Forma Scientific 3658 User manual

Forma Scientific, Inc.

P.O. Box 649

Marietta, Ohio 45750

U.S.A.

Telephone: (614) 373-4763

Telefax: (614) 373-4189

________________________________________

Models:

3658/3659, 3660/3661

and 3662/3663

Laboratory Refrigerator

Manual No. 7003658

IMPORTANT!

READ THIS INSTRUCTION MANUAL.

Failure to read, understand and follow the instructions in this manual may result in

damage to the unit, injury to operating personnel and poor equipment performance.

Caution: All internal adjustments and maintenance must be performed by

qualified service personnel.

March 1994

Forma Scientific, Inc.

______________________________________________________________________________

ii

The material in this manual is for information purposes only. The contents and the

product it describes are subject to change without notice. Forma Scientific, Inc. makes no

representations or warranties with respect to this manual. In no event shall Forma

Scientific, Inc. be held liable for any damages, direct or incidental, arising out of or

related to the use of this manual.

Forma Scientific, Inc.

______________________________________________________________________________

iii

The Occupational Safety and Health Administration (O.S.H.A.) has revised Section 1910-

147, The Control Of Hazardous Energy (Lockout/Tagout).

Hazardous energy may be: electric, air, hydraulic, water, steam, gravity, spring & all

other equally hazardous energy.

This revised regulation, states that you will de-energize all potential sources of energy (may

be more than one energy source) prior to performing service or maintenance on any

equipment. It also states that a lock shall be placed on the de-energized control, along with a

verified test (use of a voltmeter or other equipment) to insure no accidental starts. If you are not

familiar with this regulation, review the O.S.H.A. Regulation, Section 1910-147.

In field service, full compliance with this regulation is difficult at best. Troubleshooting must

often be performed with hazardous energy applied; therefore extreme caution must be followed

during these troubleshooting steps. Only Qualified Personnel Must Perform This Work. This

phase of the repair work must be coordinated through the customer's facilities maintenance

department or designated person.

When performing service or maintenance as an outside contractor/worker, follow the

Outside Work Force's Lockout/Tagout system. Be alert for new types of lockout/tagout

devices.

√Always use the proper protective equipment (clothing, gloves, goggles etc.).

√Always dissipate extreme cold or heat, or wear protective clothing.

√Always follow good hygiene practices.

√Each individual is responsible for his/her own safety.

For your safety adhere to all DANGER and CAUTION statements.

Danger: This word is used to call attention to immediate hazards of

equipment or conditions which, if not avoided, could result in personal

injury, loss of life or property damage.

Caution: This word is used to call attention to potential hazards of

equipment or conditions which, if not avoided, could

result in personal injury, loss of life or property damage.

Forma Scientific, Inc.

______________________________________________________________________________

v

DO YOU NEED INFORMATION OR ASSISTANCE ON FORMA SCIENTIFIC

PRODUCTS?

If you do, please contact us 8:00 A.M. to 5:00 P.M. (Eastern Standard Time) at:

1-614-373-4763 Direct

1-800-848-3080 Toll Free, U.S. and Canada

1-614-373-4189 FAX

29-8205 Telex

International customers please contact your local sales group.

Forma's Customer Service Group can provide information on pricing, give you quotations,

take your order and provide delivery information on major equipment items.

The Forma Product Service Group can supply technical information about proper setup,

operation or troubleshooting of your equipment and fill your needs for spare or replacement parts or

provide you with on-site service.

Whatever Forma products you need or use, we will be happy to discuss your applications or

problems. If you are experiencing technical problems, working together, we will help you locate the

problem and, chances are, correct it yourself .... over the telephone without a service call.

When more extensive service is necessary, you can count on Forma Scientific, Inc. for on-the-

spot repairs by our trained professional field technicians. In addition to checking the reported problem, our

technicians also check basic operation, such as:

Control Calibrations Electrical Circuits

Temperature Recorders

CO2Levels Blowers/Fans

Compressors R.H. Levels

The following cities and their surrounding areas are covered by Direct Service personnel:

Atlanta, GA

Chicago, IL

Denver, CO

Hartford, CT

Los Angeles, CA

Newington, NH

Philadelphia, PA

San Francisco, CA

Washington, PA

Austin, TX

Columbus, OH

Detroit, MI

Memphis/Nashville, TN

New York City, NY

Raleigh/Durham, NC

St. Louis, MO

Boston, MA

Dallas/Ft. Worth, TX

Ft. Pierce, FL

Lexington, KY

Newark, NJ

Orlando, FL

San Diego, CA

Washington, DC

In the areas listed above, where service coverage is by Direct Service personnel, we offer

our Bi-Annual Performance Check. This program provides a complete checkout of your

equipment twice a year and keeps minor problems from becoming major ones. If you are

located in one of the areas listed above, and you would like to know more about our Bi-Annual

Performance Check, please contact our Product Service Department on the Toll-free 800

number.

