GGM gastro LUNA User manual

LUNA CONVECTION OVEN

INSTALLATION AND USER MANUAL

4I memak.com

LUNA CONVECTION OVEN

INSTALLATION AND USER MANUAL

LUNA

TABLE OF CONTENTS

REAMBLE..................................................................................................... 7

Manual...........................................................................................................................7

Figures ...........................................................................................................................7

Warning Signs................................................................................................................8

Guarantee terms ...........................................................................................................9

Manufacturer Company ............................................................................................. 10

Product Informaon ................................................................................................... 10

Informaon about the Machine................................................................................. 11

Manufacturing Design................................................................................................ 12

Dimensions of Product ............................................................................................... 13

Product Technical Informaon ................................................................................... 13

START-UP OF THE PRODUCT....................................................................... 14

General Rules for Unpacking the Machine ................................................................ 14

Load Structure............................................................................................................ 15

Transportaon of the Product.................................................................................... 15

Forkli Usage.............................................................................................................. 16

Rules Regarding Stocking the Machine:..................................................................... 17

ASSEMBLING THE PRODUCT ...................................................................... 17

Clean Water Treatment.............................................................................................. 19

Fermentaon Cabinet Connecon Water Connecon.............................................. 19

Electrical Connecon Rules........................................................................................ 20

WORKING PRINCIPLE OF THE OVEN ........................................................... 20

Purpose and Locaon of the Oven............................................................................. 20

Condions in which the Oven should not be used.................................................... 20

Required Rules for Correct Use of the Machine........................................................ 21

LUNA CONVECTION OVEN INSTALLATION AND USER MANUAL I 5

TOUCH CONTROL PANEL SIGNALS.............................................................. 22

Device Descripon ..................................................................................................... 22

Manual Cooking ......................................................................................................... 23

Fermentaon Chamber Interface Descripon........................................................... 26

Recipe Screen............................................................................................................. 28

Add Recipe Screen...................................................................................................... 30

Language Opon ........................................................................................................ 32

Failures Causes .......................................................................................... 33

Phase Sequence Failures............................................................................................ 33

Phase Thermal Failure................................................................................................ 34

Fuse Failure................................................................................................................. 35

Sengs Screen ........................................................................................................... 36

Sengs > Oven Display .............................................................................................. 38

Sengs > Cooking Screen.......................................................................................... 39

Sengs > Power Screen............................................................................................. 40

Sengs > Aspirator Screen ........................................................................................ 41

Sengs > Fermentaon Screen ................................................................................. 42

SAFETY ...................................................................................................... 43

Rules ........................................................................................................................... 43

PERSONNEL PROTECTIVE EQUIPMENT ....................................................... 44

GENERAL CLEANING .................................................................................. 45

Cleaning Rules ............................................................................................................ 45

Periodic Cleaning Schedule........................................................................................ 45

Tray Rack Cleaning...................................................................................................... 46

MAINTENANCE AND ADJUSTMENT............................................................ 48

Cooking Time and Temperature Seng .................................................................... 48

Operang temperature .............................................................................................. 48

Steam Injecon Seng .............................................................................................. 48

Periodic Maintenance ................................................................................................ 48

Special Maintenance .................................................................................................. 49

GENERAL RULES......................................................................................... 49

Glass Replacement ..................................................................................................... 50

Fermentaon Chamber Glass Replacement .............................................................. 51

Door Gasket Replacement ......................................................................................... 52

Lamp Replacement..................................................................................................... 53

PERIODIC MAINTENANCE SCHEDULE ......................................................... 54

FAILURE CAUSES AND APPLICABLE METHODS ............................................ 55

6I memak.com

LUNA CONVECTION OVEN INSTALLATION AND USER MANUAL I 7

REAMBLE

Manual

• The mounting instructions are part of the

device and contains information for safe

mounting of the device.

• Read all the mounting instruction before

installation.

• The mounting instruction must always be

available for the access of the installer at

the mounting site.

• The mounting instruction must be kept to

insure the lifetime of the machine.

•GGM is not responsible for any problems

arising from the use of the oven for any

other purpose rather that its own.

• The mounting instructions must be handed

over to the next operators of the device.

Figures

• All figures in this manual are exemplary.

