SolutionAir elicent REC-Duo 100 User manual

Page 1 / 17

Heat recovery unit

Instruction Manual

ENGLISH v1.4

WARNING: The equipment must only be installed by a specialised technician!

Read and apply the manual before carrying out the installation.

Keep this manual in a safe place.

Page 2 / 17

Dear Customer,

The product you purchased is a heat recovery extractor fan without ducting, suitable for wall mounting. To

ensure optimum operation and a long life, read this manual carefully in order to correctly install, use and

maintain the product. Following all the instructions ensures reliability and long life, both mechanically and

electrically.

The manufacturer declines any responsibility for damages, caused to persons or things, caused by failure to

observe the following instructions.

The product is constructed using state of the art technology and respects the standards in force regarding

electrical equipment. It conforms with the EMC European Directive in force regarding radio interference

suppression and electro- magnetic compatibility.

Contents

WARNING ADVICE ........................................................................................................................................................ 3

TROUBLESHOOTING ....................................................................................................................................................... 4

DISMANTLING AND RECYCLING ................................................................................................................................. 4

PRODUCT DESCRIPTION................................................................................................................................................ 4

OPERATING PRINCIPLE.................................................................................................................................................. 5

DIMENSIONS.................................................................................................................................................................... 5

BOX CONTENTS .............................................................................................................................................................. 6

INSTALLATION DIAGRAM.............................................................................................................................................. 7

INSTALLATION LOCATION............................................................................................................................................. 8

INSTALLATION ADVICES ................................................................................................................................................ 8

WIRING DIAGRAM ....................................................................................................................................................... 10

TIMER AND HUMIDISTAT .............................................................................................................................................. 11

SPEED SELECTION......................................................................................................................................................... 12

FIRST START-UP - PAIRING ............................................................................................................................................ 12

REMOTE CONTROL ...................................................................................................................................................... 13

SPECIFIC FUNCTIONS OF THE REMOTE-CONTROL REC DUO 100 PLUS RC ........................................................ 14

MODESL & OPERATION............................................................................................................................................... 15

LEGEND OF THE VENTILATION UNIT STATUS ............................................................................................................. 16

CLEANING AND MAINTENANCE............................................................................................................................... 17

RESETTING THE REPLACE/CLEAN FILTERS NOTICE (RED FLASHING LED)............................................................. 17

CUSTOMER SERVICE .................................................................................................................................................... 17

Page 3 / 17

WARNING ADVICE

WARNING: Serious injury or death can be caused if these instructions are not applied!

Do not use this product for uses that are different from those for which it has been designed.

After removing the product from its packaging ensure that it is complete and undamaged; if in doubt,

immediately contact a qualified electrician.

Do not leave parts of the packaging within reach of children or incompetent persons. To dispose of the

packaging and the appliance at the end of its useful life refer to the recycling norms in force in your country.

Immediately contact a qualified person (authorised dealer or the manufacturer) if the product is dropped or

knocked to check its correct functioning.

Do not touch the appliance with wet or humid parts of the body (e.g., hands or feet).

This appliance can be used by children aged from 8 years and above and persons with reduced physical, sensory

or mental capabilities or lack of experience and knowledge if they have been given supervision or instruction

concerning use of the appliance in a safe way and understand the hazards involved. Children shall not play with

the appliance. Cleaning and user maintenance shall not be made by children without supervision.

The means of disconnection from the supply mains must have a contact separation in all poles and must provide

full disconnection under overvoltage category III conditions.

If there is a combustible-fed device (water heater, gas boiler, etc. of the sealed chamber type) in the room

where the product is to be installed check that the re-circulation of air is sufficient to ensure a good combustion

for the correct functioning of these devices, precautions must be taken to avoid the back-flow of gases into the

room from the open flue of gas or other fuel-burning appliances.

To avoid the risk of fire do not using the product in the presence of inflammable

substances and vapours, such as alcohol, insecticides, petrol, etc.

The product can be connected to the supply mains only if the voltage and the frequency of the supply mains

correspond to those written in the rating label.

In the case of malfunction, anomaly or any type of fault disconnect the appliance from the electrical main

supply and contact a qualified person. Use only original spare parts for repairs.

The electrical system to which the appliance is connected must conform with the local norms in force regarding

electrical systems.

The appliance must not be used to activate water heaters, room heaters, etc.

DO NOT INSTALL ON THE CEILLING.

WARNING: Damage can be caused to the device if the following instructions are not applied!

Do not use the product at environmental temperatures more than 40°C.

Do not leave the appliance exposed to atmospheric agents (rain, sun, snow, etc.). The possible applications of

this product are illustrated in this manual.

Do not submerge the equipment or any of its parts in water or other fluids, unless specifically required by

maintenance operations.