Forma Scientific, Inc.

______________________________________________________________________________

vii

TABLE OF CONTENTS

SECTION 1 - RECEIVING

1.1 Preliminary Inspection

1.2 Visible Loss or Damage

1.3 Responsibility for Shipping Damage

SECTION 2 - INSTALLATION AND START-UP

2.1 Location and Unpacking

2.2 Leveling and Wall Mounting the Unit

2.3 Connecting to Power

2.4 Installing the Shelves

2.5 Start-Up Procedure

SECTION 3 - CONTROLS AND INDICATING DEVICES

3.1 Temperature Control Dial

3.2 Defrost Indicator

3.3 High and Low Temperature Alarm

3.4 Door Ajar Indicator

3.5 Audible Alarm Switch

3.6 Interior Lights Switch

3.7 Digital Display

3.8 Defrost Indicator (Left and Right)

3.9 Refrig Indicator (Left and Right)

SECTION 4 - ROUTINE MAINTENANCE

4.1 Defrosting the Unit

4.2 Cleaning the Drain Evaporation Tray and the Condenser

Filter

4.3 Cleaning the Unit

Forma Scientific, Inc.

______________________________________________________________________________

viii

SECTION 5 - TROUBLESHOOTING

SECTION 6 - SPECIFICATIONS

SECTION 7 - PARTS LIST

SECTION 8 - SCHEMATICS

SECTION 9 - WARRANTY INFORMATION

Forma Scientific, Inc.

______________________________________________________________________________

1-1

SECTION 1 - RECEIVING

1.1 Preliminary Inspection

This item was thoroughly inspected and carefully packed prior to shipment and all

necessary precautions were taken to ensure safe arrival of the merchandise at its

destination. Immediately upon receipt, before the unit is moved from the receiving area,

carefully examine the shipment for loss or damage. Unpack the shipment and inspect

both interior and exterior for any in-transit damage.

1.2 Visible Loss or Damage

If any loss or damage is discovered, note any discrepancies on the delivery receipt.

Failure to adequately describe such evidence of loss or damage may result in the carrier

refusing to honor a damage claim. Immediately call the delivering carrier and request

that their representative perform an inspection. Do not discard any of the packing

material and under no circumstances move the shipment from the receiving area.

1.3 Responsibility for Shipping Damage

For products shipped F.O.B. Marietta, Ohio, the responsibility of Forma Scientific,

Inc. ends when the merchandise is loaded onto the carrier's vehicle.

On F.O.B. Destination shipments, Forma Scientific's and the carrier's responsibility

ends when your Receiving Department personnel sign a free and clear delivery receipt.

Whenever possible, Forma Scientific, Inc. will assist in settling claims for loss or

in-transit damage.

Forma Scientific, Inc.

______________________________________________________________________________

2-1

SECTION 2 - INSTALLATION AND START-UP

2.1 Location and Unpacking

Locate the unit on a firm, level surface in an area of minimum ambient temperature

fluctuation. Avoid installing the unit near heat-emitting appliances, as heat can shorten

component life and cause inefficient refrigeration.

Chamber temperature is maintained through the circulation of forced air, therefore

the air inlet grill at the bottom front of the cabinet must never be blocked. Allow 4-5

inches of clearance at the back of the unit to reduce power consumption and allow free

air circulation.

Avoid placing the unit in a contaminated area where there is an excessive amount

of dust or where chemicals or gases are present.

Caution: A dedicated, grounded electrical outlet must be provided for the

unit. Consult a qualified electrician for further information.

Remove the packing material and tape. Leave the refrigerator door open for a short

time so that air can circulate freely inside.

2.2 Leveling and Wall Mounting the Unit

Use the adjustable mounts on the bottom front of the unit for leveling and

stabilizing the cabinet. Turn the levelers counterclockwise until they make firm contact

with the floor.

Note: On Models 3662 and 3663, it is especially important that the center leveler be

adjusted correctly to assure cabinet stability.