• May vary depending on the current device

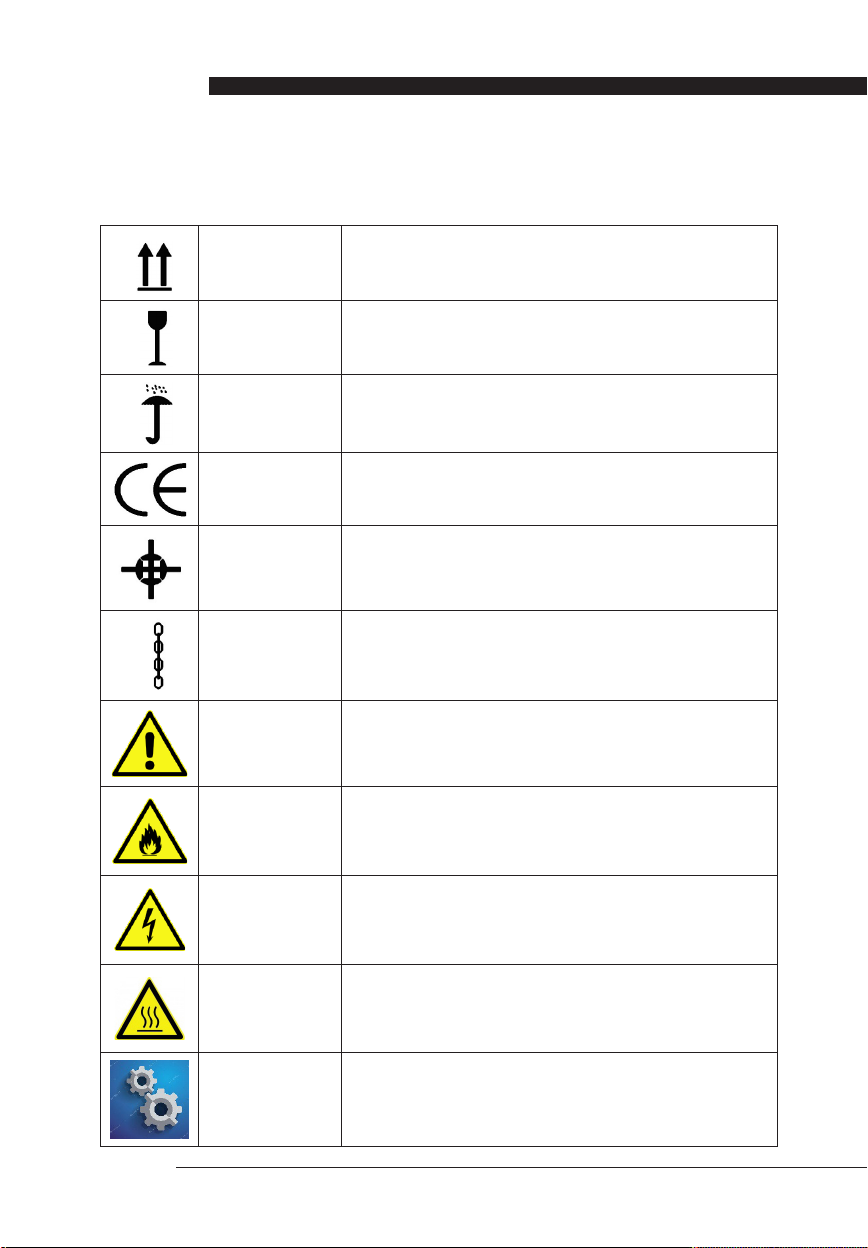

Warning Signs

This direction Move with the direction indicated by the arrows facing

upwards.

Fragile Handle the package carefully.

Keep Dry Packaged in such a way that it does not come into

contact with open air.

CE mark The machine meets the basic safety requirements.

Balance Indicates the point where the machine should be lifted.

Suspension Point Indicates where the ropes or chains must be attached.

Caution! A hazardous situation may result in serious injury or

death.

Fire Fire danger!

High voltage Caution, danger of death!

High voltage When the oven is running, the door, glass and its

surroundings reach high temperatures.

Working Spare

Parts

Do not perform maintenance and repair operations on

moving parts.

