23A1937C

Contents

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

System Description . . . . . . . . . . . . . . . . . . . . . . . 3

Power Requirements . . . . . . . . . . . . . . . . . . . . . 3

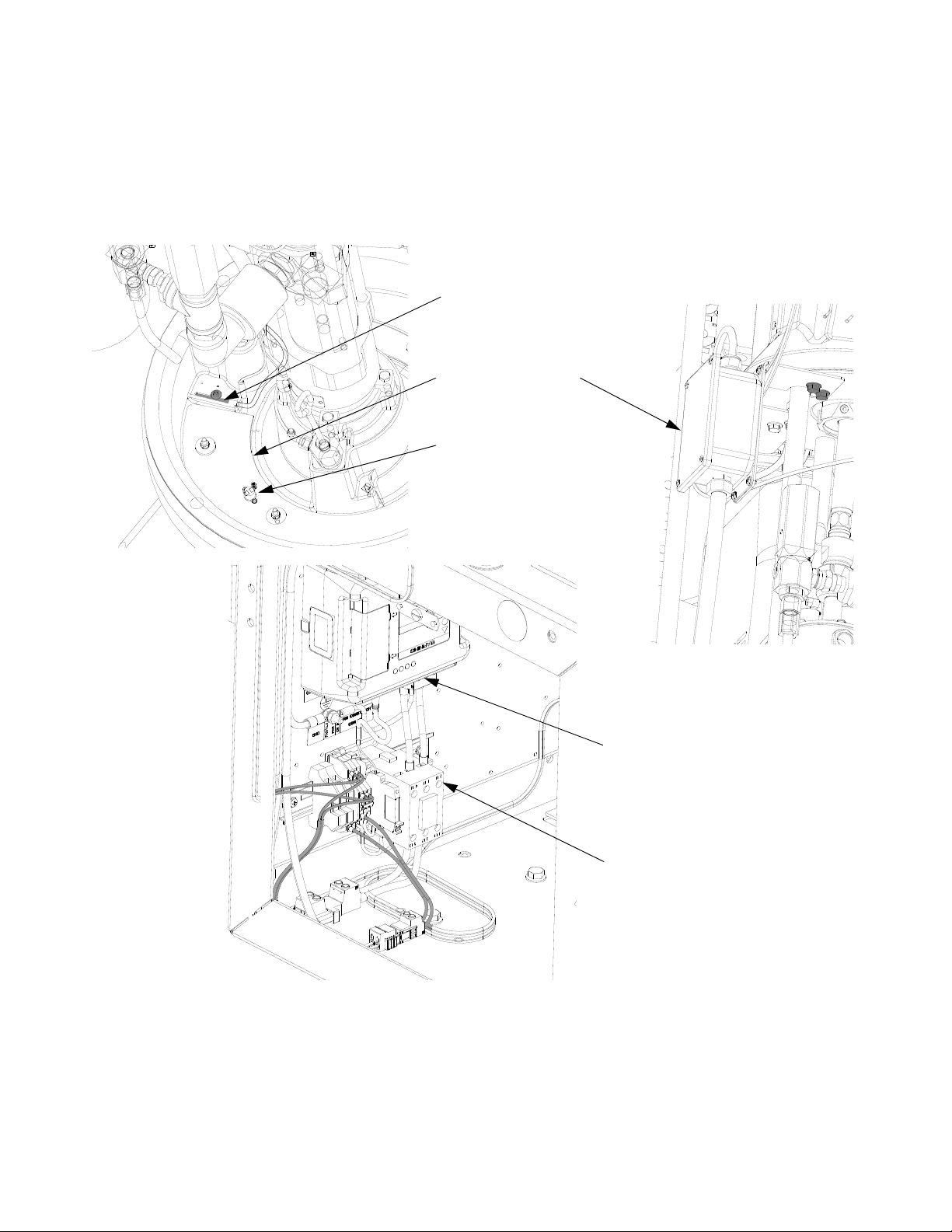