Two wall mounts are attached to the top rear of the unit. Remove the wall mounts

and reverse their position. Attach the brackets to the wall. A special bolt-nut is supplied

for concrete walls.

2.3 Connecting to Power

Connect the unit to a dedicated, grounded power source using the three-prong

power plug. Refer to the electrical data plate on the unit for electrical specifications.

Forma Scientific, Inc.

______________________________________________________________________________

2-2

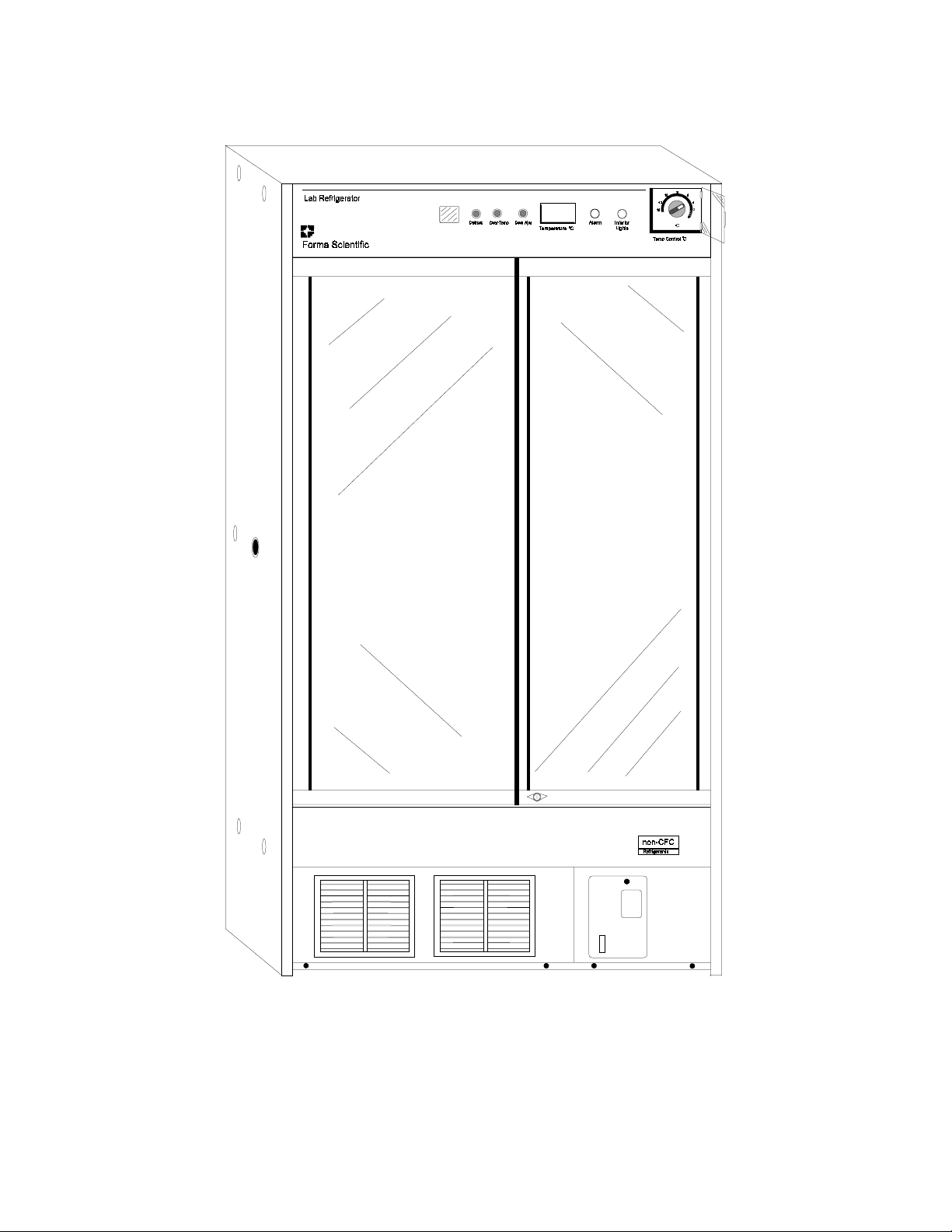

Laboratory Refrigerator

Models 3658/3659 and 3660/3661

Forma Scientific, Inc.