LUNA CONVECTION OVEN INSTALLATION AND USER MANUAL I 9

Guarantee terms

The oven detects its internal temperature with a “J” type thermocouple. Our design garantees

a maximum error of ±2°C at the highest temperatures. In case of broken thermocouple

connections, the device protects itself.

Except from the cases mentioned below, from the date of installation, or according to the

sales contract and applicable legal conditions the manufacturer warrants its product for 2 (two)

years.

Not covered by the warranty;

•Glass damage, bulbs and gaskets,

•Misuse of the device,

•In case of modifications or technical changes made to the device by people or personnel

not authorized by the manufacturer,

•Not using the original parts of the manufacturer,

•Damages caused by mechanical impacts caused by the customer’s shipment of the oven.

•Damages arising from inadequate of all the mains network systems feeding the oven.

•Malfunctions that may occur due to user negligence of the oven.

•No one, rather than the authorized personnel or authorized services of the GGM should

interfere with the modification and repair of the device in any way.

•Due to malfunctions that may occur in electric motors.

•Due to malfunctions that may occur in all electrical materials.

•In cases where the settings on the oven are mixed and corrupted.

•In case of non-compliance with the rules specified in the instructions for use.

•GGM cannot be held responsible for malfunctions or problems caused by the use of the

oven by unauthorized personnel who can’t operate it.

Product Information

1. Manufacturer Company

Information

2. Machine type

3. Machine weight

4. Machine model

5. Date of manufacture

6. Serial number

7. CE marking

8. Working voltage

9. Working frequency

10. Working power

LUNA CONVECTION OVEN INSTALLATION AND USER MANUAL I 11

Information about the Machine

Luna series ovens produced by GGM are electric convection rotary type ovens used for multi-

purposes in restaurants, hotels and patisseries.

It is compactly designed for narrow usage areas. It is easy to operate and save recipe with

touch control panel. It provides easy cleaning with its easily removable inner parts.

In addition, it is used in bakery product chains with central production for the purpose of

cooking frozen products on-site with tempered glass cover that prevents heat loss.

Since it is designed in dierent sizes, it is able to meet the needs of small, medium and large

enterprises. The specially designed air circulation system ensures a balanced distribution of

hot air to all points of the cooking chamber, ensuring stable embossing, volume retrieval and

cooking in the products.

Manufacturing Design

1. In the entire area, when placing manufacturing equipment, gaps should be left in order to

allow for inspection and cleaning.

2. When placing the machines, all connection locations must be closed in order not to leave

gaps.

3. The floor where the machines are placed must be accessible in terms of cleaning

operation or should be completely closed.

4. In cases where the equipment passes through sections such as ceilings, floor, walls,

sucient gaps must be provided between the machine and the wall for cleaning, or the

machine must be mounted on the wall so that there wont be any gap.

5. Auxiliary equipment must be detachable and reassembled to facilitate cleaning.

6. The manufacturing base should be covered with hard, smooth, easy-to-clean and non-

absorbent material.

7. For insulation, non-absorbent material should be used. These surfaces must be accessible.

8. When storing products, stacking should be carried out on pallets with a distance of at least

100 mm with the floor.

9. The containers used to collect waste products and wastewater must be made of easily

cleaned material and must be of sucient volume.

10. Doors and windows opened outside the manufacturing must be insed in such a way as to

prevent any external contamination

11. Adequate ventilation should be provided in the washing rooms.

12. Water and water vapor that comes into direct contact with products should be drinkable

water.

13. Pipes, valves and joints used for liquid materials: Either ‘on-site cleaning’ programs should

be applied for these parts, or systems that can be easily disassembled and assembled.

14. All fixed pipes must be isolated to prevent condensation.

15. In the cleaning areas, the necessary drainage systems for waste water must be installed.

16. The ground slope should be in such a way as to prevent the accumulation of water on the

surface.

17. Lamps must be protected to prevent them from dropping and breaking.

18. Electrical cables must be fixed (contact with the ground must be prevented).

19. The electrical components of the machines must be switched o to prevent dusting.

Water should be prevented from entering the electrical panels.

20. Machine parts such as fans and engines must be amounted in an accessible way.

21. The engine and other auxiliary equipment must be placed in such a way that it does not

come into contact with the ground.

