– 3 –

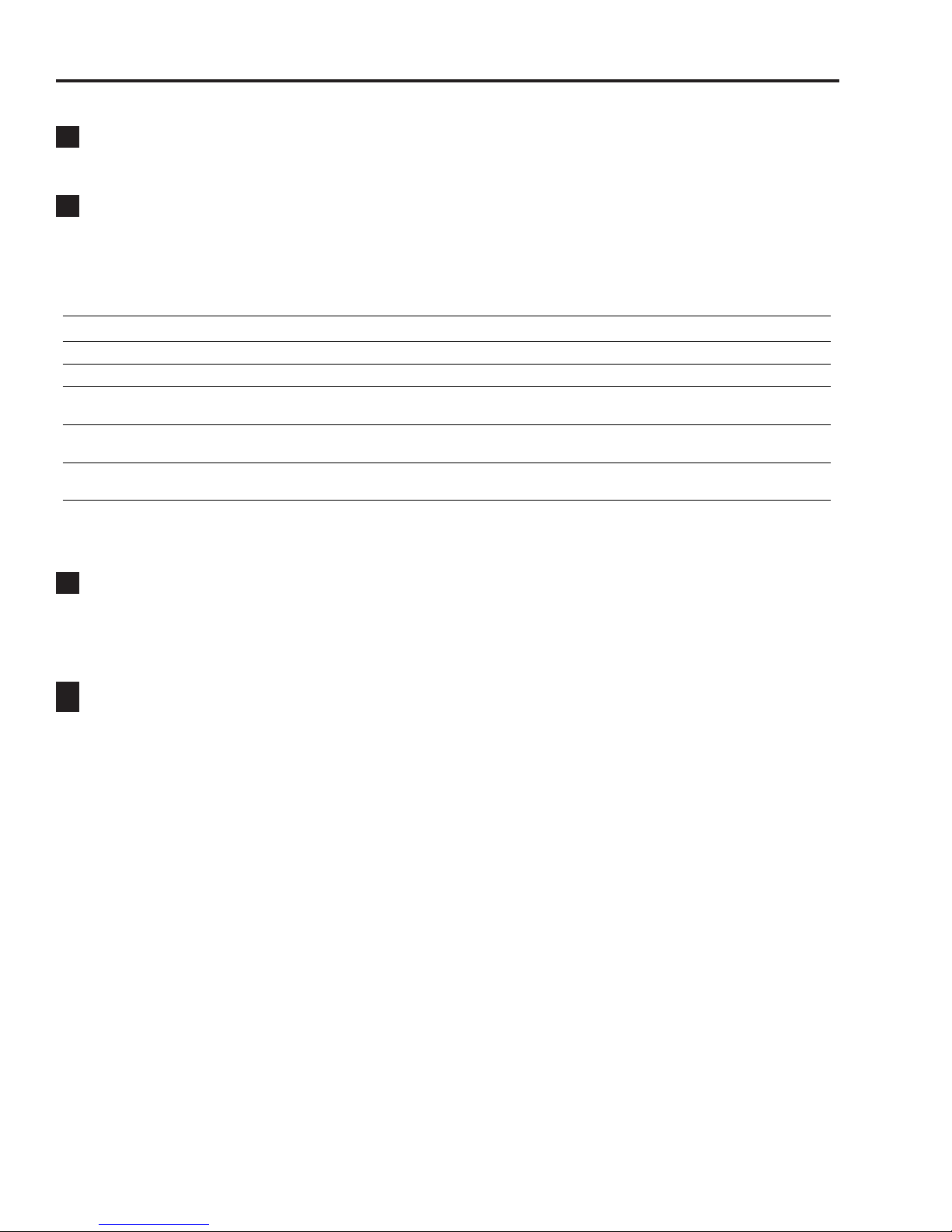

Table of Contents

Back Cover...........................................................................................................................................................................19

Brake Control Motor ........................................................................................................................................................32

Circuit Board Connections............................................................................................................................................17

Component Locator Views...........................................................................................................................................15

