Formulatrix ROCK IMAGER RI 1000 User manual

Original Instructions

Applies to:

RI 1000, RI 182, RI 54, RI 2

FRAP Benchtop & SONICC Benchtop

User’s Guide

ROCK IMAGER

®

User’s Guide

Sixth Edition

Revised January 2019

RIG-V37R019

ROCK IMAGER

ii

FORMULATRIX Product Information

Formulatrix.com

FORMULATRIX Corporate Headquarters

10 DeAngelo Drive, Bedford, MA 01730 USA Phone: +1 781 788 0228

For information requests, email [email protected]. For sales inquiries, email [email protected]. For support, email

FORMULATRIX European Representative

Carl Pedersen

Support, Europe

Phone: +44 7805512001

Acknowledgements

SONICC was invented by Garth Simpson's group at Purdue University and is exclusively licensed by FORMULATRIX.

FRAP was developed in collaboration with Vadim Cherezov (TSRI) and the JCIMPT center led by Ray Stevens and

supported by the NIH Common Fund in Structural Biology.

iii

Table of Contents...................................................................................................................................................................iii

Introduction................................................................................................................................................................................1

Symbols and Conventions................................................................................................................................................................................2

Safety Information...................................................................................................................................................................3

Regulatory Compliance......................................................................................................................................................................................3

Equipment Safety Guidelines.........................................................................................................................................................................4

Mechanical Hazards..............................................................................................................................................................................................4

Electrical Hazards....................................................................................................................................................................................................4

Laser Hazards.............................................................................................................................................................................................................5

Safety Labels..............................................................................................................................................................................................................5

Specifications............................................................................................................................................................................6

Dimensions ..................................................................................................................................................................................................................6

Computer Requirements...................................................................................................................................................................................7

Environmental Requirements........................................................................................................................................................................7

Electrical Requirements.....................................................................................................................................................................................9

Recommended Electrical Configurations..........................................................................................................................................10

Overview....................................................................................................................................................................................11

Key Features..............................................................................................................................................................................................................11

Capabilities..................................................................................................................................................................................................................11

RI 1000...........................................................................................................................................................................................................................12

RI 182 and RI 54.......................................................................................................................................................................................................13

RI 2.....................................................................................................................................................................................................................................13

Table of Contents

iv

User Interfaces........................................................................................................................................................................................................14

Imaging Methods..................................................................................................................................................................................................15

Components............................................................................................................................................................................16

RI 1000...........................................................................................................................................................................................................................16

RI 182 and RI 54.......................................................................................................................................................................................................18

RI 2....................................................................................................................................................................................................................................19

FRAP Benchtop......................................................................................................................................................................................................20

SONICC Benchtop................................................................................................................................................................................................22

Accessories...............................................................................................................................................................................................................25

Imaging Methods..................................................................................................................................................................27

Visible Light...............................................................................................................................................................................................................27

SONICC.........................................................................................................................................................................................................................29

Ultraviolet Light.....................................................................................................................................................................................................29

FRAP...............................................................................................................................................................................................................................32

FACIT..............................................................................................................................................................................................................................32

Multi-Fluorescence Imaging (MFI)..........................................................................................................................................................33

UV Absorption Imaging...................................................................................................................................................................................38

Installation and First Use...................................................................................................................................................39

First Use.......................................................................................................................................................................................................................40

Using RI 1000, RI 182 & RI 54 ...........................................................................................................................................41

Adding Plates...........................................................................................................................................................................................................41

Initiating an Imaging Session.......................................................................................................................................................................42

Searching for Plates in Storage.................................................................................................................................................................43

Viewing a Plate’s Automatic Imaging Schedule...........................................................................................................................44

Removing Plates...................................................................................................................................................................................................45

Stop the Ejection of Expired Plates........................................................................................................................................................45

Using RI 2, FRAP Benchtop & SONICC Benchtop...................................................................................................46

Instant Imaging.......................................................................................................................................................................................................46

Imaging a Plate with FRAP Benchtop...................................................................................................................................................47

Imaging a Plate with SONICC Benchtop............................................................................................................................................49

Imaging a Plate with RI 2................................................................................................................................................................................50

Viewing a Plate’s Automatic Imaging Information......................................................................................................................52