LUNA CONVECTION OVEN INSTALLATION AND USER MANUAL

I 13

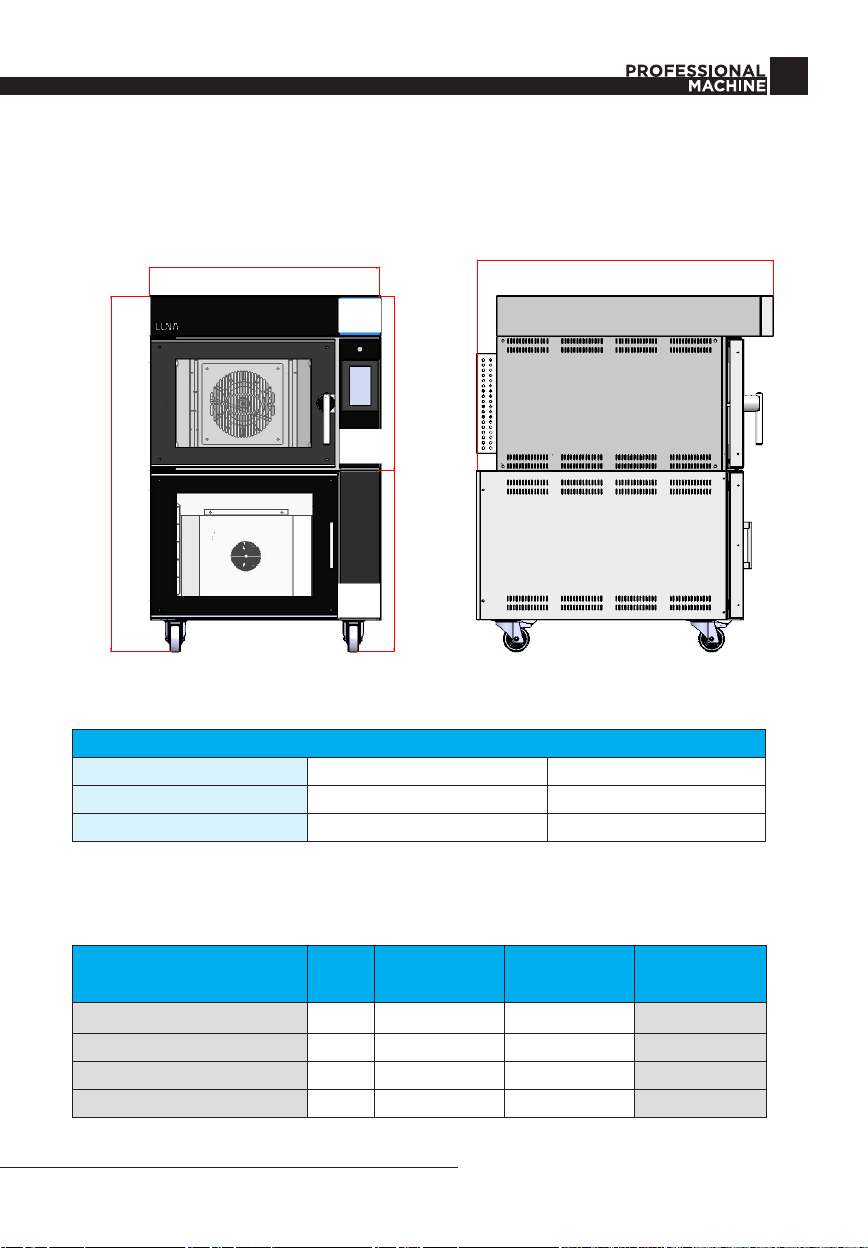

Dimensions of Product

A

B

A1

A2

1410

920

700 710

1185

LUNA COMBİNE

220 KG

2.12.2021

AĞIRLIK(G)

000

1:50

AÇIKLAMA

2.12.2021

REVİZYON NUMARASI

(REV. NUMBER)

LUNA KOMBİNE

HÜSEYİN TUĞRAL

HÜSEYİN TUĞRAL

VERİLMEYEN PAH ÖLÇÜLERİ : 0.5x45º 'DİR.

