GRAPHTEC WR3320A User manual

MANUAL NO.WR3320A-UM-151

LINEARCORDER MARK Ⅶ

W R 3320A

USER’S MANUAL

INTRODUCTION

TheWR3320Awasdevelopedbymakingfundamentalimprovementstoan

earliermodel,makingthisrecodersignificantlyeasiertouse,andgreatly

improvingfunctions,performace,andreliability.TheWR3320Acanbeused

forawindevarietyofapplicaitonsinthevariousrecordingfields.

Afterremovingthepackaging,taketimetocarefullyreadthisinstructoin

manual.Ifpowerisappliedtotherecoderimproperly,orifpartsofthe

recoderotherthenthosedesignatedinthismanualaredesmantled,condi-

tionsdangeros,orirreparabletptherecodermayoccur.

CAUTIONSBEFOREUSE

● AfterUnpacking

Aftertherecorderhasbeenunpacked,preformavisualinspection,

referringtothetableinSection5-3listingthequantitiesofacces-

sories.Iftherecorderisdamagedinanywey,orshortagesinacces-

soriesarediscovered,contactyourdealer.

● RecorderInstallationLocation

TheWR3320Ashouldbeinstalledonahorezontalbase,indoors,ina

normalintreiorenvironment.

Avoidthefollowingenvironmentalconditionswhenselectingan

installationlocation.

● Locationswithexcessivedust,drit,wihtsalineatmospheres,

orlocationssubjecttocorrosivegases

● Locationswheretemperatureorhumidityexceedthespecifica-

tionsinthismanual

● Locationssubjecttodirectsunlight

● Locationssubjecttoexcessivevibrationorshock

● LocationssubjecttolightningorothersurgevoltagesorEMI

● PowerSupply

Useapowersupplywithin±10%ofthenominalvoltagewihta

minimumlinecapacityof10A(for100-Voperation)andonethat

allowseasyprotectivegrounding.

CAUTION

Thereisalinevoltageselectoronthebottompanelof

theWR3320Aenablingittobeusedatotherthan

100-V.Itisextremelyimportanttosetthissupply

voltageselectortotheconditionsofthelinetobeused

beforperforminganyotheroperations.

● RecordingPaper

TheWR3320Ausesheat-sensitivepapar.Featuresoftheheat-sensi-

tivepaparsuchascoloringcharacteristicandsurfacesmoothness

exertagreatinfluenceonthequalityoftherecordedtrace.Thus,it

isextremelyimportanttouseonlyGraphtecʼ srecordingpaper.

● Pens

Thepensshouldnotbetouchedexceptwhenbeingreplaced.Donot

reducepenpressuretoextremelylowlevels,orallowthepentorise

upoffthepaper,asthismaydamagethepens.

● DataStorage

Recordingreliesonathermalreactionbytheheat-sensitivepaper.

Observethefollowringprecautionswhenhandlingrecordingdata.

● Donotplacethepaperinlocationssubjecttodirectsunlight.

● Donotplacethepaperinlocationssubjecttohightem-

pretatures(50℃orhigher).

● Papershouldbekepsinalocationwhichisasdarkaspossible.

Iftherecordingdataarestoredunderfluorescentlightorunder

naturallight,therecordeingdensitywilldeteriorateafterafew

months.

● Donotstorerecordingsinsidevinylchloridebags.

● Donotplacerecordingsondampdiazocopypaper.

● Avoidcontactingrecordingswithacids,alcoholoresterke-

tones.Thesemaycausediscoloration.

● PenProtectionFunction

Penheatsourceisturnedoffandpenmotionissuspendedtoprotect

thepentipunderthefollowingconditions.

● Whenpaperhasrunout

● WhentheSTOPbuttonhasbeenpressedtostoppaperfeed

● Whenthepenlifeleverhasbeenpusheduptoraisethepenoff

thepaper

● MountingPaper

Checkthattheheatswitchhasbeenturnedoff,andifithas,mount

thepaper.

● WariningBeeper

Whenthefollowingconditionsoccur,awarnigbeepersounds,the

penheatsourceisturnedoff,andpendriveisstopped.

