Foam r Manual 8

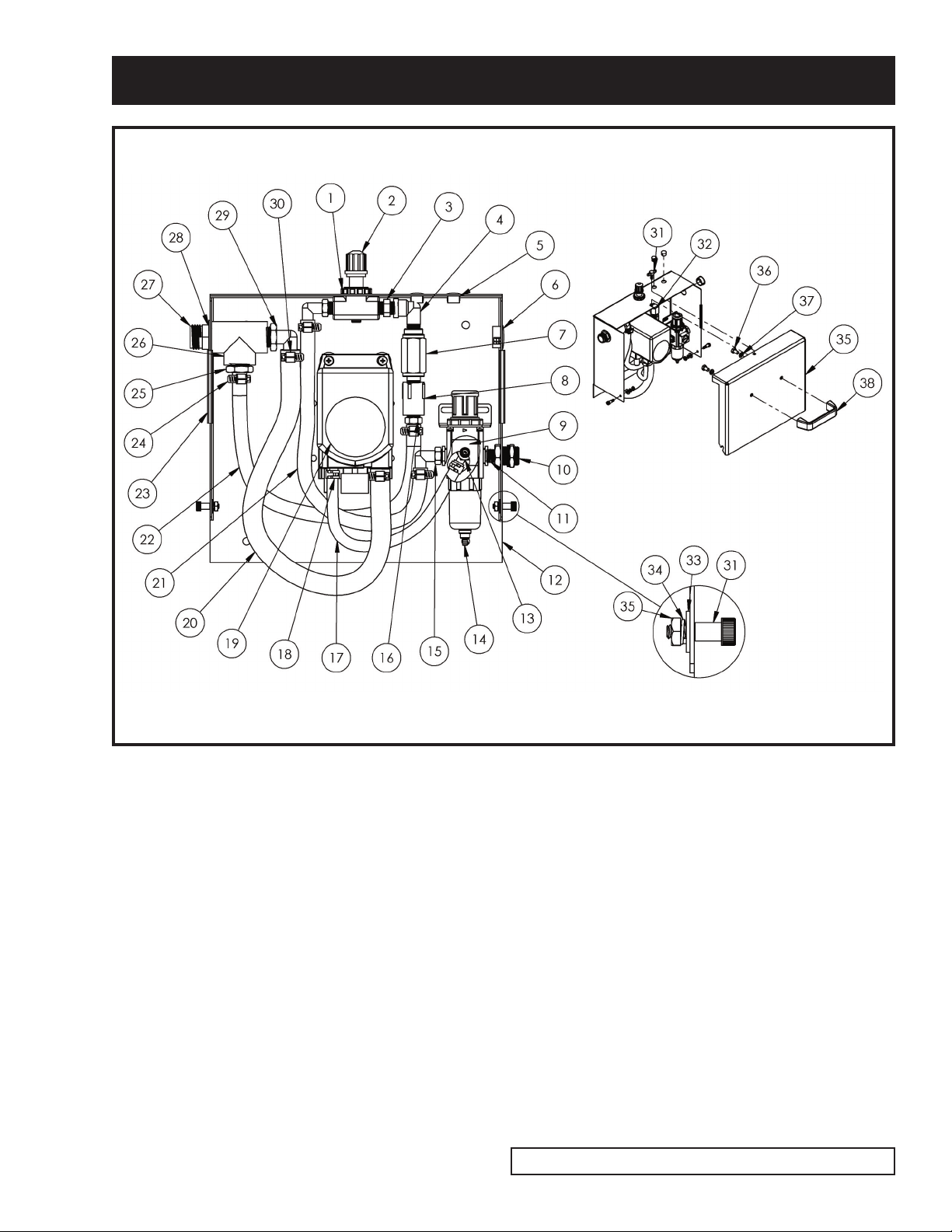

