2 - UNPACKING

Goods receipt check

On receipt of the goods, check that the material corresponds to that

indicated in the transport documents.

If defects are found, such as:

- marks on the structure or the cover;

- controls broken or not working;

- missing pieces or other;

Inform the transporter and our commercial technical service immediately.

The packaging (plastic bags, polystyrene, cartons, etc...) must never be

disposed of in the environment but sent to an authorized company.

3 - INSTALLATION

The slicer is delivered ready for installation according to the name plate data

(see page 4).

The installation must be made by qualified personnel.

Make sure that the mains supply has the same characteristics as the

machine.

If the machine is wet or very damp, do not install or use. Have a

precautionary check made by the technical service to ensure that the

electrical components have not suffered any damage.

Page 10

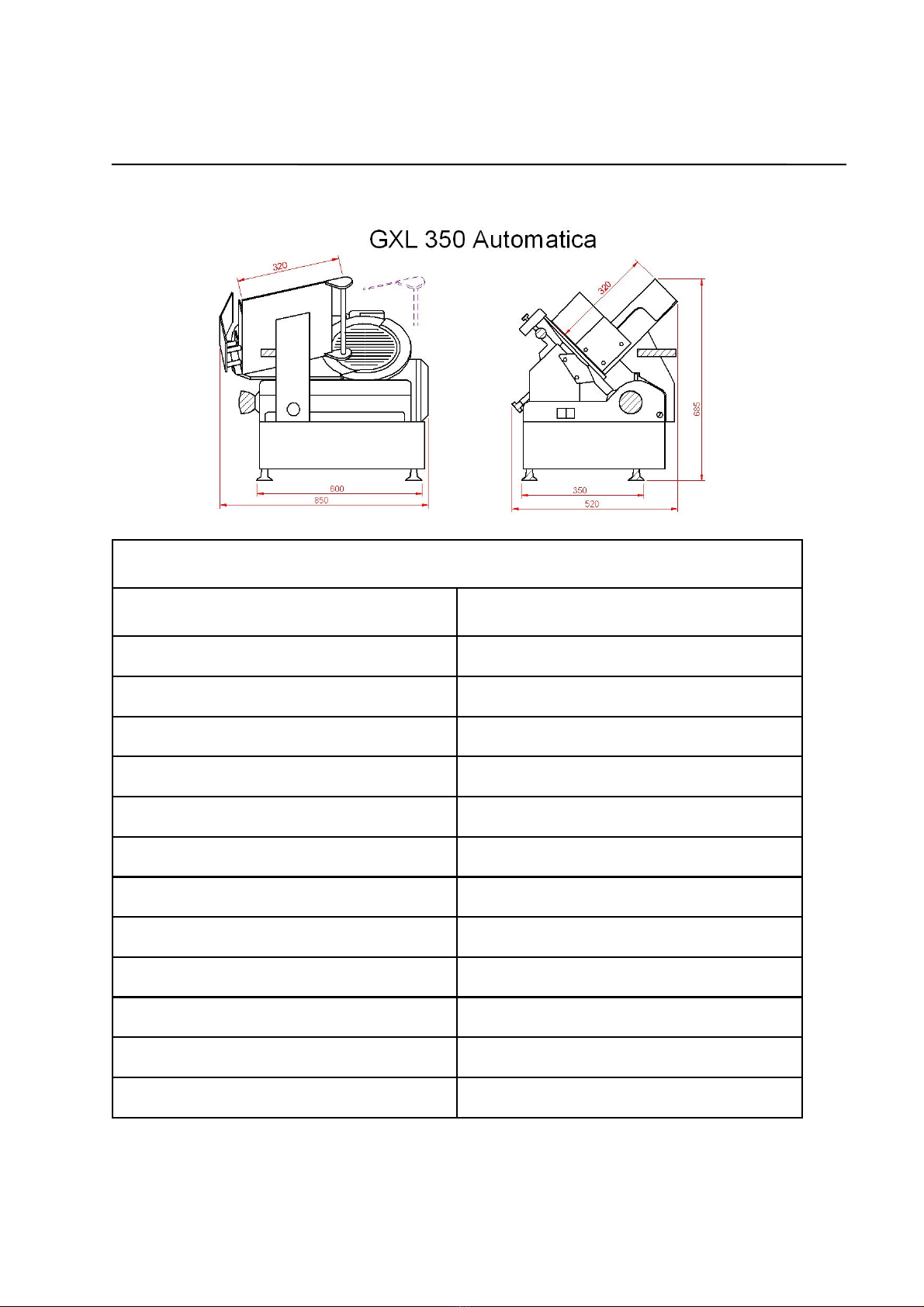

Positioning area

The recommended working height is

about 800 mm from the ground.

The size of the supporting surface

must take account of the machine

size, see the “Overall dimensions”

paragraph. Leave enough space

around the machine to work safely

and allow the operator to load and

unload the food onto the food

carriage, the cutting and collection of

slices free of any close obstacles or

impediments.

On the side of the carriage at the end

of its stroke, a minimum space of 600

mm must be provided in order to avoid

any crash caused by the automatic

movement of the carriage itself.