● Whenpaperhasrunout

● Whenthepenlifeleverhasbeenpusheduptoraisethepen

offthepaper

● High-FrequencyInput

Theaccuracyoftheservosystemisonlyguaranteediftheservo

amplifierisnotstaurated.Notethatiffrequencieshigherthanthe

penresponsespeedareinputtothesystem,theamplifierwill

saturate.

TABLEOFCONTENTS

1. PARTSNAMESANDFUNCTIONS………………………………………… 1

1.1 TopPanelWhenHorizontallyMounted………………………………… 2

1.2 BottomPanelWhenHorizontallyMounted…………………………… 2

1.3 RearPanel………………………………………………………………… 2

1.4 ControlPanel……………………………………………………………… 4

1.5 PaperFeedSection………………………………………………………… 7

1.6 AmplifierUnit……………………………………………………………… 8

1.7 PenMotorandMarker…………………………………………………… 10

1.8 ReplacingthePen………………………………………………………… 11

2. PREPARATIONSFORUSE………………………………………………… 12

2.1 LoadingPaper……………………………………………………………… 12

2.1.1 Paper………………………………………………………………………… 12

2.1.2 LoadingRollPaper………………………………………………………… 13

2.1.3 LoadingZ-FoldPaper……………………………………………………… 14

2.1.4 PaperSetting……………………………………………………………… 14

2.2 PowerConnection………………………………………………………… 16

2.2.1 Preparation………………………………………………………………… 16

2.2.2 Connection………………………………………………………………… 16

2.3 ConnectingInputLines…………………………………………………… 17

2.3.1 Preparation………………………………………………………………… 17

2.3.2 ConnectingInputCables………………………………………………… 18

2.3.3 ConnectionWithoutInputCables……………………………………… 19

2.4 NoiseFilterSetting………………………………………………………… 20

3. MEASUREMENTANDRECORDING……………………………………… 21

3.1 InputWavaformRecording……………………………………………… 21

3.2 SensitivityFineTuningandCalibration………………………………… 22

3.3 MarkerOperation………………………………………………………… 22

3.4 PrinterOperation(Option)……………………………………………… 23

4. CONTROLBYEXTERNALSIGNALS……………………………………… 28

4.1 RecordingControl………………………………………………………… 28

4.1.1 PaperFeedStop………………………………………………………… 29

4.1.2 PaperFeedExternalSync(CHRT.CLK)………………………………… 29

4.1.3 PaperFeedExternalSync(CHRT.Volt)………………………………… 30

4.1.4 RecordingOn/Off………………………………………………………… 30

4.1.5 EventMarker……………………………………………………………… 31

4.1.6 PaperOutSignalOutput………………………………………………… 31

4.1.7 TimingSignalOutput…………………………………………………… 31

4.1.8 TimingInput…………………………………………………………… 32

4.2 PrintControlfromExternalEqupment…………………………………… 33

4.2.1 Printer(ExternalModeA)………………………………………………… 33

4.2.2 Printer(ExternalModeB)………………………………………………… 35

5. Howtomounttherackangle……………………………………………… 40

6. SPECIFICATIONS…………………………………………………………… 41

6.1 LinearcorderSpecifications……………………………………………… 41

6.2 PreampsSpecifications…………………………………………………… 42

6.3 Accessories………………………………………………………………… 42

7. OUTERVIEWS……………………………………………………………… 43

1. PARTSNAMESANDFUNCTIONS

Fig.1-1TopPanel

Fig.1-3RearPanel

Fig.1-2BottomPanel

Handles Servoamplifierheatsink

Rubber

foot

Rubberfoot Stockerfrontcover

Stockerfrontcover Paperhold-downbar

Tentionroller

Sprocket

Preamplifier

Thumbwheelswitches(option)

Operatingpanel

Penliftlever

Writingpanel

Handles Servoamplifier

heatdispersionplate

Rubberfoot

⑤

⑥

④

⑦

(option)

⑧

③

②

①

-1-

Fig.1-4FromtPanel

⑨

1.1 ToppanelWhenHorizontallyMounted

Fig.1-1isoftheWR3320ALinearcordertoppanel.

