SECTION 2

LOCATION & INSTALLATION

2.1 SAFETY PRECAUTIONS

Do not attempt to operate your Frozen Drink Machine until the safety precautions and

operating instructions in this manual are read completely and are thoroughly understood.

2.2 INSTALLATION

Placing your Frozen Drink Machine in a highly visible area will enhance sales.

CAUTION: Do not attempt to share the dedicated electrical outlet with any other

appliance; this will cause the circuit breaker to trip.

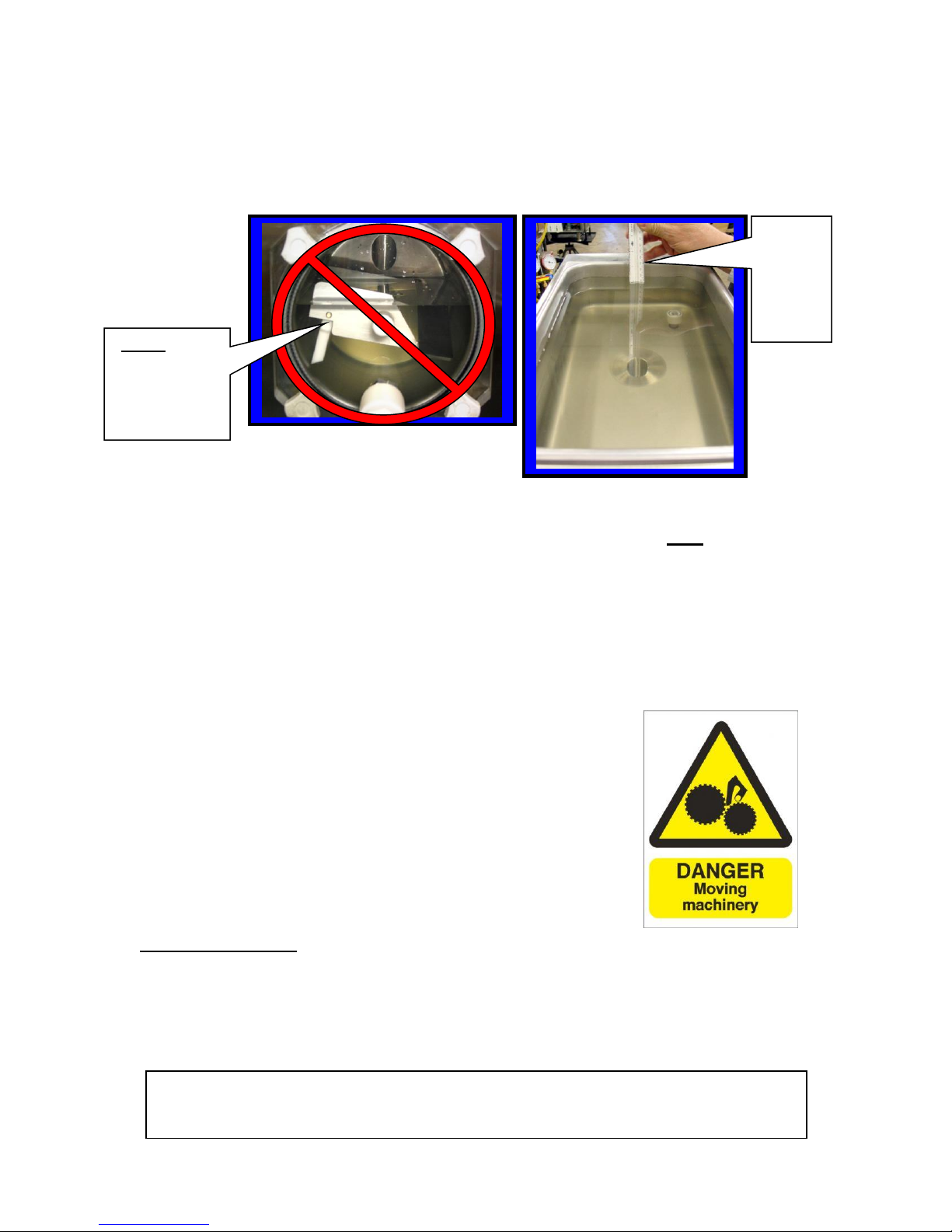

1. Remove the machine from the shipping container.

2. Place the unit on a sturdy platform able to hold the weight of the machine when full of

product. (Usually about 250 lbs.)

