GAZ VALDAI GAZ33104 Technical manual

LIMITED LIABILITY COMPANY "AVTOZAVOD "GAZ"

(LLC "AVTOZAVOD GAZ")

VALDAI

VEHICLES FAMILY

OPERATING INSTRUCTIONS

331043902111 ИЭ

RUSSIA

NIZHNIY NOVGOROD

2

Introduction

"VALDAI" vehicles are intended for transportation of goods over differ

ent roads in moderate climate conditions at the ambient air temperature from

plus 45° C to minus 45° C.

1) Service Book for 'VALDAI' vehicle is attached to this Operating Instructions.

"VALDAI" vehicles family presented in this Operating Instructions com

prises the following models:

GAZ33104 vehicle — 4x2 type with threeseat cabin.

GAZ331041 vehicle — 4x2 type with threeseat cabin and extended wheel

base.

GAZ331043 vehicle — 4x2 type with sixseat cabin and extended wheel

base.

The manufacturer reserves the right to constantly alter its vehicle design,

therefore some units and parts may slightly differ from those described in this

Operating Instructions.

You can surely expect reliable operation of the vehicle provided you ob

serve maintenance schedule specified in this Operating Instructions and Serv

ice Book1).

3

1.VEHICLE IDENTIFICATION DATA

Identification number of the vehicle (VIN) and identification numbers of

cabin or allmetal body, engine and cargo body vehicle chassis refer to the ve

hicle identification data.

Vehicle Identification Number (VIN) appears on the right frame side

member before the rear spring front bracket (Fig.1.1).

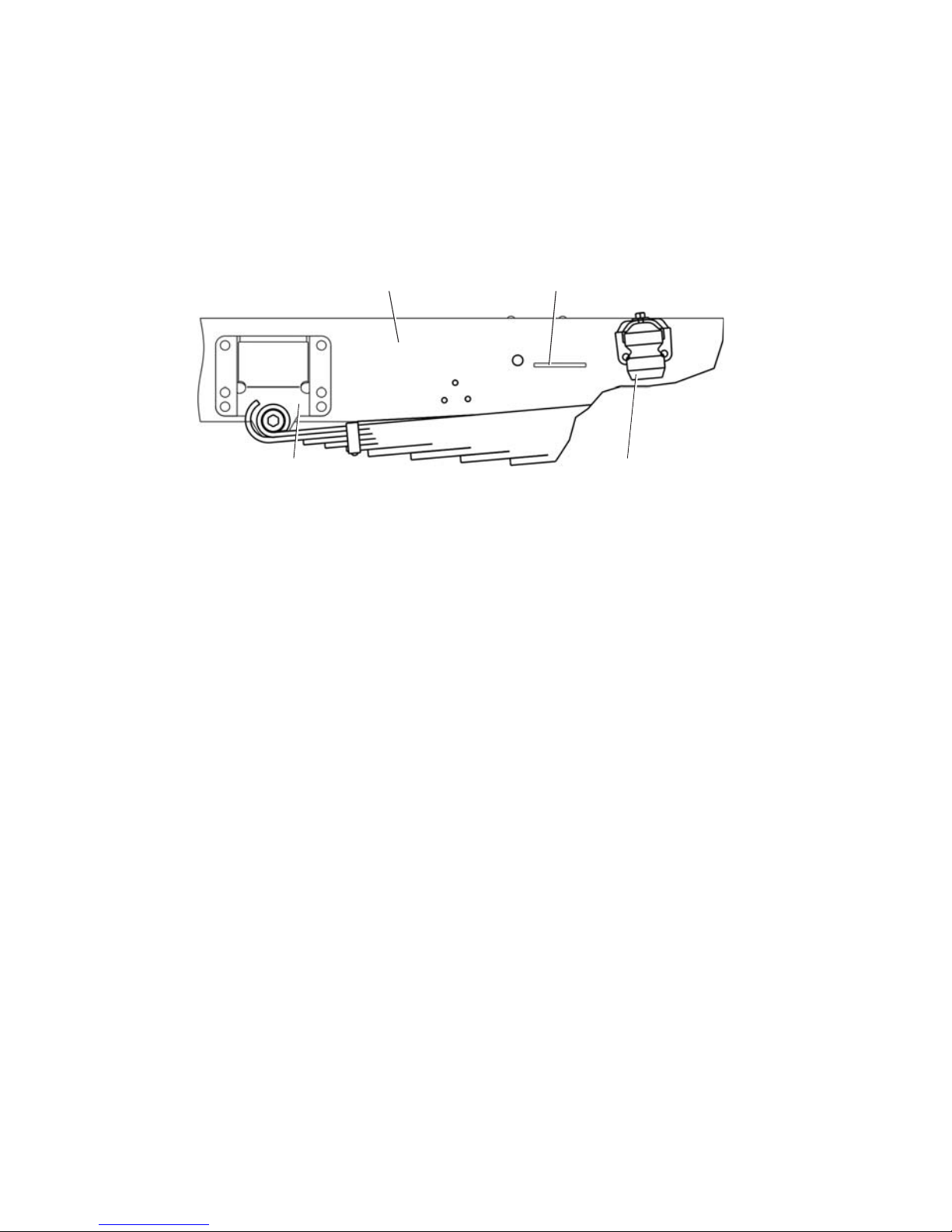

Fig. 1.1. Location of VIN or Chassis Number:

1 — rear spring rear bracket; 2 — frame side member, right; 3 — location of identification number;

4 — rubber restraint cushion

Example of Vehicle Identification Number:

X96 33104050000125, where:

X96 — manufacturer international identification code,

331040 — vehicle index,

5 — model year code,

0000125 — vehicle serial number.

