第- 2 - 页

Catalog

1 Overview..................................................................................................................................... - 3 -

1.1 product chracteristic................................................................................................................... - 3 -

1.2 Product application、specification and apllying range.............................................................. - 3 -

1.3 Model meaning .......................................................................................................................... - 3 -

1.4 Applying environment and working condition .......................................................................... - 3 -

1.5 Affect to environment and energy.............................................................................................. - 4 -

1.6 Safety ....................................................................................................................................... - 4 -

2 Product technical charateristic .................................................................................................... - 4 -

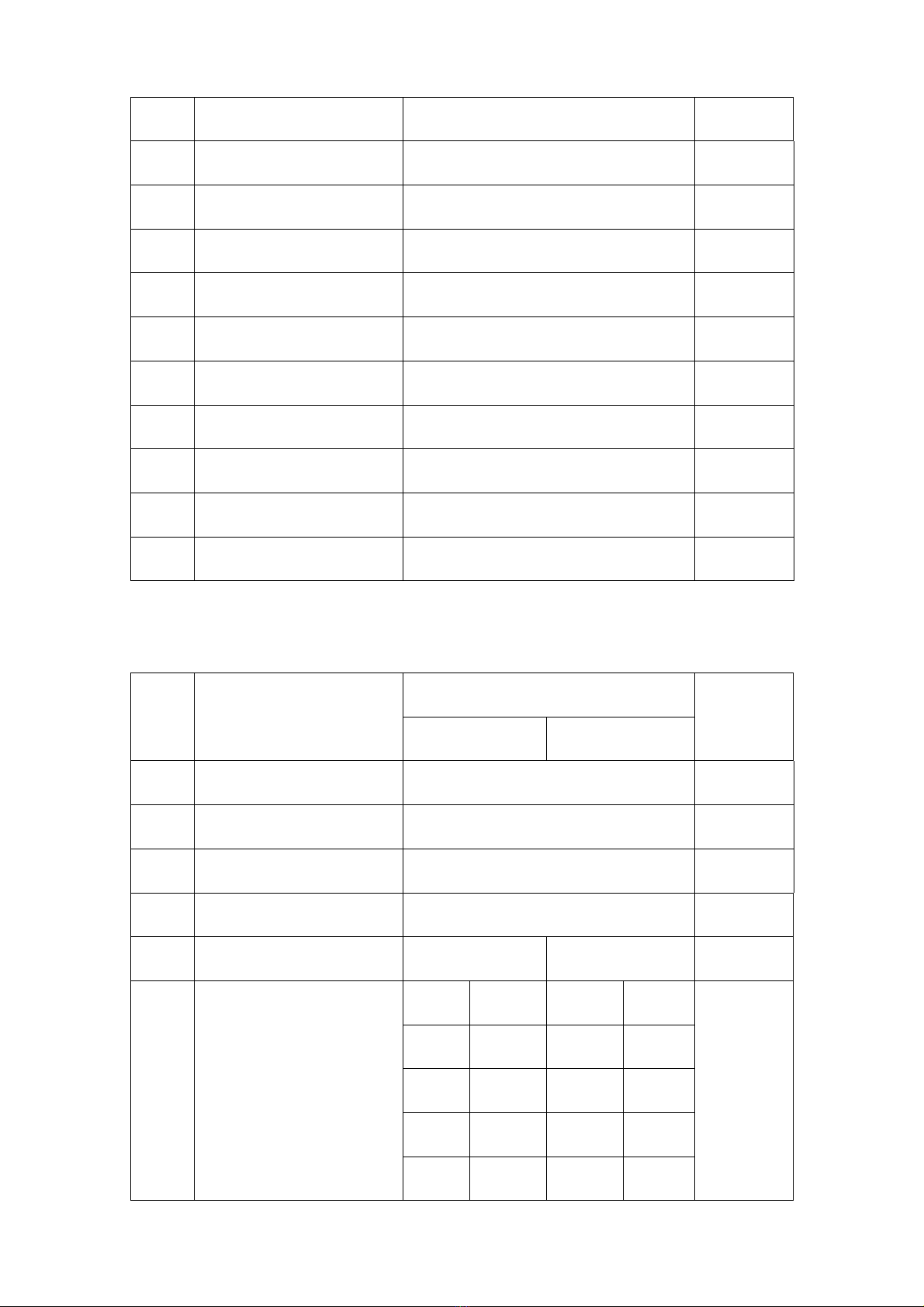

2.1 Main performance parameter..................................................................................................... - 4 -

2.2 Main structure parameter ........................................................................................................... - 5 -

2.3 Transmission system parameter ................................................................................................. - 6 -

