Unless you are particularly adept at assembling flat-pack/knock-down

furniture, we understand building ready-to-assemble furniture can be a

frustrating experience for some. To help avoid confusion and to make

the assembly process quicker and smoother, we have provided some

helpful tips. Before you begin the assembly, please read the following:

1. Due to the size and/or weight on most of the ready-to-assemble furniture, it is

highly recommended that the assembly should be done near the area of its

intended location. Make sure you have enough space to move around during

the assembly. ALWAYS have at least two people to help with transporting and

assembling of the product to avoid any potential injury and/or damage.

2. To protect from damage, assemble the item on a clean, protective surface,

such as on a carpet or cardboard.

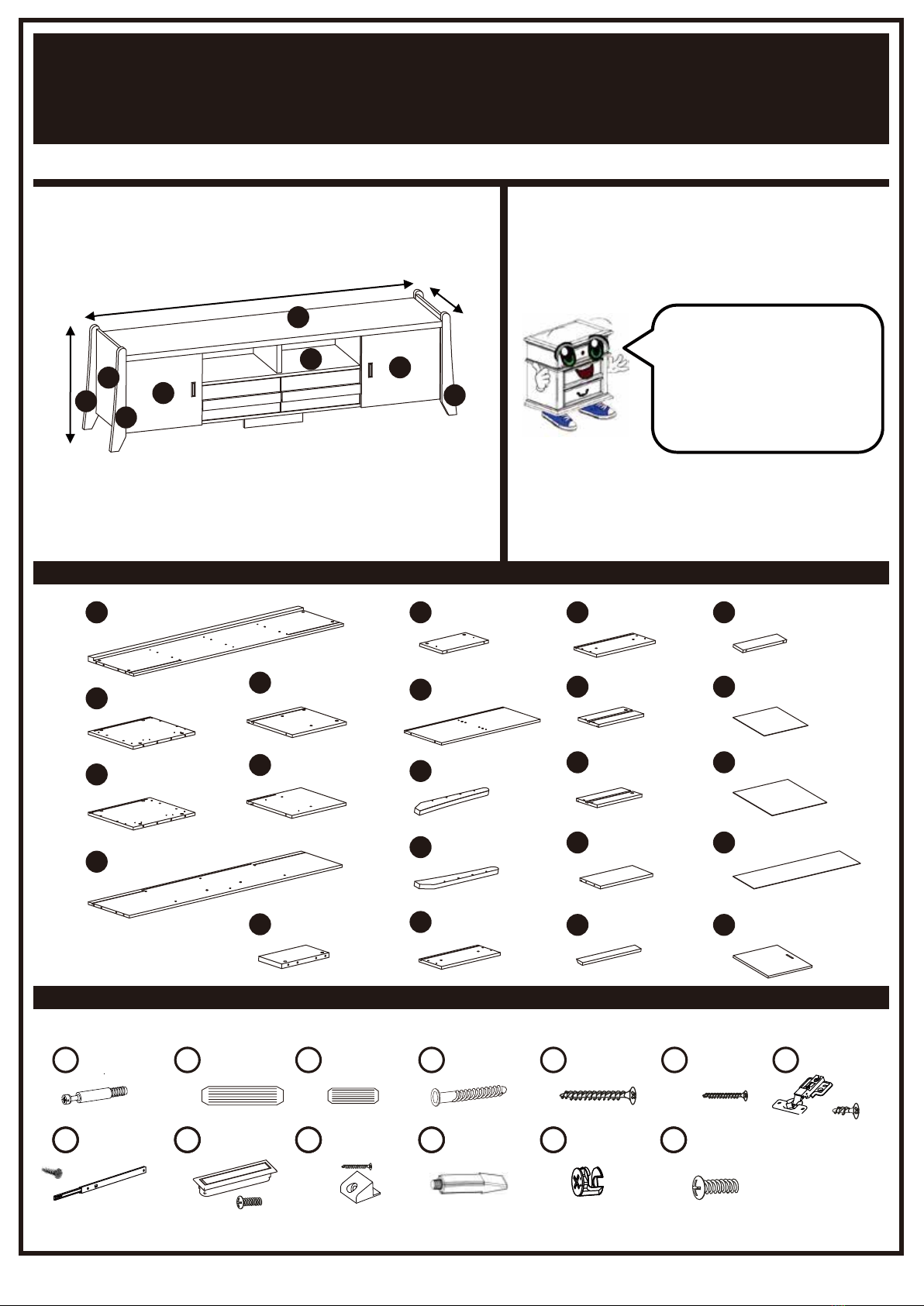

3. Make sure you have taken all the parts and hardware out of their packaging.

Do not throw away packaging material until assembly is completed.