Model year is a period equal on the average to calendar year during which

the vehicles with identical design features are being manufactured.

Chassis identification number is marked on the right side member of the

frame of cargo body vehicles intended for supplying to other plants for manu

facturing special vehicles (Fig. 1.1).

Example of Chassis Number:

33104050000125, where:

331040 — chassis index,

5 — model year code,

0000125 — chassis order number.

Cab identification number is located under the hood on the front outer

panel, on the left in direction of vehicle movement (see Fig. 1.2, arrow "A"

view).

1 4

3

2

4

Example of Cab (Body) Number:

33104050000125, where:

331040 — cabin index

5 — model year code,

0000125 — cabin serial number.

Fig. 1.2. A — Location of Cab Identification Number

Д245.7 E2 engine number is stamped on the nameplate (Fig. 1.3) located

on the cylinder block in the middle portion on the righthand side.

Fig. 1.3. Д245.7 E2 Engine Nameplate

The nameplate contains the following data:

a — engine index;

b — engine serial number

Vehicle identification data also appear on manufacture's plate (Fig. 1.4)

located on the rear pillar of the cab right door.

Chassis, cab and engine numbers refer to the identification data of chassis

and special configuration vehicles for supplying to the other plants for making

their own special vehicles having their own index. Nameplate "GAZ" is not

installed and vehicle identification number does not appear on chassis and the

above vehicles.

5

Fig. 1.4. Manufacture's Plate with Vehicle Identification Data, where:

a — vehicle identification number;

b — gross vehicle weight;

c — gross vehicle weight with trailer;

d — maximum front axle weight;

e — maximum rear axle weight;

f — engine index

2. USEFUL HINTS

1. Procedure of engine starting is described in section 6.2. "Engine Start

ing and Stopping".

After cold engine starting do not run it immediately at high speed because

cold oil passes slowly to rubbing surfaces and they may be got damaged at the

engine high speed.

2. The engine efficient performance and its wear mostly depend on engine

operating temperature. It is necessary to maintain coolant temperature within

the limits of 80–95° C. At the ambient air temperature of 5° C and below in

stall cold weather radiator cover.

3. Do not operate the starter continuously for more than 15 seconds. For

the second attempt of engine starting, allow not less than 30 seconds. Not more

than three engine starting attempts are permissible. Should the engine fail to

fire after these attempts, check the starter power circuits, the starter itself, the

engine fuel system and the storage battery for good condition.

Never move the vehicle using the starter and turn on the starter with the

running engine.

4. After cold engine starting do not run it at high speed. Warm the engine

up at 10001400 rpm. Never drive the vehicle with cold engine. Coolant tem

perature before starting movement should be not less than 40° C.

X96

Д-245.7Е2

33104050140794

7500 кг

-кг

2400 кг

1-

2-

540 кг0

a

b

c

d

e

f

LLC AUTOMOBILE PLANT GAZ““”

ENGINE

6

5. If the engine has been operated at heavy duty cycle let it run for 3 min

utes at idle speed before stopping to decrease smoothly the temperature of tur

bocharger to avoid its premature damage.

6. To prevent damaging of the gearbox when towing the vehicle, discon

nect the propeller shaft flange from the axle drive. Then fix reliably the dis

connected end of the propeller shaft via a wooden block to the vehicle nearest

frame element.

7. Do not eliminate free axial displacement of steering arm pin ball head as

to drag link because the travel equal to 3,4 mm with the shutdown engine is

required for power steering drive proper operation.

8. To avoid dislocating of relative position of the steering gear and steer

ing wheels, never set out the adjustment of the drag link length (except for the

cases specified in given Operating Instructions).

9. To avoid overheating of power steering drive system, do not run the en

gine for a long time at high speed (more than 30 minutes) when the vehicle is

at parking place.

10. With operating engine do not keep the steering wheel turned as far as

it will go for more than 15 sec. because it may cause damage of the power steer

ing pump. Never start the engine with power steering tank empty or insuffi

cient oil level.

11. When the ambient air temperature is below 35° C fill the power steer

ing system with special liquid (see subsection "Lubrication Chart").

12. Watch out for tightness of air pipelines, cylinders and pneumatic valves.

Break of air tightness reduces braking efficiency.

13. To avoid storage batteries failure, timely switch over regulated volt

age level.

14. If any of the red pilot lamps lights up on the instrument cluster or buzzer

operates on the run, stop the vehicle, detect and eliminate the trouble.

15. The brake pads are to be replaced at service stations only.

3. SAFETY PRECAUTION RULES

Strictly follow the safety precaution rules during vehicle operation.

Never warm up the engine in the enclosed space. The engine exhaust gases

contain toxic end product of fuel combustion, monoxide carbon including (gas

without fume and color), which, when inhaling, causes severe intoxication and

it may even lead to fatal case. It is also not recommended to turn on the pas

senger compartment ventilation at parking place with the operating engine.