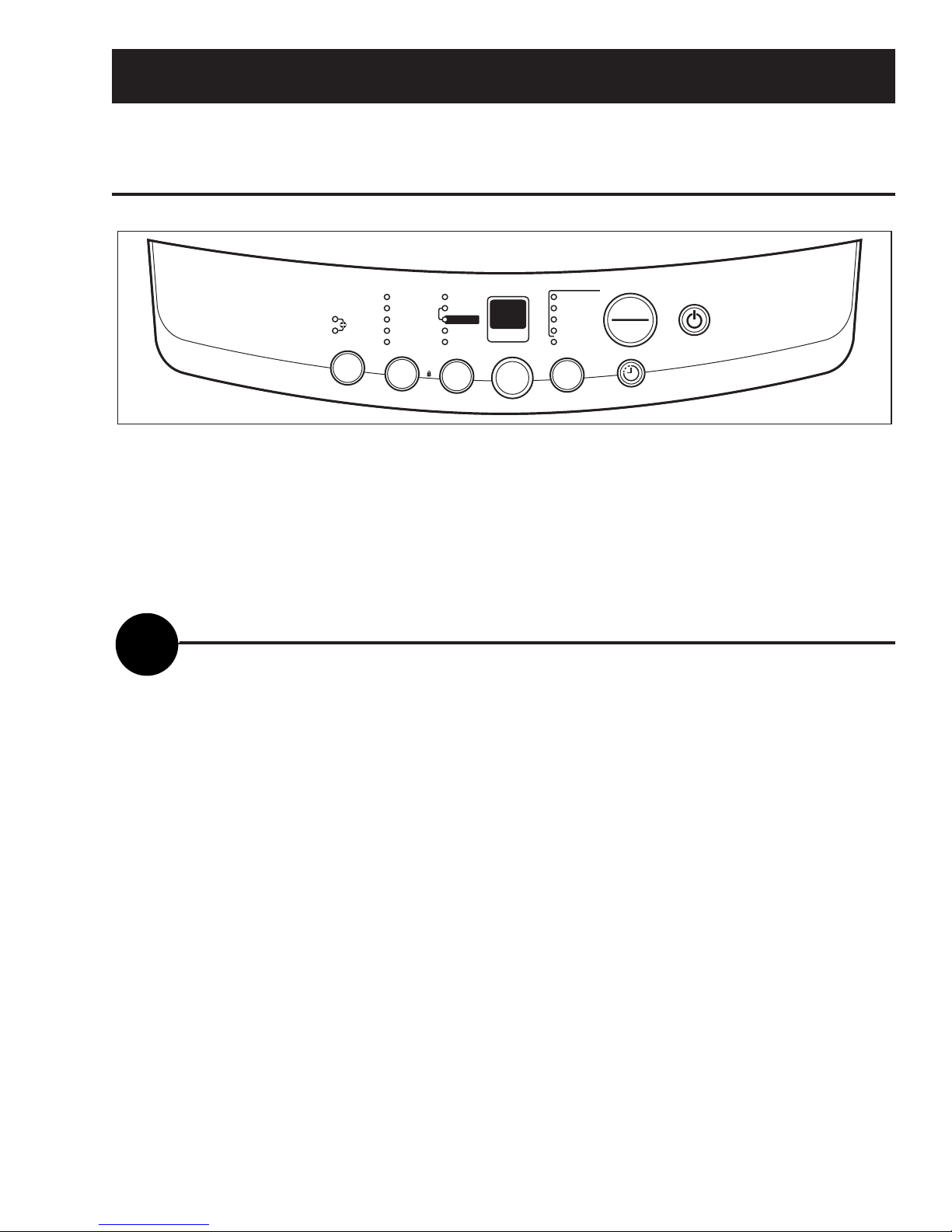

Control Features................................................................................................................................................................ 9

Control Panel and PCB ................................................................................................................................................18

