TSP & Remote TSP Controller Users Manual

2

Table of Contents

General Information................................................................................................................................................. 3

TSP Specifications................................................................................................................................................ 5

Remote TSP/NEG Controller Specifications......................................................................................................... 6

Approvals .............................................................................................................................................................. 7

Installation................................................................................................................................................................ 8

Receiving and Unpacking...................................................................................................................................... 8

Safety Notices....................................................................................................................................................... 8

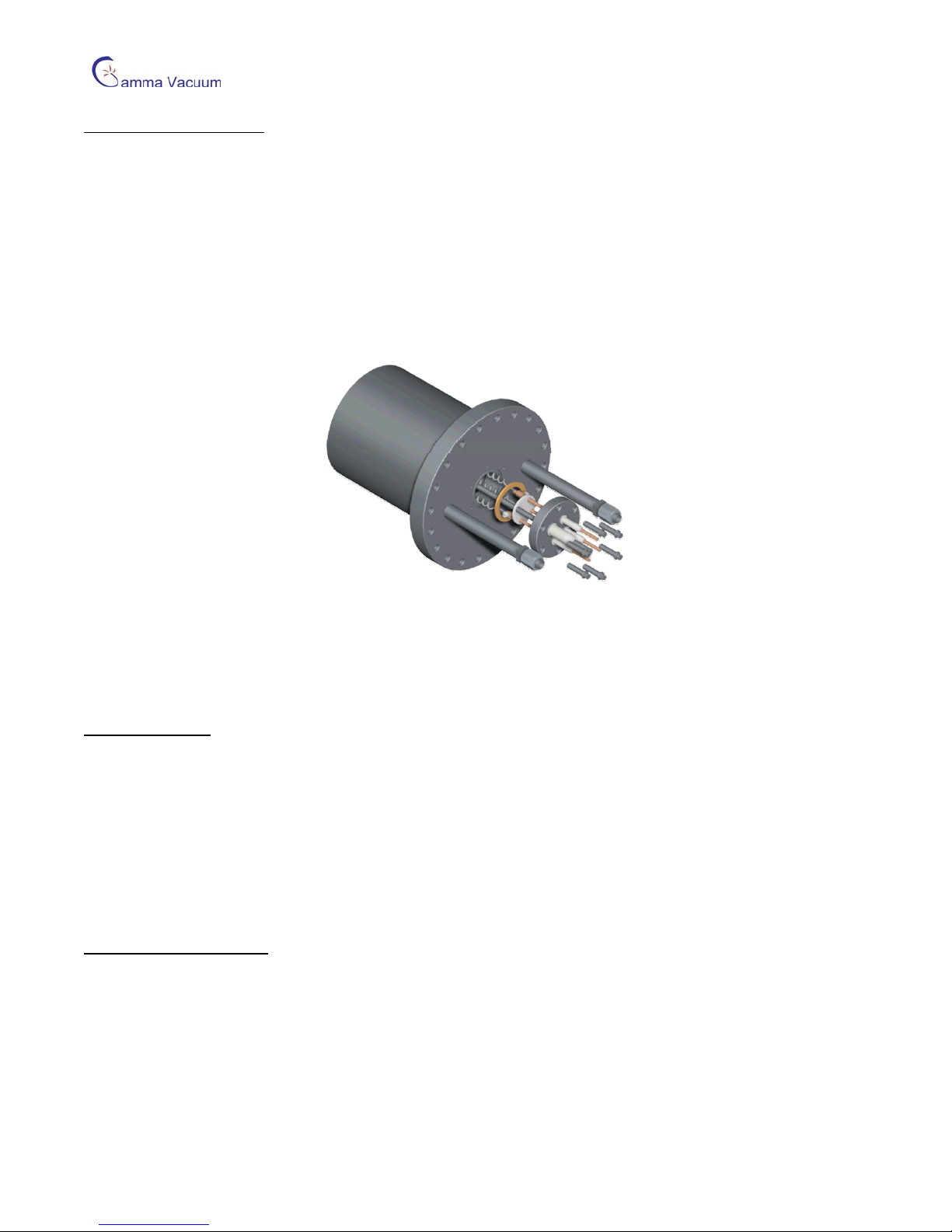

TSP Installation Procedure ................................................................................................................................... 9

Remote TSP Controller Installation Procedure................................................................................................... 10

Dual TSP Installation Procedure......................................................................................................................... 11

Remote TSP Controller Operation....................................................................................................................... 12

Description .......................................................................................................................................................... 12

Menu Display....................................................................................................................................................... 12

TSP Configuration (Config) Menu....................................................................................................................... 13

TSP Settings Menu ............................................................................................................................................. 15

TSP Sublimation Screen..................................................................................................................................... 17

Procedures and Additional Information.............................................................................................................. 18

Cold Start Procedure........................................................................................................................................... 18

Degassing Filament Procedure........................................................................................................................... 18

Normal Operation................................................................................................................................................ 18

Titanium Consumption ........................................................................................................................................ 19

Filament Replacement Procedure....................................................................................................................... 19

TSP Controller Connections................................................................................................................................. 20

Description .......................................................................................................................................................... 20

Power Input, J1 ................................................................................................................................................... 20

MPC/MPCe Controller, J2 (J2/J3 for Dual only).................................................................................................. 20

MPCe Serial Interface, J112 (MPCe Backpanel)................................................................................................ 21

Warranty & Service................................................................................................................................................ 24

Service................................................................................................................................................................. 24

Warranty.............................................................................................................................................................. 24

Returning Material............................................................................................................................................... 26

Return Material Authorization Form.................................................................................................................... 27