684-021 9

Service

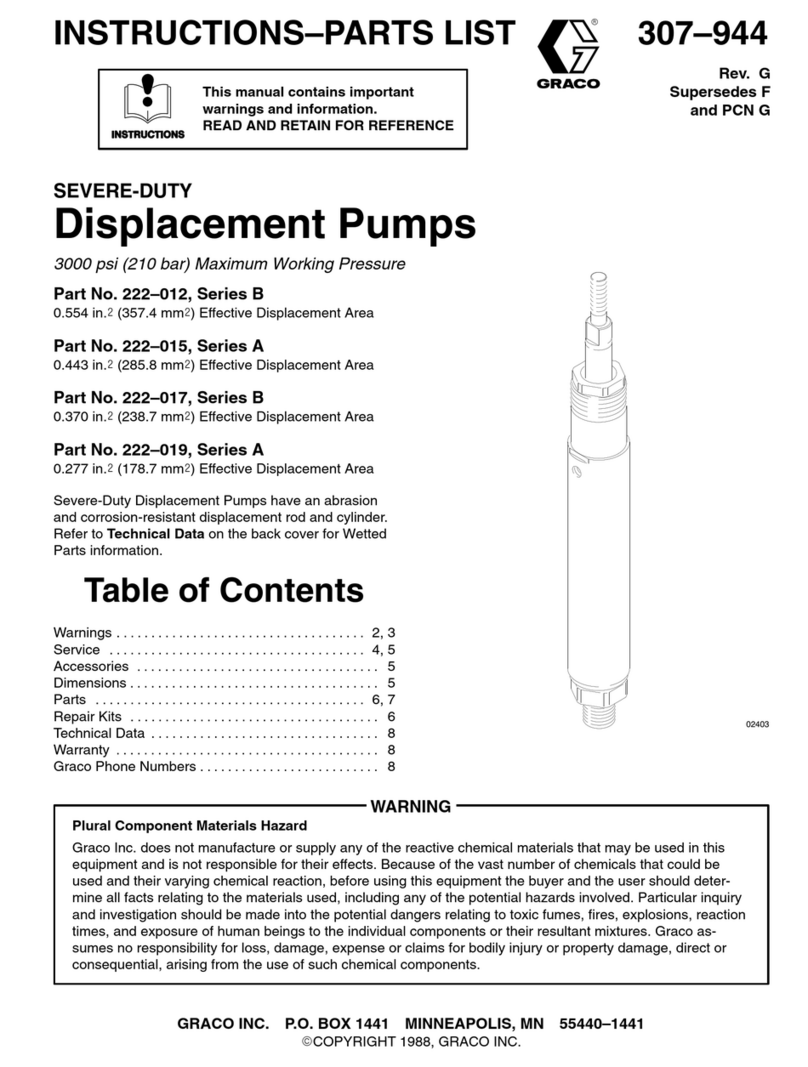

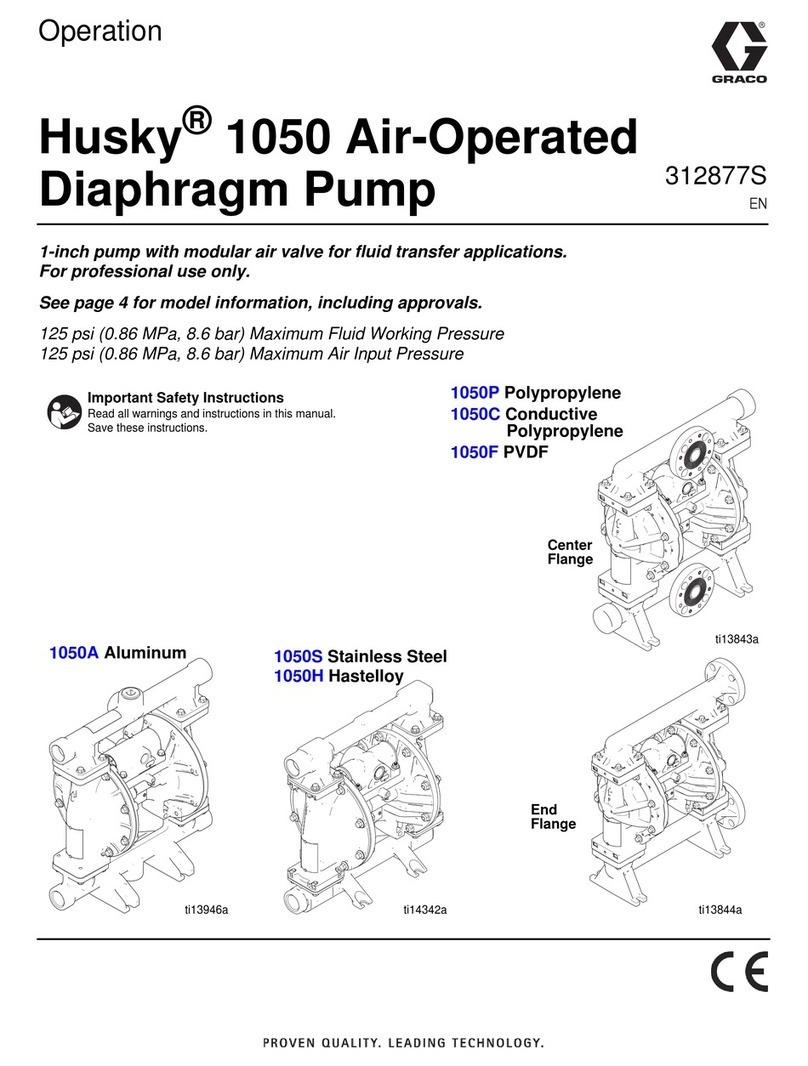

Displacement Pump Disassembly

NOTE: Repair Kit 218-741 is available. Use

all parts in the kit for the best results.

1. Remove the pump from the fluid container.

Operate it until as much of the fluid has

been pumped out as possible.

2. Relieve the pressure and remove the air

and fluid hoses from the pump.

