4 308-316

FIRE, EXPLOSION, AND ELECTRIC SHOCK HAZARD

Improper

grounding, poor air ventilation, open flames, or sparks can cause a hazardous condition

and result in fire or explosion, electric shock and other serious injury

.

D

All electrical wiring must be done by trained and qualified personnel.

D

Ground the equipment and the object being sprayed. See

Grounding the System

on page 5.

D

Provide fresh air ventilation to avoid the buildup of flammable fumes from solvent or the fluid be

-

ing sprayed.

D

Extinguish all the open flames or pilot lights in the spray area.

D

Electrically disconnect all the equipment in the spray area.

D

Keep the spray area free of debris, including solvent, rags, and gasoline.

D

Do not turn on or of

f any light switch in the spray area while operating or if fumes are present.

D

Do not smoke in the spray area.

D

Do not operate a gasoline engine in the spray area.

D

If there is any static sparking while using the equipment,

stop spraying immediately

. Identify

and correct the problem.

WARNING

WARNING

Table

of Contents

Symbols 2.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warning 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pour

Nozzle Performance Information

4.

. . . . . . . . .

Terms 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Grounding

the System

5.

. . . . . . . . . . . . . . . . . . . . .

Connecting

the Hoses

6.

. . . . . . . . . . . . . . . . . . . . . .

The

Solvent Flushing System

6.

. . . . . . . . . . . . . . .

Operation 7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Piston

Rod Safety Lock

7.

. . . . . . . . . . . . . . . . . . . . .

General

Startup

7.

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lubricating

Parts

9.

. . . . . . . . . . . . . . . . . . . . . . . . . .

Needle/Nozzle

Assembly Maintenance

9.

. . . . . . .

Needle/Nozzle

Assembly Repair or

Replacement 10.

. . . . . . . . . . . . . . . . . . . . . . . . .

Air

V

alve Piston and Spool

Maintenance 14.

. . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service 17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lubricating

Parts

17.

. . . . . . . . . . . . . . . . . . . . . . . . .

Tools 17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing

the Gun from the Production Line

18.

.

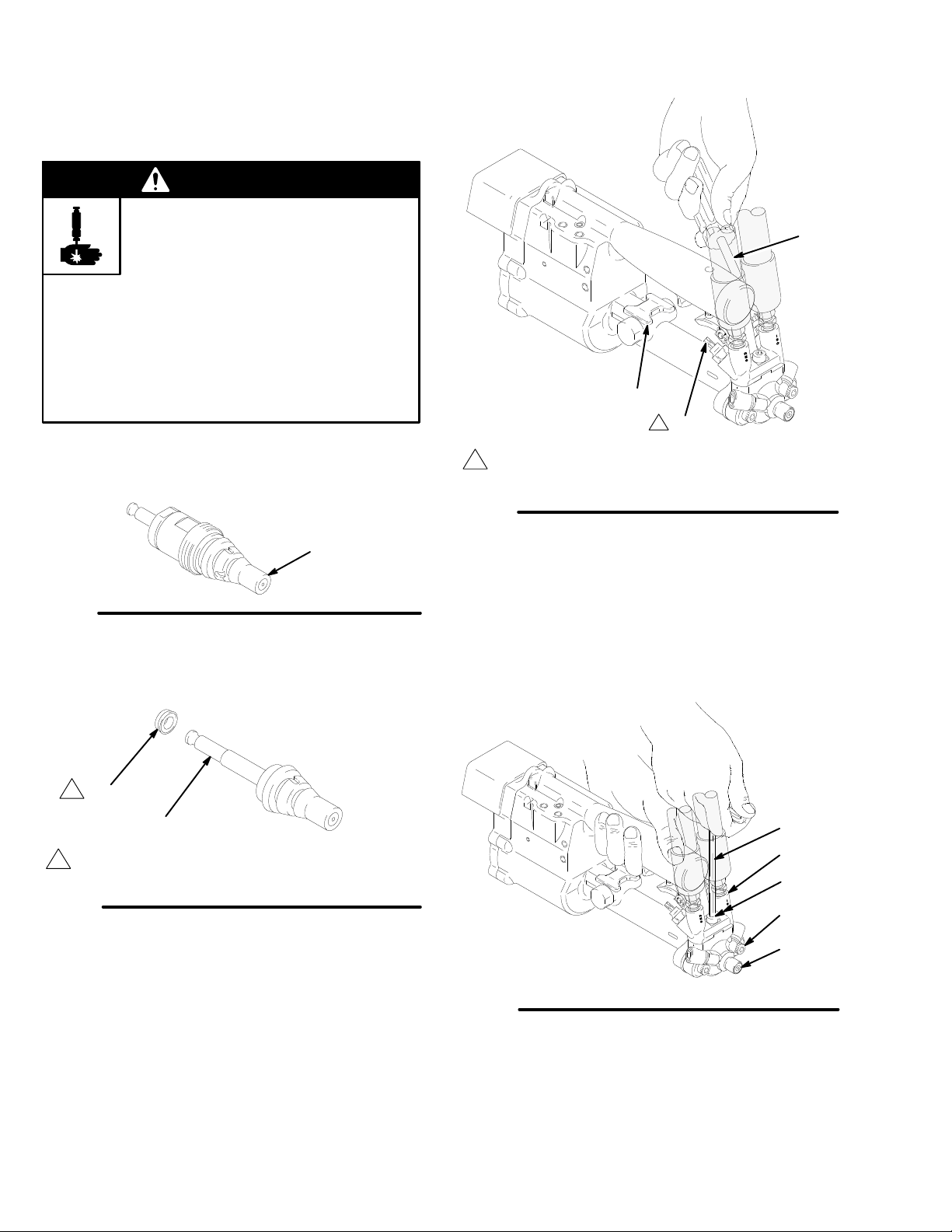

Solenoid

V

alve 20.

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Receptacle

Assembly

21.

. . . . . . . . . . . . . . . . . . . . .

Air

V

alve Piston Assembly

22.

. . . . . . . . . . . . . . . . .

Piston

Rod Safety

24.

. . . . . . . . . . . . . . . . . . . . . . . .

Air

V

alve Spool Assembly

25.

. . . . . . . . . . . . . . . . . .

Trigger

Switch

27.

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Assemble

the Gun

28.

. . . . . . . . . . . . . . . . . . . . . . . .

Install

the Gun on the Production Line

29.

. . . . . . .

Manifold

Needle V

alves Replacement

30.

. . . . . . .

Parts 32

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories 34

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graco

Phone Numbers

34.

. . . . . . . . . . . . . . . . . . . . . .

Technical

Data

35.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warranty 36

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pour

Nozzle Performance Information

The

0.215 in. (5.46 mm) diameter nozzle was

designed to optimize pour foam quality at a flow rate of

80 grams per second, with the two foam components

heated to 150

_F (66_

C). Depending on the specific

system, these parameters may need to be adjusted

slightly to obtain the desired results.