02/ 2019

DUSPOL

®

analog 1000

7

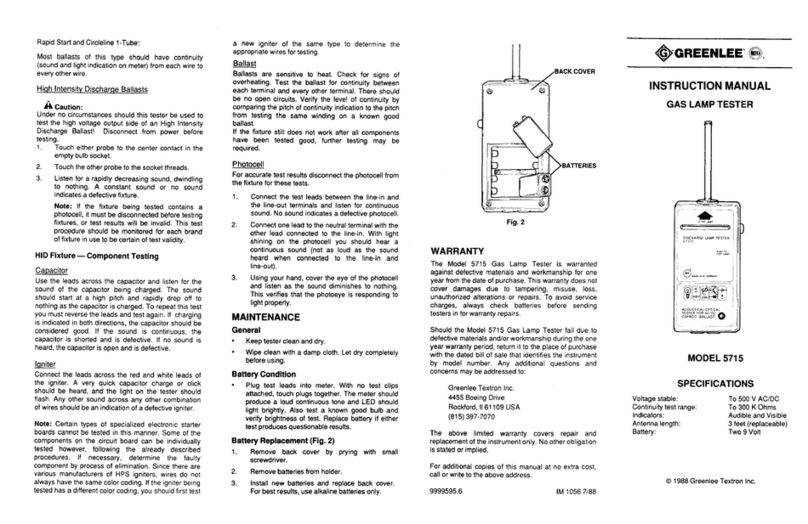

4. Checking the absence of voltage of an installation

(figure A/B)

For checking the installation, please test the absence of volt-

age by checking the voltage indication, the phase indication

(the phase indication only works in an earthed AC voltage

mains) and the vibration motor (the vibration motor is activated

by actuating both push-buttons). The installation is only free

of voltage, if all three test circuits (voltage indication, phase

indication and vibration motor) are signaling the absence of

voltage.

- Apply the two probe tips L1/+ 2and L2/- 3to the system

parts to be tested.

- The level of voltage applied is indicated by means of the

LED step indicator 8.

- Actuate both push-buttons 5to connect the plunger coil

level indicator 4, the 12 V LED step (+/ -) and an internal

load in the voltage tester.

- Alternating voltages (AC) are indicated by the +24 V LED

and the -24 V LED lighting up simultaneously.

- Direct voltages (DC) are indicated by the +24 V LED or the

-24 V LED lighting up. The polarity indication Jshows the

SRODULW\ (+ or -) applied to the probe tip L2/+ 3.

- To differentiate between low-energy and high-energy volt-

ages (e.g. capacitively induced interference voltages), an

internal load in the voltage tester can be connected by ac-

tuating both push-buttons (see section 5).

5. Load connection with vibration motor ¿JXUH$%

Both handles L1 6and L2 7are equipped with push-buttons

5. Actuate both push-buttons to switch to a lower internal re-

sistance. Here, voltage is applied to a vibration motor (motor

with unbalanced mass). From approx. 200 V on, this motor is

set in rotary motion. With the voltage increasing, the motor's

speed and vibration increases as well. The duration of the test

with a lower internal resistance (load test) depends on the level

of voltage to be measured. In order to avoid an inadmissible

warming of the device, it is provided with a thermal protection

(controlled reduction). With this controlled reduction, the speed

of the vibration motor is reduced and the internal resistance

increases.

The load connection (with both push-buttons being actuated)

can be used ...

- to suppress reactive voltages (inductive and capacitive

voltages),

- to charge capacitors,

- to trip 10 mA/ 30 mA RCD safety switches. The tripping

of the RCD safety switch is done by testing the external

conductor (phase indication) to PE (earth). (figure D)

([WHUQDOFRQGXFWRUWHVWSKDVHLQGLFDWLRQ¿JXUH&

- Fully grasp the handles L1 6and L2 7, in order to en-

sure a capacitive coupling to earth.

- Apply the probe tip L2/+ 3to the system part to be tested.

During the single-pole external conductor test (phase in-

dication), make absolutely sure not to touch the probe tip

L1/- 2and that it remains contactless.

- If an "R" symbol is shown on the LC display 9, the exter-

nal conductor (phase) of an AC voltage is applied to this

system part.

Note:

The single-pole external conductor test (phase indication)

can be carried out in an earthed mains from 230 V, 50/60 Hz

(phase to earth) on. Protective clothing and insulating condi-

tions on site might impair the function.

Attention!

The absence of voltage can only be determined by means of

a two-pole test.

7. Phase sequence test¿JXUH()

- Fully grasp both handles L1 6and L2 7, in order to en-

sure a capacitive coupling to earth.

-

Apply the probe tips L1/-

2

and L2/+

3

to two external

conductors (phases) of a three-phase mains (without actua-

tion the push-buttons

5

) and check whether the external

conductor voltage of e.g. 400 V is applied

.

- A clockwise phase sequence (phase L1 before phase L2)

is given, if an "R" symbol is shown on the LC display 9.

Nothing is shown on the LC display, if no clockwise phase

sequence has been detected.

- The phase sequence test always requires a countercheck!

If the LC display shows the clockwise phase sequence by

means of the "R" symbol, the LC display must show noth-

ing during the countercheck with the probe tips L1/- 2

and L2/+ 3being inverted.

If the LC display shows the "R" symbol in both cases, the

earthing is too weak.

Note:

The phase sequence test can be carried out in an earthed

three-phase mains from 400 V - 900 V, 50 / 60 Hz (phase to

phase) on. Protective clothing and insulating conditions on site

might impair the function.

8. Technical data

- regulation: DIN EN 61243-3: 2015, IEC 61243-3: 2014

- nominal voltage range: 12 V to 1,000 V AC/DC

- nominal frequency range f: 0 to 60 Hz

- max. indication error: Un±15%, ELV Un+0% -15%

- Impedance (internal resistance) of measuring circuit/ load

FLUFXLWNȍNȍ

- current consumption of measuring circuit: Is< 6,0 mA

(1,000 V)

- current consumption of load circuit: Is< 550 mA (1,000 V)

- polarity indication: + 24 V LED, - 24 V LED, + 12 V LED,

- 12 V LED (with push-buttons being actuated)

H[WHUQDO FRQGXFWRU WHVW SKDVH LQGLFDWLRQ 8n230 V,

50 Hz/ 60 Hz

SKDVHVHTXHQFHWHVW8n400 V, 50 Hz/ 60 Hz

YLEUDWLRQPRWRUVWDUW8n200 V

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com