SAYFA

(PAGE)

0,20 0,30 0,50

0,10

0,10

0,20 0,15 0,10 0,05

0,05

120 mm - 400 mm

30 mm - 120 mm

6 mm - 30 mm

3 mm - 6 mm

0,5 mm - 3 mm

DIN 7168 - m

DIN 7168 - f

GENEL ÖLÇÜ TOLERANSI

2.12.2021

TARİH

KONTROL

ONAY

ÇİZEN

ÇİZGİ BİÇİMİ

PROFILE OF A LINE

SALGI

CIRCULAR RUNOUT

DAİRESELLİK

CIRCULARITY

DÜZLEMSELLİK

FLATNESS

YÜZEY BİÇİMİ

PROFILE OF A SURFACE

EĞİKLİK

ANGULARITY

SİLİNDİRİKLİK

CYLINDRICITY

GENEL SALGI

TOTAL RUNOUT

DOĞRUSALLIK

STRAIGHTNESS

SİMETRİ

SYMMETRY

DİKLİK

PERPENDICULARITY

PARELELLİK

PARALLELISM

EŞ EKSENLİLİK

CONCENTRICITY

POZİSYON

POSITIN

A4

İZ DÜŞÜM METODU

(PROJECTION METHOD

DIMENSIONS INMILLIMETERS)

PARÇA NUMARASI

(REF. NUMBER)

RESİMHANE

HARİCİ

DEĞİŞİKLİK

YAPILAMAZ

MAL.VERSİ.

SERTLİK

(HARDNESS)

MALZEME

(MATERİAL)

B

C

D

E

F

A

23456781

C

1410

920

700 710

1185

LUNA COMBİNE

220 KG

2.12.2021

AĞIRLIK(G)

000

1:50

AÇIKLAMA

2.12.2021

REVİZYON NUMARASI

(REV. NUMBER)

LUNA KOMBİNE

HÜSEYİN TUĞRAL

HÜSEYİN TUĞRAL

VERİLMEYEN PAH ÖLÇÜLERİ : 0.5x45º 'DİR.

SAYFA

(PAGE)

0,20 0,30 0,50

0,10

0,10

0,20 0,15 0,10 0,05

0,05

120 mm - 400 mm

30 mm - 120 mm

6 mm - 30 mm

3 mm - 6 mm

0,5 mm - 3 mm

DIN 7168 - m

DIN 7168 - f

GENEL ÖLÇÜ TOLERANSI

2.12.2021

TARİH

KONTROL

ONAY

ÇİZEN

ÇİZGİ BİÇİMİ

PROFILE OF A LINE

SALGI

CIRCULAR RUNOUT

DAİRESELLİK

CIRCULARITY

DÜZLEMSELLİK

FLATNESS

YÜZEY BİÇİMİ

PROFILE OF A SURFACE

EĞİKLİK

ANGULARITY

SİLİNDİRİKLİK

CYLINDRICITY

GENEL SALGI

TOTAL RUNOUT

DOĞRUSALLIK

STRAIGHTNESS

SİMETRİ

SYMMETRY

DİKLİK

PERPENDICULARITY

PARELELLİK

PARALLELISM

EŞ EKSENLİLİK

CONCENTRICITY

POZİSYON

POSITIN

A4

İZ DÜŞÜM METODU

(PROJECTION METHOD

DIMENSIONS INMILLIMETERS)

PARÇA NUMARASI

(REF. NUMBER)

RESİMHANE

HARİCİ

DEĞİŞİKLİK

YAPILAMAZ

MAL.VERSİ.

SERTLİK

(HARDNESS)

MALZEME

(MATERİAL)

B

C

D

E

F

A

23456781

(Figure 1)

LUNA2-F

HEIGHT ( A ) mm / inc 1.410

WIDTH ( B ) mm / inc 920

DEPTH ( C ) mm / inc 1.185

Product Technical Information

LUNA2-F Bakery

Department

Maya

room Total

Weight Kg 120 100 220

Pan Capacity (40x60) Adet 5 12 5

Cooking Area m22.4 -2.4

Connection Strength Kw 7.5 3.3 10.8

START-UP OF THE PRODUCT

• Installation is carried out by the sta of the manufacturer or by the personnel authorized

by the manufacturer.

