Instruction Manual

Mini-Chest Freezer KBT 02-51

Nomination

That cooling appliance must be so set up, that an optimal ventilating is guaranteed, that means

around must min. 20cm be free.

Places with to high heat (max. +28°C) or straighter sun beams are to avoid, because this may be a

reason to the outfall of the cooling appliance.

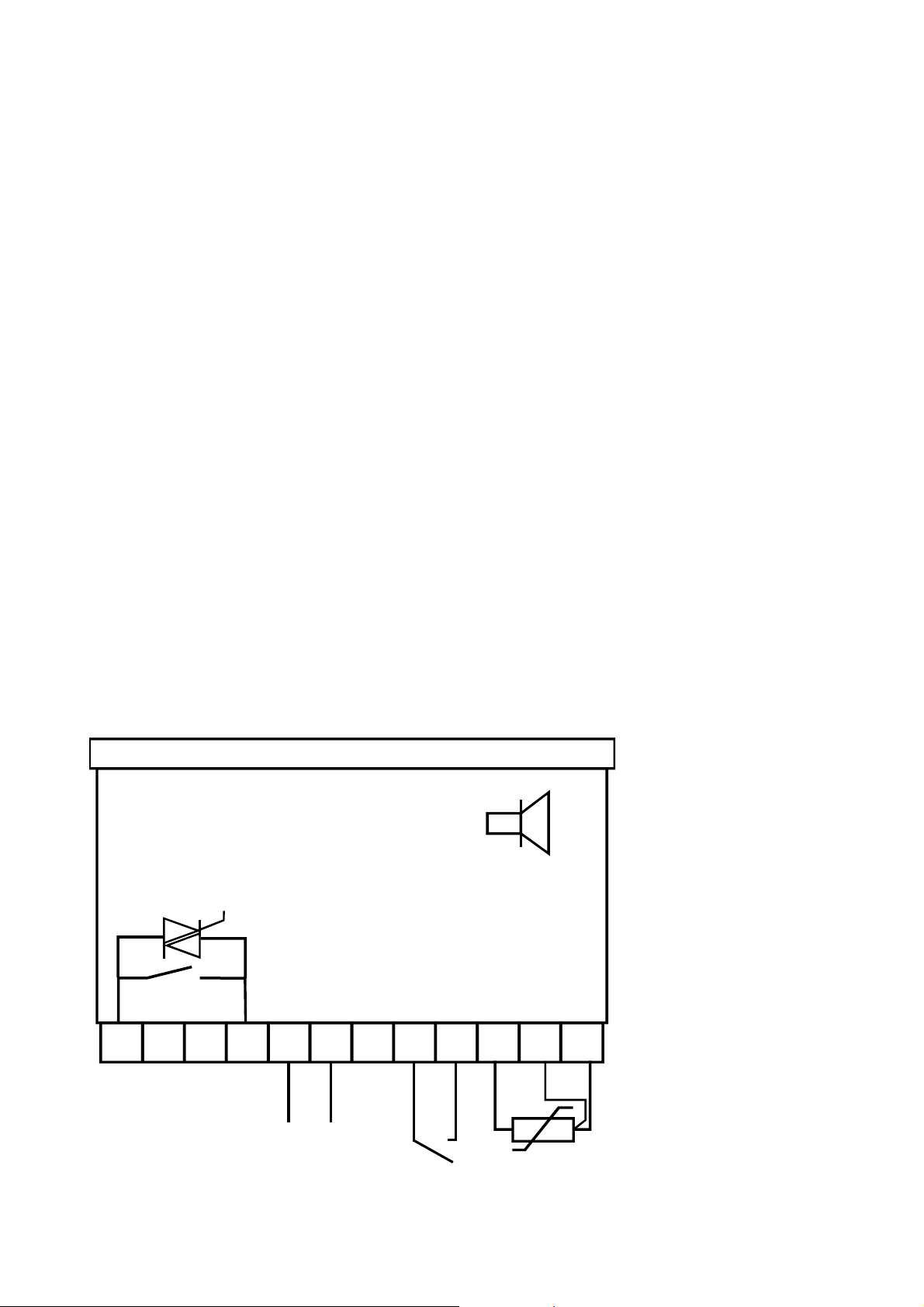

Technical building

The machine of the cooling appliance consists of an hermetic closed compressor refrigeration

system.

