•When a check valve is used, a 3/16” (4.7mm) air bleed hole must be drilled in

the PVC pipe above the pump. Drill the hole at a 45º angle toward the bottom

of the sump to avoid splashing water outside the sump pit. Make sure the hole

is above the water line, and below the check valve. If a hole is not drilled

above the pump, an air lock may prevent the pump from operating.

•The pump must receive 115V AC +/- 5% and 60 Hz from the AC outlet.

•

•

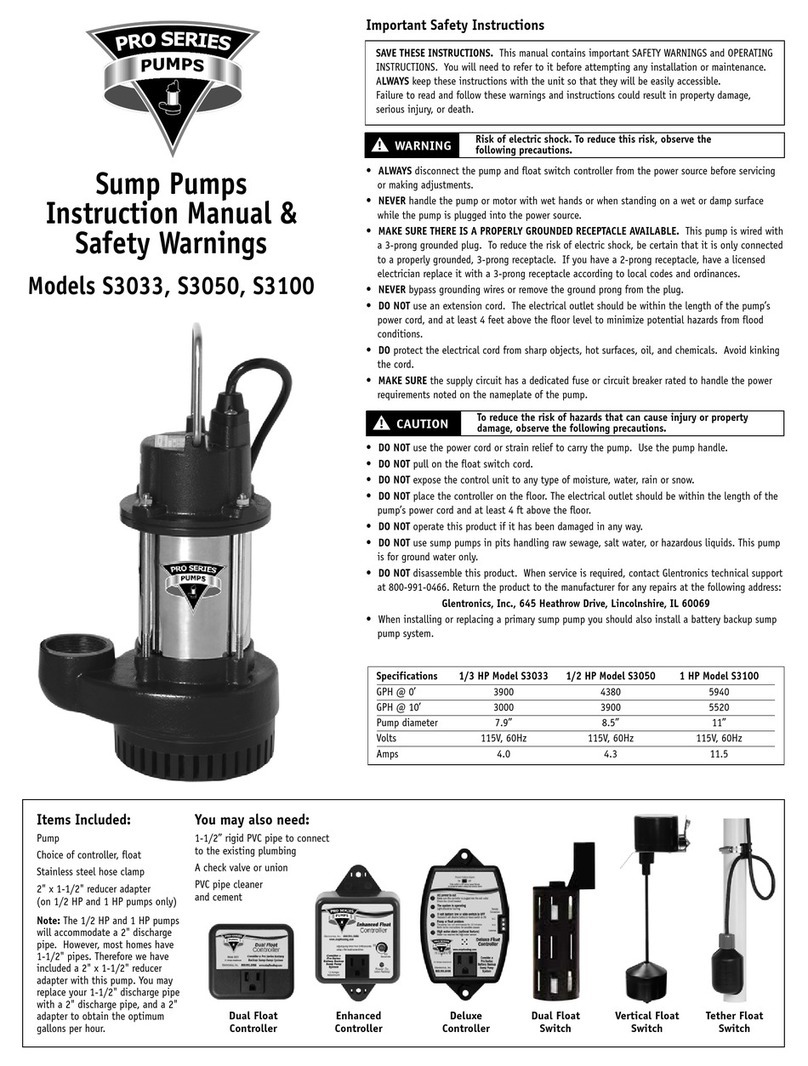

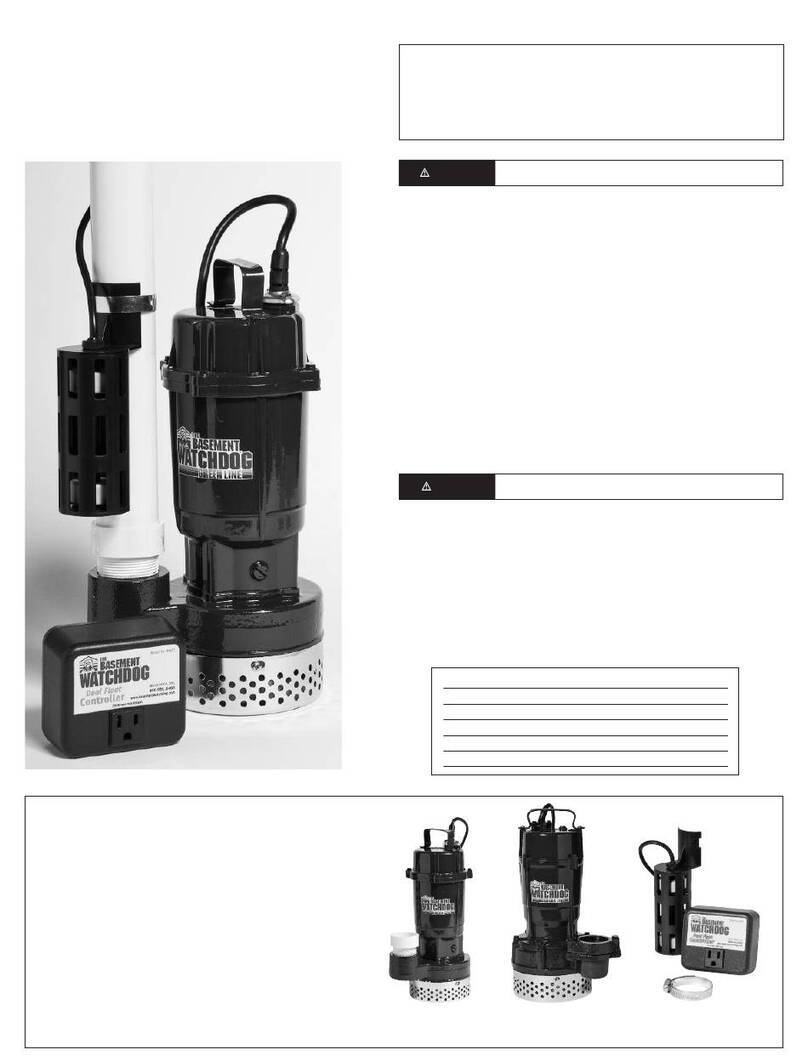

This pump will not provide protection during a power outage. With the risk of

property damage from high water levels, the addition of a Pro Series battery backup

sump pump system is highly recommended.

After the initial installation, be sure to check the operation by filling the sump