7

4. SPECIFICATIONS

4.1. GENERAL DATA

Vehicle model GAZ33104 GAZ331041 GAZ331043

Vehicle type Biaxial, cargo, with rear axle drive

Vehicle capacity, kg:

— with cargo body without canvas top 3605 3445 3150

— with cargo body and with canvas top 3500 3330 3045

Vehicle gross mass, kg 7400 7400 7400

Vehicle kerb mass, kg:

— with cargo body without canvas top 3500 3730 3800

— with cargo body and with canvas top 3605 3845 3905

Overall dimensions, mm

— length 6050 7565 6770

— width (over mirrors) 2643 2643 2643

— height (over cabin, unladen) 2260 2260 2265

— height (over canvas top, unladen) 3060 3060 3060

Wheelbase, mm 3310 4000 4000

Front wheels track, mm 1740 1740 1740

Rear wheels track (between centres of twin tyres),

mm 1701 1701 1701

Ground clearance, fully laden, mm 177 177 177

Minimum turning radius (front outer track), not

more, m 6,4 7,7 7,7

Maximum speed with full load without trailer on

flat, smooth highway, km/h 95 95 95

Fuel consumption1) when running with constant

speed, l/100km:

— 60 km/h 13,5 13,5 13,5

— 80 km/h 18,0 18,0 18,0

Overhang angles (fully laden), deg.:

— front 27 27 27

— rear 14 10 14

Maximum climable gradient for fully laden vehicle,

% (degree) 25 (14) 25 (14) 25 (14)

Cargo body loading height, mm 1070 1070 1070

4.2. ENGINE AND ITS SYSTEMS

Model D245.7 E2

Type Diesel, 4stroke, with turbocharger, with

supercharged air cooling, liquid cooling

Number of cylinders and their arrangement 4, vertical inline

Cylinders firing order 1—3—4—2

Direction of crankshaft rotation right

1) The fuel consumption specified is not considered to be a rate but serve only for determining

of vehicle technical state.

8

Cylinder bore and piston stroke, mm 110x125

Displacement, l 4.75

Compression ratio 17

Rated power, net, kW (h.p.), not less:

at 2400 min1 engine speed 86.7 (117.2)

Maximum torque, net, N•m (kgf•m):

at 13001600 min1 engine speed 413 (42.1)

Minimum engine idle speed, min1 800

Maximum idle speed limited by governor, min1,

not more 2600

Ventilation system open

Fuel injection pump Inline, 4plunger, valve type, 7732005

(ЯЗТА) with full range rpm governor and

booster fuel pump

Booster fuel pump Plunger type, for manual and automatic

fuel priming

Injectors ЯЗДА 455.111201050, closed type;

injection point pressure 23,5+1.2MPa

(230 kgf/cm2)

Fuel filters:

— coarse filter Gravitation filter with gauze element

— fine filter With paper renewable filter element

Oil system Combined: under pressure and spraying

Oil cooler Fullflow, constantly operating

Oil filter Fullflow, with renewable filter element

Cooling system Liquid, closed, with forced coolant circula

tion, with expansion tank

Supercharging system Gas turbine, with one turbocharger C14

with radial centripetal turbine, centrifugal

compressor and air cooler of supercharging

air of secondary surface type

4.3. TRANSMISSION

Clutch Singleplate, dry, friction type, with torque

vibration damper on driven plate. With di

aphragm pressure spring. With hydraulic

drive

Gearbox Mechanical, 5speed, with constant gear

mesh, with synchromesh unit on II and III,

IV and V gears

transmission ratios:

— 1st gear 6.555

— 2nd gear 3.933

— 3d gear 2.376

— 4th gear 1.442

— 5th gear 1.000

— reverse gear 5.735

Cardan drive Two open type divided propeller shafts,

three universal joints on needle bearings

9

Final drive Bevel, hypoid type

— transmission ratio 3.417

Differential Bevel, geartype

Axle shafts Full floating

4.4. RUNNING GEAR

Frame Stamped, riveted

Wheels Disk type, with 6,00x17,5 rim

Tires Pneumatic, radial, size 215/75R17,5

Front wheel geometry:

— camber Max. 1°

— pivot transverse inclination 8°

— lengthwise inclination of king pin 5°

— toein (of every wheel to vehicle longitudinal

axis) 7"±3"

Springs Four, longitudinal, semielliptic with ad

ditional springs in rear suspension

Shock absorbers Hydraulic, telescopic, dual acting. Mount

ed on the front axle

4.5. STEERING SYSTEM

Type of steering gear Screwball nut

— transmission ratio 19.8 (in the middle position)

Power steering Hydraulic, integrated, built in steering gear.

Power steering pump is a geartype. НШ14

Steering column Height and tilt adjustable

4.6. BRAKE SYSTEM

Service brake system Doublecircuit, with pneumatic drive

Brake gears Disk type

Emergency brake system Each circuit of service brake system

Parking brake system With pneumatic drive of brake chambers

with spring energy accumulators installed

on rear wheel disk brakes

4.7. ELECTRICAL EQUIPMENT

Wiring system Single wire. Negative terminals are connect

ed to vehicle frame

Rated voltage, V 12

Alternator A/C, with builtin voltage regulator and

rectifier block, 1631.370110

Storage battery Two (6CT 110A)

Starter AZS 3385"Искра"

