53261 BF53261 BF53261 BF53261 BF53261 1

4 BF58338 BF55338 BF56338 BF53338 BF55338 BF53338 1

5 BF58339 BF55339 BF56339 BF53339 BF55339 BF53339 1

6 BF56342 BF55342 BF56342 BF53342 BF57342 BF57342 1

7 BF58325 BF55325 BF56325 BF53325 BF57325 BF518325 1

8 BF56258 BF55258 BF56258 BF53258 BF57258 BF57258 1

9 BF58276 BF55276 BF56276 BF53276 BF55276 BF53276 1

10 40240.1 40240.1 40240.1 40240.1 40240.1 40240.1 1

11 BF58252 BF55252 BF56252 BF53252 BF57252 BF18252 1

12 BF40214 BF40214 BF40214 BF40214 BF40214 BF40214 1

13

VIS M4X5 THCF VIS M4X5 THCF VIS M4X5 THCF VIS M4X5 THCF VIS M4X5 THCF VIS M4X5 THCF

4

14 BF58277 BF55277 BF56277 BF53277 BF57277 BF53277 1

15 BF53319 BF53319 BF53319 BF53319 BF53319 BF53319 8

16 BF53350 BF53350 BF53350 BF53350 BF53350 BF53350 1

17 BF53394 BF53394 BF53394 BF53394 BF53394 BF53394 2

18 BF58401 BF55401 BF56401 BF53401 BF57401 BF57401 1

19 BF56351 BF55351 BF56351 BF53351 BF57351 BF57351 1

20 BF53326 BF53326 BF53326 BF53326 BF53326 BF53326 1

ULYS600

ULYS700

ULYS800V

ULYS900

ULYS1100

ULYS

1100

XXL

ULYS 600 ULYS 700 ULYS 800 ULYS 900 ULYS 1100

ULYS

1100

XXL

Rep

Ref a ticle

BF58380 BF55380.1

BF56380 BF53380.1

BF57380 BF518380

1

BF40101 1 1 1 1 2

2

2

BF40102 1 1 1 1 2

2

3

BF53361 1 1

1

4

BF53372 1

5

BF53369 2 2 2

6

BF53367 2 2 2

7

BF53364 1 1

1

8

BF53360 1

9

BF53363 1

10

BF53366 2

2

11

BF53368 2

2

1

2

BF53370 2

2

13

BF53371 2

14

BF53362 1 1

15

BF53365 1 1

16

BF53374 2

17

BF53375 2

18

BF53376 1

19

BF53373 2

20

BF518370

1

ULYS 600

ULYS 700

ULYS 800V

ULYS 900

ULYS 1100

ULYS 1100 XXL

12

Le fabricant soussigné : The undersigned manufacturer :

FONDIS SA /ZI de Vieux-Thann, 18 rue Guy de Place-68801 THANN Cedex–France

Unité de production / Manufacturing plant : FONDIS

Déclare que l’équipement, désigné ci-après : herewith declare that the products :

Modèle / Model

U

LYS

600

U

LYS

700

U

LYS

700

ZE

U

LYS

800V

U

LYS

900

U

LYS

900

ZE

U

LYS

1100

Genre / Kind

Foyer à combustion solide/Inset appliance fired by solid fuel

Classification /

Categorisation

Appareil à porte fermée/Appliance operating with firedoors closed

Marque / Trade Mark

FONDIS

FONDIS

FONDIS

FONDIS

FONDIS

FONDIS

FONDIS

Puissance nominale /

Nominal heat output kW

11.0 10.6 10.5 13.5 15.9 14.7 14.0

Rendement / Efficiency

78.0 %

79.1 %

86.4 %

81.0 %

78.9 %

79.9 %

78.6 %

Co moyen / Co contente

(13% O2)

0.13 %

0.12 %

0.01 %

0.11 %

0.16 %

0.02 %

0.13 %

Emissions de CO (mg/m3

0 13%O2)

1635

1533

146 1298

1919

238 1576

Consommation Bois

(kg/h) 3.04 2.53 2.59 3.58 4.32 3.96 3.81

Température moyenne

des fumées (°C) 250 290 263 251 289 235 271

Est conforme / is in conformity :