______________________________________________________________________________

2-3

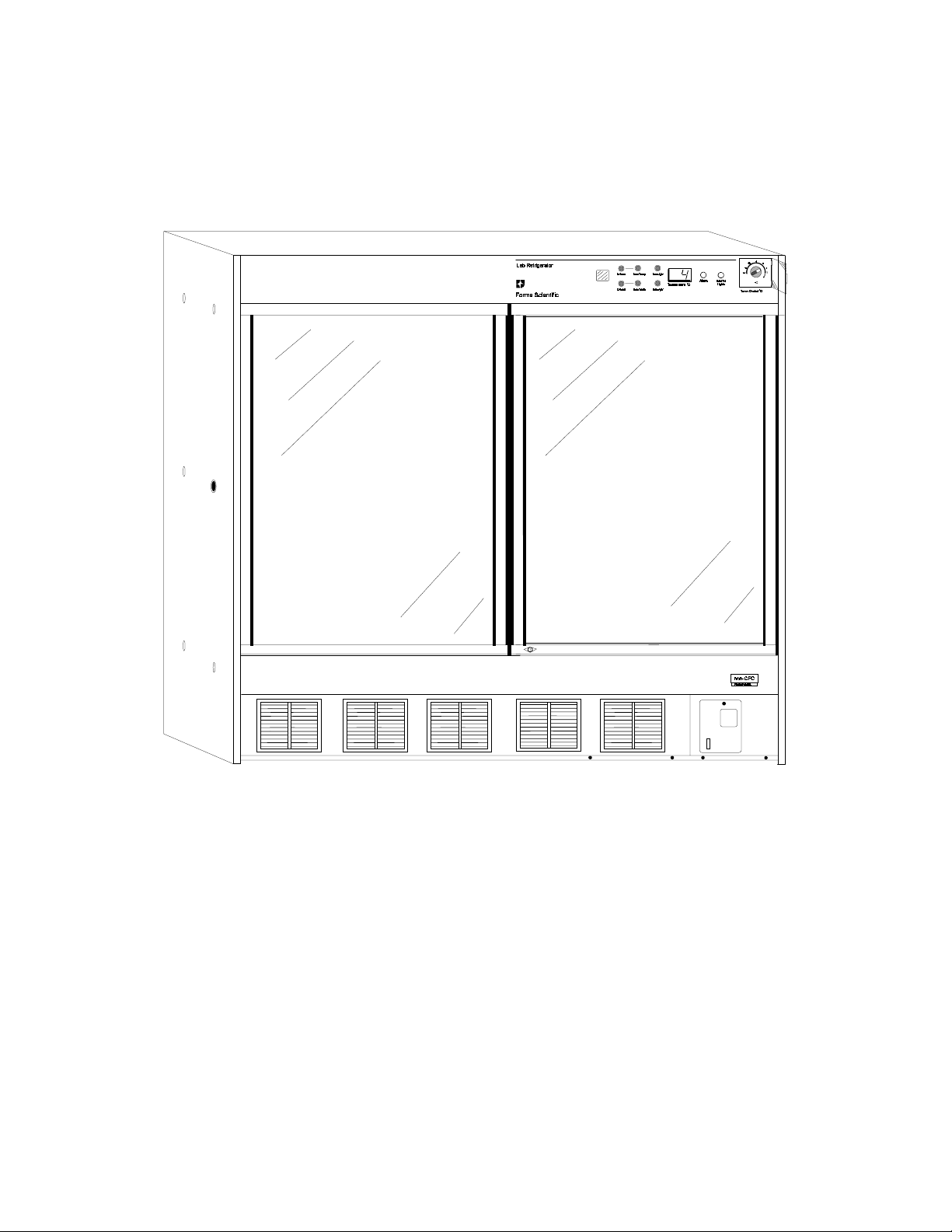

Laboratory Refrigerator

Models 3662 and 3663

Forma Scientific, Inc.

______________________________________________________________________________

2-4

2.4 Installing the Shelves

Adjust the shelves to suit the height of the items placed inside by inserting the shelf

support clips into the slots at the desired level. Make sure that the shelves are secure

before placing product on them.

2.5 Start-Up Procedure

1. After connecting the unit to a power source, set the temperature control dial to the

desired setpoint.

Note: When the unit is plugged in the audible alarm will sound. To temporarily

silence the alarm, place the alarm switch in the "out" position.

Alarm switch position: in = on, out = off.

2. Allow the chamber temperature to cool down to setpoint.

3. Turn the fluorescent light on to check its operation, then turn it off during normal

operation.