Itshowsthepenmotorsandpreamplifiersfor8channels,the

markersandprinthead,andthecontrolpanelneartheprinthead.

Thereisapaper-holdingrolleronthewritingpanelside,and

underneaththatitthefrontcoverforthepaperstoragearea.This

coverhasbeenspeciallymoldedtoenableabettergripwhenthe

recorderisbeingcarried.

1.2 BottomPanelWhenHorizontallyMounted

Fig.1-2showsthebottompanelwhenitisverticallymounted.The

fuseholdercanbeseen.Notethatthissideoftherecorderisusedfor

heatdissipation.

① FuseHolder

Thiscanbepulldeoutbyturningitcounterclockwisewitha

Philipsscrewdriver.Itisveryimportanttoonlyuseafuseof

thespecifiedratingwhenreplacingthefuse.

1.3 RearPanel(withInputTerminalStrip)

Fig.1-3showstherearpanel.Allconnectionstoexternaldevicesare

madefromthispanl.

② ProtectiveGroundTerminal

Thisprotectivegroundlineterminalisprovidedtoestablish

thesamepotentialdifferencewithgroundformetalpartsof

therecorderwhichoperatorsmighttouchwiththeirhands,

suchasthoseofthechassis.Apartfromthechassis,themain

powersuppyvoltagetransformersecondaryneutralpointand

powersuppyconnectorprotectivegroundarealsoconnected

internally.

③ PowerConnector

Thecenterconductorofthisthree-lineinputconnectoristhe

protetivegroundterminal.Notethatonlythededicatedpower

cableprovidedwiththesystemmaybeconnectedhere.

-2-

④ ReferenceVoltageOutputConnectors

Theblackconnectoroutputsthesamevortageasthechassis

andtheredconnectoroutput+1V±0.2%.Theoutput

resistanceis200Ω,andtheseareusedforpreamplifiersensi-

tivitycalibration.

⑤ InputConnectors

Theseinputconnectorsareconnecteddirectlytotheir

correspontingchannelpreamplifierinputs.theblackGcon-

nectorsareguardconnectors,thered(−)terminalisafloating

ground,andthered(+)terminalisthesignalpositive-side

inputterminal.Theaccessoryinputcablescanbeconnected

here.

⑥ ShortingBar

TheblackGandred(−)terminalsareconnectedtoametal

fixture,andthisoperationisexplainedbelow.

⑦ PrintingExternalInputConnector(Option)

Thisisusedforinputofcharactersignalsfromanexternal

keyboardtocontroltheprinter.SeeSecting4belowfordetails

ontheterminalstrip.

⑧ ExternalControlSignalConnector

Thisisusedforinputofexternalsignalstocontrolpaperfeed,

penheating,markers,andotheroperations.SeeSection4for

details.

1.4 FrontPanel(Stockerfrontcover)

fig1-4Showsthefrontpanel

⑨ Externalfeedsetting,REWIND/FEED

SwitchingoftheexternalfeedcontrolandswitchingfromREWIND

keytoFEEDkey.

-3-

1.4ControlPanel

Power

Thisswitchispressedandlockedto

turnthepoweron,atwhichpointthe

redlamplights.Itispressedonce

againtoturnpoweroff,therebyextin-

guishingtheredlamp.

PRECAUTIONS

Makethefollowingchecksbefore

powerisapplied.

●TheSTOPswitchshouldbedepressed.

CHARTEXT

Thisisthepaperfeedselectionswitch.

Whenpressedandlocked,paperisfed

insyncwiththeexternalpulsesignal.

Ifpressedonceagaintoreleasethe

lock,theCHARTSPEEDswitchon

theoperatingpanelcanbeusedto

specifypaperfeedspeed.

TIMING

Thisdialusedtoselectthegeneration

frequencyofthesignalwhichoperates

thetimemarker.Timingpulsesare

generatedat10min,1min,10s,or1s

intervalsaccordingtotheselectionof

10M,1M,10Sor1S.Thecorresponding

puleswidthsareapproximately7,4,0.7

and0.2s,respectively.Thesecanalso

beoutputtoexternalequipmentviathe

externalcontrolsignalconnector⑧.

