Gatan 656 User manual

Dimple Grinder,

Model 656

User’s Guide

Gatan, Inc.

5933 Coronado Lane

Pleasanton, CA 94588

Tel (925) 463-0200

FAX (925) 463-0204

November 1998

Revision 2

Part Number: 656.82002

Dimple Grinder User’s Guide i

Preface

About this Guide

This

Dimple Grinder User’s Guide

is written to provide procedure for the

installation of the unit, instruction on basic operations of the unit, procedures

for routine maintenance and servicing, and specifics for troubleshooting.

The Guide provides the following comment:

Note

: Used to highlight advice directed at getting the best performance from

the equipment.

Preview of this Guide

The

Dimple Grinder User’s Guide

includes the following sections:

Section 1, “Overview,”

provides an overview of the system.

Section 2,

“Installation,”

provides instruction for installation of the unit.

Section 3, “Description,”

describes the various features and different compo-

nents within the unit.

Section 4, “Operation,”

provides instruction for operation of the different

components within the unit.

Section 5

,

“Performance Check

,

”

provides instructions on optimization pro-

cedures.

Section 6

,

“Electrical Control System

,

”

contains information on the electrical

system of the unit.

Section 7, “Spares and Consumables

,

”

provides a list of spares and consum-

ables.

ii Dimple Grinder User’s Guide

Disclaimer

Gatan, Inc., makes no express or implied representations or warranties with

respect to the contents or use of this manual, and specifically disclaims any

implied warranties of merchantability or fitness for a particular purpose.

Gatan, Inc., further reserves the right to revise this manual and to make

changes to its contents at any time, without obligation to notify any person

or entity of such revisions or changes.

Copyright and Trademarks

© Gatan, the Gatan logo is registered to Gatan, Inc.

The product names AutoFilter, BioScan, Clipring, DigiPEELS, DigiScan,

DigitalMicrograph, DigitalMontage, Duo Mill, DuoPost, Gatan LowDose,

GIF, Hexlok, Hexring, HotHinge, MSC, PECS, PIPS, Toggle Tilt, and

Whisperlok are trademarks belonging to Gatan, Inc.

Dimple Grinder User’s Guide iii

Support

Contacting Gatan Technical Support

Gatan, Inc. provides free technical support via voice, Fax, and electronic mail.

To reach Gatan technical support, call or Fax the facility nearest you or contact

by electronic mail:

• Gatan Inc., USA (West Coast)

Tel: (925) 463 0200

Fax: (925) 463 0204

• Gatan Inc., USA (East Coast)