Component Identification . . . . . . . . . . . . . . . . . . . . 4

Kit Components . . . . . . . . . . . . . . . . . . . . . . . . . 4

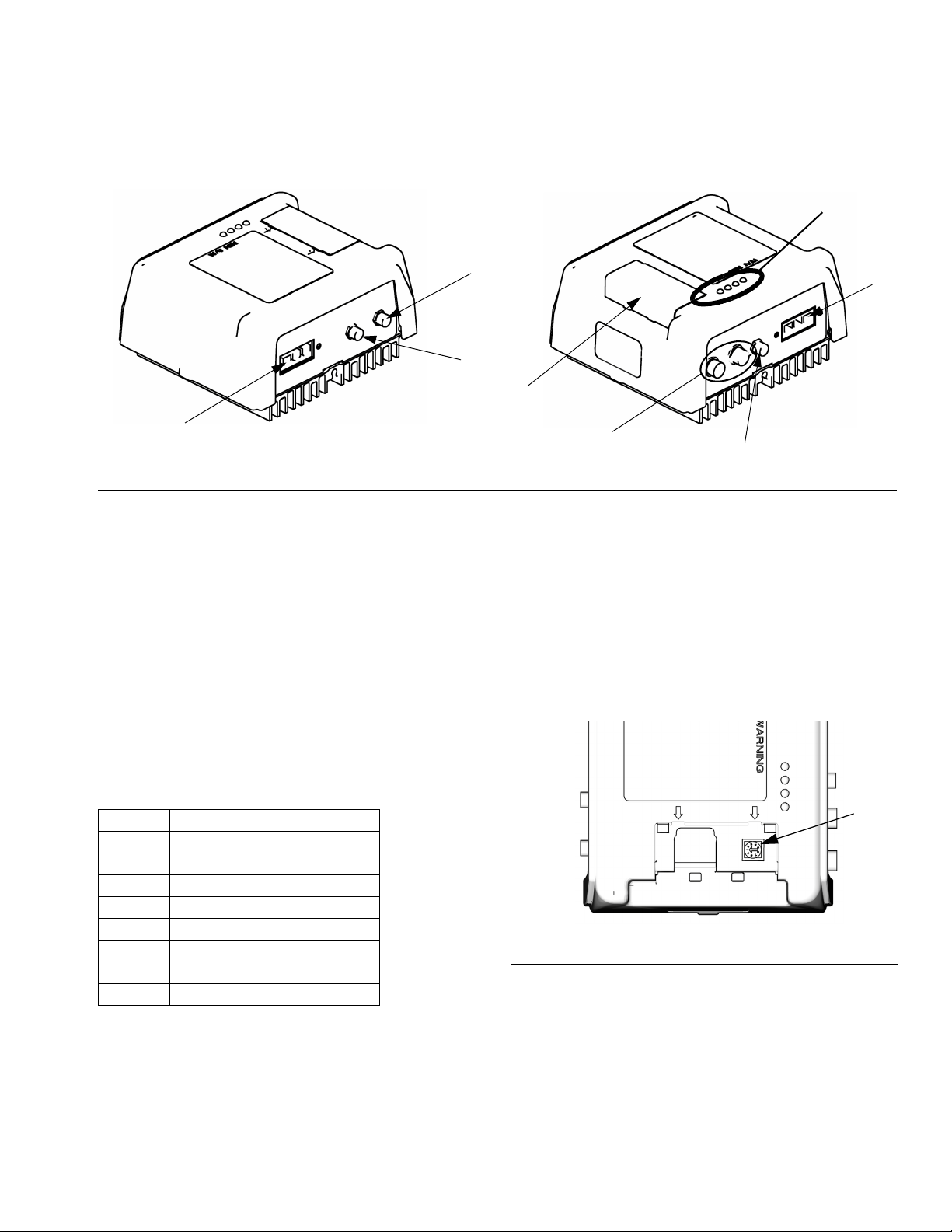

Temperature Control Module . . . . . . . . . . . . . . . 5

