2/32 03.06.20, Subject to alterations

Contents

1 General information ................................................................................................................... 3

2 Checking the scope of delivery and electrical ratings ................................................................ 3

3 Maintenance and customer service ........................................................................................... 4

4 Operating instructions ................................................................................................................ 4

5 Instruction of operating personnel.............................................................................................. 4

6 Key for code designation ........................................................................................................... 4

7 Technical specifications .............................................................................................................. 5

8 Boiler connection dimensions .................................................................................................... 5

9 Mounting the gas jacket mantel at the boiler .............................................................................. 5

10 Mounting the burner housing on the gas jacket (service position) ............................................. 6

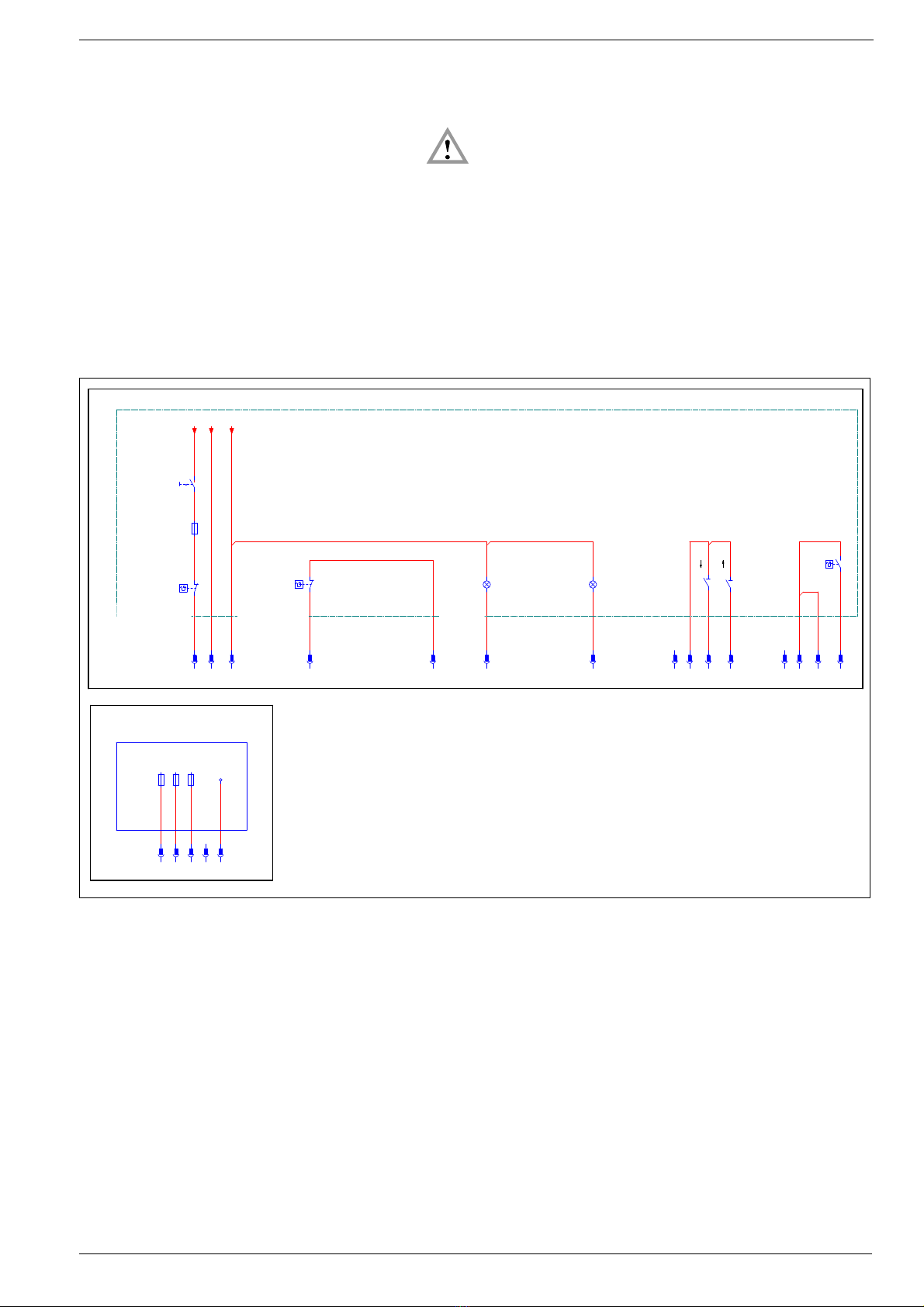

11 Terminal diagram connector pin assignments ............................................................................ 7

12 Electrical connection ................................................................................................................... 8

13 Air flap positioning motor .......................................................................................................... 9

14 Air pressure switch ..................................................................................................................... 9

15 Gas pressure monitor ............................................................................................................... 10

16 Adjusting the ignition electrode ................................................................................................. 11

17 Measuring the ionisations current ............................................................................................. 11

18 Adjusting the mixer head ......................................................................................................... 12

19 Connection diagram LMV27 ..................................................................................................... 12

20 Operating instructions and equipment description LMV............................................................ 13

21 Start-up and calibration ............................................................................................................ 14

22 Gas burner with gas train KEV

II

1 ½", KEV 2", KEV412 1 1/2“, KEV300 1“, KEV DN65 ........... 20

23 Calculation principles for gas burner adjustment .................................................................... 22

24 Adjustment tables .................................................................................................................... 23

25 Error code list LMV .................................................................................................................. 25

26 Adjustments log ........................................................................................................................ 27

27 Exploded view / spare parts list................................................................................................. 28

28 Declaration of Conformity for Gas Burners ............................................................................... 30

29 Overall dimensions .................................................................................................................. 32

30 Working ranges........................................................................................................................ 32