When cleaning or carrying out ordinary maintenance, check the integrity of the appliance.

The flow of air or fumes that is conveyed by the appliance must be clean and free of greasy elements, soot,

chemical/corrosive agents and inflammable or explosive mixtures.

Do not obstruct the air inlet and outlet of the appliance in any way whatsoever.

When using air ducting make sure that the ducting is not blocked.

For an optimum functioning of the appliance, it isnecessary to ensure an adequate re-circulation of air in the

room. Consult the local norms with regards to this.

Page 4 / 17

TROUBLESHOOTING

PROBLEM

CAUSE AND REMEDY

The appliance does not switch on

There is no voltage.

Check the main switch and/or the electrical connections.

The impeller does not turn

Check that its movement is not obstructed.

This device is equipped with a manual reset protection system

that in the event of a mechanical obstruction in the rotation will

switch off the engine.

To restore normal operation, proceed as follows:

disconnect the device from the power mains upstream;

remove the cause of the mechanical obstruction (only

qualified

personnel);

reconnect the device to the power mains.

The device will only resume normal operation if the protection

system does not detect any additional faults. If the fault persists,

contact the client support service.

The devices on the PLUS RC version

do not synchronise

Disconnect and reconnect power supply.

The remote control does not work

(only in the Plus RC version)

Check the status of the battery.

DISMANTLING AND RECYCLING

If a crossed-out wheeled bin is illustrated on a product, this means that the product satisfies the

requirements of the 2012/19/UE European Directive.

Conform to the local norms regarding the disposal of waste materials and do not dispose of old

products in normal domestic waste material.

PRODUCT DESCRIPTION

The product is a single hole, heat recovery unit without ducting, suitable for single rooms.

The heat is recovered by means of a ceramic exchange that acts as a heat accumulator. In the normal

operating cycle, the device expels stale air from the inside outwards (extraction); in this first phase the air passes

through the recuperator transferring heat to the ceramic core. In the second phase of the cycle the air flow is

reversed (intake): the external air passes through the heat exchanger capturing the previously accumulated

heat before being transferred inside. This operation alternates the flow every 60 seconds (Push-Pull).

Page 5 / 17

OPERATING PRINCIPLE

Extraction Cycle (Push) Intake Cycle (Pull)

60 seconds 60 seconds

DIMENSIONS

Main Unit –REC-Duo 100

EXTERNAL VENT EXTERNAL COWLING (PLENUM)

Page 6 / 17

BOX CONTENTS

5

6

2x

7

2

3

4

1

17

11

12

13

8

9

10

15

14

1. Ventilation Unit

2. Power supply plate cover

3. Power supply plate

4. External vent (2 parts)

5. Telescopic tube

6. Ceramic heat exchanger

7. Filters (already assembled on the heat exchanger)

8. Screws for fixing the wall power supply plate cover

9. Wall plugs

10. Screws for fixing power supply plate

11. Awl key for "RESET” button

12. Remote Control (1pc, RC version only)

13. Mounting Kit for Remote Control (RC version only)

14. Trade Seal

15. External cowling (plenum)

16. Wall mounting bracket

17. Documentation (Manual, Technical Product Page,

International Warranty, ErP Label)

16

Page 7 / 17

INSTALLATION DIAGRAM

Notes

−If total wall thickness is greater than 22cm, it can be considered to install the duct without

cowling.

−For retrofit projects we recommend to use always the cowling to allow a correct installation

of the trade seal.

−The ‘Wall Mounting Bracket’ and the REC-Duo ‘Power Supply Plate’ should be at least fixed

with 2 screws to the timber/ steel frame.

Page 8 / 17

INSTALLATION LOCATION

The location of the installation should preferably meet following requirements:

−High position in the room on the wall (above 2m height)

−Next to a timber/steel wall frame (to fix the wall mounting bracket)

−Reasonable sheltered place from outside (from wind, rain, sun)