Headlamps 62.371119

10

Turn indicator repeaters 5302.3726000 or 112.03.30.00.00001

Front marker lights 265.3712

Rear lights 7442.3716.00011 or 8502.371601

Side marker light 4472.3731

Headlamp aiming device control unit БУК24 or 281.3769 or 231.3769

Engine control switch 2126370401050 or 2108370401080

Windshield wiper 60.5205 or 70.5205

Windshield washer 1202.5208, 1102.5208

Horns 22.3721/221.3721

4.8. CABIN AND CARGO BODY

Cabin Metal, three— or sixseat

Cargo body Metal, with rear flap and body sides

Cargo body dimensions (inner), mm: GAZ33104 GAZ331041 GAZ331043

— length 3494 5000 3494

— width 2176 2176 2176

— body side height 518 518 518

4.9. MAIN ADJUSTMENT AND CHECKING DATA

Clearance between valve stems and rocking levers

on cold engine, mm

— intake 0,25

— exhaust 0,45

Oil pressure (at oil temperature of 80–85° C), kPa

(kgf/cm2):

— at rated engine speed 2400 min1 250–350 (2.5–3.5)

— at minimum idle speed 80 (0.8)

Rated engine coolant temperature, °C 80–95

Minimum engine idle speed, min1 800

Variable voltage, V 13.3–14.9

Fan and alternator belts sag under 4 daN (4 kgf), mm 12–17

Clutch pedal free travel, mm 10–30

Clutch pedal full travel, mm 190

Brake pedal free travel, mm 9–16

Total play of steering wheel in the position corres

ponding to vehicle straightforward run with run

ning engine, deg., not more 101); 25

Tire air pressure, kPa (kgf/cm2)

— front wheels 530+10 (5.4+0.1)

— rear wheels 620+10 (6.3+0.1)

1) For the vehicle within warranty period.

+0,05

–0,10

+0,05

–0,10

11

5. CONTROLS AND INSTRUMENTS

Fig. 5.1. Controls

12

Positions of controls are given in fig. 5.1.

1 — headlamp aiming device control knob depending on vehicle loading

(see subsection 8.5).

2 — plugs.

3 — warning lamps condition checkup switch.

4 — side ventilation grids.

5 — turn indicators, dimmer and horn1) switch lever. The switch lever

has six fixed positions (from I to VI) and four nonfixed positions "A" (fig. 5.2

and 5.3).

If the lever is in position I, and master light switch knob 22 — in position

II, the lower beam is on. When the lever is moved to position II upper beam is

switched on and blue indicator lights up.

Pulling the lever repeatedly from position I along the steering column (non

fixed position) switches on headlamp upper beam for a short time. Depressing

the switch lever button (in any position of the lever) turns on the horn1) (non

fixed position) — see fig. 5.2.

1) On some of the vehicles the horn is switched on by means of windshield wiper and washer

control lever (see Fig. 5.6).

Fig. 5.3. Turn indicator and dimmer

switch lever (without horn)

Fig. 5.2. Turn indicator and dimmer

switch lever (with horn)

To operate turn indicators move the lever from positions I or II up to posi

tions VI or IV (right turn) or down to positions V or III (left turn). A green

warning light comes on flashing on the instrument cluster.

After the turn is completed the switch lever is automatically returned to

position I or II. To switch on turn indicators momentarily shift the switch le

ver to suitable "A" nonfixed position. When released the lever returns to po

sition I or II.

6 — engine control, starter and antitheft device switch.The key posi

tions are given in fig. 5.4:

13

0 — all Off, the key cannot be pulled out, antitheft device is not engaged;

I — engine control switch is On; the key cannot be pulled out;

II — engine control switch and starter are On; the key cannot be pulled out;

III — engine control switch is Off; when the key is withdrawn, the anti

theft device is engaged.

To release the antitheft device fit the key, then gently swinging the steer

ing wheel to both sides turn the key to position 0.

Fig. 5.4. Engine control, starter and antitheft

device switch.

7 — windshield wiper, washer and horn 1) switch lever.

The positions of the lever (fig. 5.5 and 5.6):

0 — windshield wiper is OFF;

I — low speed of windshield wiper;

II — high speed of windshield wiper;

III — intermittent operation of windshield wiper.

In case the control lever is not equipped with horn switch (fig. 5.5), to

turn on windshield wiper and washer momentarily pull the lever (in the direc

tion of the arrow) from position 0.

Fig. 5.6. Windshield wiper and

washer lever positions (with horn)

Fig. 5.5. Windshield wiper and

washer lever positions (without horn)

1) On some of the vehicles the horn is turned on by turn indicators and dimmer switch lever

(see Fig. 5.2).

14

In case the control lever is equipped with horn switch (fig. 5.6), to turn on

windshield wiper and washer momentarily push the lever from position 0 in

the direction of arrow "A" and to turn on the horn pull the lever (from any

position) in the direction of arrow "B".

Windshield washer can be also switched on from all lever positions. Wind

shield wiper operates only when the engine control switch is on.

8 — emergency flasher warning system button switch. When in switched

on position all turn indicator bulbs and red bulb inside the button switch

(fig. 5.7) are flashing simultaneously.

Emergency flasher warning system should be switched on in case of vehi

cle accidental stop in order to inform other drivers and maintenance services

about stationary vehicle on the roadway.

Fig. 5.7. Emergency flasher warning system button

switch.

9 — rear row seats dome lamp switch of the cab (for vehicles with two

rows of seats).

10 — central ventilation grids.

11 — heating and ventilation control panel.

12 — lock button for documents box cover.

13 — documents compartment cover.

14 — space for radio set/cassette player.

