GIMA SpA DIATERMO 106

4 MA126IGBEa Manuale d’istruzioni / Instruction’s Manual / Manual de Instrucciones

INDICE / INDEX

IMPORTANTE / IMPORTANT / IMPORTANTE.......................................................3

INDICE / INDEX............................................................................................................4

1. INTRODUZIONE......................................................................................................6

1.1 CONTROLLO LISTA PARTI .................................................................................................................... 6

1.2 DESCRIZIONE GENERALE.................................................................................................................... 6

1.3 TAGLIO MONOPOLARE........................................................................................................................ 6

1.4 COAGULAZIONE MONOPOLARE .......................................................................................................... 7

2. SICUREZZA ..............................................................................................................8

2.1 GENERALE.......................................................................................................................................... 8

2.2 INSTALLAZIONE................................................................................................................................... 9

2.3 STANDARD DI SICUREZZA APPLICABILI................................................................................................ 9

3. INSTALLAZIONE ..................................................................................................10

4. CONNETTORI E CONTROLLI............................................................................11

4.1 TARGA SUL PANNELLO POSTERIORE .................................................................................................. 11

4.1.1 Dati Identificativi del Distributore....................................................................................... 11

4.1.2 Dati Tecnici .......................................................................................................................... 11

4.1.3 Significato dei Simboli Grafici............................................................................................. 11

4.2 PANNELLO POSTERIORE.................................................................................................................... 11

4.2.1 Modulo di Alimentazione della Apparecchiatura e Selettore di Tensione.......................... 11

4.2.2 Interruttore di Alimentazione............................................................................................... 12

4.3 PANNELLO FRONTALE....................................................................................................................... 12

4.3.1 Pulsanti d'uso........................................................................................................................ 12

4.3.2 Connettori............................................................................................................................. 13

4.3.3 Indicatori di avvertimento.................................................................................................... 13

5. CARATTERISTICHE TECNICHE.......................................................................14

5.1 GENERALI......................................................................................................................................... 14

6. MANUTENZIONE..................................................................................................15

6.1 GENERALITÀ..................................................................................................................................... 15

6.2 PULIZIA DEL CONTENITORE .............................................................................................................. 15

6.3 PULIZIA E STERILIZZAZIONE DEGLI ACCESSORI ................................................................................. 15

6.4 CONTROLLO DELL'APPARECCHIATURA PRIMA DELL'USO................................................................... 15

6.5 CONTROLLO E MISURA DI FUNZIONI DI SICUREZZA............................................................................ 15

* * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * *

1. INTRODUCTION....................................................................................................17

1.1 CHECK-LIST...................................................................................................................................... 17

1.2 GENERAL DESCRIPTION.................................................................................................................... 17

1.3 MONOPOLAR CUTTING ..................................................................................................................... 17

1.4 MONOPOLAR COAGULATION ............................................................................................................ 18

2. SAFETY....................................................................................................................19

2.1 GENERAL.......................................................................................................................................... 19

2.2 INSTALLATION.............................................................................................................................. 20

2.3 APPLICABLE SAFETY STANDARDS............................................................................................ 20

3. INSTALLATION.....................................................................................................21

4. CONNECTORS AND CONTROLS.......................................................................22

4.1 LABEL ON THE REAR PANEL ...................................................................................................... 22

4.1.1 Dealer's Identification Data................................................................................................. 22

4.1.2. Technical Data .................................................................................................................... 22

4.1.3 Graphic Symbols' Meaning.................................................................................................. 22

4.2 REAR PANEL.................................................................................................................................. 22

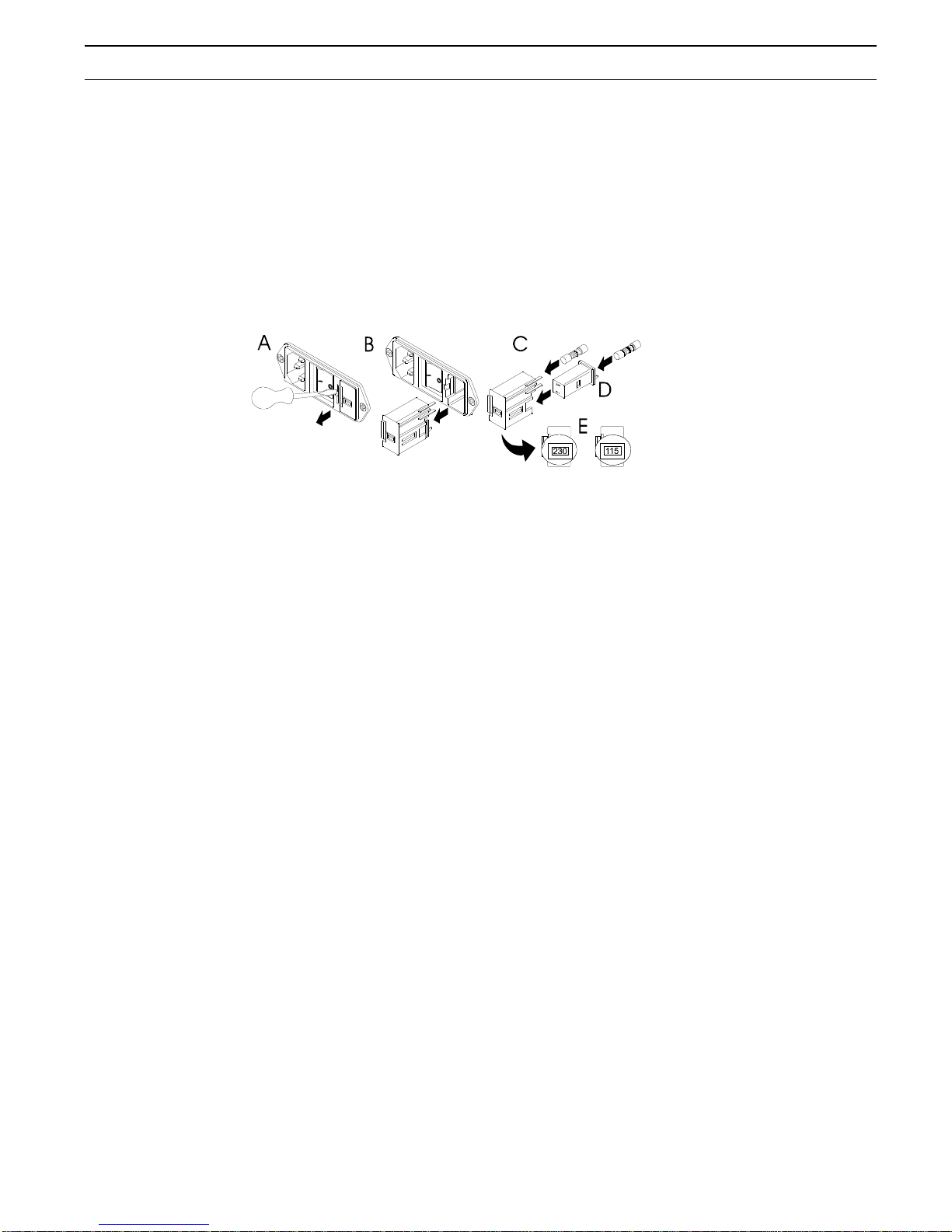

4.2.1 Equipment Mains Input Module and Voltage Selector........................................................ 23

4.2.2 Power On-Off Switch............................................................................................................ 23

4.3 FRONT PANEL............................................................................................................................... 23

4.3.1 User Keys.............................................................................................................................. 23

4.3.2 Connector ............................................................................................................................. 24