GM

COACH

OPERATION

DOOB

CONTROLS

(Cont.)

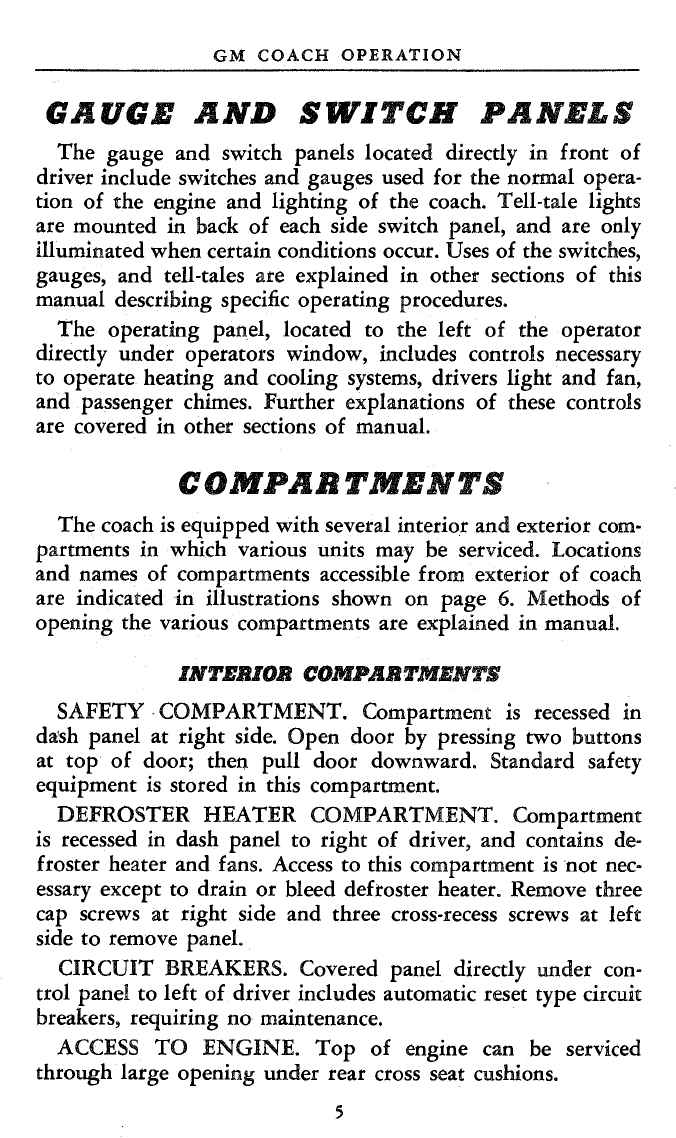

Front entrance door can be manually closed from outside

after control lever

is

pulled from latched open position. From

outside, push door until closed and latched. Unlatch door from

outside by pulling on release button which extends through

body

at

front. After button

is

pulled, door can be pulled open

from outside (see illustration, page 9).

BMBBGBNCY DOOB

Emergency door is secured shut with lever type latch handle

(page 9) .

When

latch handle

is

lifted

or

not secure!y in place,

a switch acts to

light

tell-tale, "EMERG

DOOR,"

on

left

switch

panel in front

of

operator (page 4). An alarm buzzer also ·

sounds when latch is

not

secure.

On

standard coaches, engine

control switch must be placed in

"RUN"

position before tell-

tale and alarm buzzer are energized. Some coaches have a con-

stant circuit to emergency door.