Tel (724) 776 5260

Fax: (724) 776 3360

• Gatan GmbH, Germany

Tel: 089 352 374

Fax: 089 359 1642

• Gatan, UK

Tel: 01536 743150

Fax: 01536 743154

• Nippon Gatan, Japan

Tel: 0424 38 7230

Fax: 0424 38 7228

• Singapore

Tel: 65 235 0995

Fax: 65 235 8869

• Gatan Online

http://www.gatan.com

iv Dimple Grinder User’s Guide

Dimple Grinder User’s Guide v

Table of Contents

Preface i

Support iii

Table of Contents v

List of Figures vii

Dimple Grinder, Model 656 1

1.0 Overview 1

2.0 Installation 2

3.0 Description 2

3.1 Control Panel 2

3.2 Measuring Devices 2

3.3 Counterweight 4

3.4 Specimen Rotation Axis 5

3.5 Wheel Types 5

3.6 Raise/Lower Cam 8

3.7 Stereo Microscope 8

3.8 Specimen Mounts 9

4.0 Operation 10

4.1 Adjusting Zero of Dial Indicator 12

4.2 Preparing the Specimen 13

4.3 Specimen Mounting 13

4.4 Specimen Positioning 14

4.5 Set Grinding by Dimple Depth 15

4.6 Set Grinding by Final Thickness 16

4.7 Polishing 19

4.8 Polishing to Final Thickness < 20 µm 20

vi Dimple Grinder User’s Guide

4.9 Double-Sided Dimpling 21

4.10 Specimen Removal 21

4.11 Taper Sections 22

5.0 Performance Check 22

5.1 Arm Pivot Friction 23

5.2 Zero Counterweight Scale 23

5.3 Eccentricity (Run-Out) 24

5.4 Vertical Movement of the Specimen Turntable 26

5.5 Grinding Wheel Alignment 26

5.6 Microscope alignment 27

5.7 Zero Stop Adjust 28

6.0 Electrical Control System 29

7.0 Spares and Consumables 30

Dimple Grinder User’s Guide vii

List of Figures

Figure 1 Dimple Grinder, top view. 3

Figure 2 Measuring devices. 4

Figure 3 Grinding wheel rotation axis. 5

Figure 4 Wheel position alignment. 6

Figure 5 Wheel types. 7

Figure 6 Stereo microscope. 9

Figure 7 Specimen mounts. 10

Figure 8 Set grinding by dimple depth. 16

Figure 9 Set grinding by final thickness. 18

viii Dimple Grinder User’s Guide

Dimple Grinder User’s Guide 1

Dimple Grinder,

Model 656

1.0 Overview

The Gatan Model 656 Dimple Grinder is a precision instrument used to produce

circular dimples (spherical or flat-bottomed profile) in materials such as ceram-

ics, semiconductors, metals, and combinations thereof. The principle applica-

tion is in the preparation of TEM specimens. When specimens are mechanically

dimpled prior to final thinning, the finished specimen has a more uniform thick-

ness, has a larger than usual electron-transparent area, and is very robust with a

thick rim surrounding the central thin region. In the case of neutral-particle

beam-thinning systems, the time required for final thinning is significantly

reduced with dimpling.

With most metals, a 20-µm specimen can be obtained by dimpling and the

mechanical damage introduced into the specimen surface by the grinding action

is removed with additional final thinning by electro polishing, ion-beam thin-

ning, etc. A final specimen thickness of <5 µm can routinely be produced by a

careful operator.

The Dimple Grinder is gentle enough and provides sufficient control over the

process of dimpling that many materials, such as ceramics and semiconductors,

can be thinned below 3 µm with practically no mechanical damage and viewed

subsequently in intermediate- and high-voltage TEMs without further thinning.

Additionally, the electron-transparent area may be precisely positioned in the

specimen, laterally to within a few tens of microns and vertically to within a few

microns– not always possible with other dimpling instruments.

Other applications of the Dimple Grinder include the production of accurate,

precisely-located taper sections through the surface of specimens, which may

then be subjected to analytical techniques such as EDX, SIMS, Auger, etc. In

this way, compositional profiles of segregated surface layers, coatings, and plat-

ings can be obtained rapidly and with excellent “depth resolution.”

Installation

2 Dimple Grinder User’s Guide

2.0 Installation

The Dimple Grinder operates from the standard mains voltage with no other

external services or utilities necessary. However, for reproducible high-quality

results, the Dimple Grinder must sit on a flat, vibration-free surface in a rela-

tively clean environment.

The Counterweight is packed separately and should be attached by screwing it

into position on the Platform. After installation, the zero point of the Counter-

weight scale should be checked (see Section 5.2).

3.0 Description

The base (body) of the Dimple Grinder (see Figure 1) holds the Control Panel,

the Micrometer Drive, the Magnetic Turntable with motor drive, the Raise/

Lower Cam, and the Transmission Illumination system. On top of this base sits

a pivoted Platform containing the Grinding Wheel assembly, the analog Dial

Indicator, and the Counterweight. The Platform, when in the vertical position, is

held in place by a magnetic latch (at the rear). With the Platform raised, a stereo

microscope can be mounted over the Magnetic Turntable for specimen viewing.

3.1 Control Panel

The Control Panel contains the following buttons and dials:

3.2 Measuring Devices

The Dimple Grinder incorporates two measuring devices:

• A Dial Indicator with stylus and analog display (see Figure 8).

• A Micrometer Drive connected to a digital display (see Figure 2).

Table

Depress to turn on/off motor for magnetic turntable rotation.

Arm

Depress to turn on/off motor for dimple wheel rotation.

Lamp

Depress to turn on/off transmission illumination.

Auto

Depress to turn on/off AutoTerminator.

Zero

Depress to zero Dimple Depth digital display.

Speed (dial)

Rotate to set dimpling wheel rotation speed.

Description

Dimple Grinder User’s Guide 3

Figure 1 Dimple Grinder, top view.