PresstheSTOPkeytostopthetiming

pulse,anduseEXTtosendthesignal

inputfromanexternaldevicetothe

marker.(Thepulsewidthis0.7s.)

POWER

CHART EXT

TIMING

-4-

T

Timingmark

EVENTSwitch

Thisswitchisusedtorecordevent

marksusingamarkerpen.Themark

isrecordedwhiletheswitchisdep-

ressed.

HEATSwitch

Thisswitchisusedtocontroltheheat

sourceforallpens.Whendepressed

andlocked,iftheotherswitchset-

tingsallsatisfytherecordingcondi-

tions,powerisappliedtothepens,

andrecordingcanbeperformed.

REMOTE/MANUAL

IfthisswitchissettoMANUALposition

whenthechartpaperfeedisstopped

duringtheexternalchartfeedcontrol

(CHRTSTOP),thechartpaperfeedcan

becontrolledmanually.

REWINDSwitch

Thisistherecordingpaperrewind

switch.Thisswitchisonlyeffective

forrollpaper,andwhentheSTOP

switchontheoperatingpanelisdep-

ressed.WhentheREWINDswitchis

depressed,recordingissuspended,

andpaperisrewoundataspeedof

approximately50mm/s.

Switchingof ispossible

bytheexternalfeedsettingswitch

SW1bit2.

EVENT

HEAT

REMOTE/

MANUAL

REWIND

ON

REWIND FEED

Eventmark

Recordedwhileswitchisdepressed

-5-

ThumbwheelSwitches

Theseareusedtospecifythenumer-

icalvaluesforthedatareadtothe

printer.

Thesixdigitswitchesareusedtoset

year,month,andday,orhour,minute,

andseconddata.

PRINTMODESwitches

Theseareusedtoselecttheprinter

mode.

NORMOUT:Operationtimeand

otherparamentersareautmotically

recorded.

REALOUT:Time,data,andother

infomationisautomaticallyrecorded.

DATAIN:Thisisusedtospecifydata

(year,month,andday)data.

TIMEIN:Thisisusedtospecifydata

(hour,minite,second)data.

PRTEXT1:Thisisusedtorecord

characterdatareceivedfromexternal

devices.(MODEA)

PRTEXT2:Thisisusedtorecord

characterdatareceivedfromexternal

devices.(MODEB)

PRINTSETSwitch

Thisswitchisusedtoreaddataand

timedatatotheprinter.Thedatais

readintotheCPUwhentheswitchis

pressed.

Thisswitchisusedincombination

withtheprintermodeswitchesand

thumbwheelswicthes.

Notethatitisonlyeffectivewhenthe

HEATswitchisoff,orwhenpaperis

notbeingfed.

CHARTSPEEDSwitches

Theseareusedtoselectthespeedof

paperfeed.Theyareeffectivewhen

theCHARTEXTswitchontheoper-

atingpanelisnotdepressed.

Sevendefferentspeedsettingscanbe

madeintherange5to500.Ifnoneof

PRINT MODE*

SWITCHES

PRINT SET*

CHART SPEED

THUMBWHEEL*

SWITCHES

-6-

theswitchesaredepressed,thede-

fauitspeedis5.

Note:Theswitchmarkedwithan

asteriskapplywhentheprinter

optionisinstalled.

1/1or1/10

Thisisaswitchforthechartspeed

between1/1and1/10.

Pressingthisswitchonceforlock,

itworksas1/10,alsoifreleasethis

switch,itworksas1/1.

SEC/MINSwitch

Thisswitchisusedtoselecttheunits

forpaperfeed.Ifitisdepressedand

locked,thesecondunitisselectedand

paperspeedisspecifiedinmm/s.

Whendepressedoncemoretorelease

thelock,theminuteunitisselected

andpaperisfedinunitsofmm/min.

