GAT HULL SHIELD User manual

CONTROLLER

INSTALLATION GUIDE

VERSION 20.2

CONTROLLER INTSALLATION GUIDE

2 / C o n t r o l l e r I n s t a l l a t i o n G u i d e - V e r s i o n 2 0 . 2

WARNING

RISK OF ELECTRIC SHOCK

ELECTRIC SHOCK HAZARD

•Improper installation procedures can result in electric shock!

•Always perform installation with more than one person!

•Ensure all devices are isolated from power supplies during

transducer installation!

CONTROLLER INTSALLATION GUIDE

3 / C o n t r o l l e r I n s t a l l a t i o n G u i d e - V e r s i o n 2 0 . 2

WARNING

RISK OF PERSONAL INJURY

PERSONAL INJURY HAZARD

•Installation areas may pose safety hazards!

•Always perform installation with more than one person!

•Always use appropriate safety gear during installation!

•Follow instructions to reduce risk!

•Contact a professional if in doubt!

CONTROLLER INTSALLATION GUIDE

4 / C o n t r o l l e r I n s t a l l a t i o n G u i d e - V e r s i o n 2 0 . 2

Important Safety Considerations

Electrical Installation Safety & Operational Concerns

It is recommended that installation of electrical components is conducted by a competent marine

electrician.

Ultrasonic transducers operate by high voltage current.

Working with electricity poses a serious risk of injury or death.

Always have another person present during installation as a safety precaution.

Electrical components must be installed properly for the reliable and safe operation of the watercraft.

Connect all AC connections in accordance with IEC wiring regulations.

Personal Injury & Safety Concerns

It is recommended that installation of electrical components is conducted by a competent marine

electrician.

Always have another person present during installation as a safety precaution.

You will likely be working in areas with limited access and little space to work. Tighter access and

smaller work areas pose a higher risk of injury.

Installation near water creates a risk of drowning or electrocution.

Using power tools without proper safety equipment can lead to serious injury or death.

Improperly routed cables can become a personal trip hazard.

Improperly fastened cables can become loose and pose addition safety and electrical risks.

CONTROLLER INTSALLATION GUIDE

5 / C o n t r o l l e r I n s t a l l a t i o n G u i d e - V e r s i o n 2 0 . 2

Parts & Tools Required for Installation

Ensure that you have all necessary parts and tools required to complete the installation. Take precaution

that you follow safety guidelines and wear proper safety gear and protection.

Parts Included

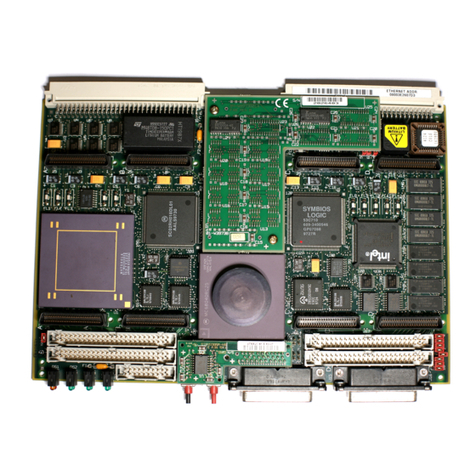

•Power Controller Module

•DC Power Cable

•Power Cable Terminals

Parts Needed

•Screws or 3M Double-Sided Tape

Tools Required for Installation

•Cable Crimping Tool or Pliers

Optional Tools May be Necessary

•Wire Cutters

•Screw Driver

•Adjustable Wrench

CONTROLLER INTSALLATION GUIDE

6 / C o n t r o l l e r I n s t a l l a t i o n G u i d e - V e r s i o n 2 0 . 2

Determining Controller Module Placement

The Hull Shield Controller Module supplies the power and signals required to operate the ultrasonic

transducers.

There are several factors to consider when determining the placement of the controller module.

1. Ease of Access - The controller should be mounted in an area where it can be easily accessible.

2. Dry & Protected - The controller enclosure is not waterproof! It should be mounted in an

enclosed area that is protected from the elements.

3. Central Location - The cables leading from each transducer must reach the controller module.

4. Proximity to Power Source - The provided power cable may require extending if the controller

module is placed too far from the power source.

IMPORTANT - READ FIRST

•Please read this manual in entirety before installing any

transducers!

•It is important that transducers are positioned in the

correct locations to be effective!

•Follow all guidelines to achieve effective placement and

results!