* à la norme européenne EN13229 de juin 2002. Lorsqu’il est installé conformément aux instructions d’installation fournies

dans la documentation. When installed in accordance with the installation instructions contained in the product documentation

La procédure d’attestation de la conformité appliquée comporte / Provisions to which the products conforms

Examen CE de type initial

EC Initial type testing

Sous la responsabilité

Under the responsability

FONDIS SA, ZI de Vieux Thann, 18 Rue Guy de

Place

68801 Thann Cedex–France

Vieux–Thann—France

Date : 04/10/2010

Nom / Name : Frédéric HAAS

Qualité / Position : Directeur Technique / Technical Manager

DECLARATION CE DE CONFORMITE

Ec Declaration of Conformity

12

Our responsibility is limited to the appliance in accordance with the standard in force when this

document was printed.

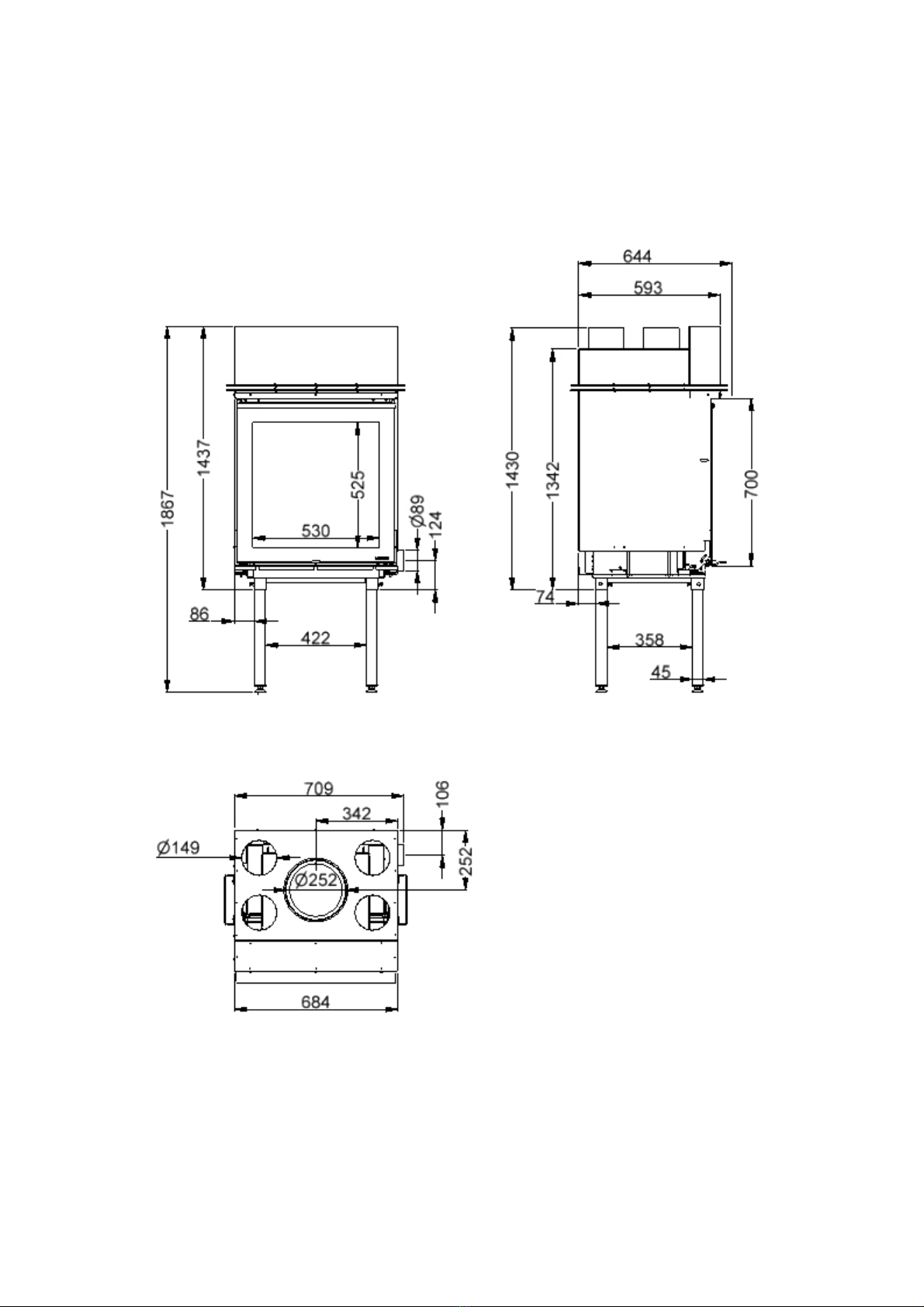

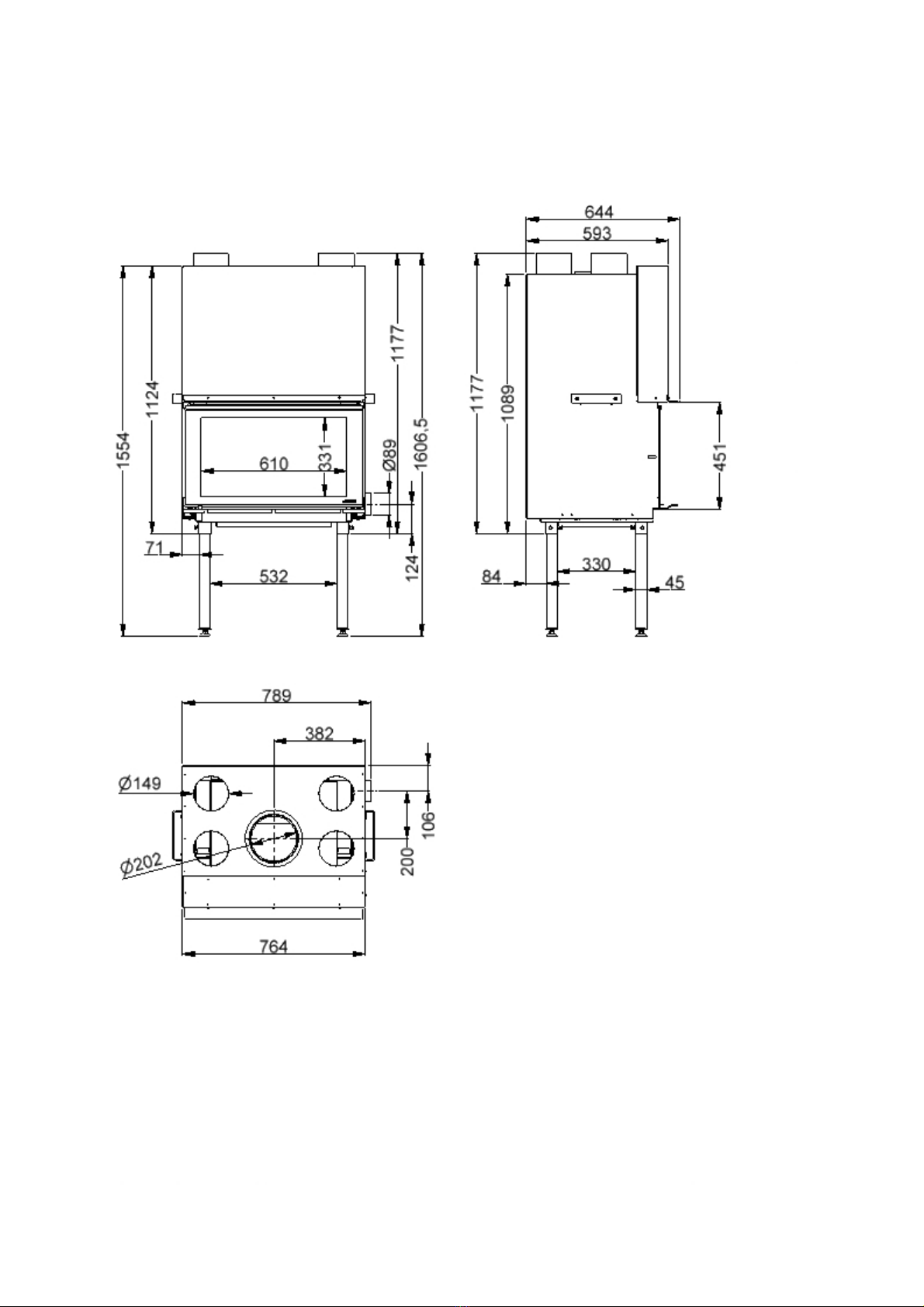

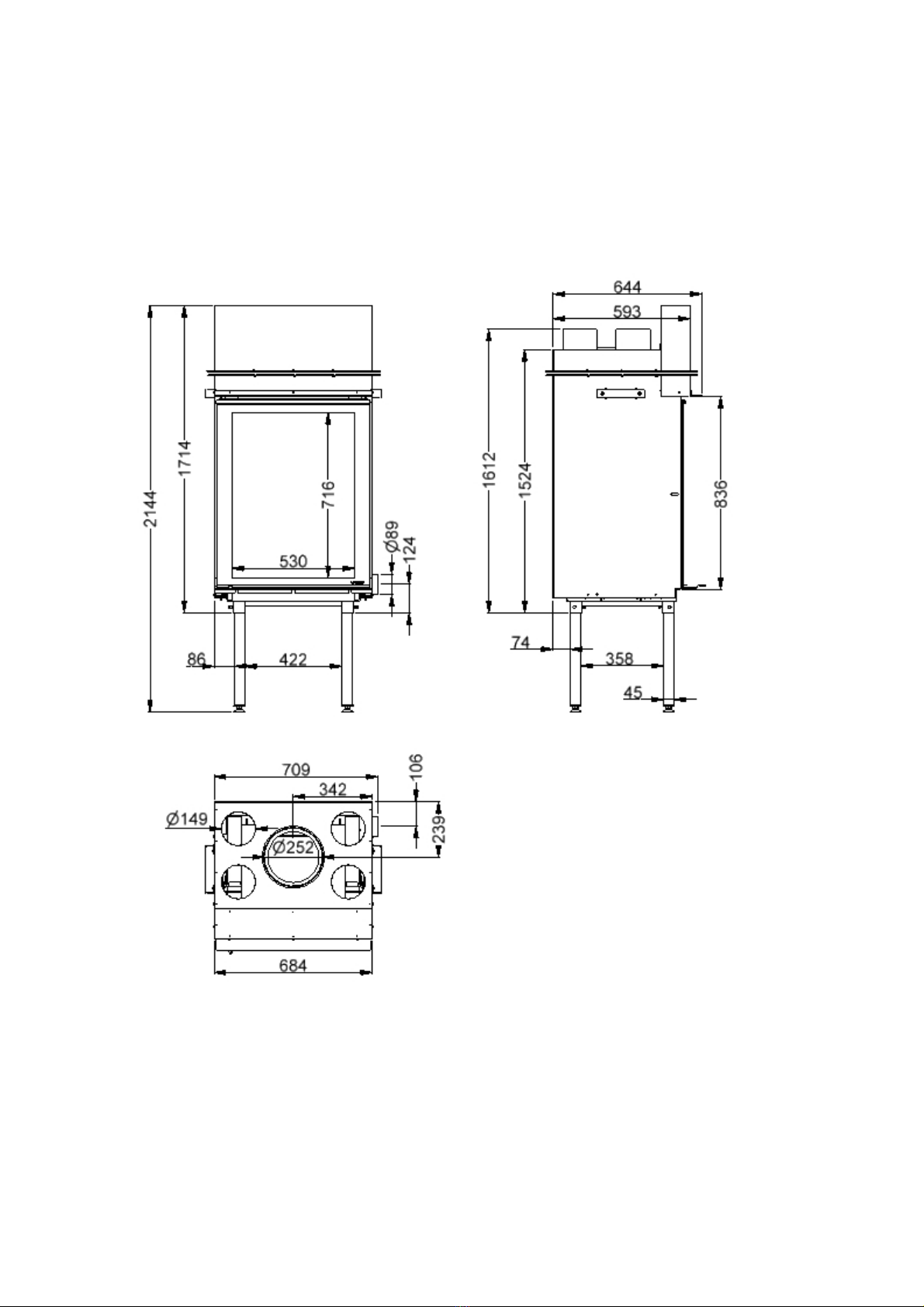

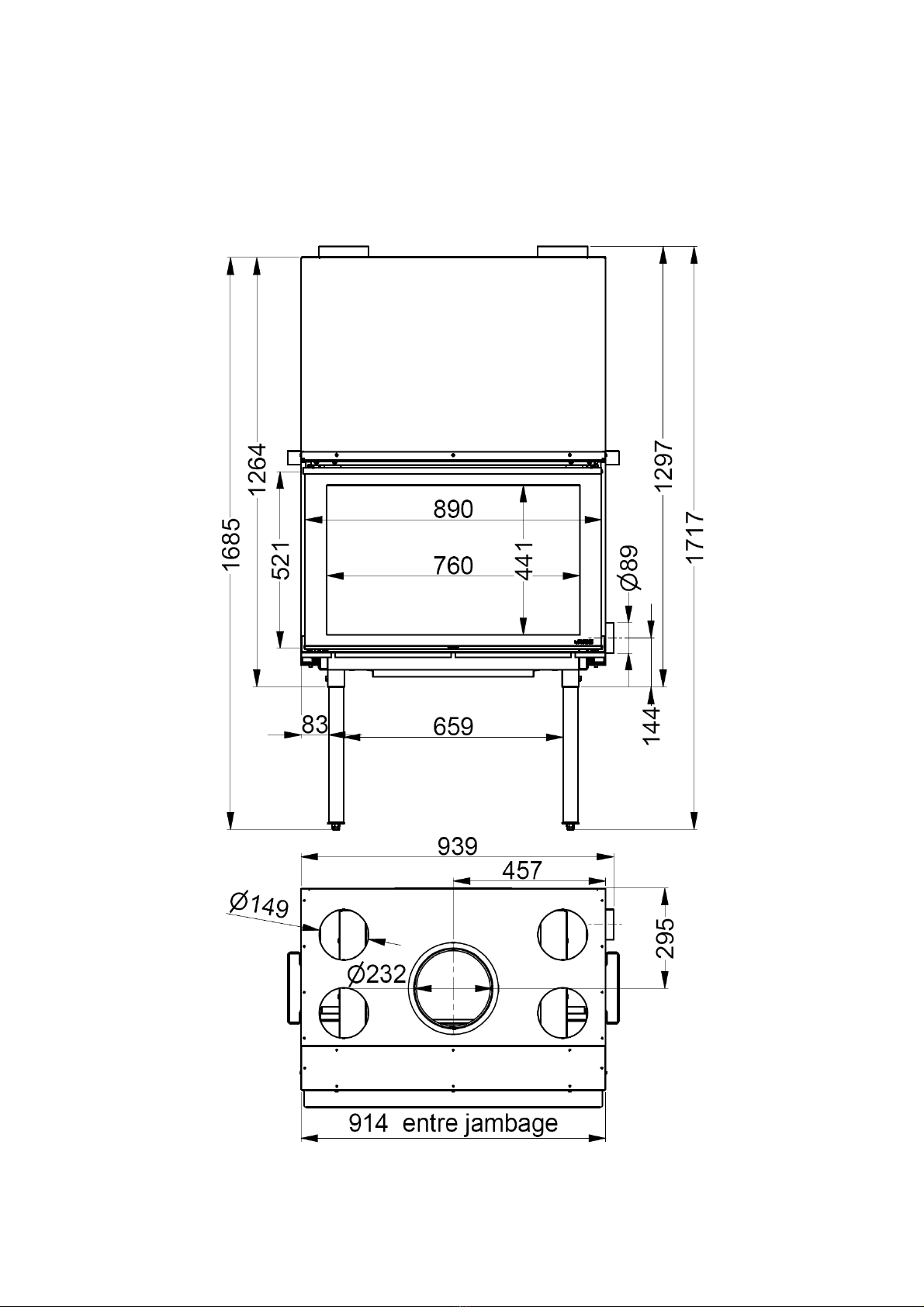

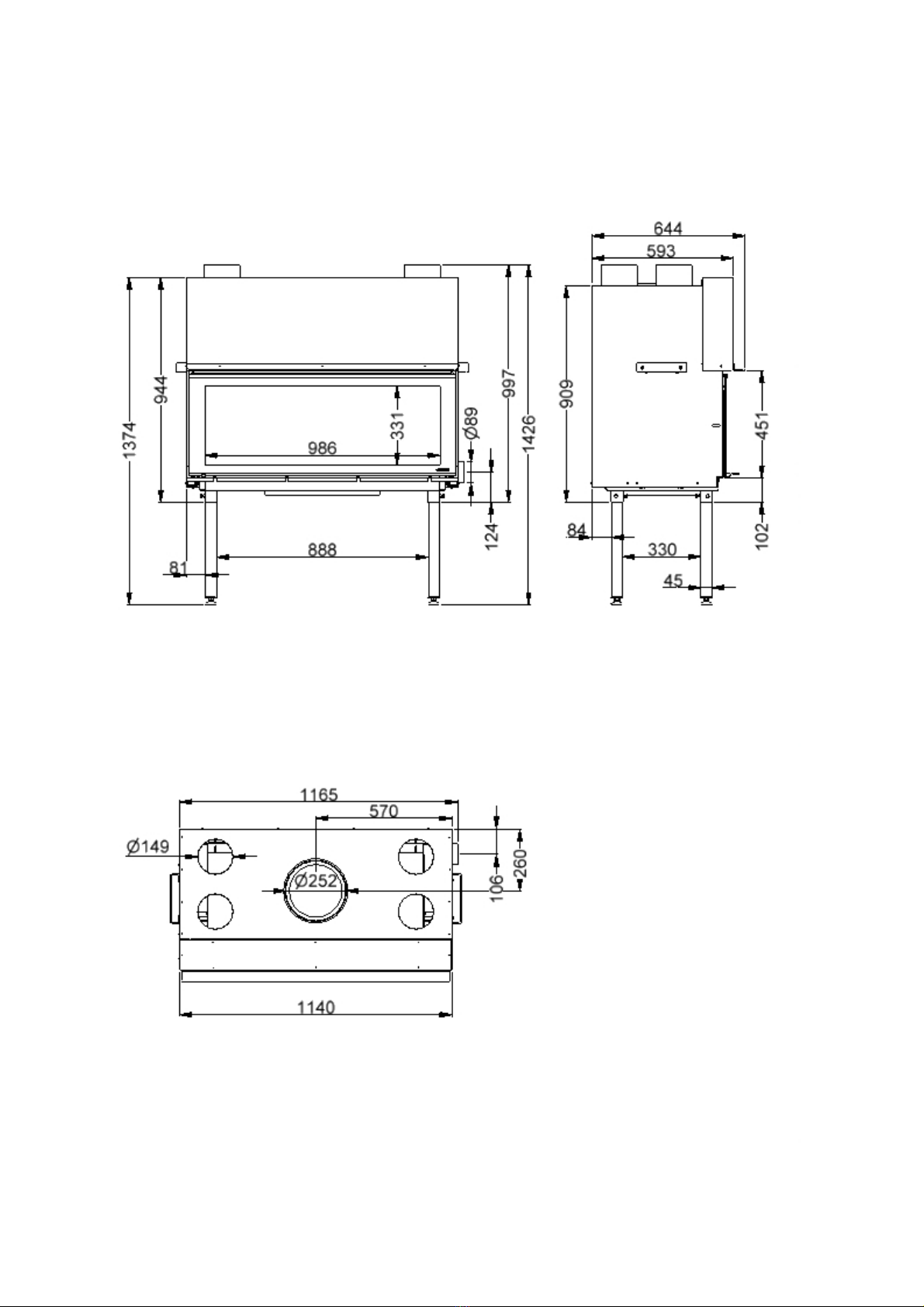

FIREPLACE CHARACTERISTICS

Length Height Width Weight

ULYS 900 915 mm 1618 mm 644 mm 264 kg

ULYS 700 764 mm 1365 mm 644 mm 200 kg

ULYS 1100 1165 mm 996.5 mm 644 mm 270 kg

ULYS 800V 764 mm 1365 mm 644 mm 200 kg

ULYS 600 684 mm 1852 mm 650 mm 244 kg

