- SAFETY2GVF Standard Topper-Hedger Manual

SAFETY

INTRO TO SAFETY

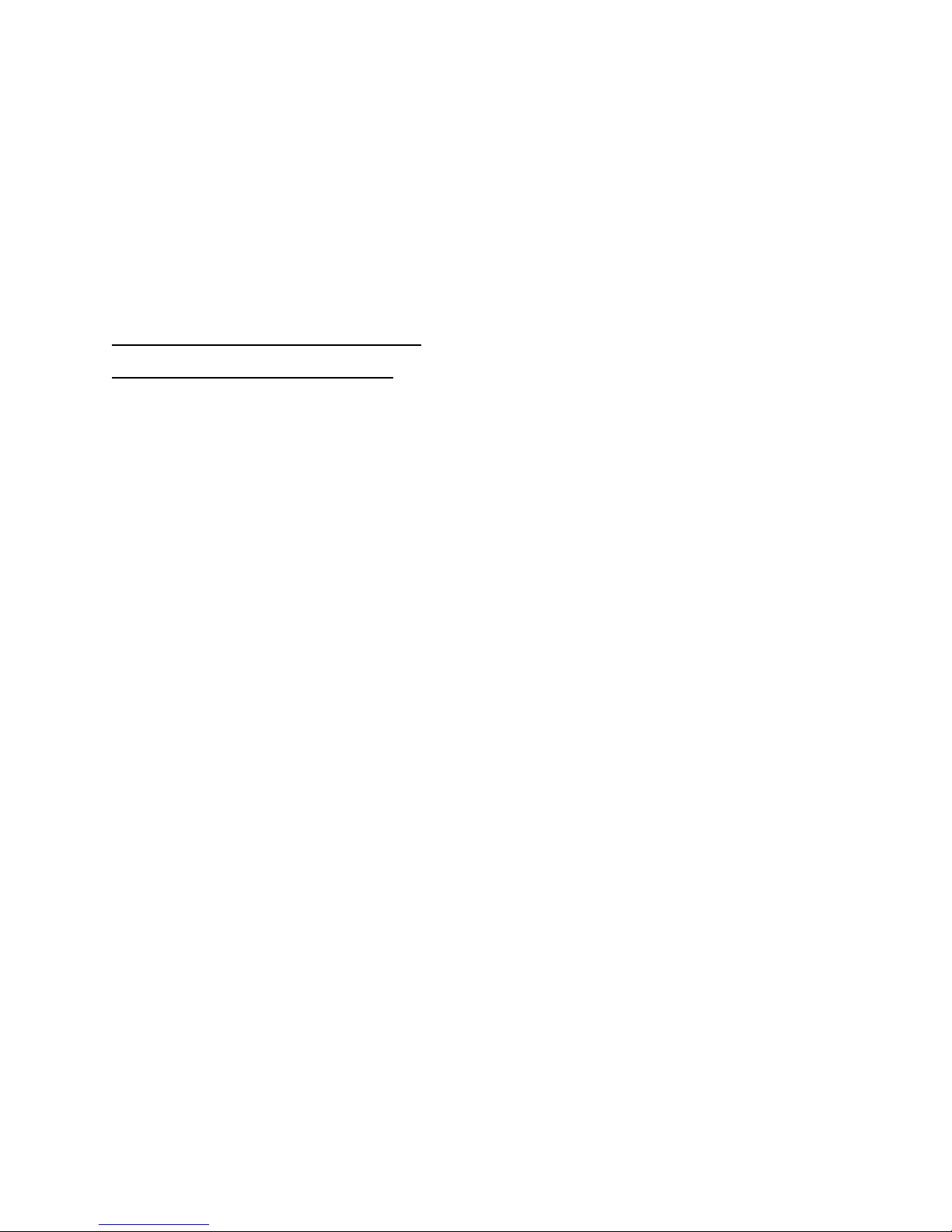

The safety of the operator is one of the main concerns

in designing a new piece of equipment. Designers

build in as many safety features as possible. However,

every year many accidents occur which could have

been avoided by a few seconds of thought and a more

careful approach to handling equipment. You, the

operator, can avoid many accidents by observing the

following precautions. To avoid personal injury, study

thefollowingprecautionsandinsistthoseworkingwith

you, or for your own self, to follow these precautions.

In order to provide a better view, certain photographs

or illustrations in this manual may show an assembly

with a safety shield removed. However, the equipment

should never be operated in this condition. Keep all

shields in place. If shield removal becomes necessary

for repairs, replace shield prior to further operation.