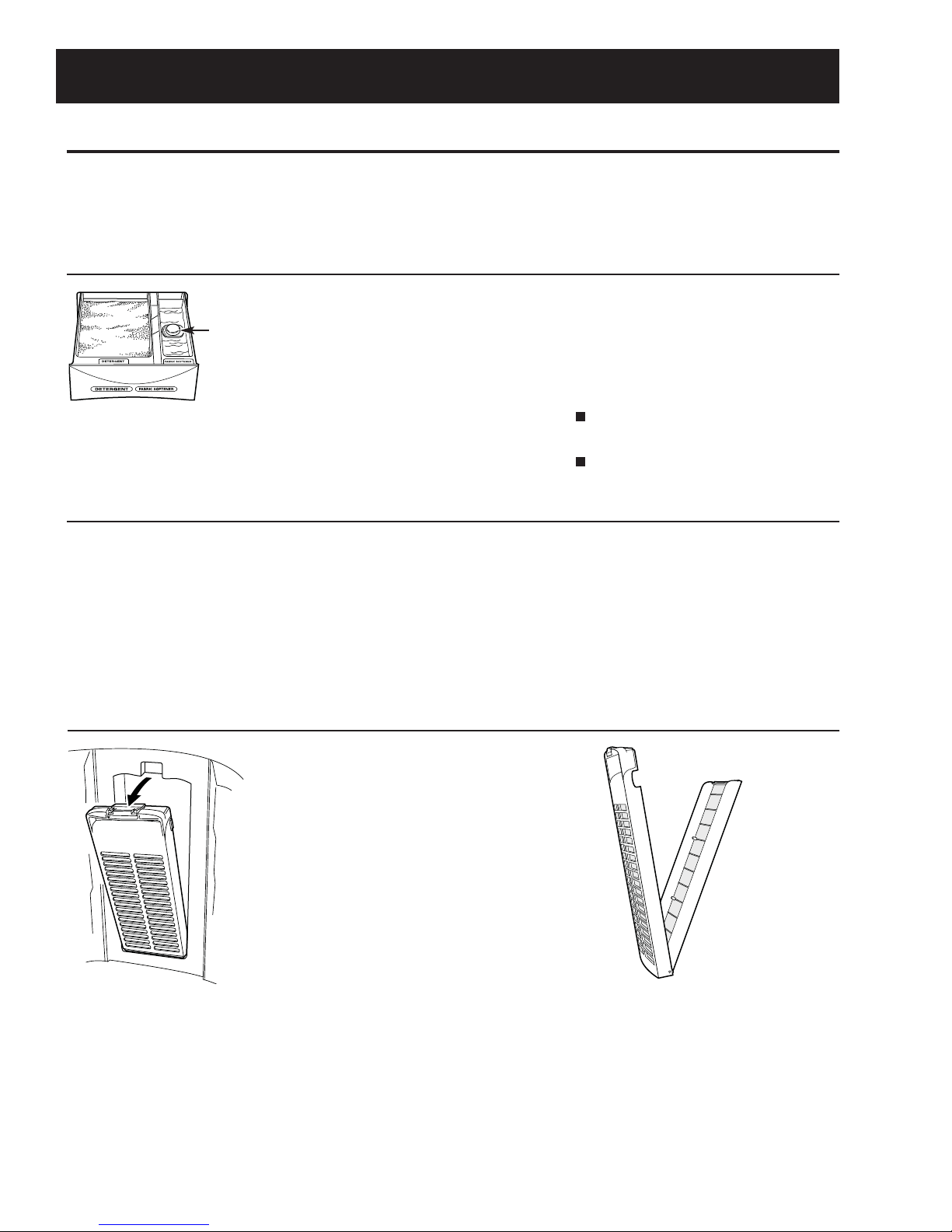

Dispenser Assembly........................................................................................................................................................25

Drain Pump .........................................................................................................................................................................25

Error Codes ..........................................................................................................................................................................34

Fuse.........................................................................................................................................................................................24