−Away from bedhead to reduce noise disturbance during the night

−Suitable for wiring from and to wall switch

INSTALLATION ADVICES

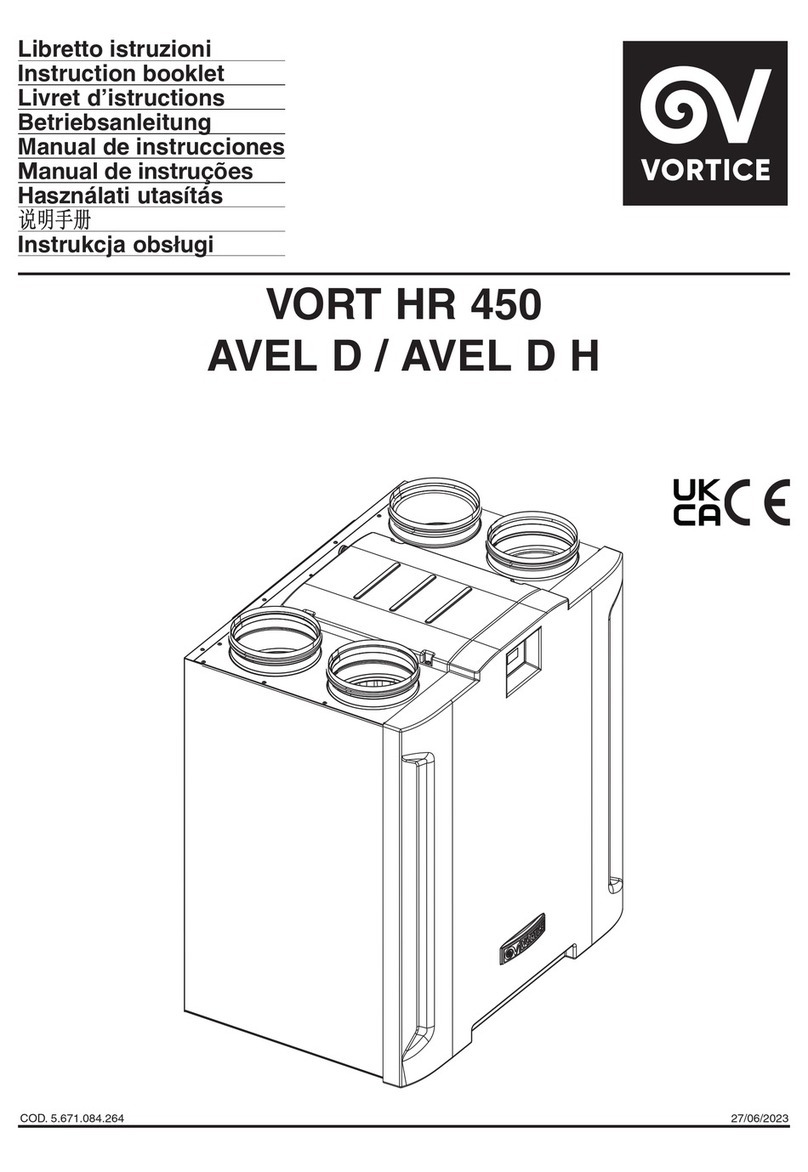

Wall Mounting Bracket Hole Diameter 110 mm

External Waterproof Membrane & Tube External Cowling (Plenum)

Drill or cut a 110mm hole through wall with a

2° slope towards outside.

(If required, remove temporary the wall

mounting bracket)

Choose location and install wall mounting

bracket from inside before installing the gib

board.

Install duct and trade seal from outside

with a 2° slope for weathertight connection.

Install external cowling from outside with the

bigger hole against the trade seal and the

slope on the top. Consider to drill a small

drain hole if cowling is exposed to rain.

Page 9 / 17

Wiring to and from switch Power Supply Plate

Electrical Connection Power Supply Plate Cover

External Vent Ceramic Core

Plan wiring from and to wall switch:

3 options to go through power supply plate.

(Switch is not included)

After installing the gib board over the

mounting wall bracket, cut out the whole

and line up the power supply plate on top.

Connect power supply plate in

accordance with wiring diagram.

(Only certified electricians)

Install power supply plate cover.

Install external vent on the cowling. Insert ceramic core into duct from inside.

Page 10 / 17

REC-Duo Unit External Cladding

WIRING DIAGRAM

Wiring diagram for 24h/7d operation

It is recommended to include a main switch to power off the whole unit for e.g. maintenance.

Insert the REC-Duo unit into the duct. The

power connectors need to line up and the

plate snaps into a magnetic mount.

Complete external cladding around the

cowling in accordance with NZ building

standards.