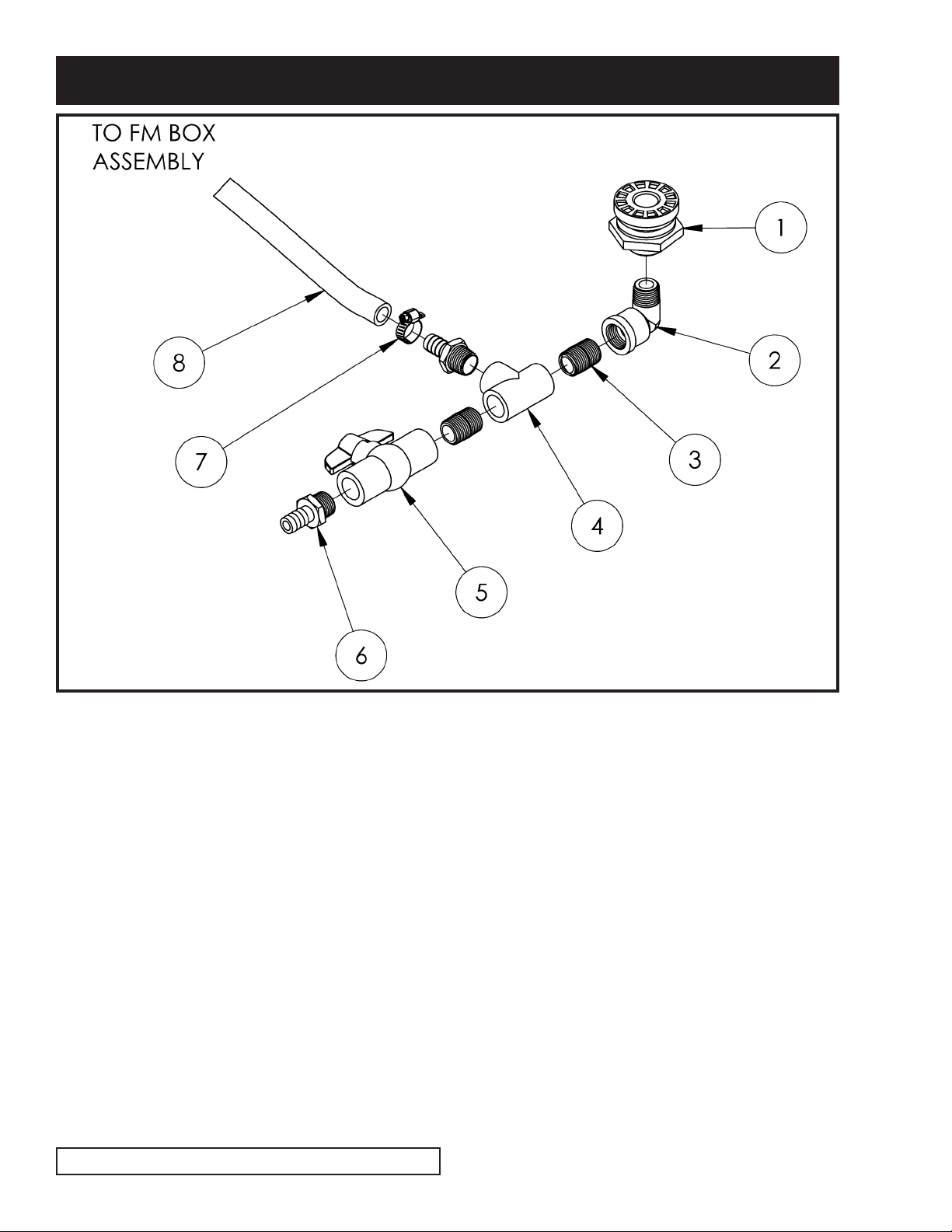

BOX PARTS LIST

ITEM # DRAMM# DESCRIPTION QTY.