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

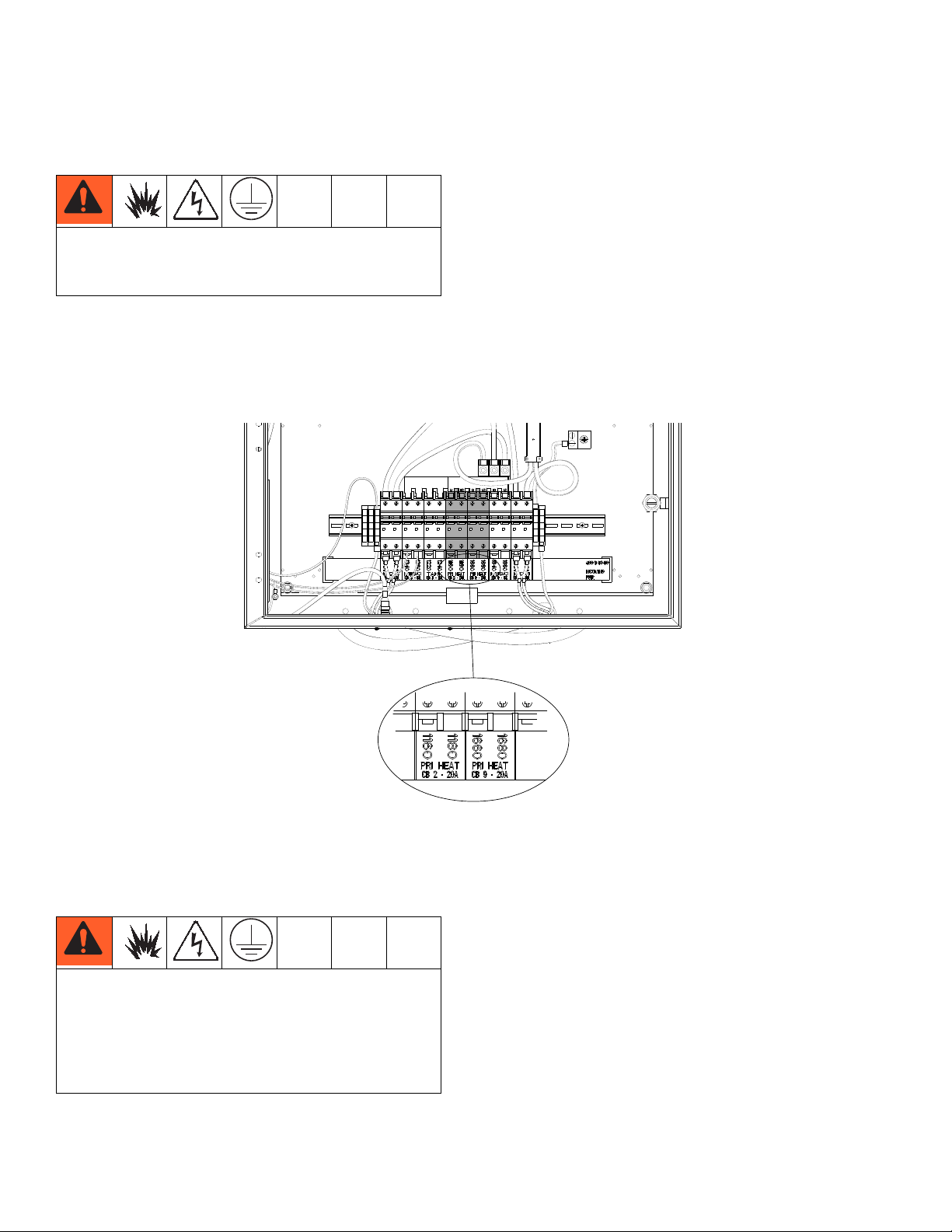

Power Requirements . . . . . . . . . . . . . . . . . . . . . 6

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Temperature Control Module . . . . . . . . . . . . . . 16