Interpreting FRAP Offset Information....................................................................................................................................................53

v

Interpreting SONICC Results.......................................................................................................................................................................54

SONICC Reference Plate Image Analysis..........................................................................................................................................56

Configuring FRAP Imaging Settings.............................................................................................................................57

Bleaching Options................................................................................................................................................................................................57

Imaging Options....................................................................................................................................................................................................58

General Options.....................................................................................................................................................................................................59

Manual Inspections..............................................................................................................................................................60

Manually Inspecting a Plate.........................................................................................................................................................................60

Manual Imaging Controls...............................................................................................................................................................................62

About Auto Focus................................................................................................................................................................................................66

About Drop Location..........................................................................................................................................................................................67

Using the Plate Type Editor.............................................................................................................................................68

Improving Images.................................................................................................................................................................79

Setting Up Plate Definitions..........................................................................................................................................................................79

Applying Plate Masks.........................................................................................................................................................................................81

Tuning Plates in ROCK IMAGER................................................................................................................................................................83

Clearing Drop Locations..................................................................................................................................................................................87

ROCK MAKER: The Crystallography Center.............................................................................................................88

Creating an Experiment in ROCK MAKER..........................................................................................................................................88

Printing a Barcode Label for a Plate......................................................................................................................................................89

Viewing and Scoring Images in ROCK MAKER..............................................................................................................................90

FAQs.............................................................................................................................................................................................93

UV FAQs......................................................................................................................................................................................................................96

SONICC FAQs..........................................................................................................................................................................................................98

FRAP FAQs...............................................................................................................................................................................................................101

Maintenance..........................................................................................................................................................................102

Maintenance Coverage FAQs...................................................................................................................................................................102

Appendix A.............................................................................................................................................................................104

Appendix B.............................................................................................................................................................................107

Index..........................................................................................................................................................................................110

1

Thank you for purchasing an automated imaging system for protein crystallization. This robust,

easy-to-use solution incubates1and captures superior-quality images of up to 1500 glass sandwich

plates or up to 1000 microtiter plates according to a user-defined schedule.

Your ROCK IMAGER must be used in the manner described in this user’s guide. Any other use may

result in damage to your ROCK IMAGER or personal injury. FORMULATRIX, Inc. is not responsible in

whole or in part for any damages caused by: improper use, unauthorized alterations, adjustments or

modifications, failure to comply with the procedures outlined in the ROCK IMAGER User’s Guide, or

use of the products in violation of applicable laws, rules, or regulations. Except as otherwise expressly

provided in this user guide, any alteration, adjustment, or modification to the products will void the

product warranty.

Read, understand, and observe all safety information and instructions in this manual before using

ROCK IMAGER. Please note specific safety requirements as explained in this user’s guide. Failure to

follow these instructions could result in serious personal injury.

Please save this guide for future reference and have it available to all operating personnel.

ROCK IMAGER is manufactured to the current technical safety-relevant regulations.

1ROCK IMAGERs 1000, 182 and 54 only

Introduction

Chapter 1

2

Convention Description

This icon denotes a caution and advises you of precautions to take.

This icon denotes a prohibited action.

This icon denotes a compulsory action and advises you of actions

you must take.

This icon denotes a caution relating to electric shock and advises you

of precautions to take.

This icon denotes a fire hazard and advises you of precautions to

take.

This icon denotes a note and alerts you to important information.

This icon denotes a laser hazard.

This icon denotes a warning.

bold Bold text denotes items you must select or click in the software, such

as menu items and dialog box options. Bold text also denotes

parameter names.

Monospace Text in this font denotes text or characters you should enter from the

keyboard.

Symbols and Conventions

ROCK IMAGER User's Guide | Chapter 1: Introduction

3

The safety recommendations in this guide are basic guidelines. If the lab where ROCK IMAGER is to

be kept has additional safety guidelines they should be followed as well, along with all applicable

national and international safety codes.

FORMULATRIX products are CE (Conformité Européenne) Machinery, Low Voltage, and EMC

directive compliant. If necessary, request the official Declaration of Conformity (DOC) from

FORMULATRIX. The product is also CDRH Chapter 21 CFR 1040.10 compliant.

Safety Information

Chapter 2

Regulatory Compliance

This device contains a laser radiation device within the barcode scanner. Do not

stare into the beam or bodily injury may occur.