4. Make sure that the unit functions properly before placing product in the chamber.

Add warm product to the chamber gradually to prevent excessive temperature rise

and subsequent activation of the alarm system. Allow enough space between the

items to permit adequate air circulation.

5. When the chamber temperature reaches the setpoint, turn the alarm switch on.

Note: Although the refrigerator will operate at under 2°C, it is not suitable for

prolonged use at this range. Always set the thermostat above +2°C. When

running the unit at the top of the range (+14°C), the audible alarm may

sound, however this does not indicate a malfunction. The audible alarm

switch may be switched off.

Forma Scientific, Inc.

______________________________________________________________________________

3-1

SECTION 3 - CONTROL AND INDICATING DEVICES

(Refer to Figures 3-1 for Models 3658/3659 and 3660)

3.1 Temperature Control Dial

The operating temperature of the

refrigerator is set by a control dial on

the front of the cabinet. The

temperature may be set between +2°C

and +14°C.

3.2 Defrost Indicator

The refrigerator has a defrost system which operates automatically. The defrost

light indicates when defrosting is taking place.

3.3 High and Low Temperature Alarm

a. High Temperature

If the chamber temperature rises above +15°C, the alarm system will activate. The

overtemp indicator will light, the digital temperature display will flash. If the alarm

switch is ON (switch button pushed in), the audible alarm will also sound. If the

chamber temperature rises to +20°C, power to the heater and fan circuit also will turn

off.

Note: During start-up, if the ambient temperature is high, it is normal for the overtemp

indicator to stay lit until the chamber temperature drops below the high temperature

alarm point. Make sure that the light goes out before loading the refrigerator with

product.

b. Low Temperature

If the chamber temperature falls below 0°C, the alarm system will activate. The

temperature display will flash and, if the alarm switch is ON (switch button pushed

in), the audible alarm will also sound. If the chamber temperature falls below

-2°C, the defrost heaters will turn on to prevent freezing.

Forma Scientific, Inc.

______________________________________________________________________________

3-2

3.4 Door Ajar Indicator

The Door Ajar indicator lights whenever the refrigerator doors are opened. If the

door remains open for 30 seconds, the audible alarm will sound.

3.5 Audible Alarm Switch

When the audible alarm switch is set to off (switch button out), the audible alarm

will not sound. When the switch is on (switch button in), the audible alarm sounds:

•When the inside temperature is above +15°C.

•When the inside temperature is below 0°C.

•If the door remains open for 30 seconds.

3.6 Interior Lights Switch

The interior lights switch controls power to the fluorescent lights inside the

chamber.

Note: The light should be off during normal refrigerator operation and turned on when

viewing the inside of the chamber.

3.7 Digital Thermometer

The digital thermometer displays the chamber temperature. The display flashes

when the temperature is below 0°C, or above +15°C, or when the door is kept open for

more than 30 seconds.

Figure 3-1, Control Panel

Models 3658/3659 and 3660/3661

Forma Scientific, Inc.

______________________________________________________________________________

3-3

Figure 3-2, Control Panel

Models 3662/3663

(Refer to Figure 3-2)

3.8 Defrost Indicators (Left and Right

Side)

Both sides of the refrigerator have

a defrost system which operates

automatically. The appropriate defrost

light indicates when defrosting is

taking place.

3.9 Refrigeration Indicators (Left and

Right Side)

Both refrigeration units have

indicating lights which light when the

units are operating.

Note: The right side indicator

will light first. The left

side will light about 10

seconds later.

Forma Scientific, Inc.

______________________________________________________________________________

4-1

SECTION 4 - ROUTINE MAINTENANCE

4.1 Defrosting the Unit

The defrost heaters automatically defrost the refrigerator. No additional defrosting

is necessary. The defrost indicator lights when the refrigeration system is defrosting.

4.2 Cleaning the Drain Evaporation Tray and the Condenser Filter

(Refer to the instruction label on the left, front of the unit.)

Clean the drain evaporation tray and condenser filter every three months.

a. Cleaning the Drain Evaporation Tray

Note: Models 3662 and 3663 have two evaporation trays and two condenser filters.

1. Remove the two thumb screws securing the bottom front cabinet cover.

2. Remove the cover and clean it.

3. Remove the evaporation tray and empty any water in it.

4. Clean the tray using a mild detergent and lukewarm water. Rinse the tray

thoroughly and return it to the refrigerator.

b. Cleaning the Condenser Filter

To prevent dust from clogging the condenser, a filter is installed above the

evaporation tray.