DIMPLE DEPTH

ZERO

AUTO STOP

ON

ARM

DIMPLE GRINDER

Model 656

SPEED

LAMP

TABLE

7

6

4

3

5

2

13

12

14

15

16

17

18

19

1

8

910

11

1. Zero stop

2. Raise/lower cam control

3. Analog dial indicator

4. Autoterminator socket

5. Pivot platform

6. Load scale

7. Counterweight

8. Microscope socket

9. Wheel motor socket

10. Main power On/Off switch

11. Power On indicator

12. Speed control (wheel)

13. Autoterminator control

14. Dimple depth zero

15. Dimple wheel axle

16. Microscope mount

17. Magnetic turntable

18. Dimple wheel

19. Micrometer drive

Description

4 Dimple Grinder User’s Guide

Figure 2 Measuring devices.

The Dial Indicator provides indication of contact between grinding wheel and

specimen and presents an analog display of dimpling progress.

The Micrometer Drive provides a digital readout for setting desired dimple

depth or final specimen thickness.

The end face of the Micrometer sits directly below the stylus of the Dial Indica-

tor (see Figure 8). When the Micrometer end face is raised (by rotating the

Micrometer Drive), it pushes up and raises the stylus by a height change, which

is indicated by the dial/digital display. The stylus and the grinding wheel axle

are both mounted to the Platform. The raising of the stylus results in a corre-

sponding raising of the grinding wheel.

A desired dimple depth (shown in the digital readout) can be set using the

Micrometer (see Section 4.5). As dimpling progresses, the “amount of dim-

pling” can be read on the Dial Indicator.

3.3 Counterweight

Located on the back of the Platform is the Counterweight that supplies the vari-

able load (from 0–40 g) applied to the specimen (see Figure 1). The desired load

can be selected by dialing in the appropriate value on the scale.

Note

: When varying the load, be sure to raise the Platform slightly so the Dial

Indicator stylus is not on the Micrometer end face.

Caution

: Dropping the pivoted Platform may cause considerable damage to the

measuring devices and will void the warranty.

Analog dial

indicator

Raise/lower

cam control

Micrometer

drive

Description

Dimple Grinder User’s Guide 5

3.4 Specimen Rotation Axis

The grinding wheel rotation axis (horizontal) is exactly orthogonal to and inter-

sects the specimen rotation axis(vertical). Producing a good dimpled specimen

requires the point of contact between specimen and grinding wheel to be on the

specimen rotation axis directly below the intersection of the two axes. Precise

alignment of the grinding wheel assembly with the specimen ensures that the

grinding wheel is within the plane of the specimen rotation axis and hence con-

tacts the specimen at the correct point.

Figure 3 Grinding wheel rotation axis.

The correct configuration is determined by the appropriate wheel diameter and

specimen mount assembly. If the diameter of the wheel is too large or too small,

the wheel tilts and its rotation axis moves away from the horizontal, which

causes the contact point to move away from the vertical specimen rotation axis

(see Figure 4).

3.5 Wheel Types

There are two types of wheels available with the Dimple Grinder:

• Grinding wheels

• Polishing wheels

Specimen

Specimen

mount

Centering

ring

Specimen

rotation

axis

Grinding

wheel

rotation

axis

Grinding

wheel Motion of

pivoted platform

Description

6 Dimple Grinder User’s Guide

Figure 4 Wheel position alignment.

Grinding Wheels

The grinding wheels are phosphor bronze, available with spherical or flat edges.

The spherical-edged wheel permits more accurate positioning of dimples and

produces a spherical profile with a smaller thin area. This wheel is more suited

to fragile or brittle specimens, such as ceramics and semiconductors.

The flat-edged wheel produces flat bottomed dimples with larger thin regions

and is better suited to tougher specimens, particularly metals.

Wheels come in different sizes. The small wheel preserves a wide, thick rim

around the thin area for fragile specimens and produces steep profiles for analy-

sis. The large wheel prepares bulk specimens for larger thin areas. All wheels

are interchangeable.

Note:

The grinding wheels wear and are considered consumable items.

