8

•Use a damp cloth or sponge to remove condensation water and for cleaning. Do

not use dry clothes or sponges to dry the unit (Risk of electrostatic charge and

sparking).

•Before starting-up and restarting, fill the drain with approx. 2 litres of water.

Prevents carry-over of refrigerant into drains.

•It is prohibited to cover any ventilation opening of the unit. Safe minimum

distance must be kept (between units) to ensure sufficient air access.

•Do not use any mechanical devices or other means (e.g., ice scrapers) to

accelerate the defrosting.

•Do not use steam or high-pressure cleaners for basic cleaning.

•Only install the units in well-ventilated rooms.

•Do not install the units in cellars or lowered rooms.

•Do not damage the refrigerant circuit.

•Do not expose the unit to temperatures higher than 70°C during transportation

and storage.

•Avoid transmitting pulsations and vibrations to the unit.

•Do not allow external forces to act on the appliance, e.g., careless handling with

a forklift or floor cleaning machine.

•Do not crush or bend pipes.

•Only qualified maintenance personnel may carry out work on the refrigerant

circuit.

•Only open the refrigerant circuit and suck off the refrigerant in well-ventilated

rooms outside store business hours (when customers are not present) or

outdoors.

•Disconnect the unit prior to all maintenance, service, or repair work.

•Disposal of the unit must be performed following Waste & Disposal-Recycling

Regulations requirements.

Failure to comply with safety requirements could lead to potential health injuries and

safety risks.

2.4. Refrigerants

Non-hazardous and environmentally friendly refrigerants HFC/HFO are used. The

specified refrigerants are non-toxic, non-flammable, do not cause any carcinogenic

effects and signs of prosoplasia.

2.5. Material damage during prolonged shutdown

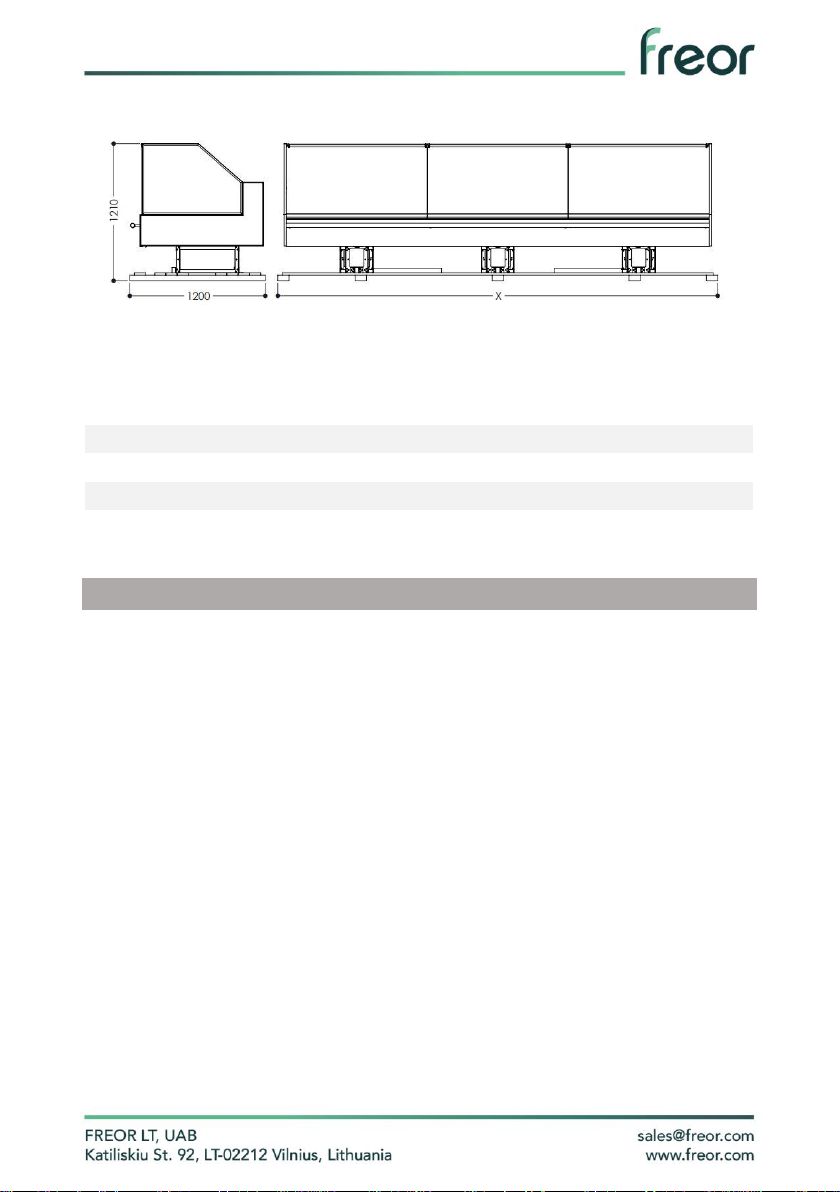

•Operate the appliance in a stable operating position (horizontal alignment).

•Operate the device only on the designated adjustable feet.

•Read the installation notes (see chapters 4, 5 and 6)

•Do not operate the unit above the climate class specified on the technical data

sticker.