Construction Hoist Fraco SEH Premium Range

Assembly and Operating Manual Page 2 of 69 doc no. 98030718-01

Table of Contents:

Section Page

1PREFACE................................................................................................................................................... 4

2SAFETY...................................................................................................................................................... 5

2.1Explanations of symbols and notes..................................................................................................... 5

2.1.1Health and safety symbol.....................................................................................................................................5

2.1.2Attention note .......................................................................................................................................................5

2.1.3Note......................................................................................................................................................................5

2.2General safety .................................................................................................................................... 5

2.3Operating safety ................................................................................................................................. 6

2.3.1Inspection procedures..........................................................................................................................................7

2.3.2Safety notes for assembly, operation and transport............................................................................................7

2.3.3Safety instructions for maintenance.....................................................................................................................7

2.4Promoting use of operating manuals .................................................................................................. 7

2.5Employees must be informed about the following:.............................................................................. 8

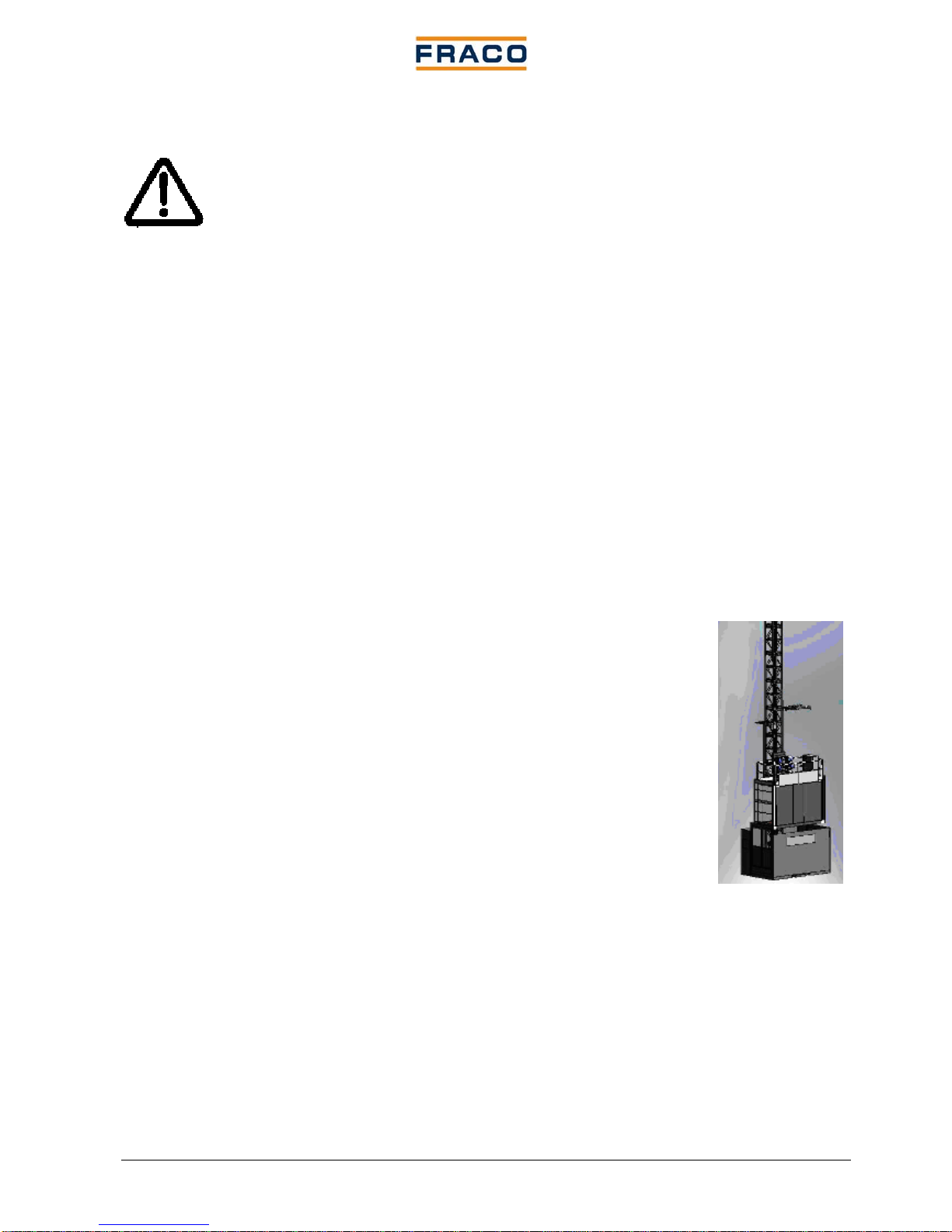

3INTENDED USE AND AREA OF APPLICATION....................................................................................... 9

3.1The following belongs to intended use,............................................................................................. 10

3.2Consequences of non-intended use of the equipment...................................................................... 10

3.3Requirements of assembly personnel............................................................................................... 10

3.4Operating personnel ......................................................................................................................... 10

4TECHNICAL DATA................................................................................................................................... 11

4.1General data..................................................................................................................................... 11

4.2Data depending on model................................................................................................................. 12

4.3Options available.............................................................................................................................. 12

4.4General dimensions.......................................................................................................................... 13

4.5Mast tie forces .................................................................................................................................. 15

4.5.1Mast tie forces for a car......................................................................................................................................15

4.6Summary of the plates and notices................................................................................................... 16

4.7Equipment ........................................................................................................................................ 18

4.7.1Fraco SEH Single...............................................................................................................................................18

4.7.2Fraco SEH - twin................................................................................................................................................19

4.7.3Electrical switch boxes and drives.....................................................................................................................21

4.7.4Ground box AL0 .................................................................................................................................................22

4.7.5Installation remote control..................................................................................................................................22

4.7.6Drop test remote control.....................................................................................................................................23

4.8Sliding gate....................................................................................................................................... 23

4.8.1Toolbox Inside the car........................................................................................................................................24

4.8.2Car lighting .........................................................................................................................................................24

4.8.3Roof Hatch..........................................................................................................................................................24

4.8.4Self erecting device............................................................................................................................................24

5REQUIREMENTS FOR THE SITE OF INSTALLATION........................................................................... 25

5.1Foundation requirements.................................................................................................................. 25

5.2Point load (Imperial table)................................................................................................................. 25

5.3Point load (Metric table).................................................................................................................... 26

5.4Electrical connection (on site)........................................................................................................... 27

6TRANSPORT............................................................................................................................................ 28

6.1Inspection on receiving the hoist....................................................................................................... 28

6.2Loading and unloading the machine................................................................................................. 28

6.2.1Lifting with a forklift truck....................................................................................................................................28

6.2.2Lifting with a crane .............................................................................................................................................28

7INSTALLATION........................................................................................................................................ 29

7.1Safety notes...................................................................................................................................... 29

7.2Assembling the base unit.................................................................................................................. 30

7.3Extending the mast sections and mast tie to the building.................................................................. 31

7.3.1Assembling the mast sections up to approx. 30 ft (9 m) high ...........................................................................31

7.3.2Assembling the mast..........................................................................................................................................32

7.4Mast tie............................................................................................................................................. 32

7.5Cable Guide system ......................................................................................................................... 33

7.6Assembly of mast sections above 30ft (9 m)..................................................................................... 34

7.7Top limit switch cam ......................................................................................................................... 35