REC-Duo 100

REC-Duo 100 MHY

REC-Duo 100 RC PLUS

Page 11 / 17

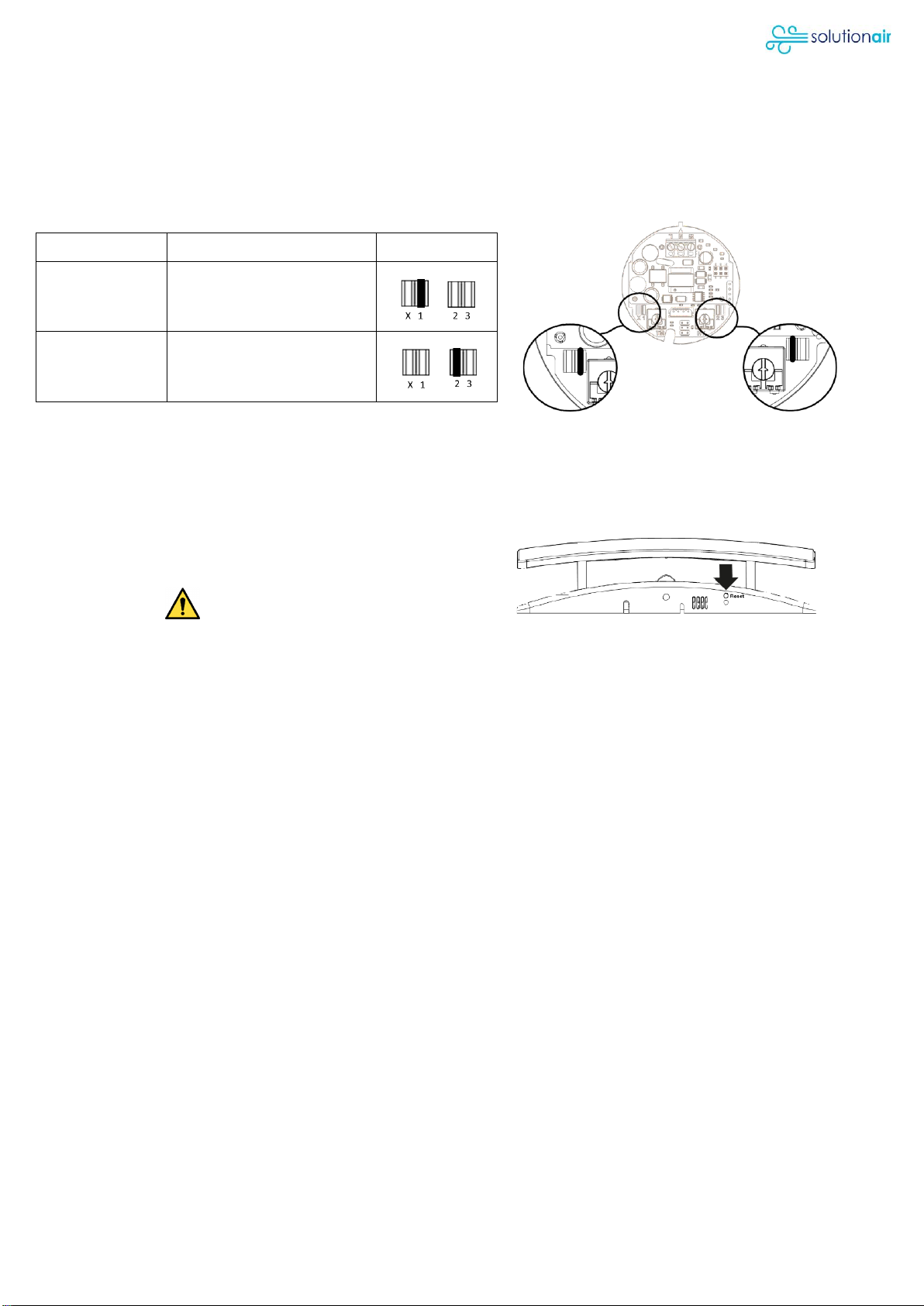

TIMER AND HUMIDISTAT

Timer (TM) and humidistat (HY) threshold regulation

TM Timer

This function is present in the REC-Duo 100, REC-Duo MHY and REC DUO 100 PLUS RC models.

Adjust the trimmer TM (screw - red) to set the timer operating time (only extraction from 0 to 30 minutes).

HY Humidistat

This function is present in the REC DUO 100 MHY and REC DUO 100 PLUS RC models.

Adjust the trimmer HY (screw - blue) to set the humidity threshold (adjustable from 40% to 90% RH - Relative

Humidity) at which the appliance will automatically switch to a higher speed.

For New Zealand we recommend to set the level between 60% and 70% RH.