4. Make sure all parts and hardware are accounted for by comparing the actual

parts and hardware to the list provided in the assembly instructions. Also

check for any irregularity such as crack, flaw or improperly drilled hole. If there

is any problem or missing piece, please contact the manufacturer or the

supplier. Please have the model number, part number and a brief description

of the problem ready will help expedite the replacement process.

5. Read the entire instruction manual and view the diagrams first before

assembling. Arrange your parts in order of use and group the identical

hardware together to make it easier to grab each piece as you begin to

assemble.

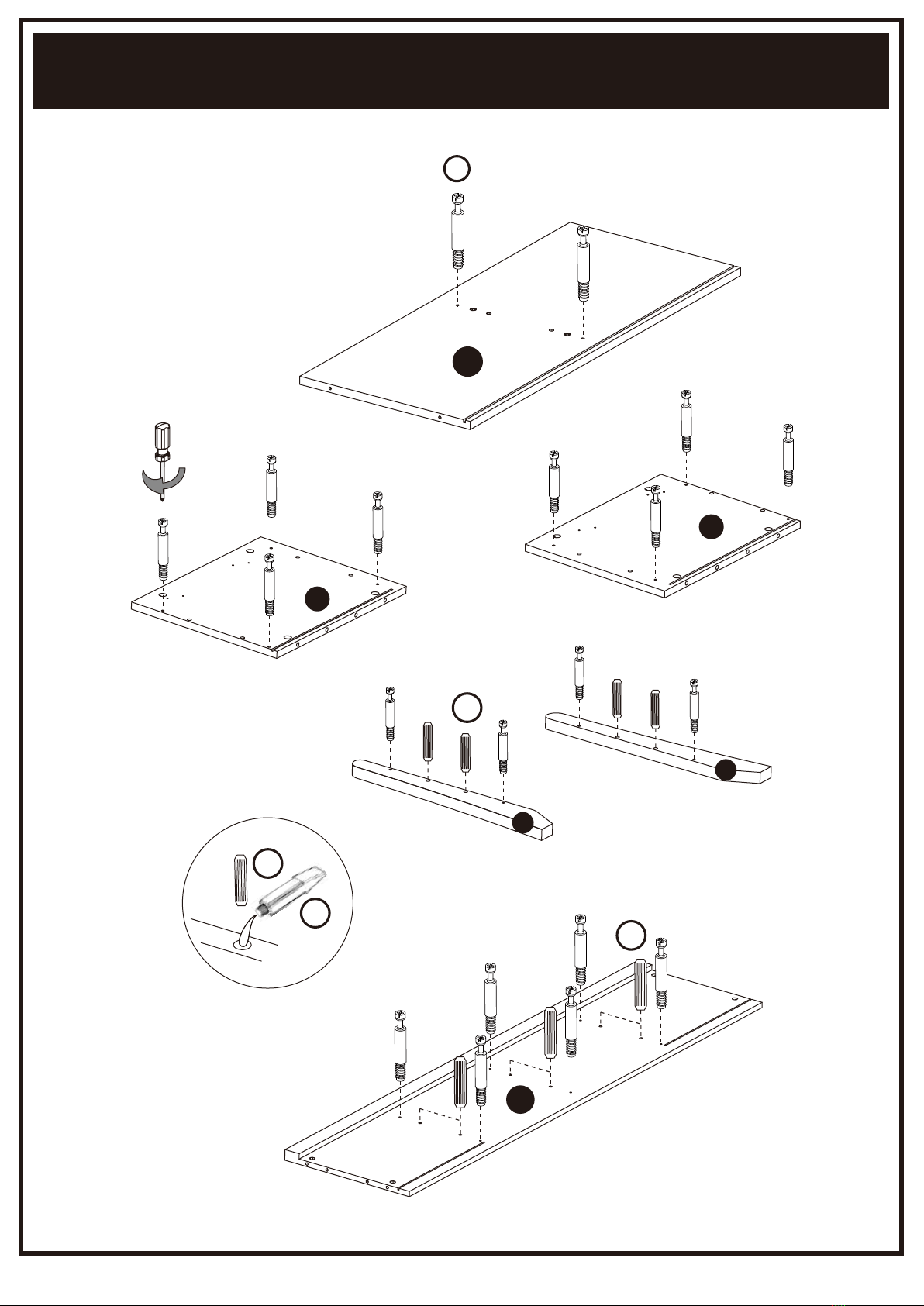

6. During the assembly process, make sure all parts are properly aligned before

tightening with the tool provided or required for the assembly. Do not use

power tools and do not over tighten.

7. When applying glue to the wood dowels to bond the parts together, please be

ABSOLUTELY certain that the parts are correct and lined up with each other

(refer to diagrams and take notice of the various pre-drilled hole locations).

When in doubt, assemble the parts together first and if the parts fit right, then

apply glue to the wood dowels.

PRE-ASSEMBLY INTRODUCTION

Page 4 of 13