2.4 Fuel and lubricating oil parameter ............................................................................................. - 7 -

2.5 Coolant parameter...................................................................................................................... - 7 -

3. Engine outline drawing.............................................................................................................. - 7 -

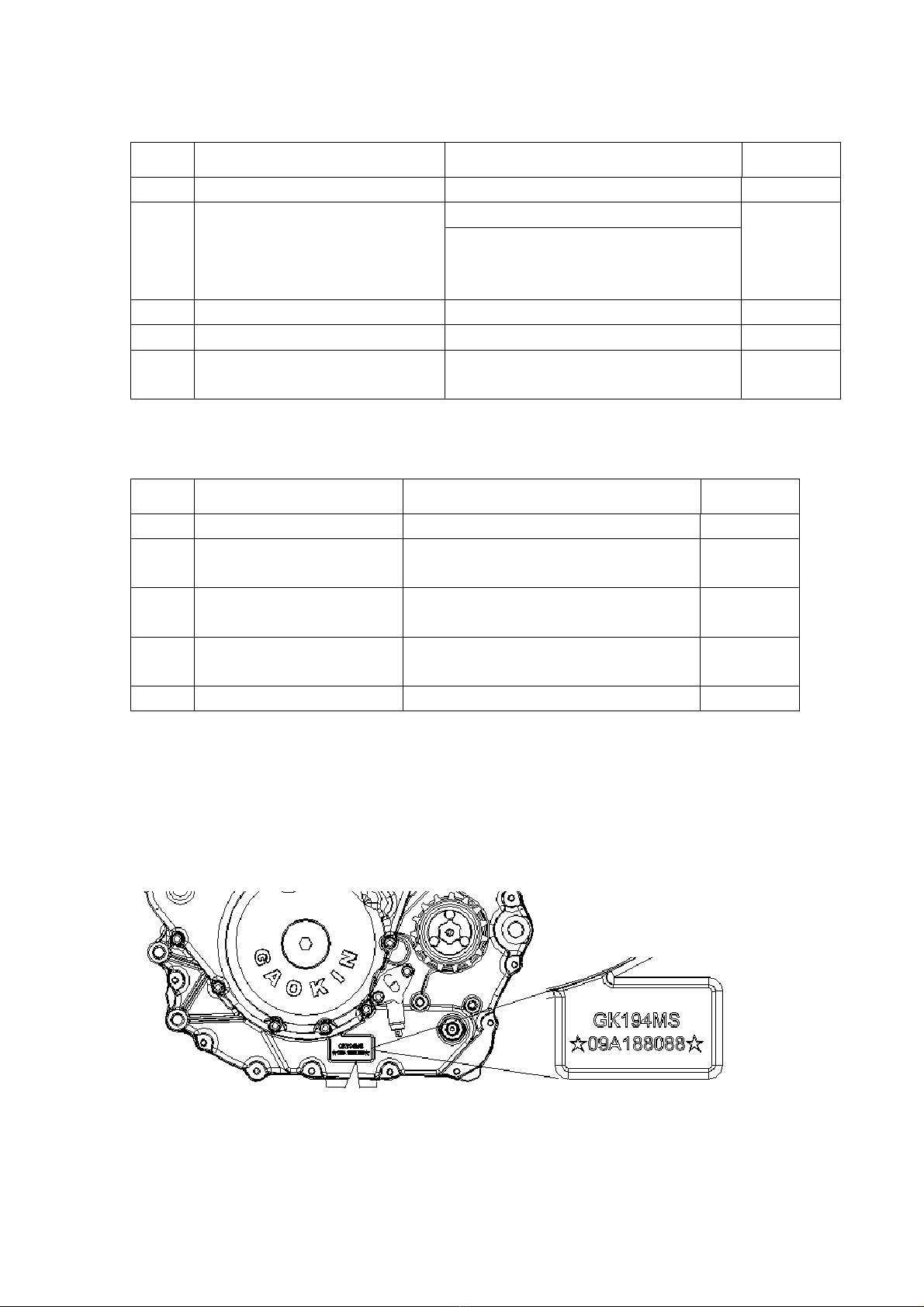

3.1 Engine model and countermark position.................................................................................... - 7 -

3.2 E02 engine outline drawing ....................................................................................................... - 7 -

4.Engine assembly requirement and accessory............................................................................ - 8 -