•Failure to follow these guidelines will result in uneven

coverage and inconsistent results!

CONTROLLER INTSALLATION GUIDE

7 / C o n t r o l l e r I n s t a l l a t i o n G u i d e - V e r s i o n 2 0 . 2

Installing the Controller Module & Cables

Review the checklist prior to installation:

I have all parts and tools required to complete the installation.

I will install the controller module in a safe, dry, and accessible location.

I have determined the mounting location has access to route cables to the transducers

and power supply/battery.

Step 1 - Mount the Controller Module

The controller module features

convenient screw holes and

slide-slots to facilitate various

mounting methods. Use

fasteners that are appropriate

for the substrate you will be

attaching the controller to (not

provided).

You can also use 3M Extreme

double-sided mounting tape

(PN: 085-04-0084) to attach the

unit to a smooth and clean

surface.

Ensure the controller module is

fastened securely!

CONTROLLER INTSALLATION GUIDE

8 / C o n t r o l l e r I n s t a l l a t i o n G u i d e - V e r s i o n 2 0 . 2

Step 2 - Attach Power Cable Terminals

Determine whether the power cable will span the distance between the battery and the

location you have chosen to mount the controller module.

The power cable can be extended with 14 or 16 gauge 2-stranded marine grade cable. It is

best to connect the cable extension using a weather-proof junction box with enclosed

terminals block.

You should attach eyelet terminals to the power

cable wires. Your product is provided with two

(2) 5/16” eyelet terminals which will fit most

marine battery posts.

If you have extended the power cable, you will

need to strip the cable jacket to expose 3/8” of

the wire.

Insert the wire into the base of the eyelet.

Using a pair of cable crimpers or pliers, clamp

the eyelet terminal onto the wire.

Ensure the terminal is securely fastened to the

cable!

Repeat this procedure for both the wires within the power cable that have the black & white

insulation. You can cut-back and discard the wire with the green insulation - it will not be used

for this installation.

CONTROLLER INTSALLATION GUIDE

9 / C o n t r o l l e r I n s t a l l a t i o n G u i d e - V e r s i o n 2 0 . 2

Step 3 - Connect Power Cable to the Battery

Be sure to connect the correct colored wire

to the proper terminal to avoid DAMAGE!

BLACK WIRE - POSITIVE 12VDC

WHITE WIRE - NEGATIVE / GROUND

It’s important to connect the cables with a

secure connection. Use the provided eyelet

terminals whenever possible.

Remove the retaining nut from the battery post.

Then position the eyelet onto the battery terminal.

Be sure that the eyelet makes firm contact with the

battery terminal.

Firmly secure the post locking nut onto the stud.

IMPORTANT! DOUBLE-CHECK THAT YOU HAVE

ATTACHED THE BLACK WIRE TO THE POSITIVE

TERMINAL AND THE WHITE WIRE TO THE

NEGATIVE TERMINAL!

REVERSE POLARITY WILL DAMAGE THE PRODUCT!

CONTROLLER INTSALLATION GUIDE

10 / C o n t r o l l e r I n s t a l l a t i o n G u i d e - V e r s i o n 2 0 . 2

Step 4 - Connect Cables to the Controller Module

Be sure that the controller module is

OFF prior to connecting any cables.

The switch located at the top of the

unit must be in the OFF position.

Connect the transducer cables to available

inputs on the bottom of the controller

module. Twist the blue locking ring

clockwise onto the threads to secure the

connectors.

DO NOT OVER-TIGHTEN!

Connect the power cable by inserting into

the socket located on the right side of the

controller module. Be sure that the cable is

firmly pressed into the socket.

SWITCH OFF!

CONTROLLER INTSALLATION GUIDE

11 / C o n t r o l l e r I n s t a l l a t i o n G u i d e - V e r s i o n 2 0 . 2

WHEN IN DOUBT - CONTACT US

For installation support, please contact us at info@hullshield.net

Table of contents

Popular Controllers manuals by other brands

Rockwell Automation

Rockwell Automation Allen-Bradley Logix 5000 Series Programming manual

Geco

Geco GH20SB user manual

Comar Condensatori

Comar Condensatori QSR6 user manual

Tyco Security Products

Tyco Security Products DSC TL8803GI-IL2 manual

Motorola

Motorola 700 Series Installation and use

Crestron

Crestron onCue BPC-8 Supplemental guide