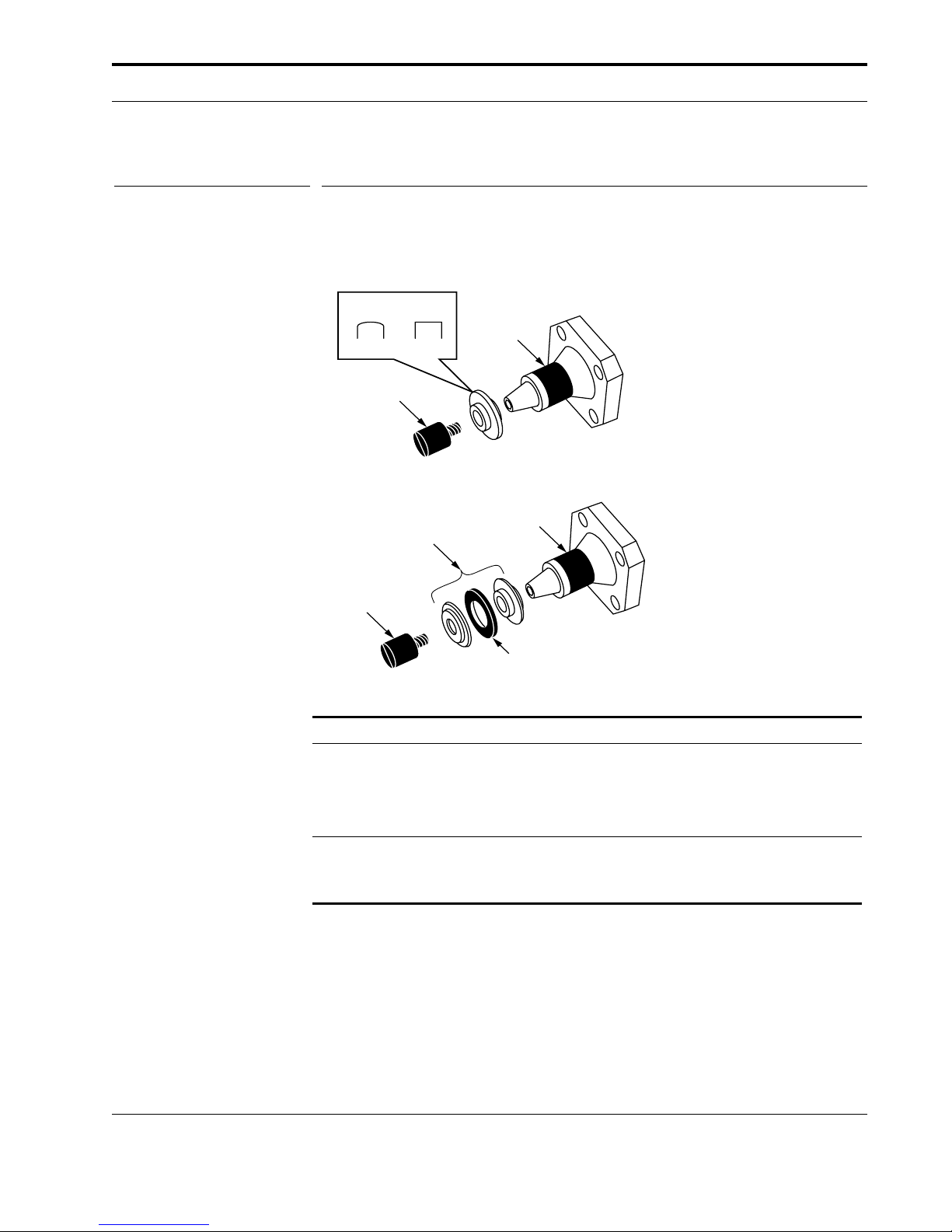

Polishing Wheels

The polishing wheel consists of male and female parts that hold a central felt

polishing ring (see Figure 5).

Standard

grinding wheel

contact point

Specimen

Specimen

rotation

axis

Pivot point

of rotating

grinding arm

Large

grinding wheel

contact point

Standard

grinding

wheel

Large

grinding

wheel

β

Specimen

mount

Description

Dimple Grinder User’s Guide 7

Figure 5 Wheel types.

The following table presents the material and sizes of the different wheels:

Note:

The polishing rings have a limited lifetime and should be replaced regu-

larly. Take care not to get the felt polishing rings contaminated and do not mix

different polishing compounds on the same ring.