15 — plug.

16 — glove box lock handle.

17 — ashtray. Removal of ashtray is shown in fig. 5.8.

Fig. 5.8. Ashtray

15

To empty the ashtray pull it, push spring catcher upwards and remove the

ashtray from its slot. Fit the ashtray back liftingup the spring catcher.

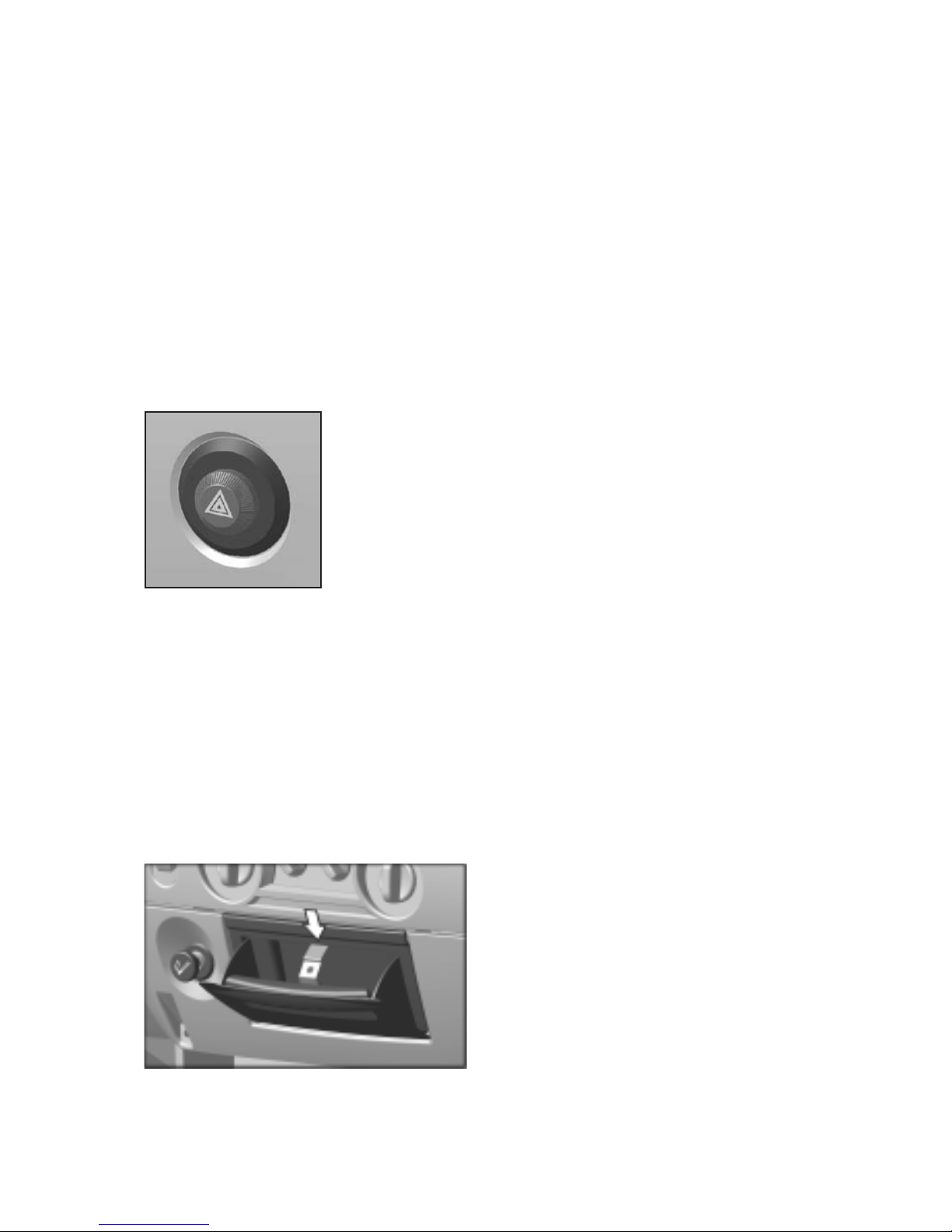

18 — gearbox lever.

Engage reverse gear only after full stop of the vehicle. When reverse gear

is engaged the backing light goes on in the tail lamps.

Fig.5.9. Changeover layout:

19 — cigarette lighter. To use the lighter, push its handle and release it.

The lighter kickout with a click means that the coil is hot. Do not reuse the

lighter sooner that in 30 s.