3. Level the machine by turning the adjustable part of the leg. The machine must be level

front to back as well as left to right.

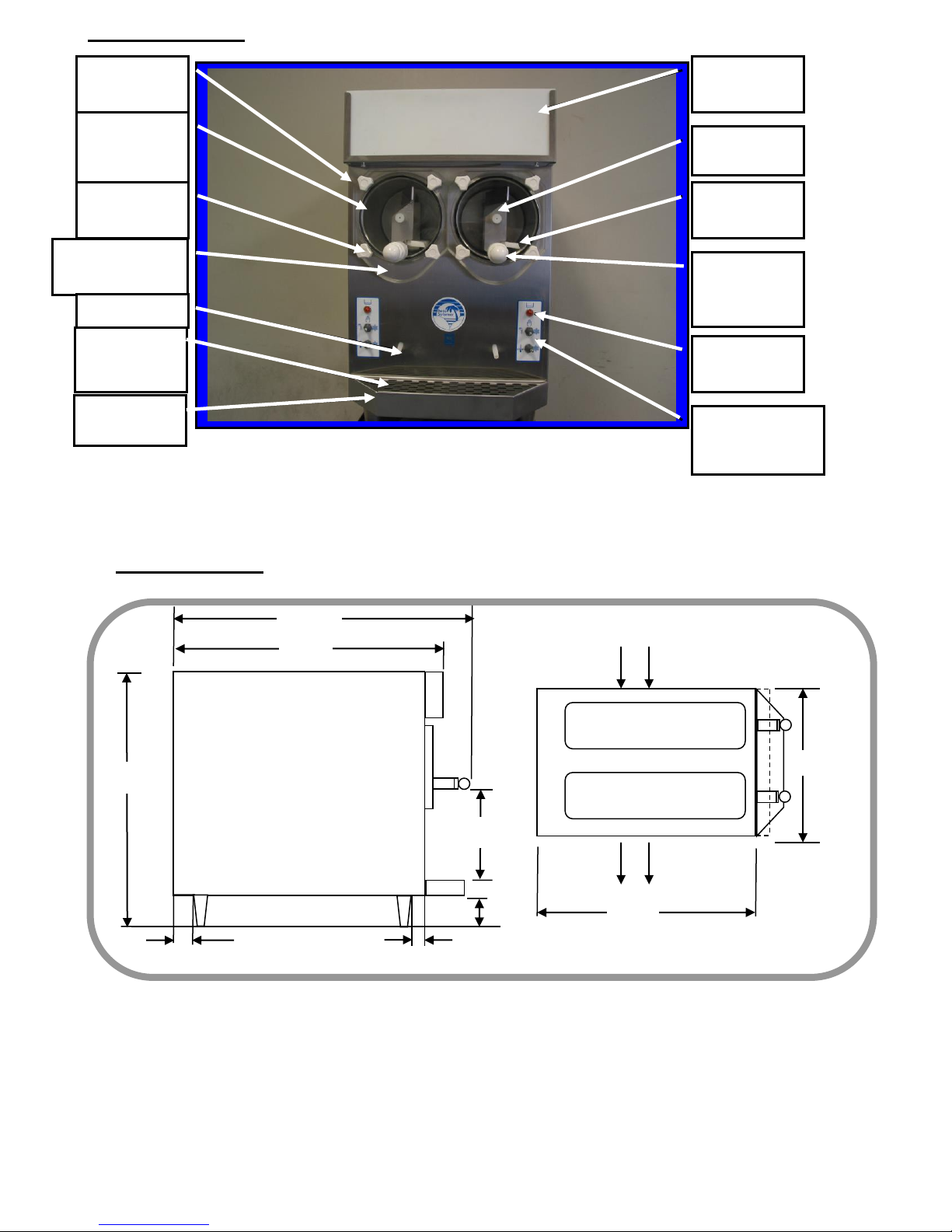

4. Air-cooled condensers must have correct ventilation. Air intake is at the right side of

the machine and discharge through the left side; 8” is required on intake (right) side

and 24” on the exhaust (left) side & 8” clearance restrictions at the back. In addition,

12” clearance above the machine is also required for access.

NOTICE: Locating the unit in direct sunlight, near cooking equipment or any high

heat area will reduce the performance of your machine.

CAUTION: Extended operations under severe heat condition can damage the cooling

system.