with water and observing the pump operation through several full cycles.

•In instances where the discharge line is exposed to freezing temperatures, the pipe

must be sloped downward so any remaining water will drain out. Failure to do so

will prevent water from exiting the sump and damage the pump if the line freezes.

Installation Instructions

Prior to Installation

1. Visually inspect your pump. Products may be damaged during shipping. If the

product has been damaged, contact your place of purchase or Glentronics, Inc.

before installation.

2. Make sure the float switch bracket is level and the float switch and float switch rod

is straight.

3. Thoroughly read the instructions provided to learn specific details regarding

installation and use. This manual should be retained for future reference.

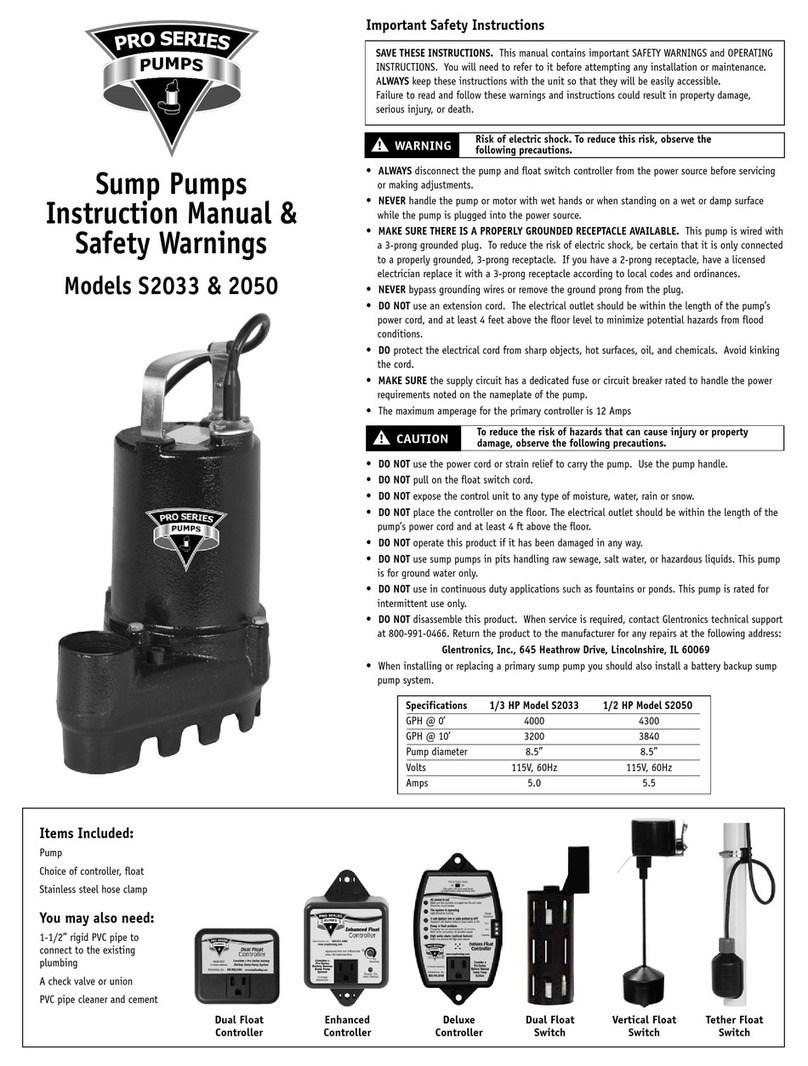

1.