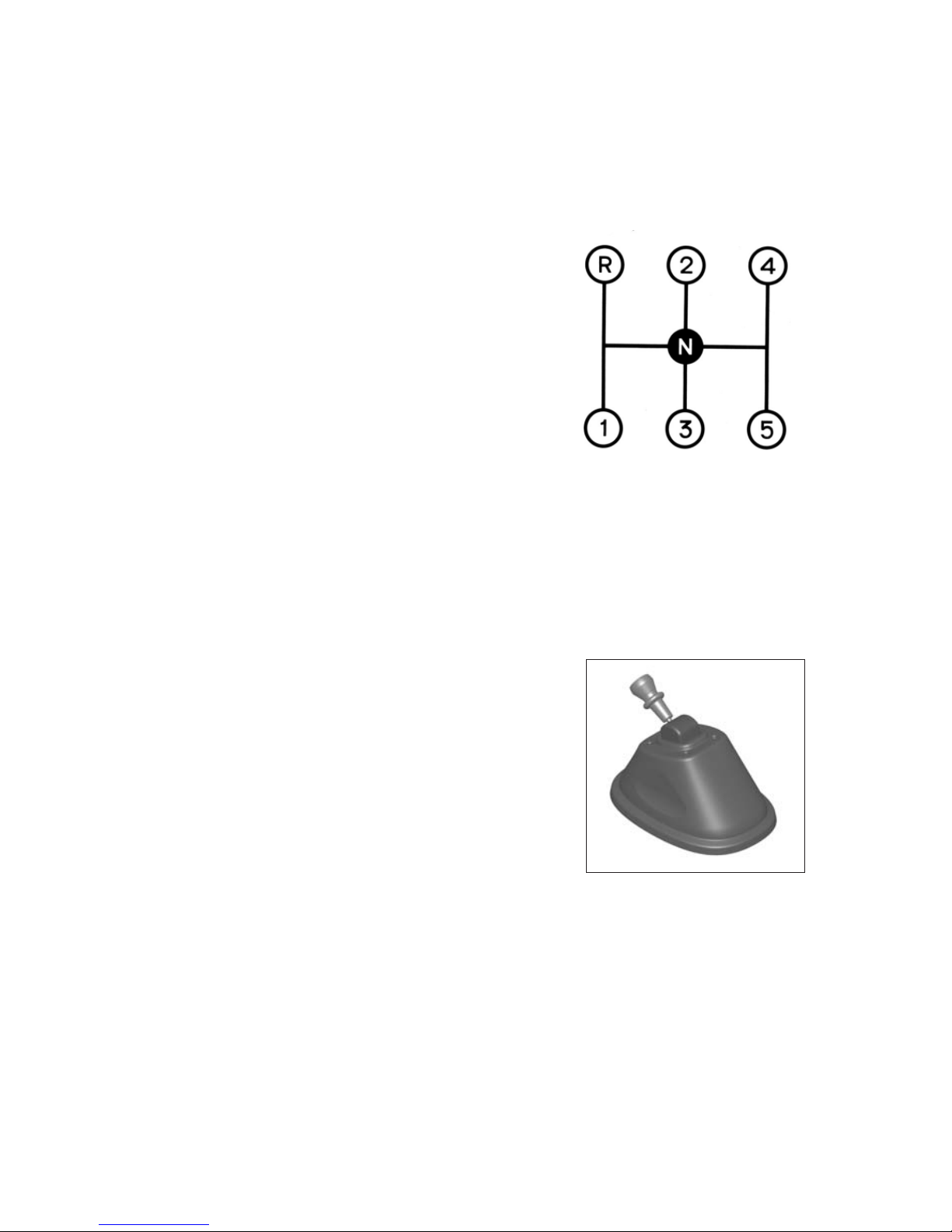

20 — parking brake lever. For braking the vehicle pull the brake control

lever up. If the engine control switch is on warning lamp 9(fig. 5.14) is flash

ing on the instrument cluster. For releasing the brake pull up the control lever

lock coupling. With the brake released the warning lamp goes out.

Fig. 5.10. Parking brake lever

21 — instrument lighting control knob.

22 — master light switch. The switch has five fixed positions (fig. 5.11):

0 — all external lighting is OFF.

I — clearance lights, instrument cluster lighting, rear license plate lamp

and some electrical equipment controls lighting is ON.

II — additionally upper or lower beam is ON depending on the position of

turn indicators and dimmer switch lever (position I or II correspondingly).

16

III — additionally (from position I or II) front fog lamps1) are ON.

IV — additionally (from position III) rear fog light is ON.

1) Mounted on some of the vehicles

Fig. 5.11. Positions of master light switch

handle.

0I

II

III

IV

23 — ABS diagnostics button.

24 — accelerator pedal.

25 — brakes rear circuit pressure gauge.

26 — steering column adjustment control lever (fig. 5.12). Pulling the

lever and moving it upwards (within the limits of 90°) results in releasing of

the steering column. After that the steering wheel can be set in the handy po

sition for a driver and locked in this position by setting the lever to the initial

position.

Fig. 5.12. Steering column adjustment

control lever.

27 — service brake pedal.

28 — storage battery remote button switch.

29 — clutch pedal.

30 — brakes front circuit pressure gauge.

31 — fuse blocks.

32 — hood release lever. To open the hood pull lock handle to release the

catch of the lock and open the hood slightly, then push the handle back home.

17

To open the hood completely, move aside the latch mounted on the lower

front edge of the hood (fig. 5.13).