Page 12 / 17

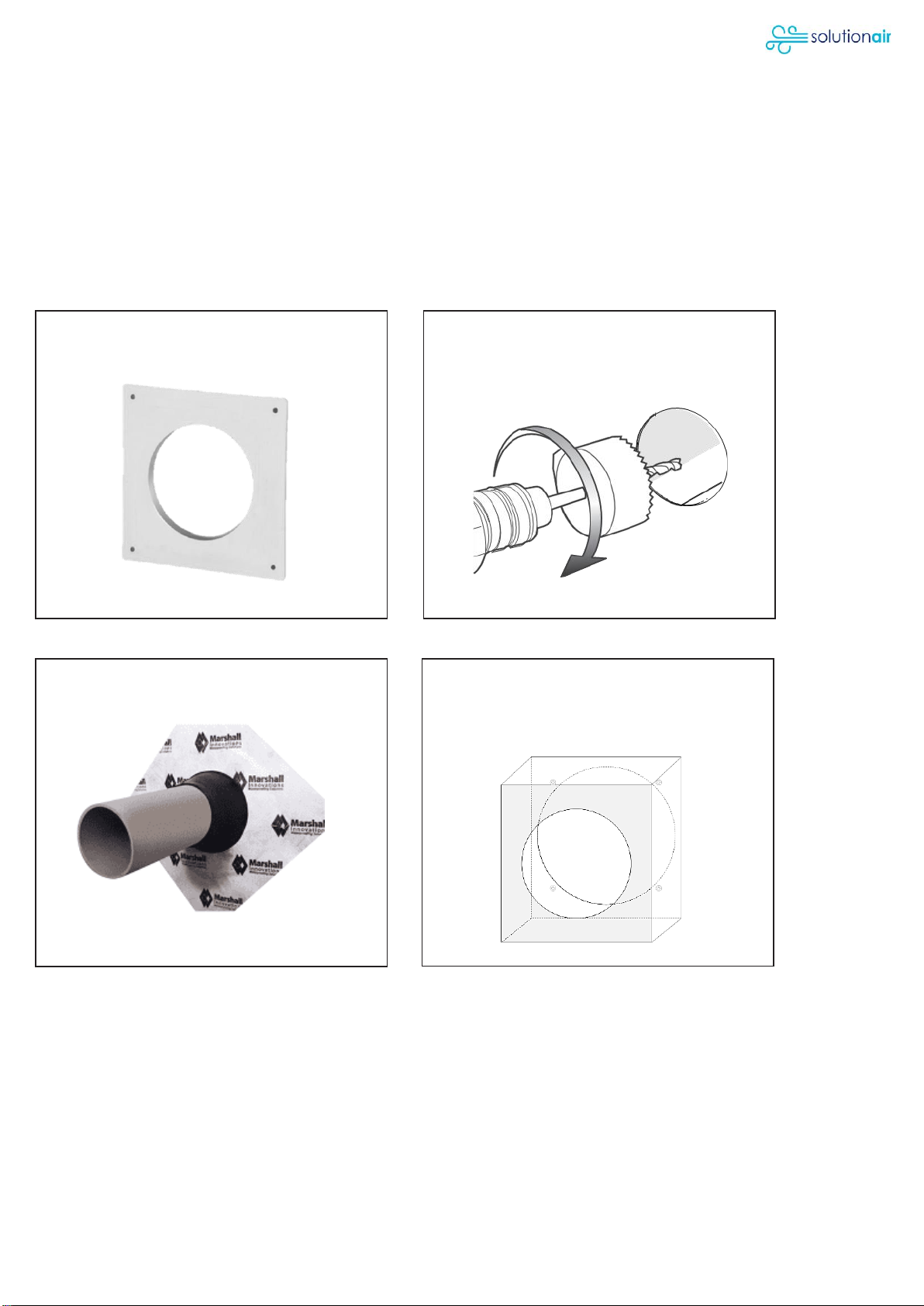

SPEED SELECTION

Selecting the 24h operating speed

REC-Duo 100 and REC DUO 100 MHY

Models with two possible operating speeds for continuous operation (24 h) with alternating flows (Push-Pull).

Select the speed simply by moving the jumper as shown in the figure below, to one of the two positions (see

table).

Jumper

Speed Setting

Jumper 1

Speed 1 (factory setting)

Jumper 2

Speed 2

REC-Duo 100 PLUS RC

Speeds can be selected and adjusted via remote control.

FIRST START-UP - PAIRING

Note

Use always the supplied awl key to press the "RESET" button

located at the base of the front support of the ventilation unit.

DO NOT USE METALLIC OBJECTS!

REC-Duo 100 and REC DUO 100 MHY

For optimum operation, installation in pairs is recommended.

DEVICE PAIRING

These devices must be connected to the same circuit and powered by the same switch. Once powered, they

start operating in extraction mode (Push), as shown by the green indicator light on the device. To synchronise

flows, change the mode from extraction to intake on one of the two devices by pressing the "RESET" button

located on the device whose rotation direction is to be changed.

The intake mode (pull) is identified by a yellow indicator light. After the initial start-up and synchronisation, the

devices store the assigned alternating rotation direction. They will not need to be re-synchronised.

REC-Duo 100 PLUS RC

For optimum operation, installation in pairs is recommended, up to a maximum of 6 devices.

DEVICE PAIRING

Once powered, they start operating in extraction mode (Push), as shown by the green indicator light on the

device. To synchronise flows, change the mode from extraction to intake on one of the two devices by pressing

the "RESET" button located on the device whose rotation direction is to be changed. The intake mode (pull) is

identified by a yellow indicator light. The devices communicate with each other wirelessly.

To activate communication within the system, synchronise the devices as indicated below.

Press the "RESET" button on each device for at least 3 seconds. The blue led will begin to flash. Perform the same

operation on all the installed devices within 60 seconds. When all LEDs turn green or yellow, the synchronisation is

complete. During this phase do not press any button on the remote control.