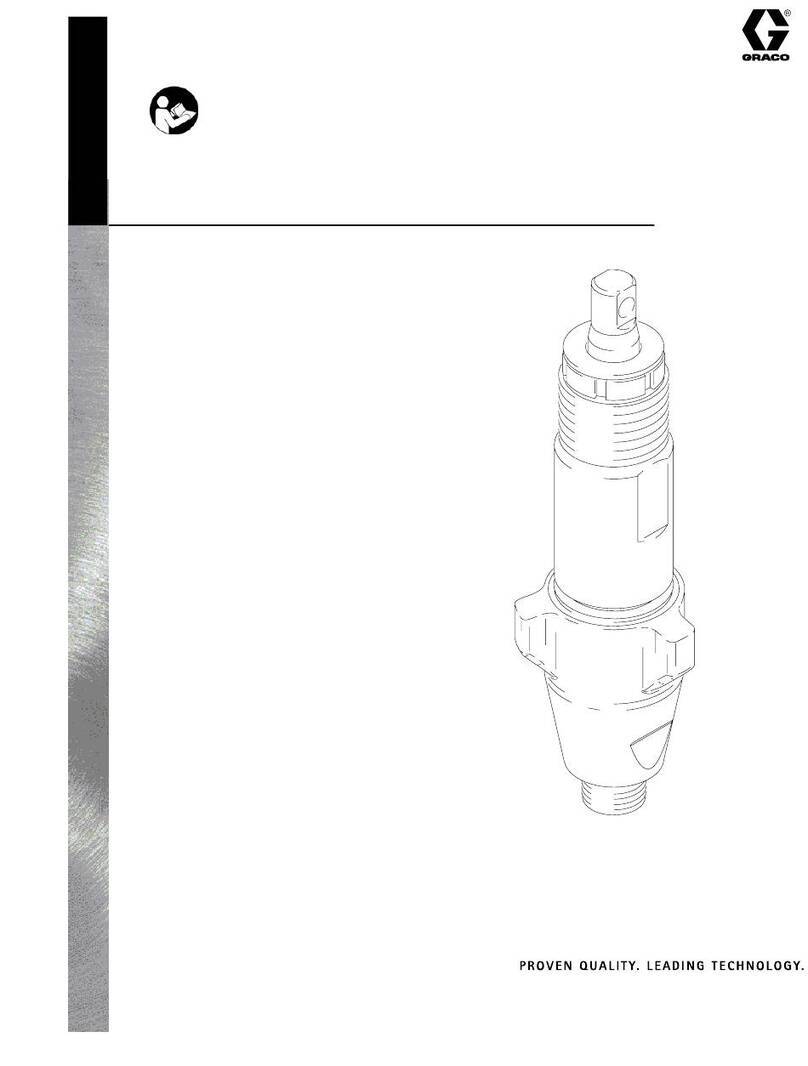

3. Remove the intake valve housing (26) by

removing the retaining pin (24) and the o-

rings (28) and pulling the valve out of the

cylinder (34). Disassemble the valve.

Clean and inspect the parts. See Print

946-964.

4. Release the clamp (16) holding the

retainer housing (29) to the air motor base.

Slide the displacement cylinder (34) down

from the air motor and pull the

displacement rod (35) out of the

connecting rod (5).

5. Push the displacement rod out through the

bottom of the cylinder. Remove the piston

housing (33) by removing the retaining pin

(32) and the o-ring (28) and pulling the

piston from the displacement rod.

Disassemble, clean and inspect the parts.

6. Take the retainer housing (29) off of the

cylinder (34) and remove the packing

housing (31), bearing (25) and packing

(18).

7. Clean and inspect all the parts. Refer to

the Cleaning Procedure. Replace the

parts as necessary.

Displacement Pump Assembly

NOTE: Lubricate the o-rings, throat packings,

and piston seals with waterproof approved

sanitary lubricant when reassembling.

1. Install the u-cup packing (18) and throat

bearing (25) in the throat packing housing

(31). The lips of the u-cup must face down

into the housing, and the lip of the bearing

must face up. Install the o-ring (21) on the

outside of the housing.

2. Place the throat packing housing (31) on

the top of the cylinder (34). Make sure the

gasket (20) is in place on the top of the

cylinder (34). Install the retainer housing

(29) on the cylinder so the hole (A) in the

housing is slanting downward toward the

cylinder. Secure with the clamp (16).

3. Install the piston seal (27) on the piston

housing (33). Place the ball (14) on the

seat of the housing. Install the piston

housing in the displacement rod (35) so

the holes in both parts align. Secure with

the retaining pin (32) and one o-ring (28).

4. Slide the displacement rod (35) up through

the cylinder (34) so it protrudes from the

retainer housing (29). Install the gasket

(20) on the top of the retainer housing.

Make sure the drip shield (19) is in place

on the connecting (5), then reconnect the

displacement rod to the connecting rod.

5. Slide the retainer housing (29) and cylinder

(34) up to the base of the air motor (1),

and secure with the clamp (16). Make

sure the drip shield (22) is in place on the

cylinder.

6. Install the o-ring (21) on the intake valve

housing (26). Place the ball (13) on the

seat of the housing (26), and install the

ball stop pin (30) in the top holes of the

housing.

7. Slide the intake valve housing (26) up into

the cylinder (34) until the bottom holes of

the housing align with the holes in the

cylinder. Secure using the retaining pin

(24) and two o-rings (28).

8. Install the gasket (23) and clamp 917)

when reconnecting the fluid line to the

pump fluid outlet.

9. Reconnect the ground wire if it was

disconnected during service.

Any damaged rubber parts

must

be replaced

as they will harbor microorganisms that can

contaminate the fluid.

:$51,1*

To reduce the risk of serious injury whenever

you are instructed to relieve pressure, always

follow the Pressure Relief Procedure.

:$51,1*