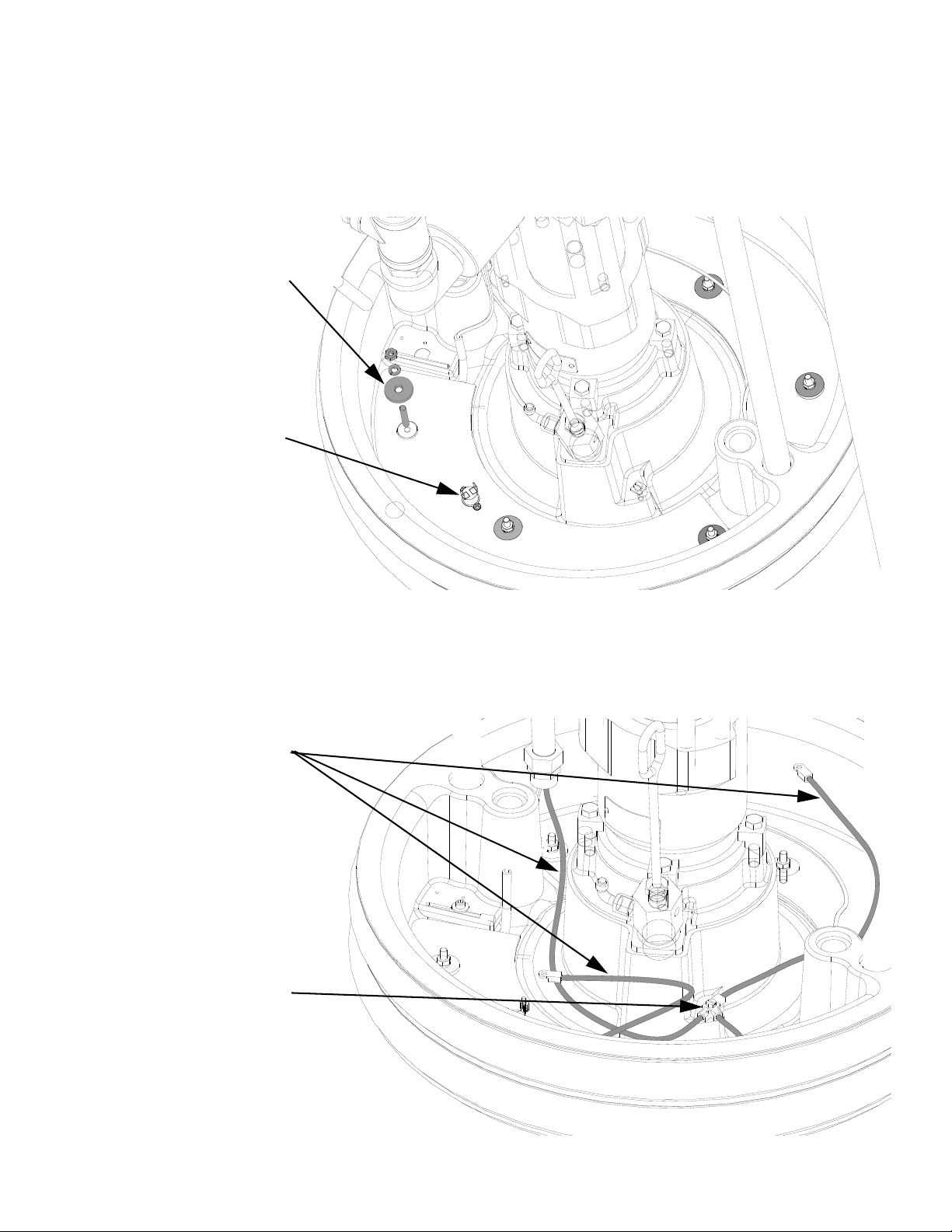

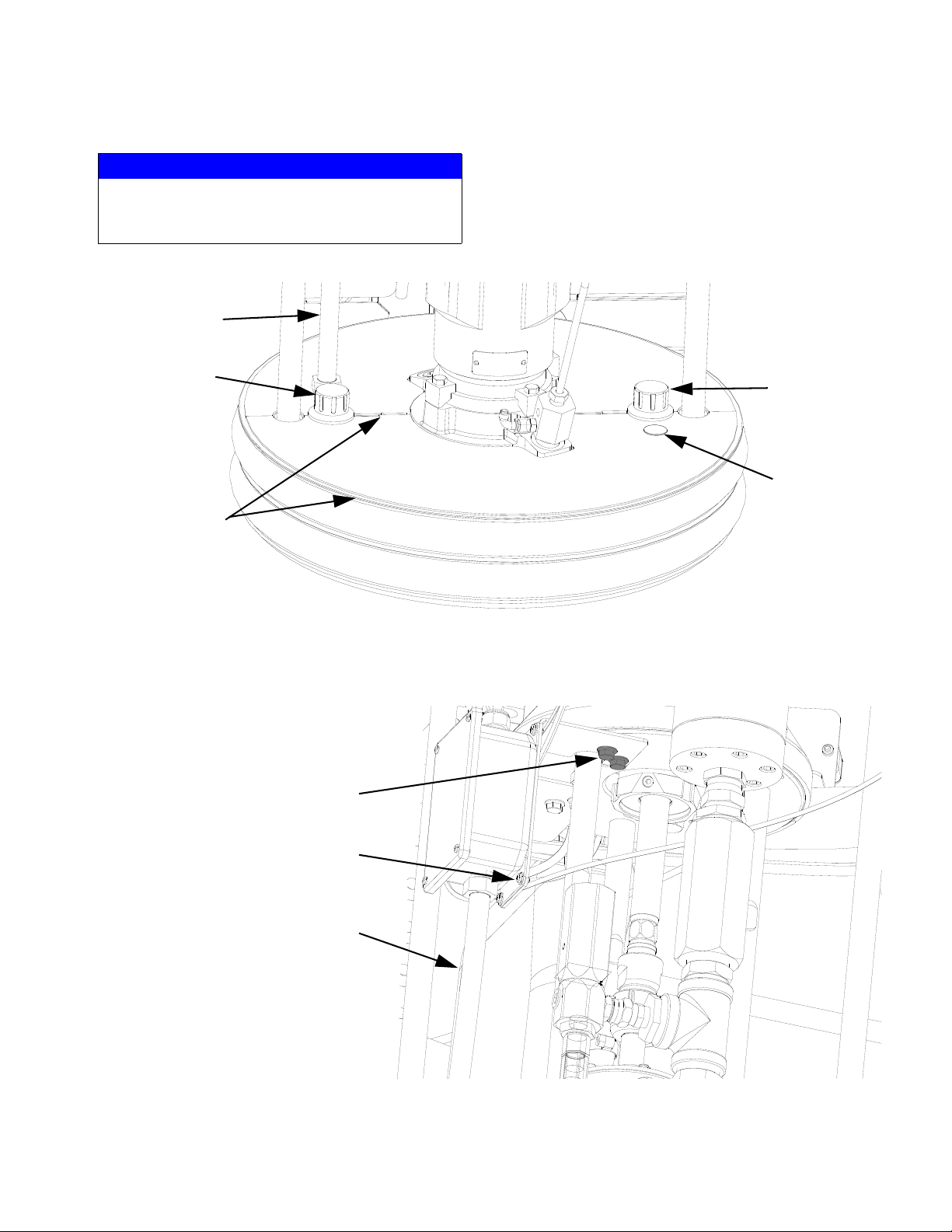

Platen Maintenance . . . . . . . . . . . . . . . . . . . . . 17

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Common Problems . . . . . . . . . . . . . . . . . . . . . . 18