2.

3.

Use a pit that conforms to all local codes

and is large enough to accommodate the

pump and float switch. The minimum

requirements for the 1/3 HP pump with the

vertical float switch are 9-1/2” in diameter

and 14” deep. However, larger sump pits

are preferred, since they will extend the

discharge cycle and reduce the number of

times the pump turns on.

Clean the pit of all debris. The pump’s

strainer must be kept clear.

The pump should not be set directly onto a

clay, earthen, or sand base. Install bricks

or blocks under the pump to provide a solid

base.

4.

5.

The pump should be level.

Install discharge plumbing according to

local, regional and state codes. Rigid PVC

pipe is recommended.

6. An in-line check valve is recommended to

prevent back-flow. This check valve is

mandatory when sharing a discharge line

with another pump (i.e. a back-up pump or

a second primary pump).

(a)

When a check valve is used, a 3/16”

(4.7mm) air bleed hole must be drilled in the PVC pipe above the pump.

Drill the hole at a 45º angle toward the bottom of the sump to avoid

splashing water outside the sump pit. Make sure the hole is above the water

line, and below the check valve. If a hole is not drilled above the pump, an

air lock may prevent the pump from operating.

7. Install a gate valve or ball valve if required by any codes.

8. The pipe must be positioned in a downward slope so any remaining water will drain

away. Failure to do this will prevent water from exiting

the pit and damage the pump if the line freezes.

9. If you are replacing an old sump pump:

(a)a nplug the pump from the outlet.

(b) Loosen the check valve or rubber union by unscrewing

the bottom hose clamp. (If the existing system is

installed without a check valve or rubber union, saw

the pipe apart above the sump pit.)

(c)

(d)

Remove the old pump and unscrew the pipe and adapter.

If the adapter fits into the new pump, screw the pipe into the pump. If not,

cut a piece of rigid PVC pipe and connect it to the new adapter by cleaning and

cementing the two pieces together. (Follow the instructions on the PVC cleaner

and cement.)

(e) Lower the pump into the sump by the handle.

(f) To avoid debris pouring onto the float, it should be positioned on the side

opposite of the drain tile. Note: It is desirable to have the vertical float below

the drain tile that empties into the pit (see Diagram A).

The vertical float switch

must be moving freely at all times. Make sure the float switch does not come

into contact with other pumps, wires, pipes or any other object that may be in

the sump pit. The float switch must not come into contact with the sump pit

floor or wall. If the float switch does not move freely the pump will not activate.

(g) Connect the pipe on the pump to the existing discharge pipe with a rubber union

or check valve and tighten the hose clamps securely.