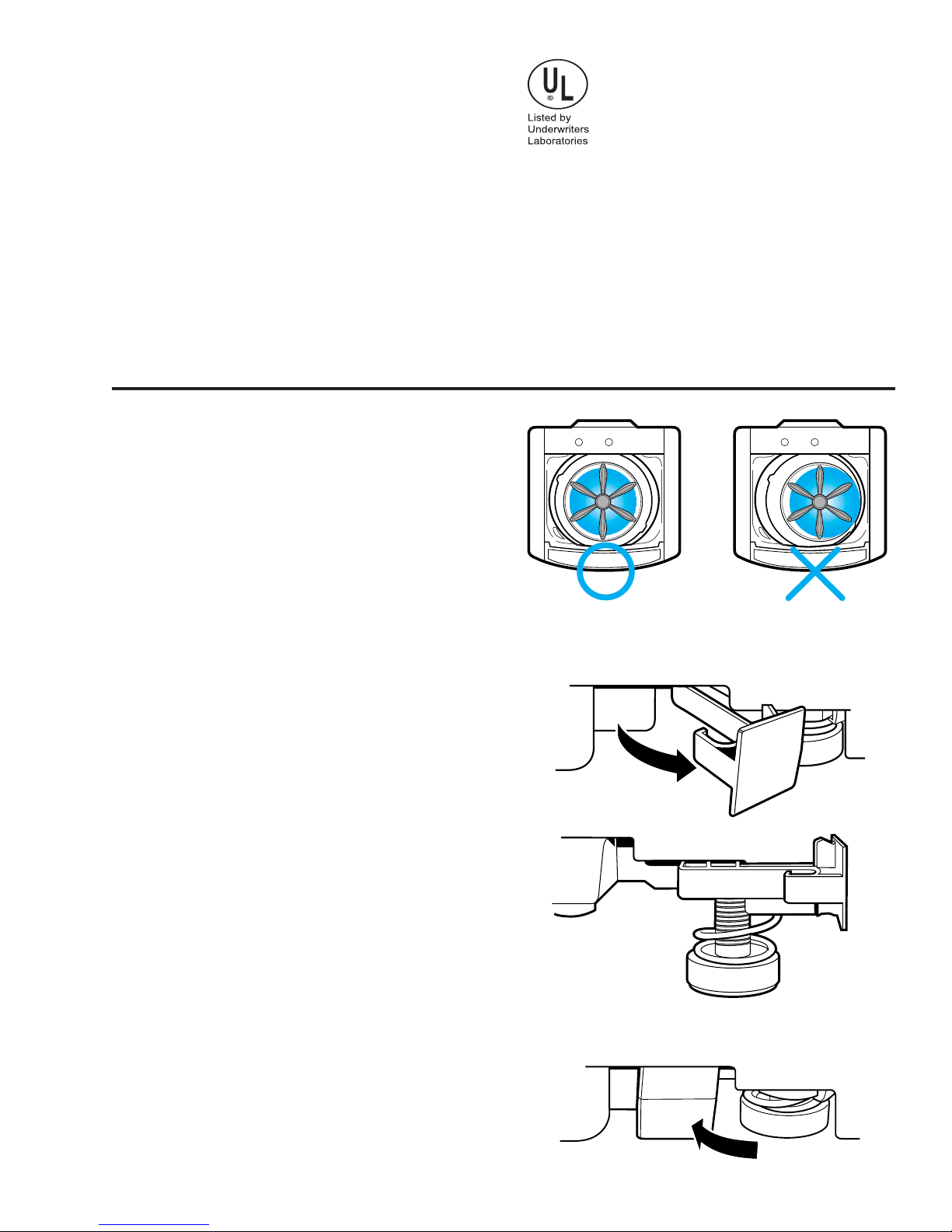

Installation ........................................................................................................................................................................... 6

Introduction......................................................................................................................................................................... 5

Lid Switch and Harness .................................................................................................................................................23

Nomenclature .................................................................................................................................................................... 4

Outer Tub and Suspension Assembly.....................................................................................................................29

Pressure Sensor.................................................................................................................................................................21

Schematic.............................................................................................................................................................................36

Service Test Mode.............................................................................................................................................................35

Shaft Assembly..................................................................................................................................................................33

Shaft Assembly and Brake Overview .....................................................................................................................31

Special Features................................................................................................................................................................ 8

Top Cover..............................................................................................................................................................................24

Troubleshooting ................................................................................................................................................................34

Unbalance Switch.............................................................................................................................................................22

Warranty .............................................................................................................................................................................37

Wash Basket ....................................................................................................................................................................... 28

Washer Components......................................................................................................................................................18

Washing Motor and Belt................................................................................................................................................27

Water Valve.........................................................................................................................................................................20