UNPAIRING A DEVICE

To cancel synchronisation between devices, press the "RESET" button for at least 3 seconds. The LED will turn BLUE

and start flashing slowly; release the button. Press the "RESET" button a second time for a further 3 seconds. The

LED will start flashing faster; release the button. Press the "RESET" button one last time for at least 3 seconds. The

LED will stop flashing and after a few seconds it will turn GREEN or YELLOW. The selected device is no longer

Page 13 / 17

synchronised with the other devices. If the MASTER device is removed (see "Legend of the ventilation unit status"),

cancel the synchronization of all installed devices. Then repeat the above sequence of re-synchronization of the

entire product group.

PAIRING REMOTE CONTROL TO THE VENTILATION UNIT

Press the "RESET" button on the device to be connected to the remote control, for at least 3 seconds. When the

LED flashes BLUE, synchronisation mode has begun. To confirm the pairing, press any button on the remote

control (except the "0” key). The pairing is complete.

UNPAIRING REMOTE CONTROL FROM THE VENTILATION UNIT

Press the "RESET" button on the device to be disconnected from the remote control, for at least 3 seconds. When

the LED flashes BLUE, synchronisation mode has begun. To unpair, press any button on the remote control

(except the "0” key). The cancellation of the pairing is complete.

PAIRING A REMOTE CONTROL WITH SEVERAL VENTILATION UNITS

It is possible to control several REC DUO 100 RC ventilation units (maximum 6 units) with a single remote control. In

this case, all the remote-control functions, including the "Timed Boost", will work on all the ventilation units.

REMOTE CONTROL

REC-Duo 100 PLUS RC only

The product is a radio transmitter designed for operating the REC-Duo 100 PLUS RC.

ACTIVATING THE REMOTE CONTROL

Remove the transparent pull tab from the remote-control battery

compartment. The remote control is enabled to operate in a

radius of approximately 20m with the battery in a good

functioning state. To synchronise the remote control with the

product, refer to the “FIRST START-UP –PAIRING” instructions.

DESCRIPTION OF CONTROLS

0 - ON/OFF

Device on/off.

1 - PUSH-PULL MODE¹

24 h operation at the set speed. Automatic: operation with

alternating flow.

2 - SPEED 1¹

Low speed setting.

3 - SPEED 2¹

High speed setting.

4 - TIMER-SET BOOST²

Timer-set operation in ejection only at maximum speed.

5 - SLEEP MODE¹

Maintains the selected operating mode at the set speed 1. To exit

this mode before the end of the 8 hours, press any key (except 0).

6 - FORCED FLOW CONTROL¹

The devices operate either in ejection only or in injection only.

Press once: ejection mode. Press twice: injection mode.

7 - FREE COOLING (no inversion)¹

No inversion of flow. Press once: flow inversion stops in the

direction of rotation active at that moment. Press twice: all the

devices invert flow and maintain this set direction of rotation.

1: Function that controls all products paired with the remote control.

2: Function that controls the single product paired with its own remote control (not valid if only one remote control is used on

several devices - see paragraph "PAIRING A REMOTE CONTROL WITH SEVERAL VENTILATION UNITS").

LED Indication Signal:

Every time a button is

pressed an LED light on

the remote will indicate

that the command has

been received.

Page 14 / 17

SPECIFIC FUNCTIONS OF THE REMOTE-CONTROL REC DUO 100 PLUS RC

RESTORE FACTORY SETTINGS

Press for a few seconds and simultaneously release the 0, 1, 6 and 7 KEYS on the remote control. The LED will

flash RED and PURPLE. When they stop flashing, the devices will return to the previous mode, but with the

factory-set values.

CUSTOMISATION OF FACTORY SETTINGS

To increase and/or decrease the limit values, press and release the keys repeatedly as shown below.

SPEED ADJUSTMENT 1 - KEYS 2

Speed 1 can be set between 30% and 70%. In the factory settings mode, this value is 30%. The setup is reflected

on all synchronised devices.

Sequence:

1. Select KEY 2 - SPEED 1.

2. To enter SETUP MODE, press KEY 2 and KEY 3 simultaneously for a few seconds. The

STATUS LED on the product indicates when this mode is activated by FLASHING

BLUE.

3. Press KEY 2 to reduce the speed or press KEY 3 to increase it. The increase or

decrease in speed is shown by the respective increase or decrease in the

frequency with which the BLUE LED flashes. During the speed adjustment phases,

if you want to increase or decrease the previously set one, between one signal

and the other (flashing blue), a red visual signal is interposed which indicates that

the signal has come to fruition.

4. Press the 0 KEY to exit the SETUP MODE or alternatively wait about 10 seconds

without pressing anykeys.

