6

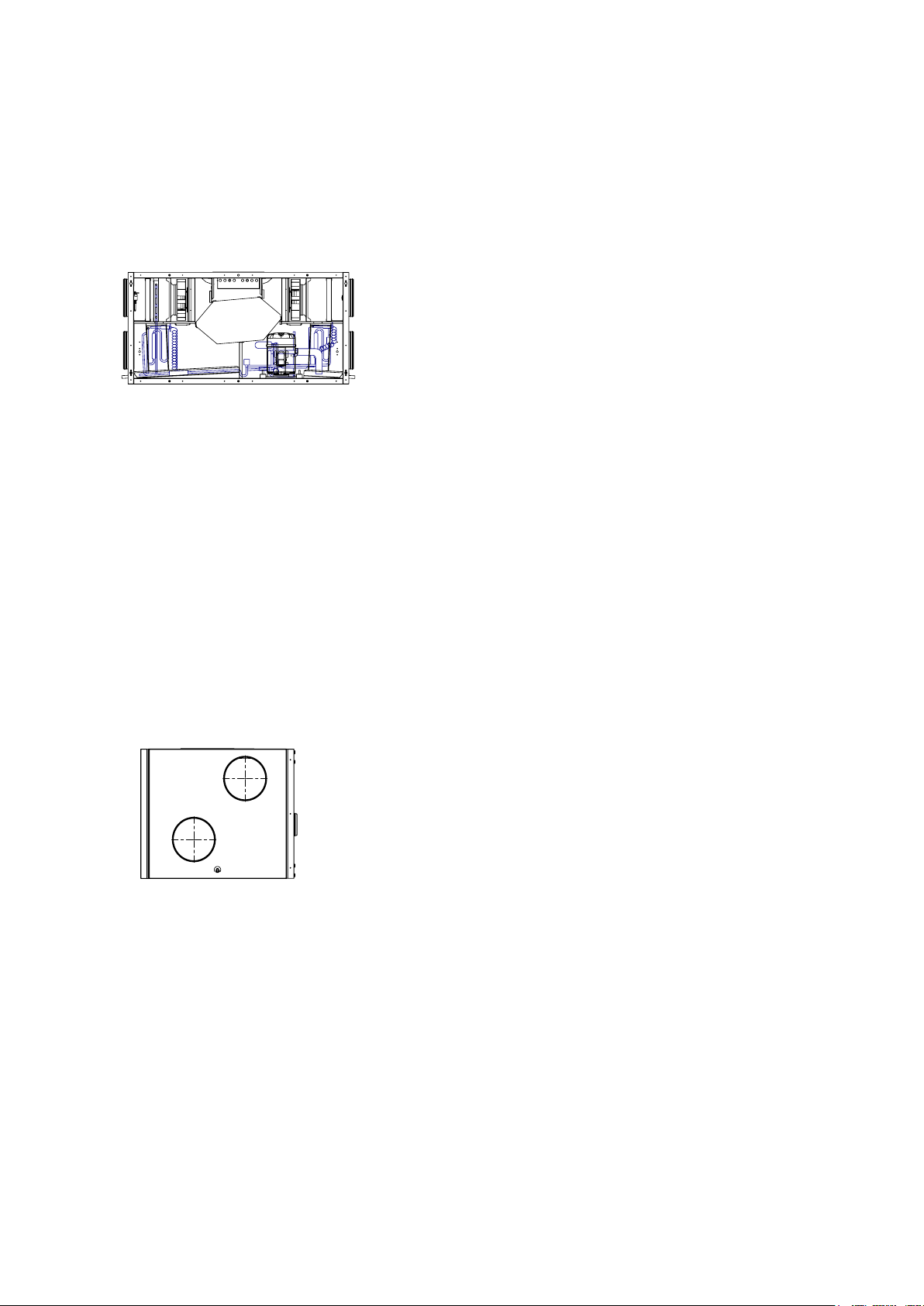

Friskluft

Afkast

Udsugning

Indblæsning

Lufttæt samling

100 mm

Lufttæt samling

No water in the water traps:

- drain clogged

- negative pressure resulting in false air

Condensation drain

The units can give o 5-8 litres of condensation in a day.

Therefore, it is important that the condensation drains

have been carried out correctly.

The condensation drain pipes must be mounted with the

necessary gradient from the condensation connections

on the unit and to the internal drain.

On each condensation drain pipe a water trap must be

tted, because there is negative pressure in the chamber

where the condensation tray is installed.

If the unit is mounted in a cold attic, the condensation

drain pipes must be insulated so that the condensation in

the pipes does not freeze up.

However, it is recommended that the water traps are

installed

in a heated space to ensure that the water in the water

traps does not freeze.

If installation problems make it impossible to secure the

condensate drain pipe from freezing using insulation,

it will be necessary to mount a thermostat-controlled

heating coil around the condensate drain pipes.

In connection with checking and replacing lters, it is

recommended that the water traps are checked and then

lled with water if necessary.