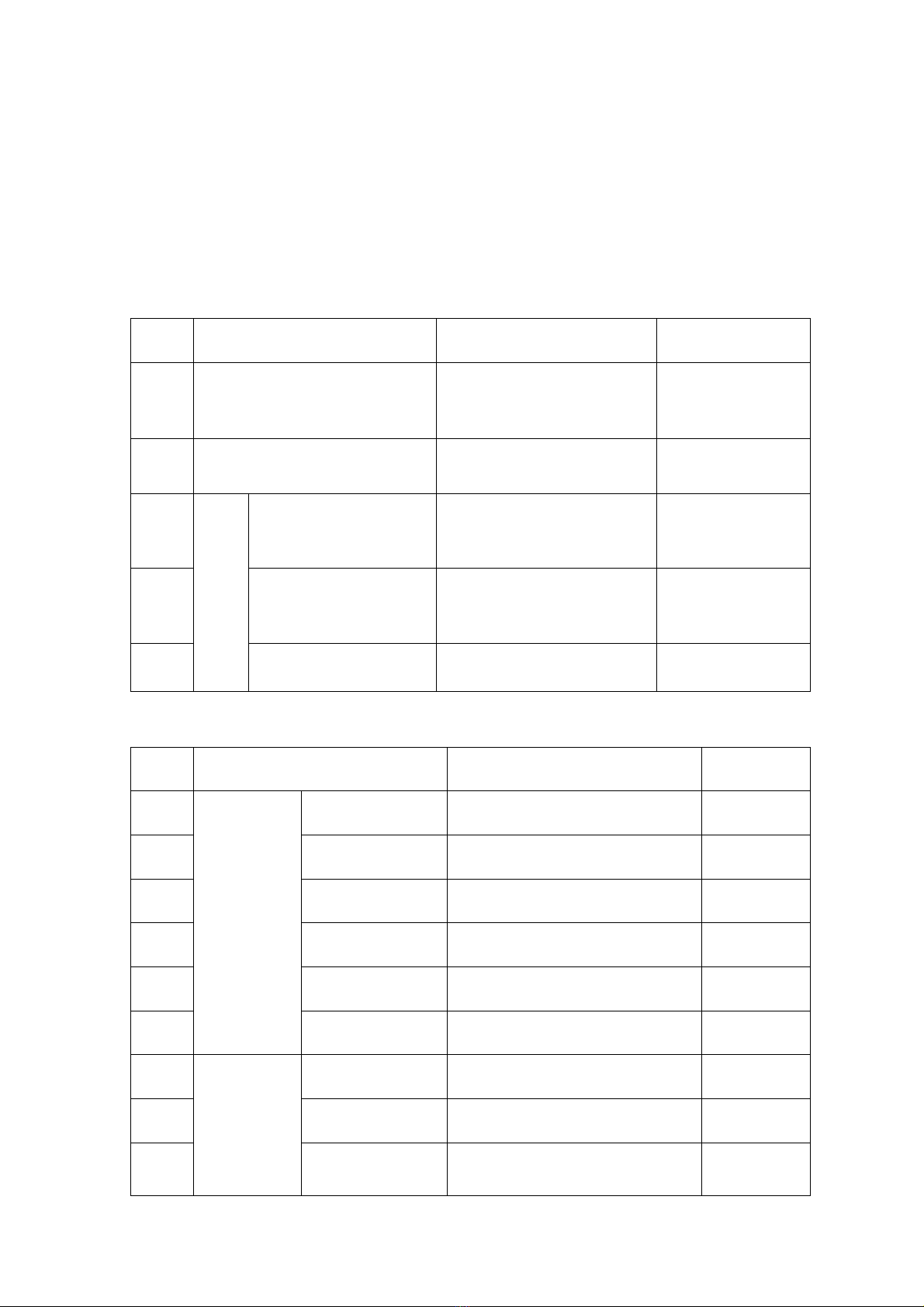

4.1 Engien assembly ........................................................................................................................ - 8 -

4.2 Inlet and exhaust system ............................................................................................................ - 8 -

4.3 Fuel supply system..................................................................................................................... - 9 -

4.4 Coolant system......................................................................................................................... - 10 -

4.5 Electrical equipment system .................................................................................................... - 10 -

4.6 EFI system.................................................................................................................................- 11 -

5.Engine usage、maintenance and fault solution………………………………………………- 13 -

5.1 Engine using and cautions........................................................................................................ - 14 -

5.2 Maintenace............................................................................................................................... - 16 -

5.3 Common fault check list .......................................................................................................... - 20 -

Annex files…………….................................................................................................................... - 25 -

Annex 1E02 outline drawing...................................................................................................... - 26 -

Annex 2Carburetorwireconnectingdrawing ............................................................................ - 27 -

Annex 3EFI wire connecting drawing........................................................................................ - 28 -

Annex 4Carburetorwiresandconnectormodel ........................................................................ - 29 -

Annex 5EFIwiresandconnectormodel ..................................................................................... - 30 -