Caution:

Be careful to ensure that the male and female surfaces of the wheels

and axle assembly are kept clean. Do not flood the male taper with solvents to

clean the axle, as this may flush grit or compounds into the axle assembly lead-

ing to wear and impaired performance. Clean the axle with a lens tissue lightly

Wheels Material Edges Size (mm)

Grinding

Phosphor bronze Spherical 10

15 (standard)

20

Flat 15

Polishing

Male/female parts

supporting a felt ring 10

15 (standard)

20

Durlon rim

polishing wheel

10 mm, 15 mm,

and 20 mm

Dimple

wheel

axle

Spherical rim grinding wheel,

10 mm, 15 mm, and 20 mm

or

Flat rim, grinding wheel,

15 mm only

Dimple

wheel

axle

Thumb

screw

Thumb

screw

Felt

ring

Spherical

Grinding wheel

Flat

Description

8 Dimple Grinder User’s Guide

moistened with water or a solvent (e.g., acetone) if the contamination is difficult

to remove.

3.6 Raise/Lower Cam

The Raise/Lower Cam

allows the Platform (and the grinding wheel) to be very

gently lowered and must

always

be used to raise or lower the Platform through

the final part of its movement.

To lower the Platform

1. Rotate the Raise/Lower Cam toward the back.

This will rotate the Cam stop to the rear.

2. Manually lower the Platform as far as it will go.

3. Rotate the Raise/Lower Cam slowly toward the front.

This will rotate the Cam stop to the front and in the process gently lower the

grinding wheel onto the specimen for the last few microns of grinding.

3.7 Stereo Microscope

The stereo microscope (see Figure 6) projects a true image and is designed to

accurately fit the microscope mount around the Magnetic Turntable. The cross

hair within the eyepiece is aligned to the center of rotation of the Turntable. By

selectively positioning the specimen, the microscope can be precisely located

on a specific feature.

Illumination

The stereo microscope, which plugs into the light socket left of the Control

Panel (see Figure 1), contains both a Reflection and Transmission Illumination

systems. Certain materials that become transparent during final thinning may,

when mounted to glass specimen mounts, be observed by the Transmission Illu-

mination system.

Depress the

L

AMP

button on the Control Panel to turn off the “reflected” micro-

scope lamp and turn on the “transmitted” lamp mounted beneath the Turntable.

A beam will be projected through the center hole in the Turntable and illumi-

nate the specimen from below.

Description

Dimple Grinder User’s Guide 9

Figure 6 Stereo microscope.

3.8 Specimen Mounts

The specimen mount is held in position by a centering ring on the Magnetic

Turntable. To accommodate the various diameter grinding and polishing

wheels, three different, appropriately-sized mounts are available to insure the

proper grinding-wheel axis orientation (see Figure 7).

The standard mount, for use with the standard 15-mm diameter wheel, is cylin-

drical in shape and made of stainless steel. Opaque specimens are normally

mounted on the stainless-steel mount. For transparent specimens or for materi-

als that become transparent when very thin, such as silicon, a glass (pyrex)

specimen mount is available that allows the progress of thinning to be moni-

tored in transmitted light.

Y adjust

X left

adjust

X right

adjust

Adjustment

tool

Specimen

mount Microscope

mount

Centering

ring

Align circular

spot with

microscope

crosshairs

View through microscope

Microscope

field-of-view,

60X

Circular spot

generated by

grinding wheel

Operation

10 Dimple Grinder User’s Guide

Figure 7 Specimen mounts.

The specimen mount for use in conjunction with the small, 10-mm diameter

wheel has a conical shape to prevent fouling of the grinding wheel axle assem-

bly.

The specimen mount for the large, 20-mm diameter wheel is a simple disc.

Note:

The specimen mounts should be periodically checked for smoothness and

flatness. This may be done either with the stereo microscope or a free-standing

dial indicator.

4.0 Operation

There are two methods by which specimens can be dimpled:

• Set grinding by dimple depth.

Specimen mount

(stainless steel)

Centering

ring

Microsope

mount

Centering

ring

Microsope

mount

Microsope

mount

10-mm

grinding wheel

15-mm

grinding wheel

Specimen mount

(pyrex or

stainless steel)

Specimen mount

(pyrex or

stainless steel)

20-mm

grinding wheel

Table of contents