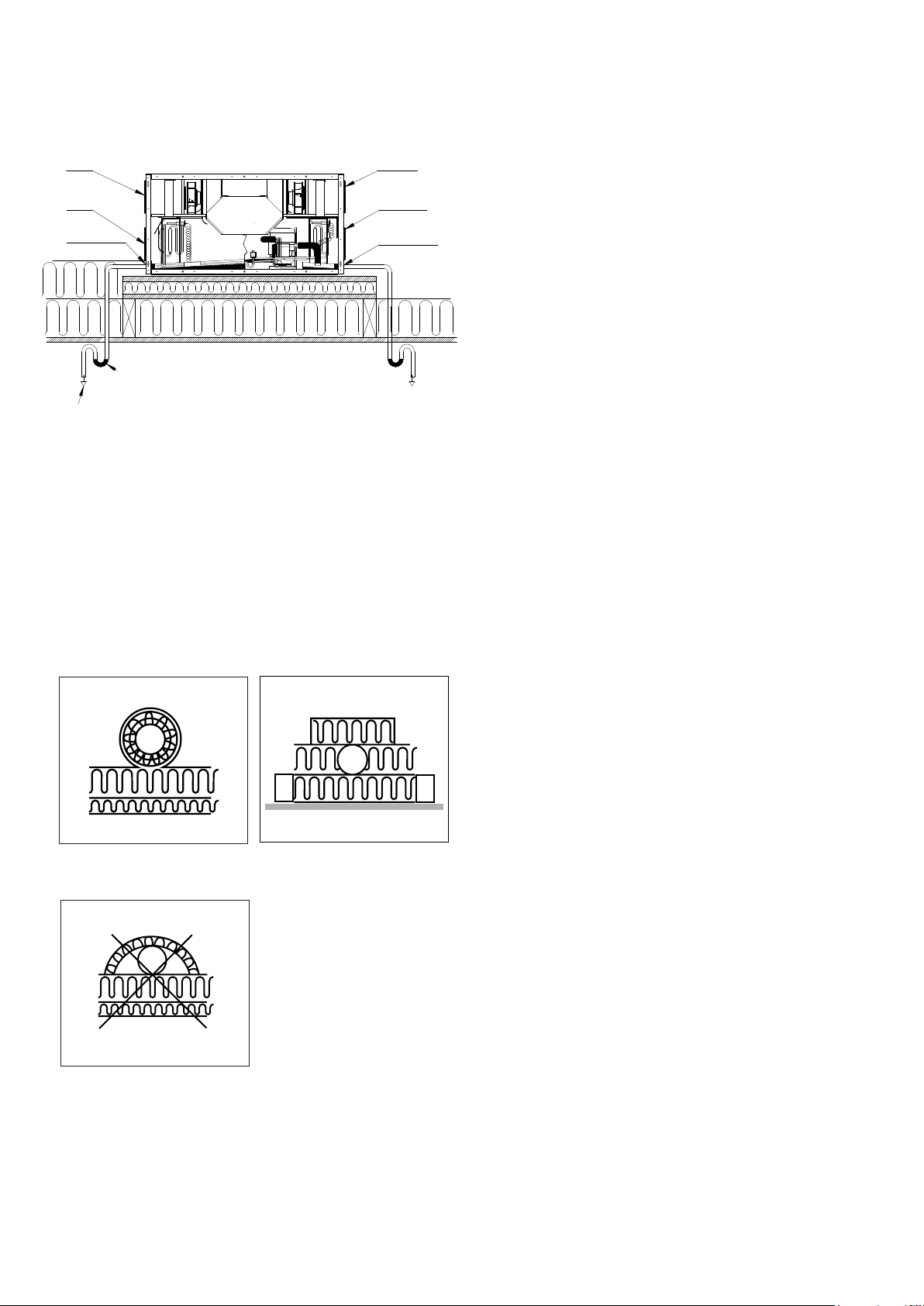

Insulation of ducts in cold attics

In order to benet from the unit‘s high heat recovery rate, it

is necessary that the ducts are insulated properly.

Genvex recommends the following:

Supply air and extract air ducts:

In order to minimise the loss of heat from the duct system

in cold attics, the supply air and extract air ducts must be

insulated with a minimum of 100 mm insulation.

If insulation type A is chosen, it is recommended that

insulating is done with two layers of 50 mm lamella mat

nished o with paper or foil on the outside and that the

joints between the two insulation layers are staggered.

If the ducts are positioned on the rafter foots, then type

B can be used. The insulation must always be tightly

wrapped around the ducts, especially on fresh air and

exhaust air ducts in cold rooms.

Fresh air and exhaust air ducts:

It is recommended that fresh air and escape air ducts are

insulated with a minimum of 50 mm insulation. The fresh air

duct is insulated to prevent warm air in the attic heating up

the fresh air during the summer.

Make sure to seal tightly, especially where the ducts are

led through the roof or out through gables in order to avoid

condensation damage.

Contact your local supplier for instructions about national

guidelines concerning insulation.

Premium Preheat range

Isolering af kanaler, alt. A

Isolering af kanaler, alt. B

Forkert isolering af kanaler