1 230501 PANEL NUT NEEDLE VALVE 1

2 230500 NEEDLE VALVE W/NUT 1/4PTF POLY 1

3 220023 NIPPLE HEX 1/4 NPT NY 1

4 220124 ELBOW ST 1/4 NPT NY 1

5 300845 PLUG PANEL 1/2 BLACK NY 2

6 300852 PLUG PANEL 7/8 BLACK 1

7 230241 VALVE CHECK 1/4 F NPT X 1/4 M NPT PVC 1

8 220086 COUPLING 1/4 FPT SCH80 1

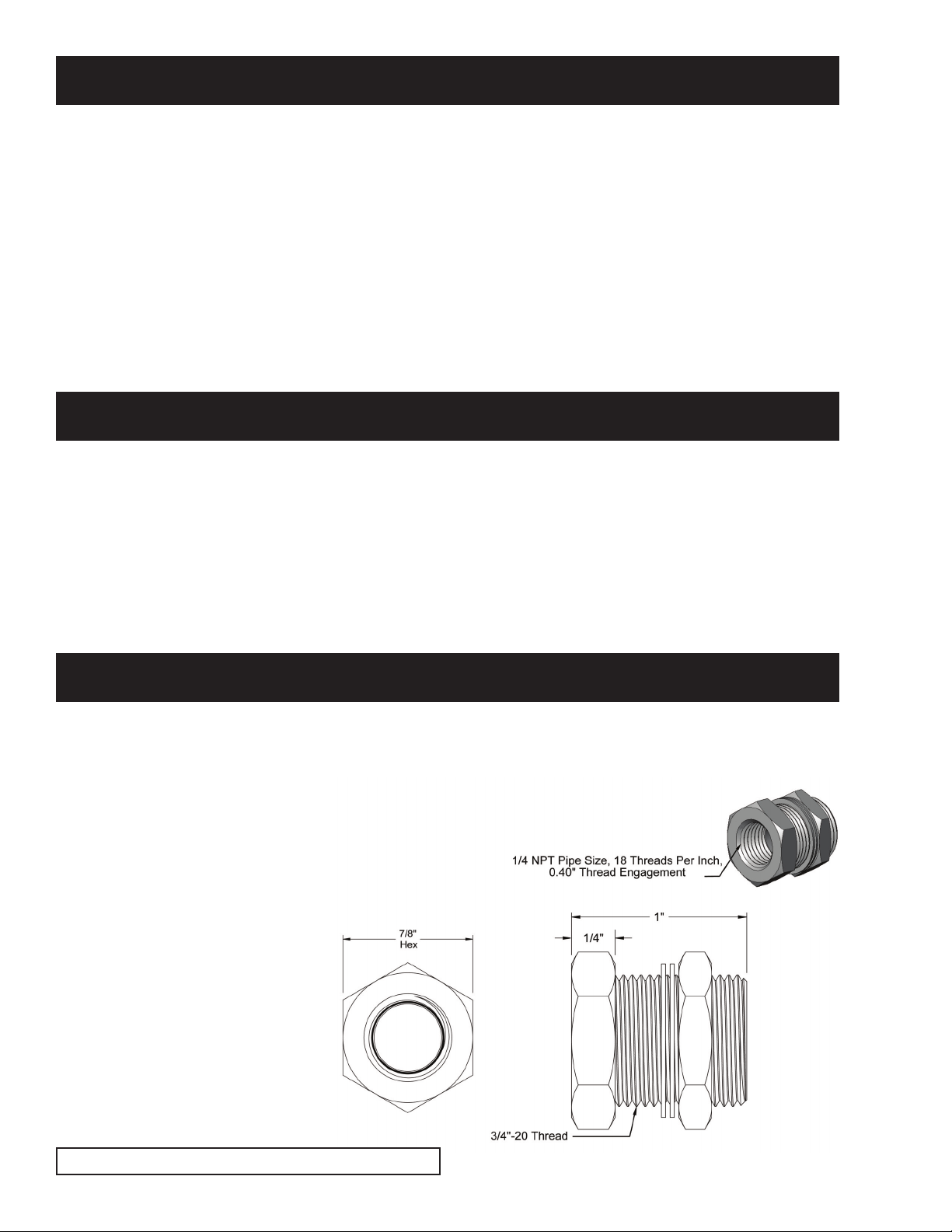

9 AGP-21 GAUGE PORT PNEUMATIC 1

10 220502 FITTING BLKHD 1/4FPT BR 1

11 220046 NIPPLE CLOSE 1/4NPT BR 1

12 D12051B P BOX FM20 STL PAINTED 1

13 220235 BARB ELL 1/4 X 1/8 NPT NY 1

14 AFR-2233 REGULATOR AIR 20-130 PSI 1

15 220230 BARB ELL 3/8 X 1/4 MPT NY 2

16 220229 BARB 3/8 X 1/4 MPT NY 1

17 250061 1/4” HOSE 12”

18 220410 1/2” O.D. SPRING CLAMP 2

19 200031 PUMP AIR DRIVEN 5.0 GPM VITON 1

20 250040 1/2” HOSE 18”

21 250062 3/8” HOSE 14”

22 250062 3/8” HOSE 14”

23 100100 EDGING 3” LG 2

24 220400 1/2” HOSE CLAMP 4

25 220228 1/2NPT X 3/8 BARB FITTING 1

26 220609 TEE THREADED 1/2 FPT SCH80 1

27 220018 ADAPTER 1/2 MPT X 3/4 GH BR 1

28 116200 SHIM 7/8 X 1 3/8 X .062 1

29 220234 BARB ELL 1/2 X 1/2 NPT MALE NY 1

30 220403 3/4” HOSE CLAMP 2

31 110403 BOLT SHOULDER 1/4 X 3/8 X 10-24 2

32 111641 PPH MS 10-24 X 1 SSTL 4

33 111730 WASHER FLAT #10 SSTL 6

34 111731 WASHER LOCK #10 SSTL 6

35 111820 NUT HEX #10-24 SSTL 6

36 114053 THUMB SCREW 1/4-20 X 5/8 1

37 114103 NUT-J 1/4-20 1

38 D11908 WC COVER 1

39 110020 5/16-18 X 1/2” LG HHCS GR.5 2

40 110321 5/16” LOCK WASHER 2

41 8300875 HANDLE 1