STOPSwitch

Thisisusedtostoppaperfeed.Paper

feedisstoppedbydepressingand

lockingthisswitch.Ifitispressed

oncemoretoreleasethelock,paperis

fedatthespecifiedspeed.

PaperRWIND/FeedExternalSetting

Thisswitchisfortheselectionofexternal

chartfeedmode.

SW1-IOFF:Externalpulsesync

chartfeed(CHRTCLK)

ON:Externalvoltagesync

chartfeed(CHRTVOLT)

SwitchtheREWINDfunction.

SW1-2OFF:FEED

ON:REWIND

(Factorysetting)

-7-

STOP

SEC/MIN

1/1 or 1/10

PAPER

RWIND/FEED

EXTERNAL

SETTING

ON

1 2

ON

1 2

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

CHRT CLK/CHRT

VOLT

REWIND/FEED

SWI

1.6 AmplifierUnit

ThisDCamplifierisusedtoamplifyminuteinputsignals.Thereare

twotypesofnuitwithdifferentsensitivities.

1.5PaperFeedSection

(1)RollPaper/Z-FoldPaperSwitch

Ifrollpaperisused,settheswitch

totherollposition.Notethat

rewindofZ-foldpaperisnot

possible.

(2)PenLifeLever

Ifthisleverospulledforward,the

paperfeedrollercanbefreely

rotated.IfthepaperfeedSTOP

switchisreleasedwhilethislever

israised,thebeeperwillsound,

andneitherpendeflectionnor

anyrecordingoperationis

performed.

(3)PaperDetector

Apaperdetectorisprovidedand

whenpaperrunsout,abeeper

soundsandrecordeingisstopped.

Thisisusedtoturninputonandoff

andalsoforthecalibrationvoltage.

MEAS./OFF/CAL.VSwitch

MEAS.:Thepenmovesaccordingto

theinputsignal.

OFF:Theinputsignalisnotsupplied

tothepen.

CAL.:Thecalibrationvoltageisinput.

IfthisswitchisturnedtotheCAL.V

setting,theamplifierinputchanges

toground,andthepenisdeflectedac-

cordingtotheinternalvoltage20mm

(AH3301A)or40mm(AH3302A).

Thiswidthis

variedusingtheGAINknob,asex-

plainedbelow.

mV/VSwitch

Thisswitchisusedtoselecttheunits

fortheRANGEnumericalvaluesas

eithermVorVunits.

Fig.1-5PaperFeedSectionSwitches

①

②

③

Fig.1-6(1)

-8-

RANGESwitch

IftheAH3301Apreamplifierisused,

thisswitchhastheninesettings1,2,

5,10,20,50,100,200,and500

units/cm.IfthemV/VissettomV,

then,forinstance,thesensitivityis

expressedbysayingthatthepnehasa

deviationof1cmat5mV.

GAINCONTROL

LocatednexttotheRANGEdial,this

isusedtointerpolatethestepwise

variationinthesensitivityofthe

RANGEswitch.Sensitivityincreases

asthisdialisrottatedclockwiseand

decreasesasitisturnedconunterclock-

wise.Whenchangingthesettingof

theMEAS/OFF/CAL.Vswitchfrom

offtoCAL.V,ifthesettingisadjusted

sothatthepenisdeflected20mm

(AH3301A),or40mm(AH3302A),

thenthesensitivityisthatselected

bytheRANGEdial.

POSITIONCONTROL

Thisdialisusedtospecifythepen0

positionelectrically.Whentheinput

is0V,thepencandeflecttoany

arbitraryfull-scaleposition.

AmplifierScrewCover

Theamplifireholdingscrewisunder

thiscover.Itcanbepushedtothe

leftwiththefingernail,andwill

thenrevealthescrewunderneath.

Removethisscrewtotakeoutthe

preamplifier.

Filter

Thisisusedtoeliminatelinenoise

(hum)mixedwithinputsignals.

Ifthepreamplifierisremoved,a

switchlabeledOFF,−20dB,and

−40dBcanbeseen.

