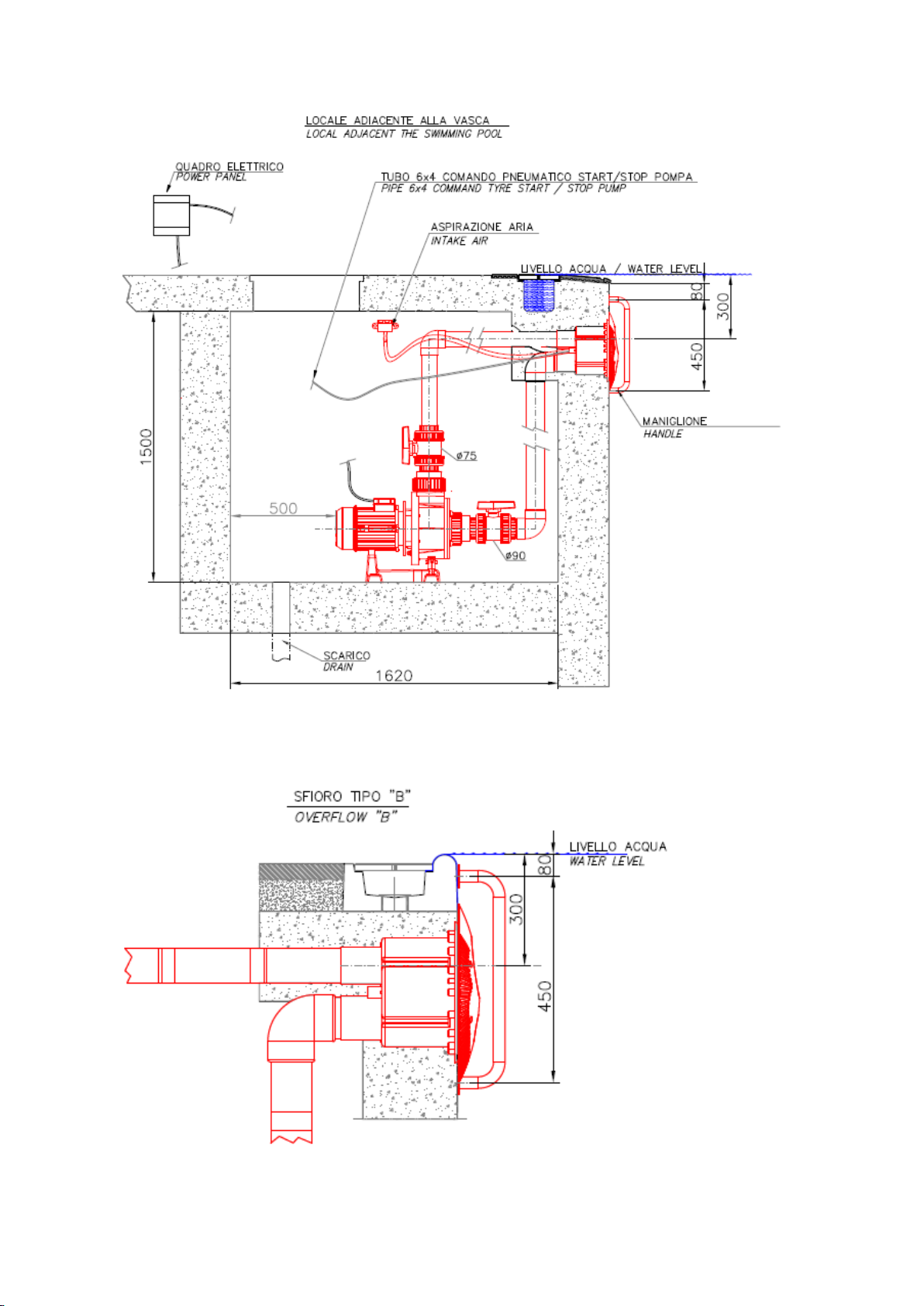

3. INSTALLATION

Normally the PUMPEX swimming pool pumps

are installed between the skimmer/balance

tank and the swimming pool filter.

The pump should be placed on a flat, solid

foundation with the shaft in horizontal

position and the prefilter cover uppermost. It

must be possible to remove the transparent

cover so that the prefilter basket can be

removed for cleaning.

The suction pipe must have as minimum the

same diameter as the pump suction line with

continuous slope in order to avoid long

priming times. If the suction line exceeds 10

meters, the extra pressure loss should be

considered.