NB: During the speed adjustment phase, the full-scale value is highlighted by a

GREEN light signal.

SPEED ADJUSTMENT 2 - KEYS 3

Speed 2 can be set between 70% and 100%. In the factory settings mode, this value is approximately 90%. The

setup is reflected on all synchronised machines.

Sequence:

1. Select KEY 3 - SPEED 2.

2. To enter SETUP MODE, press KEY 2 and KEY 3 simultaneously for

a few seconds. The STATUS LED on the product indicates when

this mode is activated by FLASHING PURPLE.

3. Press KEY 2 to reduce the speed or press KEY 3 to increase it.

The increase or decrease in speed is shown by the respective

increase or decrease in the frequency with which the PURPLE

LED flashes. During the speed adjustment phases, if you want

to increase or decrease the previously set one, between one

signal and the other (flashing purple), a red visual signal is

interposed which indicates that the signal has come to fruition.

4. Press the 0 KEY to exit the SETUP MODE or alternatively wait

about 10 seconds without pressing any keys.

NB: During the speed adjustment phase, the full-scale value is

highlighted by a GREEN light signal.

LED INTENSITY ADJUSTMENT

The brightness of the LED on the product is adjustable from maximum to off. This parameter can be set

individually on each REC DUO 100 PLUS RC.

Sequence:

1. Press KEY 4 and KEY 5 simultaneously for a few seconds to enter SETUP MODE. The STATUS LED on the product

indicates when this mode is activated with a PURPLE light.

2. Press KEY 2 to reduce the brightness or press KEY 3 to increase the brightness. The increase or decrease of the

brightness value is shown by the respective increase or decrease of the LED brightness.