1. Grasp the filter and pull it forward. Clean with water and return it to its original

position.

2. After cleaning both the evaporation tray and the condenser filter, secure the

bottom front cover by aligning the three pins at the top of the cover and by

installing the two thumb screws.

Forma Scientific, Inc.

______________________________________________________________________________

4-2

4.3 Cleaning the Unit

Caution: Never splash water on the outside of the unit, as water can cause

malfunctioning of the electronic components. Do not clean the

unit with scrubbing brushes, acid, benzene, thinner, powdered

soap, cleanser or hot water. These agents can damage the

cabinet's finish.

Plastic and rubber parts can be damaged by these materials, especially volatile

agents such as benzene. When a mild detergent is used to clean the unit, rinse (twice)

thoroughly with distilled water (50K Ohm to 1M Ohm).

Caution: Always unplug the unit before beginning the cleaning procedure.

1. Remove all shelves from the chamber.

2. Clean the interior with a soft cloth soaked in a mild detergent. Rinse the interior

surface at least twice with sterile distilled water (50K Ohm to 1M Ohm).

Caution: Purity of the distilled water used in cleaning must be within the 50K

Ohm to 1M Ohm range to protect, and prolong the life of the

stainless steel. The use of tap water or distilled water outside the

specified range will decrease the operating life of the unit and

will void the warranty.

3. Wipe up any water that has collected on the bottom of the unit.

4. Replace the shelves.

Forma Scientific, Inc.