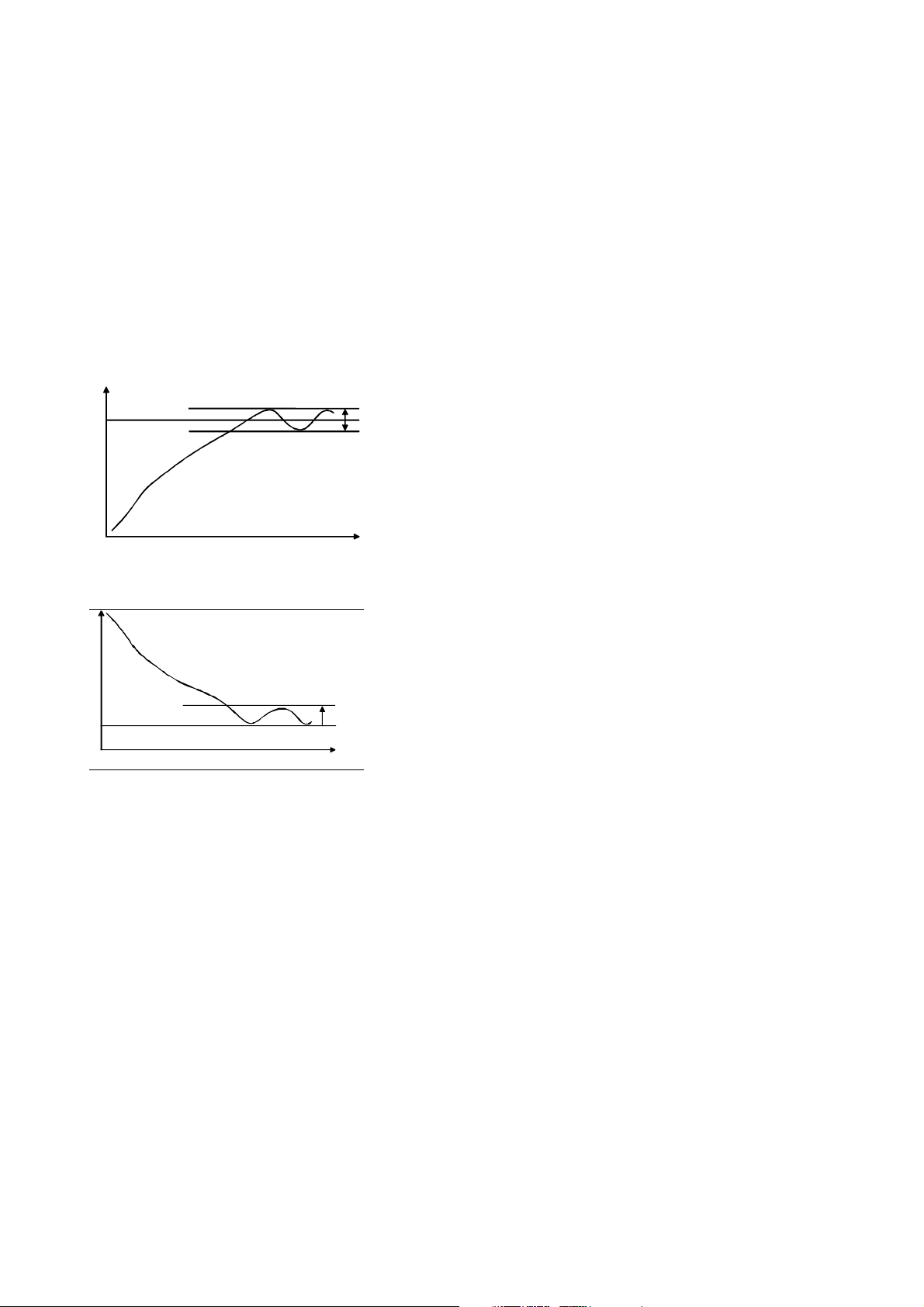

The refrigerating machine of the KBT 02-51 is regulated with an two-step-regulator.

The chamber consists of stainless steel 18/10.

Housing of stainless steel. Only front panel is with white RAL 9003 electrostatic coated.

Set in operation

Put the cable in a socket with earthing-contact. Voltage, currency and frequency are shown on the

rating plate.

Switch on the cooling machine, then must light up the green pilot light in the switch.

Attention: Take care that the white lid is on the top of the chamber and closes tightly to avoid new

air with humidity inside the chamber which leads to high icing.