3. Press the 0 KEY to exit the SETUP MODE or alternatively wait about 10 seconds.

Page 15 / 17

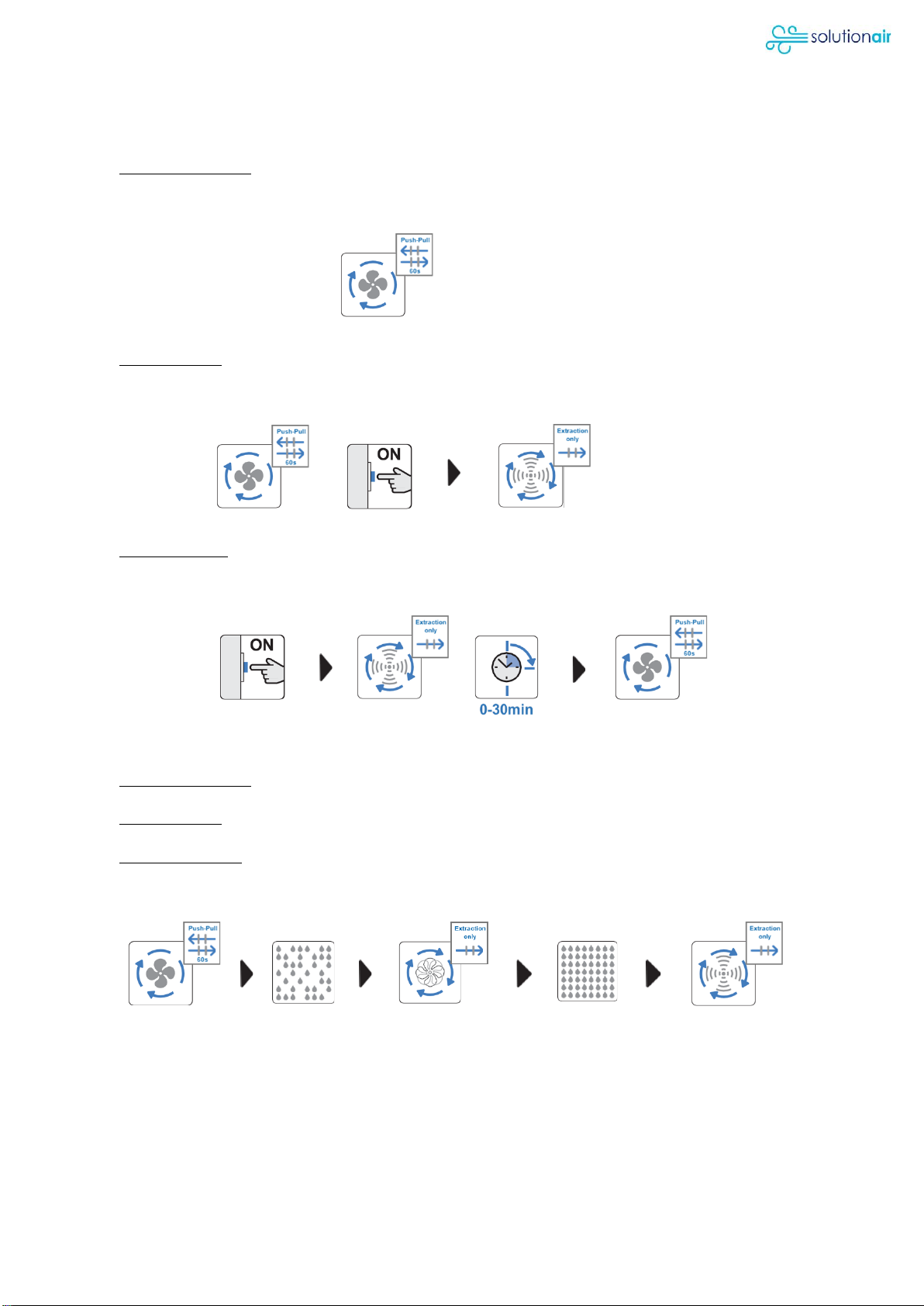

MODESL & OPERATION

REC-Duo 100

(I) 24h/7d operation: Alternating flow heat recovery mode (push-pull) at one of the two

fixed speeds that can be selected in the installation phase (see paragraph SPEED

SELECTION).

(II) Manual Boost: For faster air circulation, it is possible to activate the maximum speed

(boost) that only works in extraction, via remote control (light switch or dedicated switch

or RLS switch - not included in the supply).

(III) Boost duration: Adjustable timer is provided for setting maximum speed (boost) duration

from 0 to 30 minutes (see paragraph TIMER AND HUMIDISTAT). At the end of the timer

cycle, the unit automatically returns to the pre-set speed in 24-hour push-pull mode.

REC-Duo 100 MHY and PLUS RC

(I) 24h/7d operation: see REC DUO 100 (I)

(II) Manual Boost: see REC DUO 100 (I)

(III) Humidity control: Automatic faster air circulation (boost) with increase of humidity level.

Humidity threshold adjustable from 40% to 90% RH (see paragraph TIMER AND

HUMIDISTAT).

Once the room humidity is back to the pre-set level on the humidistat, the device

automatically switches to the 24-hour push-pull operating speed.

Page 16 / 17

LEGEND OF THE VENTILATION UNIT STATUS

LED

DESCRIPTION

STATUS

100

100

MHY

100

PLUS

RC

●

GREEN

EXTRACTION

●

●

●

●

YELLOW

INTAKE

●

●

●

●

RED

BOOST WITH TIMER

●

●

●

FLASHING RED

DIRTY FILTER NEEDS CLEANING

●

●

●

●

BLUE

MHY OPERATING

●

●

FADING BLUE

SLEEP FUNCTION OPERATING

●

FADING YELLOW OR GREEN

FREE COOLING (RC BUTTON 7)

●

FLASHING YELLOW OR GREEN

FORCED FLOW OPERATING

(RC Button 6)

●

FLASHING WHITE/LIGHT BLUE

RECEIVING COMMAND FROM RC

●

FLASHING RED/PURPLE

RESTORE FACTORY SETTINGS

●

●

PURPLE

LED INTENSITY ADJUSTMENT

●

FLASHING BLUE

DURING SPEED REGULATION 1

●

FLASHING PURPLE

DURING SPEED REGULATION 2

●

FLASHING LIGHT BLUE

SYNCRONISING DEVICES

CANCEL SYNCRONISATION

CANCEL RC PAIRING

●

FLASHING BLUE WITH EXTENDED

SEQUENCE

INDICATES A SLAVE UNIT

●

FLASHING GREEN

INDICATES A MASTER UNIT

●

Page 17 / 17

CLEANING AND MAINTENANCE

Do not use acid, corrosive or abrasive cleaners.

Do not use pressure washers, steam cleaning equipment.

We recommend replacing filters after a maximum of two cleanings.

RESETTING THE REPLACE/CLEAN FILTERS NOTICE (RED FLASHING LED)

Press the button "RESET" located at the base of the front support of the ventilation unit for more than 5 seconds.

When the LEDs turn violet, the reset successfully completed.

Use always the supplied awl key to press the "RESET" button.

DO NOT USE METALLIC OBJECTS!

CUSTOMER SERVICE

Contact:

Solutionair Customer Service

Email: enqui[email protected].nz

Phone: 0800 484 3269

This manual suits for next models

2

Table of contents

Popular Heating System manuals by other brands

MERK

MERK MEnV 180 Pro Operating & assembly instructions

Polypipe

Polypipe Silavent CMX Installation and operating instructions

nilan

nilan Combi 302 Polar Top Installation instruction

2VV

2VV ALFA 95 II vertical quick start

Etherma

Etherma EZ-800 Installation and operating instructions

Vectaire

Vectaire WHHRC180DC Installation, operating and maintenance instructions