Filter Switch

Fig.1-6(2)

-9-

1.7 PenMotorandMarker

Ifthisswitchissettoeither−20dB,

or−40dB,thenthenoisecomponent

willbereducedto1/10or1/100,

respectively.

ThefilterisbuiltintotheAH3301A

preamplifiers.

Fig.1-9amdFig.1-10showstandard

characteristicsfortheWR3320A

Linearcorder.

(1)HEATSwitch

Whenthisswitchisturnedoff,power

tothethermalpenisturnedoff.

Simultaneously,theservoamplifier

inputfallstoground,severingitscon-

Fig.1-9

Filter: OFF

Filter: -20dB

Filter: -40dB

Filter: OFF

Filter: -20dB

Filter: -40dB

OFF

-20dB

-40dB

OFF

-20dB

-40dB

0.1 0.2 0.5 0.7 1 2 3 4 5 7 10 20 30 40 50 70 100 120 150 (Hz)

Pen motor: GW3310

Preamplifier: AH3302A

RANGE 1V /㎝

Pen motor: GS3310

Preamplifier : AH3301A

RANGE. 2V/ ㎝

40

10

9

20

8

7

6

5

4

3

2

1

振

幅

(㎜) WR3320A Frequency characteristics

0.1 1 10 100 120 (Hz)

1

10

20

40

80

100 ㎜

WR3320A Frequency characteristics

-10-

1.8 ReplacingthePen

1.Turnoffthepowerswitch.

2.Usetheaccessorypenspannertoloosenthescrewonthepen

motorshaft,andthenremovethepen.

3.Beforeattachingthepen,slightlybendthespringplantetoincrease

thepenpressure.

4.TurnonthePOWERswitchandturnofftheHEATswitch.

Insertthenwepenintothepenmotorshaft,positionthepentip

inthecenterofthechartpaper,andlightlytightenthescrewwith

theaccessorypenspanner.

5.QuiklyrotatethePOSITIONknobtwoorthreetimestocheckthe

perperndicularityofthepen,asshowninFig.1-11(c).

Ifthependeflectsfromthecenterline,theresultwillbeasin(a)

or(b).

nectionwiththepreamplifier.Thisis

usedforalignmentwhenreplacing

pens.

(2)HeaterControl

Thisdialisusedtoadjustthermalpen

coloringdensity.Linedensityin-

creasesasthisisturnedclockwise.

Notethatifthedensityisincreased

morethannecessary,thismayreduce

thelifeofthepens.

(3)ThermalPen

Exremelysmallheatersareattached

tothepentip,andwhenpowerissup-

pliedtothem,theyimmediatelyget

hotformingalineonthethermal

paper.

(4)EventMarker(TimeMarker)

Therearetwoheateronthepentip.

Normallytheheateronthesprocket

holesideisonandisusedtodrawthe

baseline.Thetimemarkerontheop-

positesideperformsinthesameway.

Fig.1-11

Fig.1-10PenMotorandMarker

①

②

③

④

(a)

Center line

(b) (c)

Center line Center line

Recording

-11-

6.Setthepenpressureat18-20g.

Todothis,applya50gpenpressuregaugetpthepentipand

adjustthepenpressureuntil18to20gisobtainablewhenthe

penisfloatinsligtlyabovethesurfaceofthepaper.

7.Finally,tightenthescrewsecurely.

-12-

2. PREPARATIONSFORUSE

2.1 LoadingPaper

2.1.1 Paper

BothrollpaperandZ-foldpapercanbeusedwiththeWR3320A.

Typealsodifferaccordingtopendeflectionamplitudeandthenumber

ofchannelsthatcanbeaccepted.Inallcases,thelengthis100m.

PRECAUTIONS

Itisextremelyimportanttoturnthepowerswitchoffand

removethepowercordbeforemoutingchartpaper.

①Thecoloringcharacteristicvariesgreatlywiththecoloringagent

usedandthepapersurfacefinish.

②Recordingdependsuponthermochemicaleffects,andconse-

quentlymaybesubjecttodiscolorationifrecordingsarestored

inlocationsexposedtodirectsunlight,subjecttohightem-

peratures,orwheretheycanbeexposedtoultravioletlight.