• The manufacturer is not responsible for the failures in the installation made by

unauthorised personnel. Despite the labor guarantee, the manufacturer is not responsible

for the failures during the installation by unauthorised personnel.

• The manufacturer cannot be held responsible for the place where the machine was

installed and its technical and legal compliance.

• All operations must be carried out in accordance with the directives of a single authorized

personnel.

• Operators and personnel at your disposal must wear protective clothing suitable for the

operation

General Rules for Unpacking the Machine

• Before unpacking the machine; inspect for any damage from the transport. Check if

all the parts in the shipping document are present. In case of missing parts, inform the

manufacturer within 24 hours.

• When the installation of the machine is complete, dispose of the packaging material in

accordance with applicable legal regulations.

• Store the materials used to lift the machine in a suitable place for future usage. (Figure 2)

(Figure 2)

LUNA CONVECTION OVEN INSTALLATION AND USER MANUAL

I 15

Load Structure

The machine can be shipped in the following ways:

• Completely assembled;

• Partially assembled;

• Completely unassembled; the pieces are stacked on a pallet or optionally to any wooden

structure.

The vehicle to which the machine will be transported must have the necessary lifting capacity.

(See the machine’s technical information table). In addition, the minimum loading areas of the

vehicle should be as follows. (Width: 2300mm; Length: 5000mm)

The lifting vehicle used to lift must have sucient lifting capacity and fork length.

The manufacturer is not responsible for accidents, damages and machine failures caused by

non-compliance with the rules in this section.

Transportation of the Product

General Rules for Lifting and Moving the Machine

• Before starting the operation, determine and inspect the entire transport area, the parking

area of the vehicle performing the transport and the area where the machine will be

installed. Make sure there are no hazardous situations.

• Make sure that the lifting capacity of the vehicle that will carry out the lifting and

transporting of the machine is sucient. Weights are stamped on the packaging and/or

are included in this manual.

• Check that the lifting ropes and chain types are approved and that the capacity indicated

by the manufacturer is clearly written on the ropes. Before using the lifting ropes, check

for damage and wear.

• Do not tie knots to the lifting ropes, do not bend them and follow the rules set out by the

manufacturer. The same rules are applyed to chains and strappings.

• Pay particular attention to the removal of the machine centically.

• When the machine is installed and moving, do not climb on top of it and do neither go

under it.

• Care should be taken not to place unauthorized personnel in the loading area.

• In order not to cause any accidents and injuries; all operators must stand at a safe distance

while the machine is being lifted.

• When removing the machine, care should be taken not to shake the system.

Forklift Usage

• Place forklift forks at the bottom of the pallet and make sure that the fork is at least 20 cm

from the opposite side.

• Use a forklift with sucient lifting capacity and fork length.

• Ensure slow transport and safe transport.

• Check that the oven (the material on the pallet) is balanced on the forklift forks.

(See Figure 4 and Figure 5)

Figure 4 Figure 5

The lifting vehicle used to remove the machine; must have sucient lifting capacity and fork

length.

The packaging structure of the product is carried out in accordance with the European and

World’s norms. After the machine control process is finished, it is packaged with bubble wrap,

compressed with stretch nylon and in accordance with the standards are placed in the box and

ready for the shipment.

!WHEN RECEIVING THE PRODUCT PLEASE CHECK THE CONDITION OF THE

PACKAGING CAREFULLY

DO NOT TAKE THE DELIVERY OF A PACKAGE WHICH PACKANGING IS UNMADE DAMAGED,

CRUSHED OR SCRATCHED. PLEASE REPORT THIS SITUATION TO THE MANUFACTURER BY

TAKING A PHOTO AND TAKING A SHORT NOTE SUMMARIZING THE SITUATION.

LUNA CONVECTION OVEN INSTALLATION AND USER MANUAL I 17

Rules Regarding Stocking the Machine:

• The machine must be stored in a closed place away from the dust, moisture and heat

source.

• The media values allowed for storage are as follows: Temperature: -5 C to 45 C

• Maximum humidity: 60%

• It is necessary to ensure that there is no risk of vehicle collision in the place where the

machine is stored.

• Enclosed parts should be checked regularly.

• Never stack the machines on top of each other.