ULYS XXL 1165 mm 1217 mm 647 mm 325 kg

For manufacturing reasons, dimensional variations may occur compared to theoretical

dimensions. This is due to tolerance and manufacturing imperatives. In addition, given

the expansion of the various materials, the appliance may show some slight

deformation when hot.

13

EXPLODED VIEW

DECLARATION DE CONFORMITE

FIREPLACE CHARACTERISTICS

1.INSTALLATION GUIDE

1.1. RESPONSIBILITIES 15

1.1.1. INSTALLER S RESPONSIBILITIES 15

1.1.2. OBSERVANCE OF REGULATIONS 15

1.2. CHIMNEY FLUE 15

1.2.1. NEW FLUE 15

1.2.2. EXISTING FLUE 15

1.2.3. DIMENSIONS OF THE CHIMNEY FLUE 16

1.2.4. DISTANCE OF THE CHIMNEY FLUE IN RELATION TO FUEL MATERIALS

1.3. OUTSIDE AIR INLET 17

1.4. INSTALLATION AND MINIMUM DIMENSIONS OF THE FIREPLACE 17

1.4.1. INSTALLATION OF THE FIREBOX 17

1.4.2. FITTING AND LEVEL CONTROL 18

1.4.3. MINIMUM DIMENSIONS OF THE FIREPLACE 19

1.4.4. FLOOR 19

1.5. VENTILATION OF THE HOOD 20

1.5.1 CONVECTIVE AIR INLET 20

1.5.2 CONVECTIVE AIR OUTLET 20

1.6. PARTITION INSULATION 21

1.6.1. WALL AND CEILING INSULATION 21

1.6.2. INSULATION OF THE WOOD NICHE 21

1.7. CONNECTION OF THE APPLIANCE 21

2. USER GUIDE 23

2.1. WARNINGS 23

2.2. FIRST FIRES 23

2.3. FIREBOX IGNITION 23

2.4. LOADING 23

2.5 2.5. RELOADING 23

2.6. POWER LEVEL SETTING 24