The door should only be opened under the direction of trained FORMULATRIX

personnel (applies to RI 1000, RI 182, RI 54, SONICC Benchtop, and FRAP

High voltage components in the electronics drawer. Do not disassemble or

electric shock may occur.

Only FORMULATRIX personnel are permitted to transport, assemble, or service

ROCK IMAGER.

Use only parts supplied or recommended by FORMULATRIX in this document

or via email.

4

ROCK IMAGER User's Guide | Chapter 2: Safety Information

Equipment Safety Guidelines

Mechanical Hazards

Electrical Hazards

All connections to the product must be disconnected before servicing, or injury

may result from the automatic operation of the equipment.

●Read all safety and operating instructions before operating ROCK IMAGER.

●Do not place ROCK IMAGER’s connections (power and communications cables) where

they could cause a safety hazard.

●Do not place the product in a location where it may be subject to physical damage.

●Ensure that all power connections to the product are properly grounded.

●Ensure that ROCK IMAGER receives proper air flow for cooling.

●Do not remove the nameplate, or any warning, hazard, or Equipment Identification

labels.

●Turn OFF power before inserting or removing power cables.

●Do not open the door to the ROCK IMAGER chassis without express instruction from

trained FORMULATRIX personnel (applies to RI 1000, 182, 54, and SONICC Benchtop only).

ROCK IMAGER is a complex electromechanical device. Only persons with the proper training

should service or operate the product.

Avoid damage to the power cables. Do not apply unnecessary stress, place

heavy objects on or crush the cables or fire may occur.

Switch off all power sources before removing connectors or electric shock may

occur.

Arrange cables in accordance with the Technical Standard for Electric Properties

and Extension Rules or fire may occur.

Do not use extension cables unless approved by FORMULATRIX.

All connections to the product must be disconnected before servicing, or injury

may results from the automatic operation of the equipment.

Do not use extension cables unless approved by FORMULATRIX.

5

ROCK IMAGER User's Guide | Chapter 2: Safety Information

ROCK IMAGER robots are sold with laser scanners used to detect barcodes on sample plates.

Laser Scanning devices used in ROCK IMAGER models other than SONICC are CLASS II Laser Products.

Class II lasers are considered safe because of the human eye aversion response, which will limit

exposure to no more than 0.25 seconds. Avoid staring into the laser beam.

Lasers used in SONICC imagers are CLASS IV laser products. Do NOT open the door to SONICC

Benchtop or ROCK IMAGER 1000 Dual Imager with SONICC while the laser is in use under ANY

circumstances.

Laser Hazards

Safety Labels

Do not remove or alter any safety labels or warnings from FORMULATRIX

products.

This device contains a laser radiation device within the barcode scanner.

Do not stare into the beam or bodily injury may occur.

The FRAP imager has one safety label affixed to the cover of the FRAP laser. This sticker is

viewable when the FRAP door is open.

The safety recommendations in this guide are basic guidelines. If the lab where SONICC is to be

kept has additional safety guidelines they should be followed as well, along with all applicable

national and international safety codes.

6

RI 1000 Peltier Cooled 834 x 2197 x 1085 mm

(33” x 87” x 43”)

387 kg (864 lbs)

RI 1000 Compressor Cooled 898 x 2272 x 1117 mm

(36” x 90” x 44”)

399 kg (880 lbs)

RI 1000 Dual Imager 834 x 2197 x 1230 mm

(33” x 87” x 49”)

462 kg (1019 lbs)

RI 182 865 x 1028 x 798 mm

(35” x 41” x 31”)

161 kg (355 lbs)

RI 54 755 x 1016 x 641 mm

(30” x 41” x 26”)

114 kg (252 lbs)

RI 2 419 x 580 x 354 mm

(16.5” x 22.8” x 13.9”)

23 kg (51 lbs)

SONICC Benchtop 642 x 980 x 700 mm

(25” x 39” x 28”)

~68kg (~150 lbs)

FRAP Benchtop 651 x 877 x 697 mm

(26” x 35” x 27”)

~45 kg (~100 lbs)

Specifications

Chapter 3

Dimensions

7

ROCK IMAGER User's Guide | Chapter 3: Specifications

Environmental Requirements

Ambient Temperature Range 0° C to 30° C.