IJlDIJ

WINDOWS

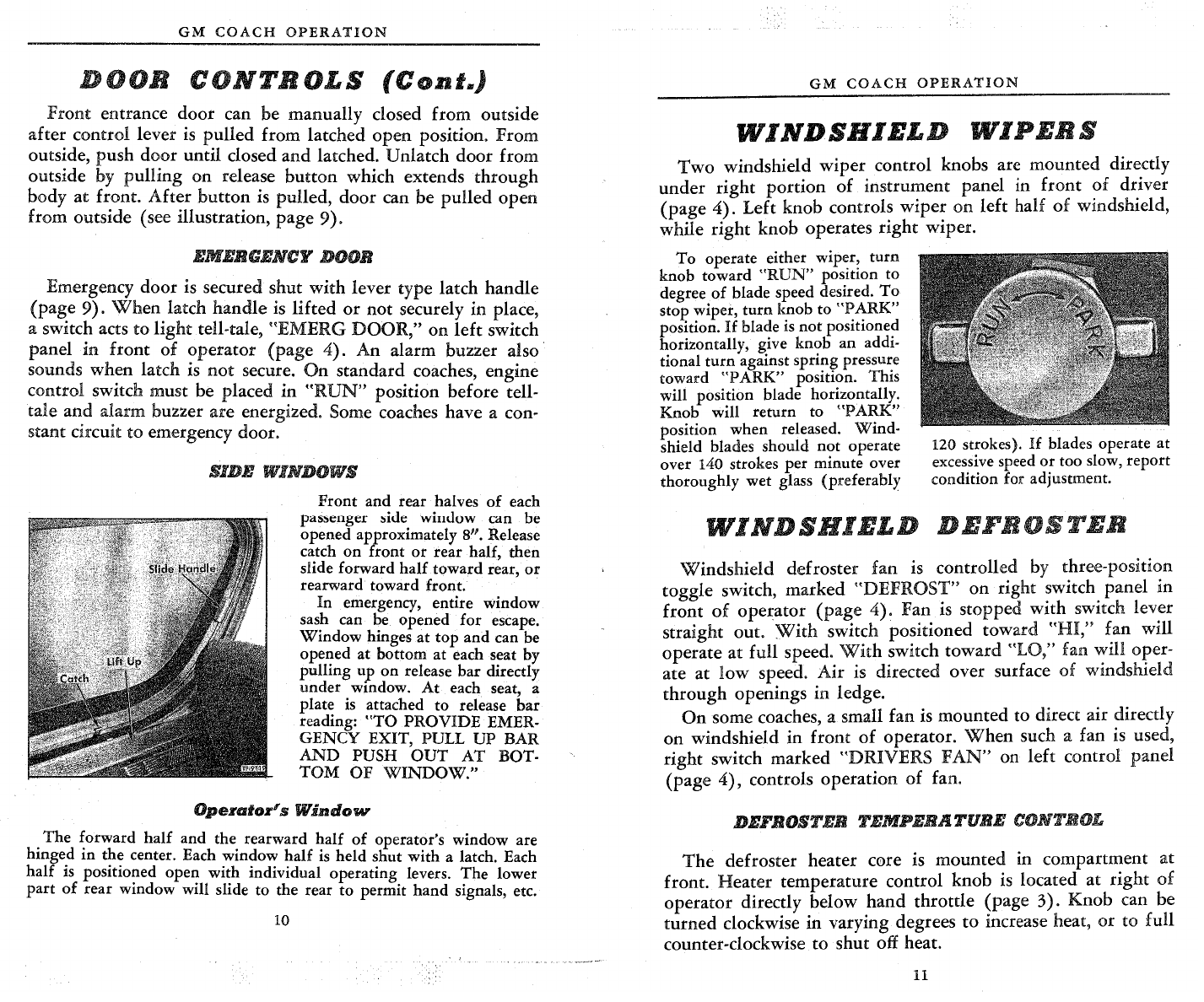

Front

and rear halves

of

each

passenger side window can be

opened approximately 8". Release

catch

on

front

or

rear half,

then

slide forward

half

toward

rear,

or

rearward toward front.

In

emergency, entire window

sash can be opened

for

escape.

Window

hinges

at

top

and

can be

opened

at

bottom at each seat by

pulling

up

on

release

bar

directly

under

window.

At

each seat, a

plate

is

attached

to

release

bar

reading:

"TO

PROVIDE

EMER-

GENCY

EXIT, PULL

UP

BAR

AND

PUSH

OUT

AT

BOT-

TOM

OF

WINDOW."

Operator's

Window

The

forward

half

and the rearward

half

of

operator's window are

hinged

in

the

center. Each window

half

is

held

shut

with

a latch. Each

half

is positioned open

with

individual operating levers.

The

lower

part

of

rear window will slide

to

the rear

to

permit

hand

signals, etc.

GM

COACH

OPERATION

WINDSBIBLD

WIPBBS

Two

windshield wiper control knobs are mounted directly

under

right

portion of instrument panel in front

of

driver

(page

4).

Left knob controls wiper on left half

of

windshield,

while right knob operates right wiper.

To

operate either

wip~r~

turn

knob toward

"RUN"

pos!Uon

to

degree

of

blade speed desired.

To

stop wiper,

turn

knob

to

"PARK"

position.

If

bla~e is

not

positione?

horizontally, give knob an addi-

tional

turn

against spring pressure

toward

"PARK"

position. This

will

position blade horizontally.

Knob will return to

"PARK"

position when released.

Wind-

shield blades should

not

operate

over 140 strokes

per

minute over

thoroughly wet glass (preferably

120 strokes). If blades operate

at

excessive speed

or

too slow,

report

condition for adjustment.

WINDSHIBLD

DBFBOSTBB

Windshield defroster fan

is

controlled

by

three-position

toggle switch, marked "DEFROST" on right switch panel in

front

of

operator (page 4). Fan

is

stopped with switch lev~r

straight out.

With

switch positioned toward

"HI,"

fan will

operate at full speed.

With

switch toward "LO," fan

':ill

Ofer-

ate at

low

speed. Air

is

directed over surface

of

wmdsh1eld

through openings in ledge.

On

some coaches, a small fan

is

mounted

to

direct air directly

on windshield in front

of

operator.

When

such a fan

is

used,

right switch marked "DRIVERS

FAN"

on left control panel

(page

4),

controls operation

of

fan.

DBFB.OSTBB

TBMPBBATUBB

CONTROL

The

defroster heater c0re is mounted in compartment at

front.

Heater

temperature control knob

is

located at right

of

operator directly below hand throttle (page 3). Knob can be

turned clockwise in varying degrees

to

increase heat, or to full

counter-clockwise

to

shut off heat.

11