OM-07305HSK SERIES

PAGE B - 3INSTALLATION

damage to the pump or components

can occur if lifting bail is not properly

secured to the base of the unit. Use only

the hardware provided from the factory

to relocate or remount the lifting bail.

NOTICE

Ensure the hydraulic hoses are correctly

attached to the hydraulic power unit for re

mote operation. Connecting these hoses

in reverse order will not allow the pump to

cycle or produce discharged fluid.

To operate the hydraulic driven sludge pump dis

mounted from the hydraulic power unit, it may be

come necessary to adjust the location of the power

unit lifting bail for level lifting. This should be done

using caution to ensure all factory provided

mounting hardware is utilized. Use only the hard

ware provided with the unit as it is appropriately se

lected to secure the load.

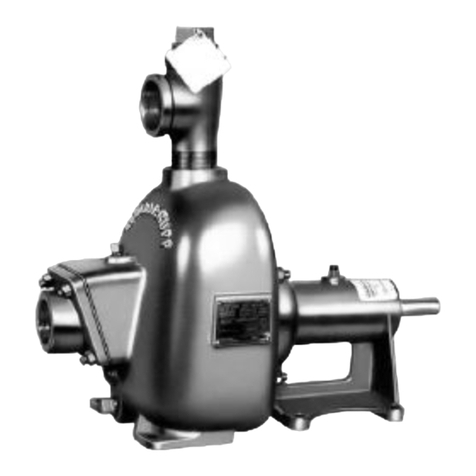

SUCTION AND DISCHARGE PIPING

Pump performance is adversely effected by in

creased suction lift, discharge elevation, and fric

tion losses. Friction losses will increase with

greater viscosity of material being pumped. See

the performance curve and notes on Page E‐1 to

be sure your overall application allows pump to op

erate within the safe operation range.

Always keep the pump as close as possible to the

product to be pumped. Keep the suction line

length, number of fittings and direction changes to

a minimum. Do not use a suction line smaller than

the pump suction connection. This pump is self‐

priming on water from a dry start to 21 foot depths.

Materials

Either pipe or hose maybe used for suction and

discharge lines; however, the materials must be

compatible with the liquid being pumped. If hose is

used in suction lines, it must be the rigid‐wall, rein

forced type to prevent collapse under suction. Us

ing piping couplings in suction lines is not recom

mended.

Line Configuration

Keep suction and discharge lines as straight as

possible to minimize friction losses. Make mini

mum use of elbows and fittings, which substantial

ly increase friction loss. If elbows are necessary,

use the long‐radius type to minimize friction loss.

Connections to Pump

Before tightening a connecting flange, align it ex

actly with the pump port. Never pull a pipe line into

place by tightening the flange bolts and/or cou

plings.

Lines near the pump must be independently sup

ported to avoid strain on the pump which could

cause excessive vibration and strain on support

brackets. If hose‐type lines are used, they should

have adequate support to secure them when filled

with liquid and under pressure.

Gauges

Most pumps are drilled and tapped for installing

discharge pressure and vacuum suction gauges.

Use only liquid filled gauges for reciprocating

pump.

SUCTION LINES

To avoid air pockets which could affect pump prim

ing, the suction line must be as short and direct as

possible. When operation involves a suction lift, the

line must always slope upward to the pump from

the source of the liquid being pumped; if the line

slopes down to the pump at any point along the

suction run, air pockets will be created.

Fittings

Suction lines should be the same size as, or larger

than, the pump inlet. If reducers are used in suction

lines, they should be the eccentric type, and

should be installed with the flat part of the reducers

uppermost to avoid creating air pockets. Valves

are not normally used in suction lines, but if a valve

is used, install it with the stem horizontal to avoid air

pockets.

Sealing

Since even a slight leak will affect priming, head,

and capacity, especially when operating with a