Temperature Control Module . . . . . . . . . . . . . . 21

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

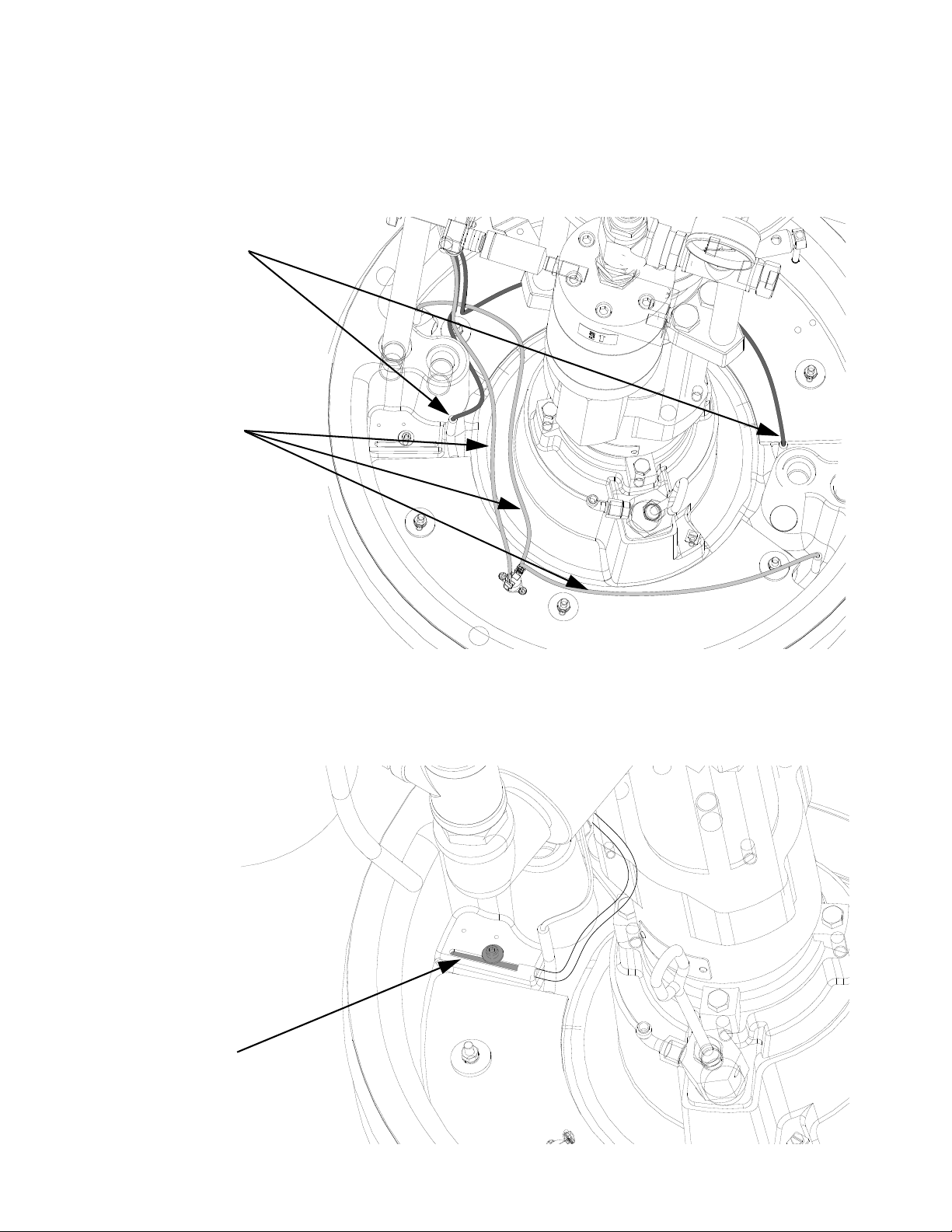

Replace Platen Heaters and Sensor . . . . . . . . . 22

Replace High Power Temperature Control Module

23

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Platen Heater Kits, 24E267 and 24E268 . . . . . 24

Heat Panel Module, 24K203 and 24K204 . . . . . 26

Heater Platen Assembly, 24C493 . . . . . . . . . . . 28

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 30

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 30