______________________________________________________________________________

5-1

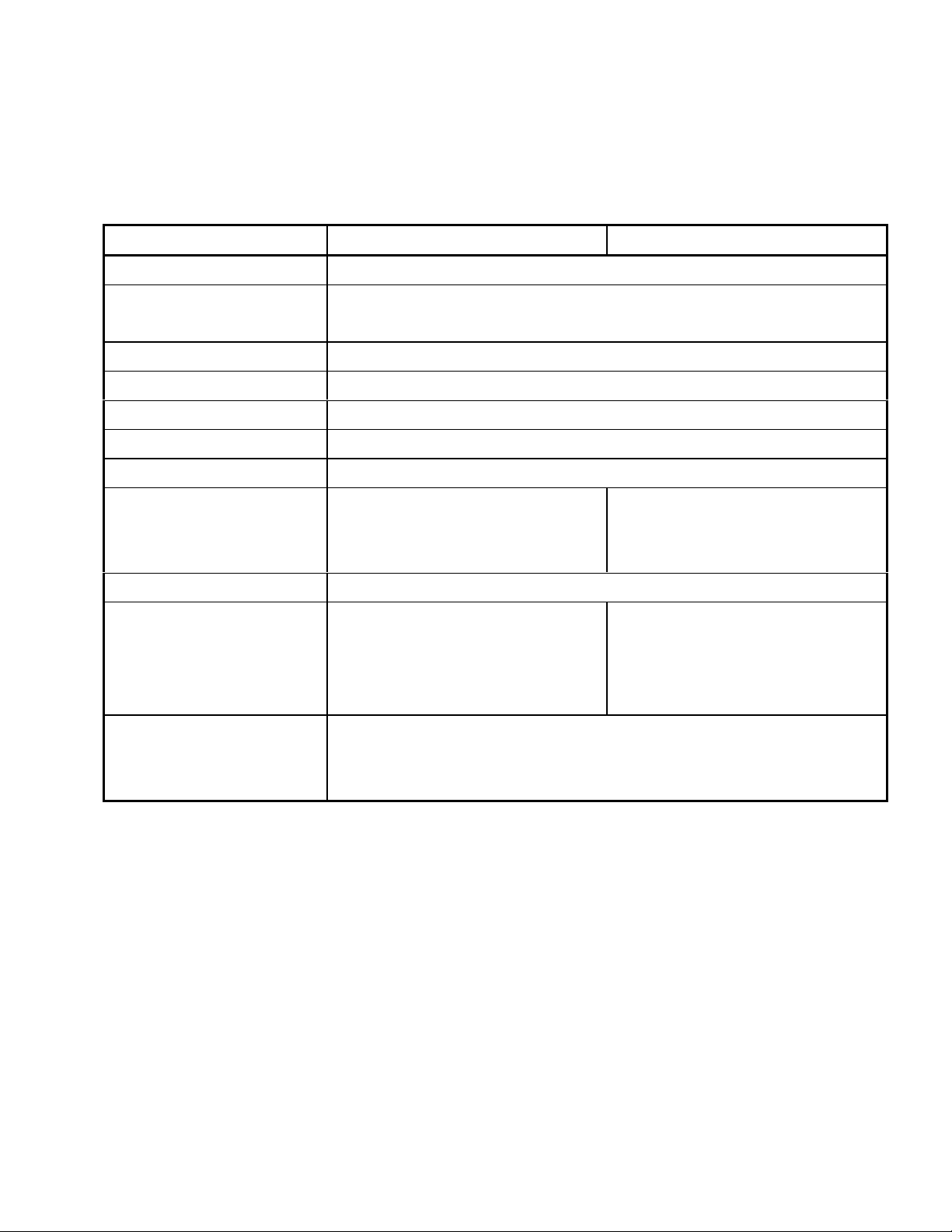

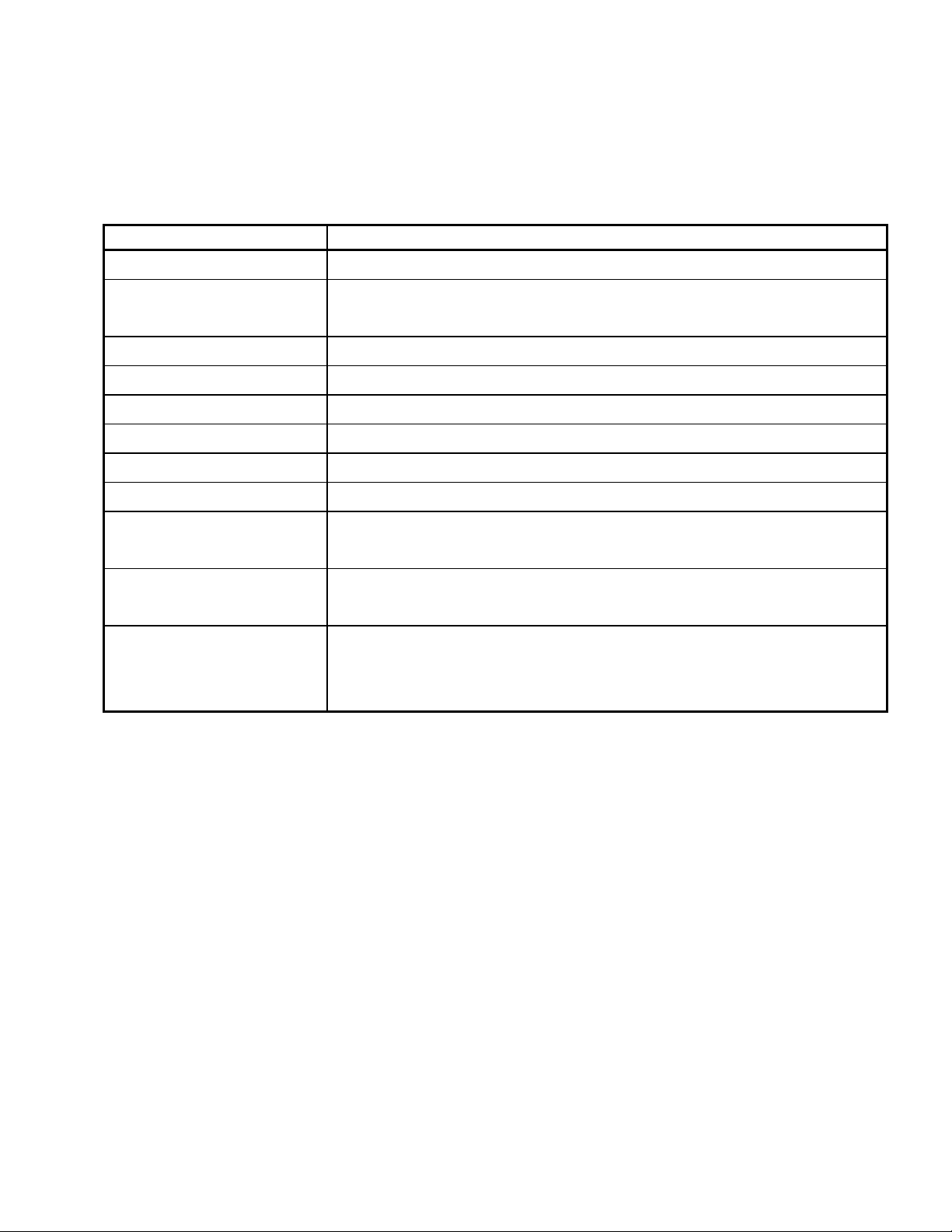

SECTION 5 - TROUBLESHOOTING

Problem Possible Cause

No Refrigeration •Check electrical power

•Electric power has failed or the freezer's

electric cord has been pulled.