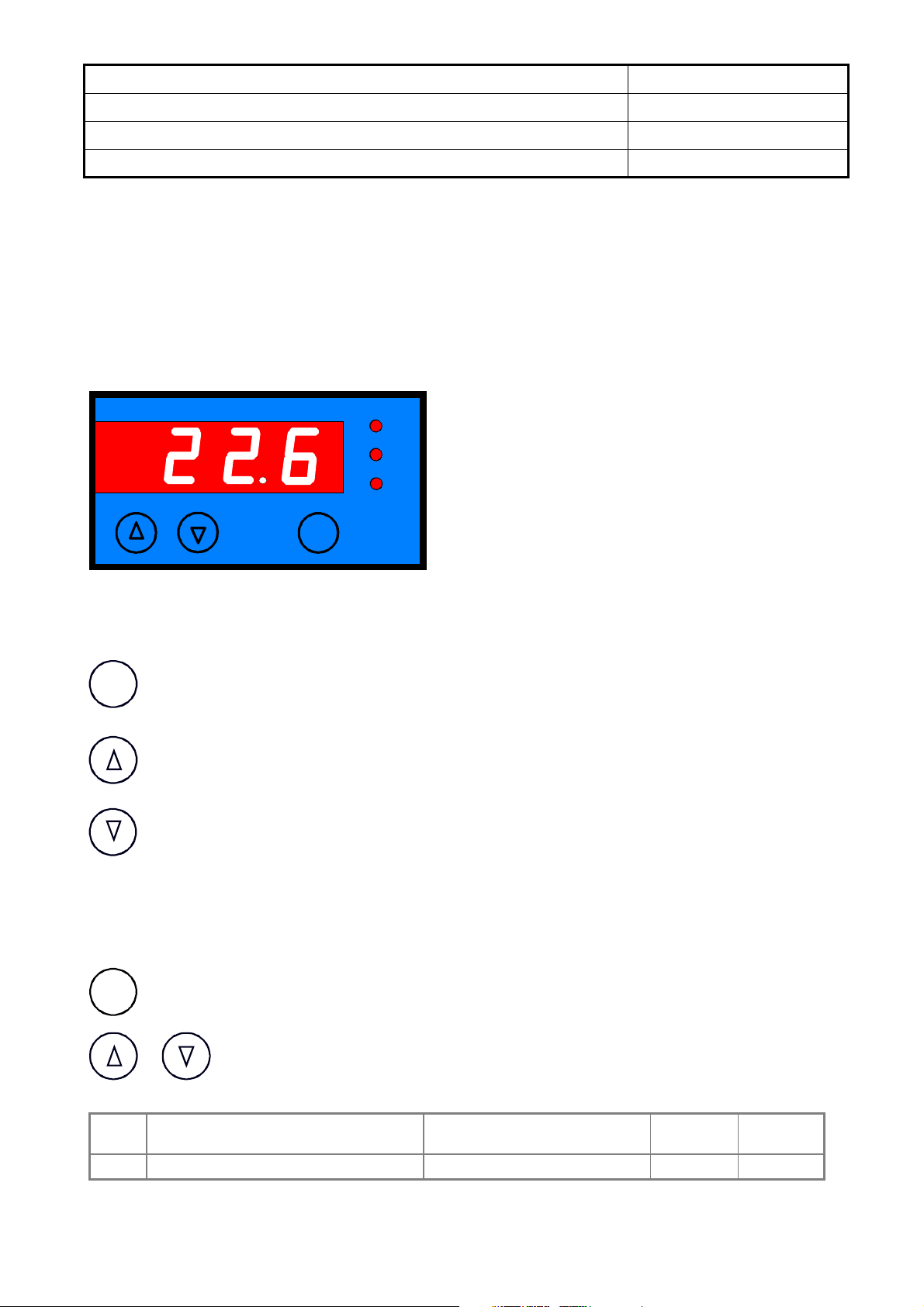

Adjusting the system

Electronic two-point control with digital display, setpoint control (SET key) and PT-100 internal

temperature sensor. Precise to +/1,0K. Control shows actual value when unit switched on. To set

the setpoint, press the SET key and then use the cursor keys to adjust. Once setting is complete,

press SET key briefly to check setpoint.

Temperature range -30 / -50°C.

Security equipment

The compressor is configured with an internal thermo-switch, which switches off at overheating. A

re-connection of the aggregate is only possible when the compressor has cooled down (after 1

hour).

Disturbance

If the equipment works not normally, may be a great temperature difference or an outfall from the

refrigeration, you have to check at first the environmental reference conditions (ambient

temperature, ventilating around the equipment). Then the condenser at the backside have to check

up on pollution and dusty and as a precaution cleaned with compressed air blow through it.

Maintenance and servicing

The hermetical cooling aplliance is convenient for the continous operation and need no

maintenance. The condenser at the backside should be regularly checked and will be cleaned, this

depends on from degree of dusty of the site. Attention! Get notice that this leads to the outfall of the

cooling appliance through overheating.