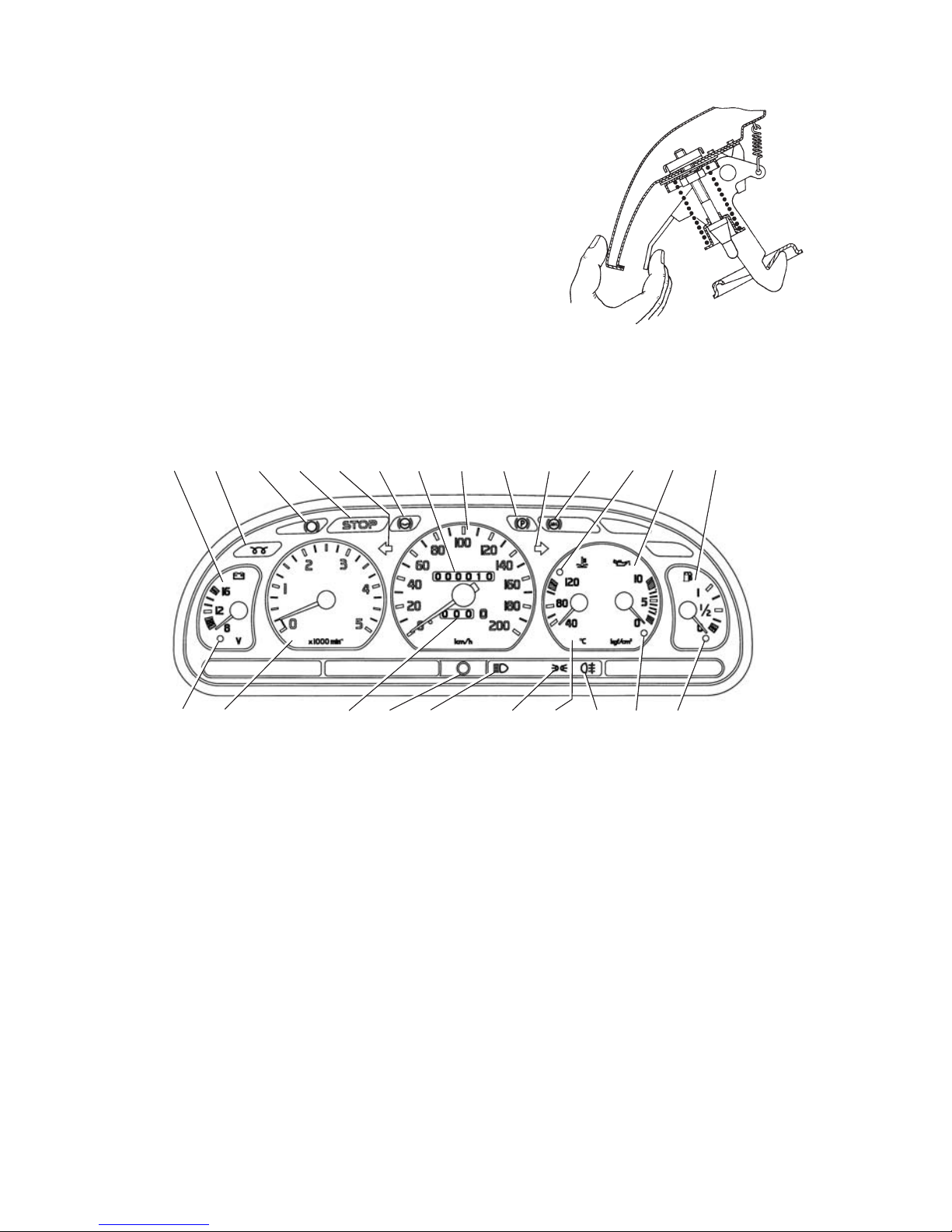

Arrangement of instruments is shown in Fig. 5.14.

Fig. 5.13. Releasing of hood latch.

Fig. 5.14. Instrument cluster.

1234567891011121314

15161718202122 192324

1. Voltmeter.

2. Warning lamp (orange) of glow plugs cuttingin.

3. Warning lamp of brake linings wear.

4. Warning lamp (red) "STOP".

5. Warning lamp (green) of left turn indicators.

6. Reserve warning lamp.

7. Total distance counter.

8. Speedometer.

9. Warning lamp (red) of parking brake engagement.

Starts flashing after turning on the engine control switch, when the park

ing brake is engaged.

18

10. Warning lamp (green) of right turn indicators.

11. Warning lamp (red) of antilock brake system (ABS) malfunction.

12. Warning lamp (red) of engine overheating.

If the lamp lights up shut down the engine and eliminate the reason of over

heating.

13. Oil pressure gauge.

14. Fuel gauge.

15. Warning lamp (orange) of low fuel level in the tank. It lights up,

when less than 10 liters of fuel remain in the tank.

16. Warning lamp (red) of oil pressure drop. Lights up when the engine

control switch is turned on. Should the lamp light up under normal conditions,

shut down the engine immediately and check oil level in the crankcase.