2.6.1. OPEN FIREBOX OPERATION 24

2.7. CHOICE OF FUEL 24

2.8. MAINTENANCE 25

2.8.1. GLASS 25

2.8.2. REFRACTORY LINING 25

2.8.3. ASHES 25

2.8.4. PAINT 25

SUMMARY

14

2.8.5. SEALING JOINTS 25

2.8.6. CHIMNEY SWEEPING

2.8.7. ANNUAL SERVICE 26

3.3. CONTRACTUAL WARRANTY 27

4.4. ANNEXES 28

4.1. OPERATION DIAGNOSTIC 28

4.2. FROM TREE TO FIRE 29

15

1.1. RESPONSIBILITIES

1.1.1. INSTALLER S RESPONSIBILITIES

The person or company that carries out the installation of the fireplace is responsible for this

installation, and also takes responsibility for the existing parts (chimney flue…)

They are hence expected to check the state of the existing installation and to carry out the

necessary modifications to comply with current regulations.

1.1.2. OBSERVANCE OF REGULATIONS

The instructions and recommendations of the guide come in addition to current regulations. They

do not replace them. We recommend that you familiarise yourself with the documents mentioned

below. The installation of the appliance must be carried out following the DTU 24.2.2 technical

guidelines. The chimney flue to which the appliance will be connected must comply with the DTU

24.1 and 24.2.2 guidelines or it will be the object of a technical notice from the C.S.T.B. (French

Scientific and Technical Buildling Centre).