Poor Refrigeration •Temperature control not properly set

•Too many unfrozen items in the chamber

•Frost on the evaporator

•Freezer door opened and closed frequently

•Back of the freezer touching the wall

Alarm System Activated •Door not closed tightly

•Too many unfrozen items in the chamber

After Service

If the unit continues to operate unsatisfactorily, contact the Forma Scientific, Inc.

Service Department with the following information:

•A description of the problem, as specific as possible

•Refrigerator model

•Serial number

Forma Scientific, Inc.

______________________________________________________________________________

6-1

SECTION 6 - SPECIFICATIONS

Model 3658 (3659) Model 3660 (3661)

Operating Temperature +2°C (+35.6F) to +14°C (+57.2°F)

Temperature Control Direct setting temperature controller with digital temperature

readout, readable to the nearest degree C.

Refrigeration 1/3 HP air cooled compressor

Capacity 17 cu. ft. (486 liters)

Interior Dimensions 31.5"W x 51.19"H x 18.31" F-B (80.01cm x 130.02cm x 46.51cm)

Exterior Dimensions 35.44"W x 70.5"H x 23.63" F-B (90.02cm x 179.07cm x 60.02cm)

Interior Light One 20W fluorescent light with control panel-mounted switch

Shelving Includes five adjustable zinc-

plated shelves

Includes five adjustable wire

shelves and five roll-out baskets

with safety catches

Insulation 1.88" (4.77 cm) Non-CFC foamed-in-place polyurethane

Electrical Model 3658: 115 VAC, 1 PH, 60

HZ, 5.7 FLA

Model 3659: 220 VAC, 1 PH,

50 HZ, 3.0 FLA

Model 3660: 115 VAC, 1 PH, 60

HZ, 5.7 FLA

Model 3661: 220 VAC, 1 PH,

50 HZ, 3.0 FLA

Shipping Weight

(Nominal)

Motor: 482 lbs (219 kg)

Air/Container: 482 lbs (219 kg)

Ocean: 482 lbs (219 kg)

Forma Scientific, Inc.

______________________________________________________________________________

6-2

SPECIFICATIONS

Model 3662 (3663)

Operating Temperature +2°C (+35.6F) to +14°C (+57.2°F)

Temperature Control Direct setting temperature controller with digital temperature

readout, readable to the nearest degree C.

Refrigeration Two separate 1/3 HP air cooled compressor

Capacity 36.5 cu. ft. (1034 liters)

Interior Dimensions 66.88"W x 51.19"H x 18.31" F-B (169.88cm x 130.02cm x 46.51cm)

Exterior Dimensions 70.88"W x 70.5"H x 23.63" F-B (180.04cm x 179.07cm x 60.02cm)

Interior Light One 40W fluorescent light with control panel-mounted switch

Insulation 1.88" (4.77 cm) Non-CFC foamed-in-place polyurethane

Shelving Includes five adjustable zinc-plated shelves and five roll-out baskets

with safety catches

Electrical Model 3662: 115 VAC, 1 PH, 60 HZ, 11 FLA

Model 3663: 220 VAC, 1 PH, 50 HZ, 5.5 FLA

Shipping Weight

(Nominal)

Motor: 821 lbs (372 kg)

Air/Container; 821 lbs (372 kg)

Ocean: 821 lbs (372 kg)

Forma Scientific, Inc.

______________________________________________________________________________

7-1

SECTION 7 - PARTS LIST

Models 3658/3659 and 3660/3661

Stock # Description

227258 Power Relay

227610 Compressor

227296 PCB Assembly

227613 Starting Relay

227614 Overload Relay

227299 Alarm Relay

227300 Starting Capacitor

227302 Defrost Thermostat

227303 Hi-Temp Thermostat

227304 Power Transformer

227305 Condensing Fan Motor

227306 Cooling Fan Motor

227307 Thermal Fuse

227308 Ballast

227309 Lamp Switch

227310 Alarm Switch

227311 Door Switch

227312 Audible Alarm

227296 Lamp

This manual suits for next models

5

Table of contents