SAFETY ALERT SYMBOL

FIG. 1: This is the safety alert symbol. It means

ATTENTION! BECOME ALERT! YOUR SAFETY

IS INVOLVED! Lookforit,bothinthismanualand

on safety decals on the equipment. It will direct your

attention to information that involves your safety and

the safety of others.

SIGNAL WORDS

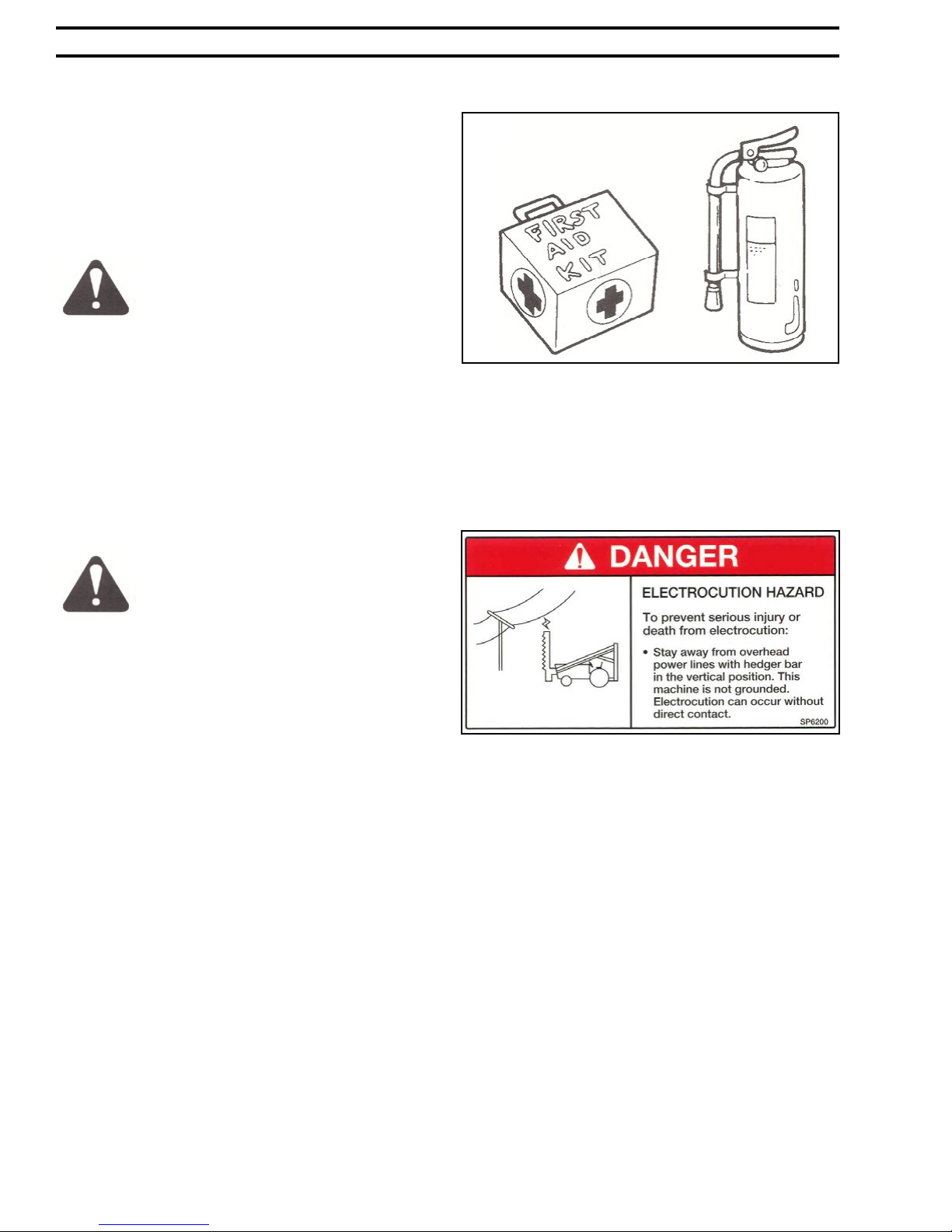

FIG. 2: The words DANGER, WARNING, or

CAUTION are used with the safety alert symbol.

Learn to recognize these safety alerts, and follow the

recommended precautions and safe practices.

DANGER indicates an imminently

hazardous situation that, if not avoided,

will result in death or serious injury.

WARNING indicates an imminently

hazardous situation that, if not avoided,

could result in death or serious injury.

CAUTION indicates an imminently

hazardous situation that, if not avoided,

could result in minor or moderate injury.

Replace any DANGER, WARNING, CAUTION or

instructional decal that is not readable or is missing. The

locationsandpartnumbersofthesedecalsareidentied

later in this section of the manual.

FIG. 1

FIG. 2