BLACKMER MECHANICAL SEAL INSTALLATION 960610

Page 1of 2FORM

522

CARTRIDGE MECHANICAL SEAL INSTRUCTIONS

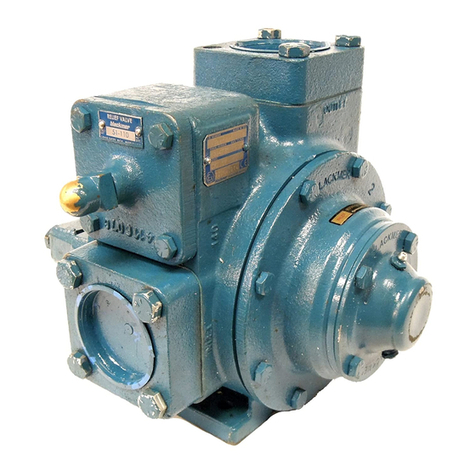

MODELS: GX, X, XH, TX, TXV, TXDI, TX1200, STX2, STX3,

STX1220, TX206, TX400 Effective FEB 2017

Replaces MAR 2003

This is a SAFETY ALERT SYMBOL.

When you see this symbol on the product, or in the

manual, look for one of the following signal words and be

alert to the potential for personal injury, death or major

property damage

Warns of hazards that WILL cause serious personal injury,

death or major property damage.

Warns of hazards that CAN cause serious personal injury,

death or major property damage.

Warns of hazards that CAN cause personal injury

or property damage.

NOTICE:

Indicates special instructions which are very

important and must be followed.

NOTICE:

Blackmer pumps MUST only be installed in systems,

which have been designed by qualified engineering

personnel. The system MUST conform to all

applicable local and national regulations and safety

standards.

These instructions are intended to assist in the

installation of Blackmer cartridge mechanical seals,

and MUST be kept with the pump.

Blackmer pump service shall be performed by

qualified technicians ONLY. Service shall conform to

all applicable local and national regulations and

safety standards.

Thoroughly review the pump manual, all instructions

and hazard warnings, BEFORE performing any work

on the Blackmer pump.

Maintain ALL system and Blackmer pump operation

and hazard warning decals.

DISCONNECTING FLUID OR PRESSURE

CONTAINMENT COMPONENTS DURING

PUMP OPERATION CAN CAUSE

SERIOUS PERSONAL INJURY, DEATH

OR MAJOR PROPERTY DAMAGE

Hazardous pressure

can cause personal

injury or property

damage

FAILURE TO DISCONNECT AND

LOCKOUT ELECTRICAL POWER

BEFORE ATTEMPTING MAINTENANCE

CAN CAUSE SHOCK, BURNS OR

DEATH

Hazardous voltage.

Can shock, burn or

cause death.

FAILURE TO DISCONNECT AND

LOCKOUT ELECTRICAL POWER OR

ENGINE DRIVE BEFORE ATTEMPTING

MAINTENANCE CAN CAUSE SEVERE

PERSONAL INJURY OR DEATH

Hazardous

machinery can

cause serious

ersonal in

ur

.

FAILURE TO RELIEVE SYSTEM

PRESSURE PRIOR TO PERFORMING

PUMP SERVICE OR MAINTENANCE

CAN CAUSE SERIOUS PERSONAL

INJURY OR PROPERTY DAMAGE.

Hazardous pressure

can cause serious

personal injury or

property damage

FAILURE TO SET THE VEHICLE

EMERGENCY BRAKE AND CHOCK

WHEELS BEFORE PERFORMING

SERVICE CAN CAUSE SEVERE

PERSONAL INJURY OR PROPERTY

DAMAGE.

Hazardous pressure

can cause personal

injury or property

damage

IF PUMPING HAZARDOUS OR TOXIC

FLUIDS, SYSTEM MUST BE FLUSHED,

PRIOR TO PERFORMING SERVICE OR

MAINTENANCE

Hazardous or toxic

fluids can cause

serious injury.