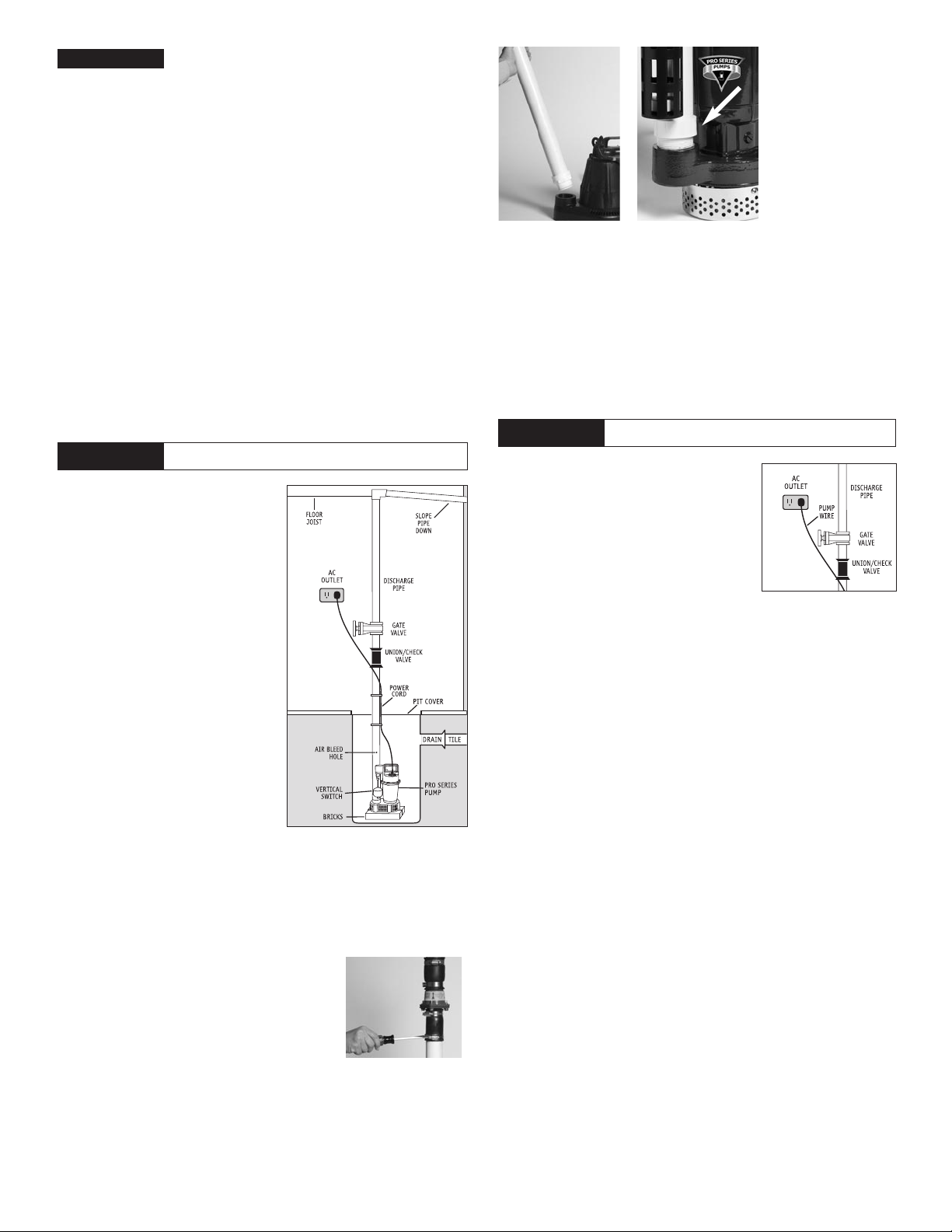

Connecting the Pump

Plug the pump directly into a properly grounded, 3-

prong receptacle. If you have a 2-prong receptacle,

have a licensed electrician replace it with a 3 prong

receptacle according to local codes and ordinances.

For a neater installation, secure the power cords to the

discharge pipe with wire ties or hose clamps. Keep the

cords separated from each other on opposite sides of

the pipe.

Completing the Installation

1. After the initial installation, be sure to check the pump operation by filling the sump

with water and observing the pump through several full cycles. Note: When the pump

activates, it should have a “normal pumping” sound. Any abnormal sound, vibration, or

lack of output is the signal of a problem. Stop the pump and refer to the

troubleshooting guide.

2. Replace the pit cover making sure not to pinch or crimp the pump wire with the

cover. The pit cover either has a ‘hole punch’ that will allow the cord to be passed

through or one can be drilled in the cover.

Product Operation

Float Switch

The vertical float switch contains a single large float. Water will lift the float to the

top of the lift rod, raise the lift rod and activate the pump. As the pump evacuates the

water from the pit the float will drop to the lower float stop, lowering the lift rod and

turning off the pump. The position of the lower float stop is the “off-point”. The

pumping range can be adjusted by moving the lower float stop up lift rod. The lift rod

has several barbs to hold the float stop in place. DO NOT lower the float stop below

the top barb or it will prevent the pump from shutting off and the pump will run

continuously. The lift rod must be able to move freely up and down to turn on and

off the pump. The default position of the lower float stop is set for maximum pumping

range. This will allow for longer pumping cycles and extend the life of the pump. After

making any adjustments to the float stop be sure to check the operation by filling the

sump with water and observing the pump operation through several full cycles.

Maintenance Check List

Maintenance should be performed 1-2 times per year.

1. Remove all debris from the bottom of the pit and pump inlet screen.

2. Remove all debris floating in the water.

3. Remove all debris from the float switch

.

4. Fill the pit with water. Make sure pump turns on at the intended level.

5.

6.

While the pump is running, make sure pump is evacuating water at a good pace.

While the pump is running, make sure a stream of water is escaping from the air

bleed hole. If not, clear the hole of any deposits or debris.

NOTICES

WARNING

WARNING

This installation must be in accordance with the National

Electric Code and all applicable local codes and ordinances.

Make sure the outlet is single phase, 115V and 60HZ

for all the pump installations.

2

9B

9C 9D

Diagram A