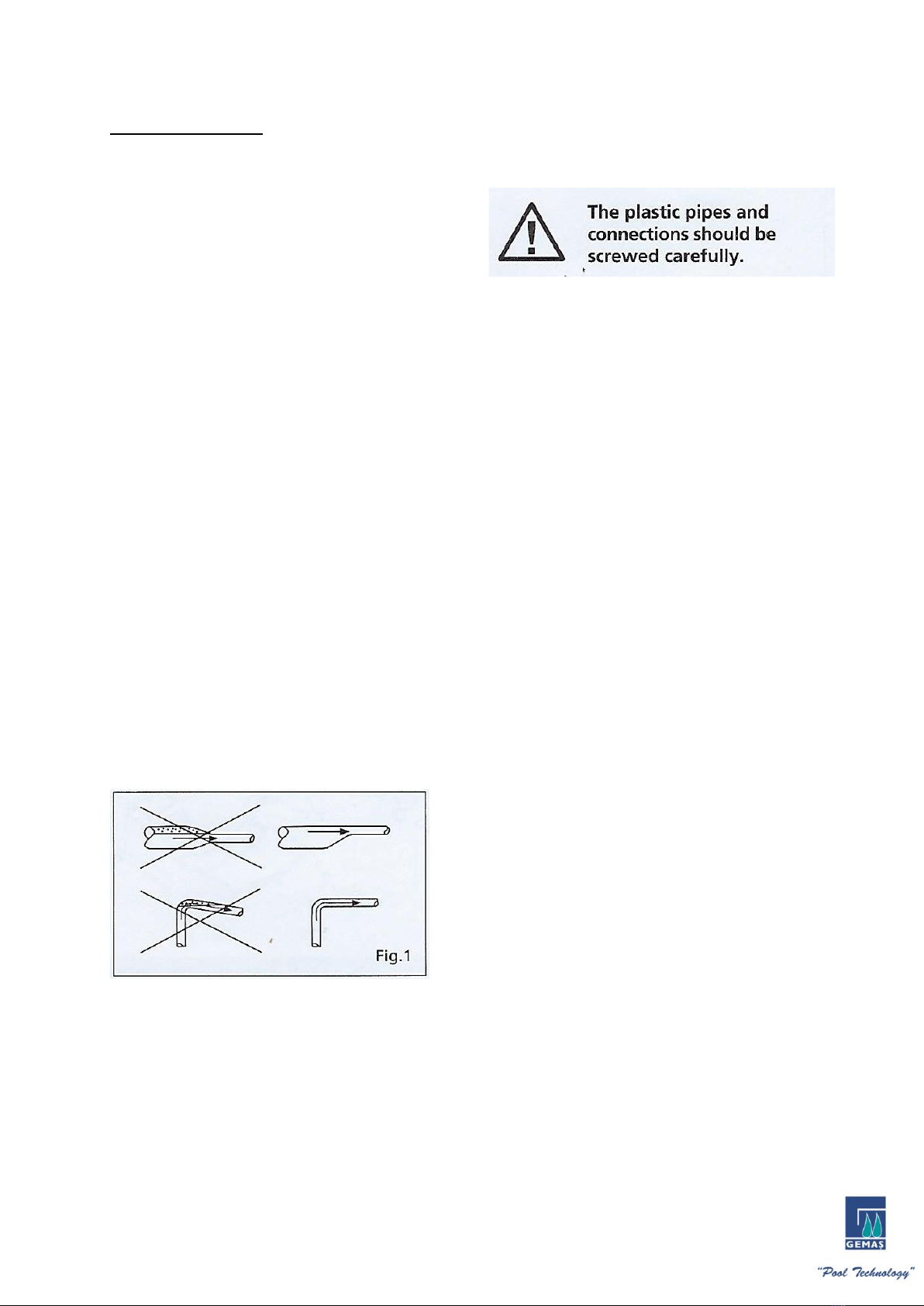

The pipes should be installed to avoid any air

leaksin its interior. The following drawing

shows a correctly fitted piping.

The pipes should be fitted in such a way that

any pressure varioation caused by

temperature changes do not effect the pump.

If the piping is very long and/or high support

the pump in front and behind. It is

reccomendable to put a retention or check

valve at the outlet.

In case of using a suction hose, it must be non-

compressible (with a reinforcement spiral).

The suction pipe/hose should be the shortest

possible in order to assure optimum working

conditions.

It’s recommendable to install shutting valves

the both sides in order to isolate the pump.

Note: The pump does not allow to work with

closed discharge valve as it may cause an

increase of the temperature and steam

formation which can damage the pump.

If there is any possibility of operating the

pump with discharge valve closed, it’s

necessary to connect one bypass/mud valve

on the discharge pipe in order to assure a

minimum liquid flow through the pump.