• In case the machine is stored unpackaged, it must be raised from the ground with the help

of wooden pallets. It should be covered to protect it from dust and dirt.

ASSEMBLING THE

PRODUCT

Pre-assembled machine:

The machine, which comes in a pre-

assembled form, requires special setup

settings in the designated area for it.

Unassembled or semi-assembled

machine:

If the machine is shipped unassembled

or semi-assembled; assembly operation

must be carried out by personnel

authorized by the manufacturer.

NOTE: The machine is taken to the first

scale. (Fig. 6)

(Figure 6)

1. 1. If no layout of the ovens has been made in advance, the oven is placed appropriately.

IMPORTANT: The distance between the oven and wall should be at least 500 mm (half a

meter). (Figure 7)

(Figure 7)

2. In case that more than one oven will be placed, it should be examined. (Fig. 8)

(Figure 8)

LUNA CONVECTION OVEN INSTALLATION AND USER MANUAL

I 19

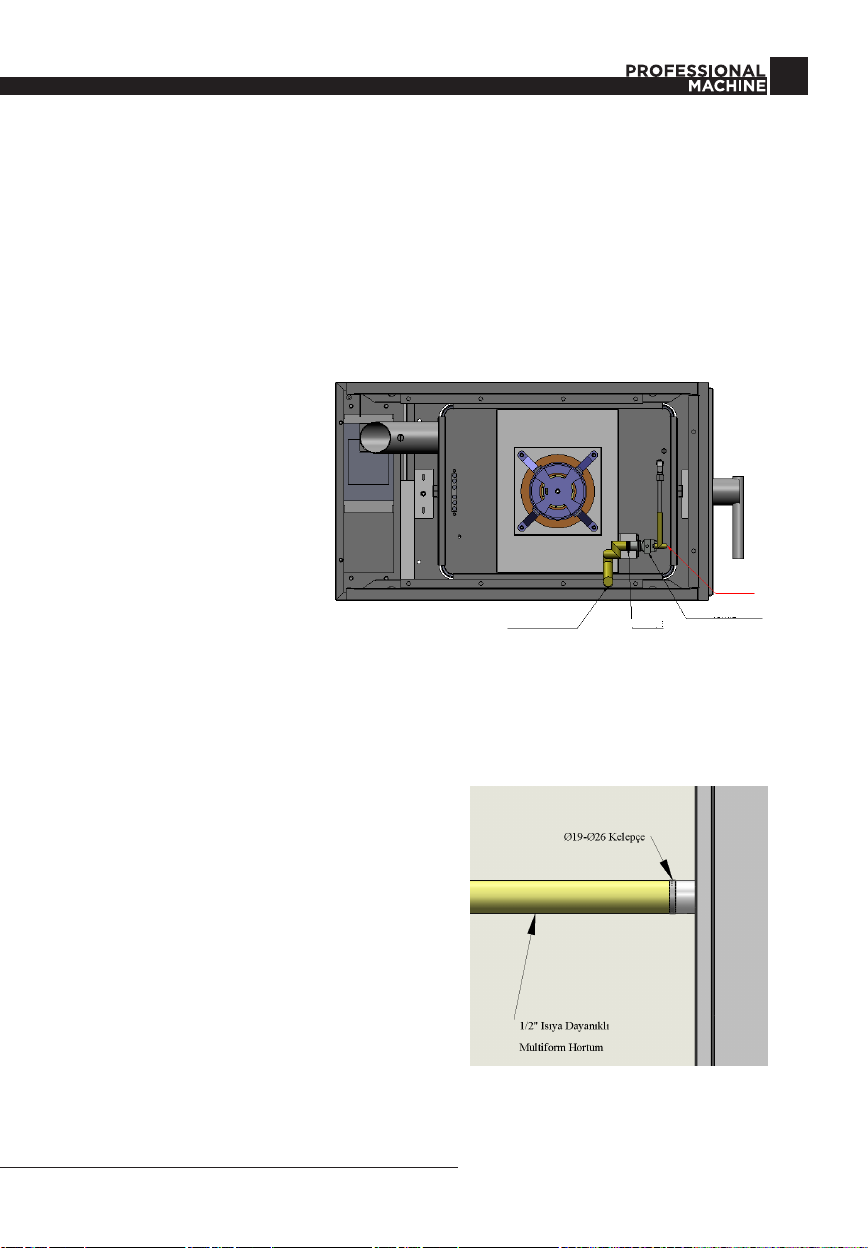

Clean Water Treatment

This system is placed in the gap at the bottom of the oven.