Operating Humidity 0 - 80% non-condensing.

Storage Humidity 0 - 80% non-condensing.

Ventilation

At higher temperatures and humidity levels (e.g. >25°C and >65% humidity), condensation may

form on the outside of the Compressor-cooled RI 1000 when operated at or below 4° C. The

system will still maintain the desired temperature in these environments. However, the

compressor-cooled RI 1000 operates best in a temperature-controlled laboratory.

Store ROCK IMAGER within the specified ranges of temperature and humidity, in a

place where it is not exposed to direct sunlight.

ROCK IMAGER 1000

●SQL Server Express/Standard Edition version 2008 R2 (Minimum) or 2014 (Recommended)

●Dedicated database server (Recommended)

●Network connection

●Remote access (e.g. WebEx, TeamViewer, VPN) (Recommended)

●Email Server access (SMTP server credentials)

●Optional: UPS unit

●Windows 7 32-bit or 64-bit, Windows 10 64-bit

●4 GB RAM

●2 GB available Hard Disk space

●Dual core 1 GHz

●1024 x 768 pixels screen resolution

●3.5 and 4.5 .NET Framework

ROCK IMAGER 182/54

●SQL Server Express/Standard Edition version 2008 R2 (Minimum) or 2014 (Recommended)

●Dedicated database server (Recommended)

●Network connection

Computer Requirements

Store ROCK IMAGER within the specified ranges of temperature and humidity, in a place

where it is not exposed to direct sunlight.

Do not block the fan vents on the ROCK IMAGER chassis.

Maintain at least 2 inches (50.8 mm) of free space between the

vents and any obstruction or surface.

8

ROCK IMAGER User's Guide | Chapter 3: Specifications

●Remote access (e.g. WebEx, TeamViewer, VPN) (Recommended)

●Email Server access (SMTP server credentials)

●Windows 7 32-bit or 64-bit, Windows 10 64-bit

●Optional: UPS unit

●4 GB RAM

●2 GB available Hard Disk space

●Dual core 1 GHz

●1024 x 768 pixels screen resolution

●3.5 and 4.5 .NET Framework

ROCK IMAGER 2

●SQL Server Express/Standard Edition version 2008 R2 (Minimum) or 2014 (Recommended)

●Remote access (e.g. WebEx, TeamViewer, VPN) (Recommended)

●Email Server access (SMTP server credentials)

●Network connection (for email access) (Recommended)

●Windows 7 32-bit or 64-bit, Windows 10 64-bit

●4 GB RAM

●1 GB available Hard Disk space

●Dual core 1 GHz

●1024 x 768 pixels screen resolution

●3.5 and 4.5 .NET Framework

SONICC and FRAP Benchtop

●SQL Server Express/Standard Edition version 2008 R2 (Minimum) or 2014 (Recommended)

●Remote access (e.g. WebEx, TeamViewer, VPN) (Recommended)

●Email Server access (SMTP server credentials)

●Network connection (for email access) (Recommended)

●Windows 7 32-bit, Windows 10 64-bit

●UPS strongly recommended for SONICC

●4 GB RAM

●1 GB available Hard Disk space

●Dual core 1 GHz

●1024 x 768 pixels screen resolution

●3.5 and 4.5 .NET Framework

9

ROCK IMAGER User's Guide | Chapter 3: Specifications

ROCK IMAGER 1000 – Peltier Cooled System

●Cooling Unit: 100-240 V, 50-60 Hz, 750 W max, 1 ph

●Robotics: 100-240 V, 50-60 Hz, 240 W max, 1 ph

●Computer: 525 W max, 1 ph

●Recommended UPS: 1500 W

ROCK IMAGER 1000 – Compressor Cooled System

●Cooling Unit: 100-240 V, 50-60 Hz, 400 W max, 1 ph

●Robotics: 100-240 V, 50-60 Hz, 240 W max, 1 ph

●Computer: 525 W max, 1 ph

●Compressors: 2x (208-230 V, 50-60 Hz, 2000 W max, 1 ph)

●Recommended UPS: 5000 W

ROCK IMAGER 1000 – Dual Imager w. Frap (Peltier Cooled)