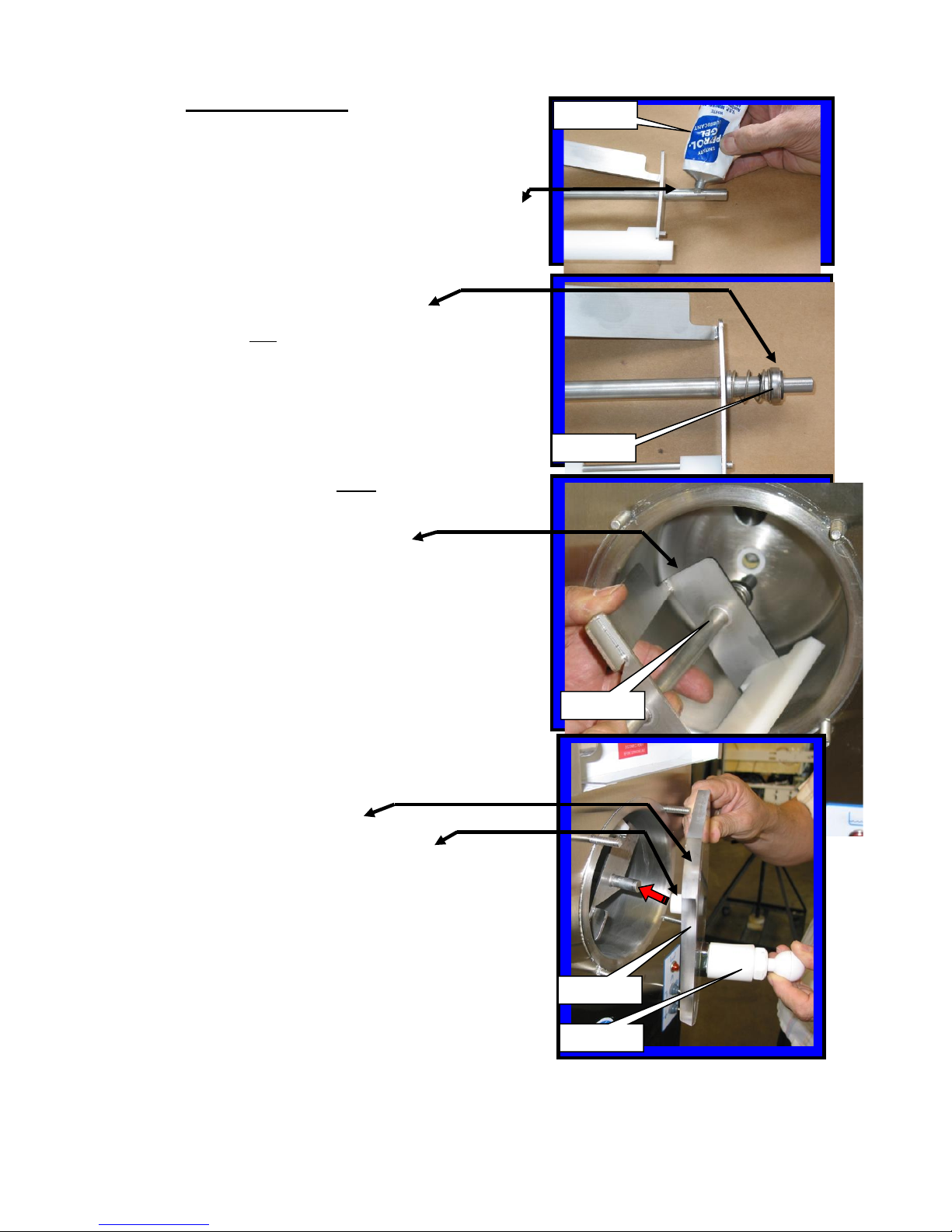

NOTICE: Establishments that serve beverages from frozen drink machines are

responsible for providing the necessary facilities for cleaning and

sanitizing their food service equipment.

5. Place the three-position switch in the OFF position (center).

6. Connect the power cord. The Frozen Drink Machine must be connected to a properly

grounded receptacle. The electrical cord furnished as part of the Frozen Drink

Machine has a three prong grounding type plug. The use of an extension cord is not

recommended. If one must be used, refer to the national and local electrical codes.

Do not use an adapter to get around grounding requirements.

SECTION 3