Since this fireplace is in compliance with current standards, it is strictly forbidden to modify the

appliance in any way.

1.2. CHIMNEY FLUE

In the case of a chimney flue ending at the level of the ceiling (installation prior to the

implementation of the current DTU), we draw your attention on the following requirements:

- either a junction of the connecting duct and the chimney duct ensuring the tightness and the

thermal resistance of the installation,

- or appropriate casing of the throat at the stack base, following the rules of fire spacing.

1.2.1. NEW FLUE

The duct must be made with materials in compliance with current standards and with technical

notice from the CSTB. The duct must also be able to sustain the maximum temperature of the

appliance. The duct must be installed following the DTU guidelines, in particular regarding its

thermal insulation.

1.2.2. EXISTING FLUE

One must check :

- - the compatibility of the duct with the use of wood as fuel,

- - the tightness and vacuity of the duct (see DTU 24.1),

- - its general stability,

1.INSTALLATION GUIDE

16

If the duct is not compatible, it is necessary to :

- either carry out a casing (see DTU 24.1) following a procedure with technical notice in favour of

this particular use,

- install a duct lining,

- or install a new duct adapted to this use.

The tubing can descend to the nozzle of the appliance, if it is the object of a technical notice for the

use as connecting duct.

1.2.3. DIMENSIONS OF THE CHIMNEY FLUE

The chimney flue must have a minimum rectangular or square section of X cm2 and a length/width

ratio of less than 2 or an equivalent section of minimum hydraulic diameter Øeq. mm. In the case

of lining, this section can be brought back to CH cm2.

In the case of casing, and under certain conditions, the minimum diameter can be brought back to

TU mm. It is highly recommended to have a duct of identical hydraulic diameter as the vent, i.e. of

diameter Øint. mm (Female nozzle Øint). Moreover, the top of the chimney must be above the roof

ridge by at least 40 cm. In any case, and in order for the fireplace to operate properly, the draft

(TI) of the duct must be between 10 and 30 Pa (1 to 3 mm of water column). Outside these

ranges, an insufficient draft will lead to fume backdrafts and an excessive draft will lead to

runaway combustion and fireplace damage.

The draft can be regulated using a draft moderator set to 2 mm of water column.

Ø int X Ø eq. CH mini TU mini

230 mm 400 cm² 200 mm 350 cm² 180 mm

1.2.4. DISTANCE OF THE CHIMNEY FLUE IN RELATION TO FUEL MATERIALS

The minimum space between the inside wall of the duct and any combustible material is

16 cm unless a technical notice of the CSTB specifies a different distance.

Even if the fire spacing requirements are followed, a supplementary insulation made with M0 class

insulant will provide improved safety.

In the living spaces, the ducts must be covered with a dressing providing a thermal insulation

sufficient to limit the surface temperature to 50°C.

- Across attics and lofts, ducts must have suitable insulation.

17

1.3. OUTSIDE AIR INLET

If the ventilation inside the room where the appliance is installed is insufficient (new house or

controlled mechanical ventilation system), an inlet of outside air specifically for the fireplace

operation must be added.

1.4. INSTALLATION AND MINIMUM DIMENSIONS OF THE FIREPLACE

1.4.1. INSTALLATION OF THE FIREBOX

It is important to follow our recommendations, as follows, in order to ensure the optimum safety

for the user.

ATTENTION, REALISER L'ARRIVEE D'AIR EXTERIEUR ET LA MISE A NIVEAU DE

L'APPAREIL AVANT DE POSER LE FOYER.

This manual suits for next models

7

Table of contents

Other Fondis Indoor Fireplace manuals

Popular Indoor Fireplace manuals by other brands

Heat-N-Glo

Heat-N-Glo SL-750TRS-C Installer's guide

Heatilator

Heatilator ION-V7 installation manual

Mustang

Mustang BASEMENT instructions

Home Decorators Collection

Home Decorators Collection SP6977 quick start guide

Superior Fireplaces

Superior Fireplaces WRE3042WH Installation and operation instructions

FireplaceXtrordinair

FireplaceXtrordinair FPX 564 Brochure & specs