●Cooling Unit: 100-240 V, 50-60 Hz, 1000 W max, 1 ph

●Robotics: 100-240 V, 50-60 Hz, 240 W max, 1 ph

●Computer: 525 W max, 1 ph

●Recommended UPS: 3500 W

1000 – Dual Imager w. SONICC (Peltier Cooled)

●Cooling Unit: 100-240 V, 50-60 Hz, 1000 W max, 1 ph

●Robotics: 100-240 V, 50-60 Hz, 835 W max, 1 ph

●Computer: 525 W max, 1 ph

●Recommended UPS: 4500 W

ROCK IMAGER 182 and ROCK IMAGER 54

●Imager: 100-240 V, 50-60 Hz, 480 W max, 1 ph

●Computer: 525 W max, 1 ph

Electrical Requirements

The power supply for the system must meet or exceed electrical requirements of the

system to avoid damage and risk of fire.

10

ROCK IMAGER User's Guide | Chapter 3: Specifications

ROCK IMAGER 2

●Imager: 100-240 V, 50-60 Hz, 150 W max, 1 ph

●Computer: 525 W max, 1 ph

SONICC Benchtop

●Imager: 100-240 V, 50-60 Hz, 1195 W max, 1 ph

●Computer: 525 W max, 1 ph

●Recommended UPS: 3340 W

FRAP Benchtop

●Imager 100-240 V, 50-60 Hz, 600 W max, 1 ph

●Computer: 525 W max, 1 ph

●Recommended UPS: 2250 W

RI 182, RI 54, RI 2

RI 1000

Recommended Electrical Configurations

11

Overview

Chapter 4

This guide presents information about all of the products in the ROCK IMAGER series, including ROCK

IMAGER 1000, ROCK IMAGER 182, ROCK IMAGER 54, ROCK IMAGER 2, and benchtop versions of FRAP

and SONICC.

●Highest reliability and plate density in the industry with multiple plate types

●Superior optics and intelligent imaging provide industry-leading image quality

●Temperature regulation options for precise temperature control from 30° C down to 4°

C

●Seamless integration with ROCK MAKER or your current crystallization software via ROCK

IMAGER API

●Visible light, UV (optional), FRAP (optional), and SONICC (optional) imaging capabilities

●Custom image scheduling

●Nightly diagnostic reports sent to FORMULATRIX for continued quality control

●ROCK IMAGERs are designed to minimize vibration to microtiter plates to prevent

environmental disturbance

●Temperature control with sensors at a variety of locations that monitor temperature to

0.1° C

●Easy to use control software that runs smoothly on an ordinary PC

Drop Location. A proprietary combination of automated lighting and image recognition reliably locates

drops in 3 dimensions.

Auto Focus and Exposure. Continuous focus algorithm is fast and reliable. Auto focus parameters

can be tuned so only the appropriate z-slices are captured. Exposure time is also automatically

adjusted to maximize image brightness.

Key Features

Capabilities

12

ROCK IMAGER User's Guide | Chapter 4: Overview

Region of Interest (ROI). Specify a region of a drop to zoom into and ROCK IMAGER will automatically

capture that area in high resolution.

Multi-Capture. Capture multiple images of each drop with user adjustable settings for variables such

as: exposure time, polarization state, and condenser aperture value.

Extended Focus Imaging (EFI). The highest optical resolution is achieved by increasing the Numerical

Aperture (NA) of the objective. A high NA is critical to obtaining images with the contrast and sharpness

required to recognize crystal edges. The trade-off, however, is that depth of field (depth of image in

focus at one time) is reduced. Combining multiple slices into one EFI image allows the best of both

worlds.

Lipidic Cubic Phase (LCP) Compatible. All systems can support LCP (or membrane crystallization)

imaging with standard microtiter plate heights. The RI 1000 can support up to 1500 individual thin-glass

LCP plates with an optional storage rack modification.

Performance. Sitting drop imaging as fast as 0.8 seconds per drop with one slice, fixed focus, and

fixed exposure.

The flagship model in the ROCK IMAGER lineup, the ROCK

IMAGER 1000 chassis can be configured to store 250, 500, or

1000 microtiter plates, or up to 1500 glass sandwich plates. It

is also the only ROCK IMAGER available with compressor-

based cooling.