This system consists of:

• Heat-resistant hose for connection

• Washing Machine Valve

The clean water treatment is brought to the desired close of the furnace by the customer.

NOTES:

• To absorb pressure from

the main switch, make

the connection with a

flexible hose.

• If necessary, install a

manually controlled valve

to turn o the system

abruptly when necessary.

• After using the oven on

the first day, check the

filters according to the

procedures in case they

are dirty.

The clean water treatment

connection type (Figure 9)

should be appropriate.

Fermentation Cabinet

Connection Water Connection

• The fermentation cabinetplumbing

connection (Fig. 10) must be suitable

Clamp

Clean water hose

Washing machine

valve

Clean water

hose

(Figure 9)

(Figure 10)

Electrical Connection Rules

• The installation of the electrical connection of the machine is carried out in accordance

with the applicable regulations and is the responsibility of the customer.

• It is the customer’s responsibility to protect electrical connections and circuits from the

power supply source.

• Use an approved and current-appropriate cable in the appropriate section of the electrical

panel. Electrical power data is available in the label information. The length of the

connection cables should be adjusted according to where the oven is used.

• Make sure that the power line is cut o as soon as you make an electrical connection.

• The places where the cable can cause damage are determined and those areas are

covered to prevent damage against contact.

The electrical panel has a ventilation system to prevent damage to electrical circuits

at excessive temperature.

Materials required for the electrical connection of the Machine;

• 3 x 16 FUSES 1 PIECE / EACH FLOOR IS REQUIRED

• AVERAGE DRAWN 13 A / PER FLOOR

• 5 x 4 ANTIGRON CABLE (SINGLE CORE)

• CABLE DIMENSIONS IT MAY VARY DEPENDING ON DISTANCE

• WASTE WATER OF FERMENTATION ROOM: FERMENTATION ROOM SINK DRAIN

• CLEAN WATER OVEN : ½’’ CLEAN WATER VALVE TO THE END FLOOR H:500 mm

• CLEAN WATER OF FERMENTATION ROOM: ½” CLEAN WATER VALVE TO THE END FLOOR

WITH H: 350 mm F

WORKING PRINCIPLE OF THE OVEN

Purpose and Location of the Oven

The oven is designed and manufactured specifically for the manufacture of products such as

pizza, dry cake, bread, in other words flour products, products that have flammable content

(containing alcohol) are excluded.

Conditions in which the Oven should not be used

It is prohibited for use under the following conditions:

• Use in the cooking of foods such as meat, fish, vegetables, fruits and cheeses unless

specified in the contract without the knowledge of the manufacturer

• Operating in situations that may cause an explosion or be harmful to the environment

• Use in environments where fire may occur

• Use in unprotected areas

• Use in cases where electromagnetic internal lock is disabled

• Use without safety and protection tools

• It is prohibited to use in cases where the specified values and properties are dierent.

This manual suits for next models

1

Table of contents

Popular Convection Oven manuals by other brands

Frigidaire

Frigidaire FEF389CFTH owner's guide

Fri-Jado

Fri-Jado TDR-P eco user manual

Salton

Salton Elite SCO912 instruction manual

Blue Seal

Blue Seal turbofan E26 Service manual

Bakers Pride

Bakers Pride Cyclone CO11-G Installation and operating instructions

Black & Decker

Black & Decker TO4000SD Use and care guide

Aroma

Aroma AeroMatic AST-910 Instruction manual & recipe guide

Watlow

Watlow MINICHEF 2000 Application guide

NuWave

NuWave Pro Plus user manual

MORGAN Catering Equipment

MORGAN Catering Equipment 22013440 INSTRUCTIONS FOR THE INSTALLATION, USE AND MAINTENANCE

Star Manufacturing

Star Manufacturing Holman CCOF-4 Specification sheet

Equipex

Equipex SODIR FC-33 Operation manual