17. Warning lamp (orange) of rear fog light turning on.

18. Coolant temperature gauge.

19. Warning lamp (green) of clearance light turning on.

20. Warning lamp (blue). Lights up when upper beam is on.

21. Trip distance counter reset button.

22. Trip distance counter.

23. Tachometer.

24. Warning lamp (red) of storage battery discharge.

19

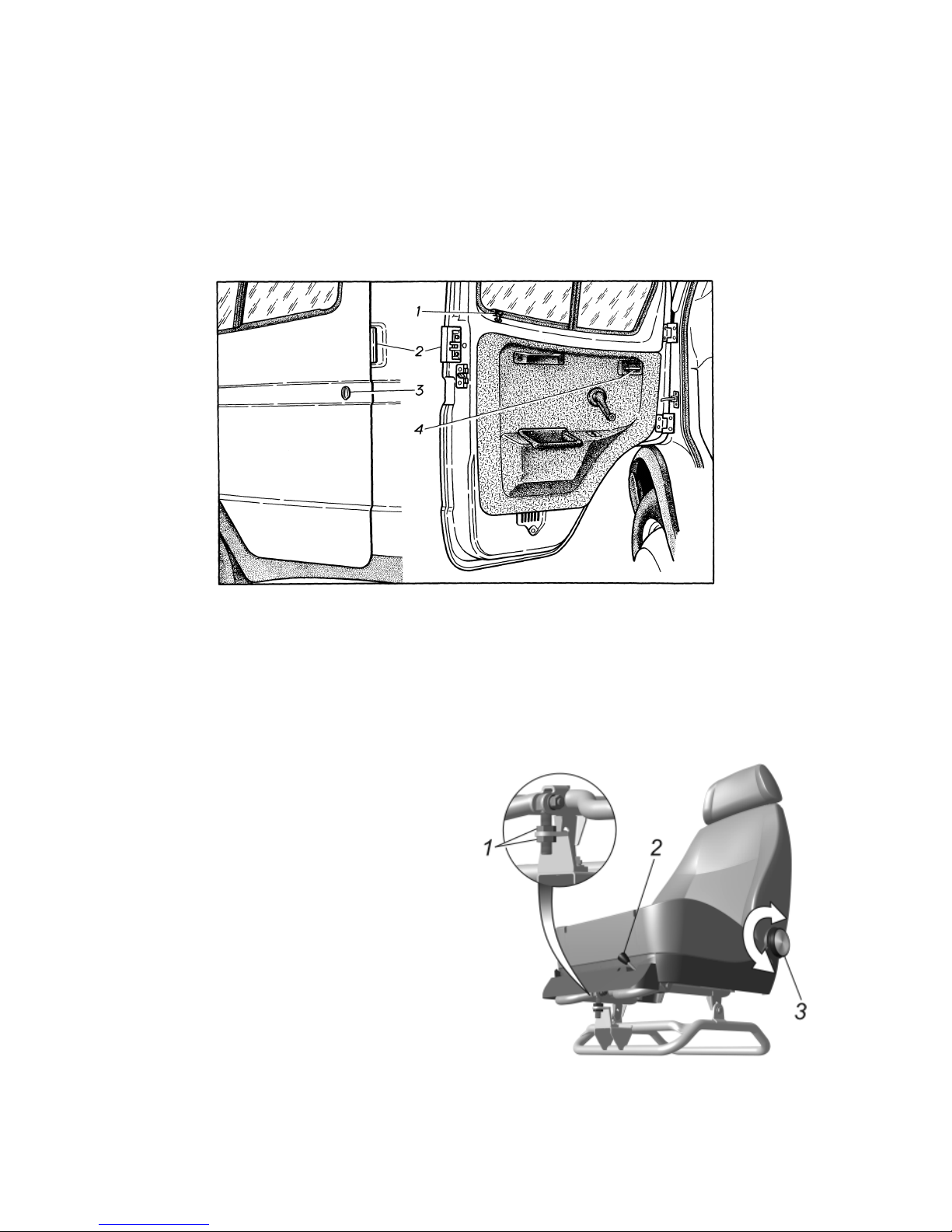

6. Doors, Seats and Seat Belts

Doors. To open the door from outside, pull handle 2(Fig. 6.1). The doors

are equipped with locks that can be locked from outside with key inserted in

lock release 3.

From inside the doors are locked by pushing down button 1.

To open the door from inside pull handle 4with lock button 1pulled up only.

Fig. 6.1. Cab Doors

1 — button; 2 — handle; 3 — lock release; 4 — handle

Never drive the vehicle with opened or partially closed doors.

Seats. For seating convenience the

driver seat is adjustable. By turning

handle 2(Fig. 6.2) the seat can be

moved in lengthwise direction. Re

quired seat backrest tilt is adjusted by

rotation handwheel 3.

For driver's convenience seat tilt is

also adjusted by means of nuts 1.

GAZ331043 vehicle is equipped

with the second row of seats — two

doubleseat passenger seats.

Fig. 6.2. Driver Seat

1 — adjusting nut; 2 — locking handle; 3 —

backrest tilt handwheel.

20

To gain access to the rear passenger seats, the front passenger seat to be

moved in the direction of the driver seat. This seat shifting mechanism is simi

lar to that of the driver's seat. Before driving the vehicle shift the passenger

seat to the extreme right position by all means, otherwise safety belt will be

ineffective.

Seat belts are effective equipment to protect the driver and any passen

gers from severe injury in road accidents.

Vehicles are equipped with two types of seat belts. Inertia reel type with

three anchorage points for driver and passengers of single and outer seats as

well as lap type with two anchorage points for passengers of centre seats. Ad

justment of the inertia reel type belts is not required. As for the lap type belts,

personal adjustment of its length is necessary because intimate mating of web

bing to hips must be ensured. Changing of webbing length is performed by

means of regulator.

To fasten the belt (Fig.6.3) it is necessary to pull the belt webbing slow

ly by the tongue over the shoulder and across the chest and push it into the

buckle nearest the wearer; a click will indicate that the belt is locked.

Upper portion of the belt should pass across the centre of the shoulder so

that it is not resting on your neck or under the arm and must have intimate

mating with the upper part of your body.

Fig. 6.3. Fastening by Seat Belt

Lap portion of the belt should be positioned as low on the hips as possible.

Otherwise release the belt and adjust its length.

To release the belt, press the red panel on the buckle. The belt will auto

matically retract to its stowed position.

Pregnant women should also wear the seat belt. But she should position

the lap portion of the belt low so that it does not come across the abdomen.

This manual suits for next models

2

Table of contents