●Up to 1000 SBS plate capacity, or 1500 thin-based

LCP plate with optional storage rack modification

●Peltier cooling to 5 °C below or 7 °C above ambient

temperature

●Compressor Cooling option available down to 4 °C

●Automated scheduled imaging

●Vibration isolated hotels

●Visible, UV, SONICC/UV-TPEF, and FRAP imaging

methods available

RI 1000

ROCK IMAGER 1000

13

ROCK IMAGERUser's Guide | Chapter 4: Overview

ROCK IMAGERs 182 and 54 feature many of the same abilities as ROCK

IMAGER 1000, although these imagers have limited plate capacity and

no compressor-based cooling option.

RI 182

●Can hold up to 182 SBS plates or up to 106 Linbro plates

●Capable of Peltier cooling to 5 °C below or 7 °C above

ambient

●Performs automatic scheduled imaging

●Vibration isolated storage

●Visible and UV imaging methods available

RI 54

●Can hold up to 54 SBS plates or up to 28 Linbro plates

●Capable of Peltier cooling to 5 °C below or 7 °C above ambient

●Performs automatic scheduled imaging

●Vibration isolated storage

●Visible and UV imaging methods available

ROCK IMAGER 2 is the smallest of the ROCK IMAGERs, useful for

those of you who aren’t interested in storage capabilities or who have

space concerns but are still interested in the high-powered imaging

offered by ROCK IMAGER.

●2 SBS plate capacity or single Linbro plate capacity

●EasyXtal plate support

●Visible and UV imaging methods available

RI 182 and RI 54

ROCK IMAGER 182 / 54

RI 2

ROCK IMAGER 2

14

ROCK IMAGER User's Guide | Chapter 4: Overview

ROCK IMAGER is controlled by the ROCK IMAGER software, which enables you to interact with your

experiment plates. Your computer screen becomes the microscope’s eyepiece and physical optics

and imager controls are replaced by on-screen controls.

All ROCK IMAGERs integrate with ROCK MAKER, FORMULATRIX’s crystallization experiment lifecycle

management software. Automated imaging is scheduled and managed through ROCK MAKER.

User Interfaces

ROCK IMAGER Software

ROCK MAKER Software

This manual suits for next models

5

Table of contents

Popular All In One Printer manuals by other brands

Xerox

Xerox DocuColor 3535 user guide

Brother

Brother DCP 350C - Color Inkjet - All-in-One user guide

Olivetti

Olivetti MY_WAY Plus user guide

Canon

Canon IMAGERUNNER 2010F Facsimile guide

Fuji Xerox

Fuji Xerox DocuPrint CM505 da Administrator's guide

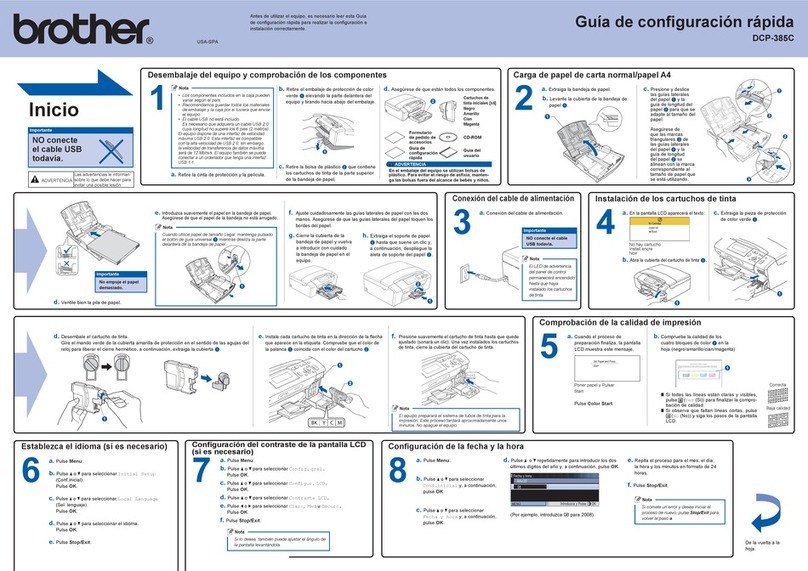

Brother

Brother DCP 385C - Color Inkjet - All-in-One Quick setup guide