③Recordingsareaffectedbyvinylchloride,diazocopies,acids,

andalcohol.

PRECAUTIONS

①Itisextremelyimportanttousethepaperspeci-

fiedbyGraphtec.

②Avoidstorageanduseofthepaperunderextreme

environmentalconditions.

③Donotplacethepaperontopofequipmentthat

generatesheat.

2.1.2 LoadingRollPaper Usedthefollwingproceduretoload

rollpaper.

①First,opentherecordingpanel

andthefrontpanel.Takethe

rollershaftinbothhands,and

keepingithorizontal,pullitup

andout.

②Settherollpaper/Z-foldpaper

switchtotheROLLside.

③Puttherollershaftintotheroll

paperasfollows.

●Turntherollershaftends

aroundsothattheflangeon

theendwithoutthegearisin

therighthand,andnowturn

Fig.2-1Preparationsfor

LoadingPaper

-13-

Rollpaper/Z-foldpaperswitch

Writingpanel

(open)

Paperhold-downbar

(pulldowntofront)

Stockerfrontcover

(opentofront)

Rollershaft

Sprockertroller

(checkthatitrotatesfreely)

Plate

Penliftlever

(pullforward)

Rollpaper/Z-foldpaperswitch

(settoROLL)

Paperfeedroller

2.1.3 LoadingZ-FoldPaper

itwiththerighthandcounter-

clockwisetoremoveit.

●Next,inserttherollershaft

intothehollowshaftofthe

paperroll,checkthatthenut

comesouttheotherend,and

thenscrewontheflangejust

removedfromtheshafttofix

thepaperrollontotheshaft.

④Holdtherollsothatthegearis

totherightasshowninFig.2-2,

thenwithonehandplacetheroll

intheLinearcorder

①Removeterollershaftasdescribed

aboveintheprocedureforloading

rollpaper.(Therollershaftisnot

repuiredwhenZ-foldpaperis

loaded.)

②Settherollpaper/Z-foldpaper

switchtoZFOLD.

③OpenthecoveroftheZ-foldpaper

boxasshownintheillustration

below,andnowloadthepaperas

showninFig.2-3above.(Insert

thepapersothatchannel1is

ontheleft-handside.)

Itisagoodideatoopenthefront

panelandtheninsertthepaper.

Itwillbeeasierthatway.

Oncethepaperisloaded,usethe

followingproceduretosetthepaper

intheLinearcorder.

①Pullthepenlifeleverforward,so

thatthesprocketrollercanbe

rotatedfreely.Takethefrontend

ofthepaperinbothhandsand

drawitoverthetopoftheplate,

passingitthroughthespacebet-

weenthesprocketrollers.Once

2.1.4 PaperSetting

NoteTherollpaper/Z-folepaper

switchmustbesettoZFOLD.

Fig.2-3LoadingZ-FolePaper

-14-

CutopenthelidoftheZ-foldpaperboxandload

(fromfrontcover)

Fig.2-2LoadingRollPaper

Sprockertroller

Plate

Insertpaper

intothisgap

Cutpaperedge

intrapezoid

Supportfrom

underneath

MustbesettoSTOP

Table of contents

Other GRAPHTEC Voice Recorder manuals

Popular Voice Recorder manuals by other brands

Philips

Philips Pocket Memo DPM8200 manual

Eurotherm

Eurotherm 346 Installation and operation manual

Avid Technology

Avid Technology AirSpeed Multi Stream Installation and user guide

Sony

Sony ICD-MX20 - Memory Stick Pro Duo Digital Voice... user manual

Sony

Sony ICD-UX200WHT - Digital Flash Voice Recorder Specifications

Sanyo

Sanyo TRC-7600 Brochure & specs

Vidicode

Vidicode Call Recorder Single II manual

Olympus

Olympus DM-420 - Digital Voice Recorder Combo user guide

Videoswitch

Videoswitch Vi400 user manual

TS-market

TS-market EDIC-mini Tiny A45 Short operating instructions

PenRecorderPro

PenRecorderPro M60 instruction manual

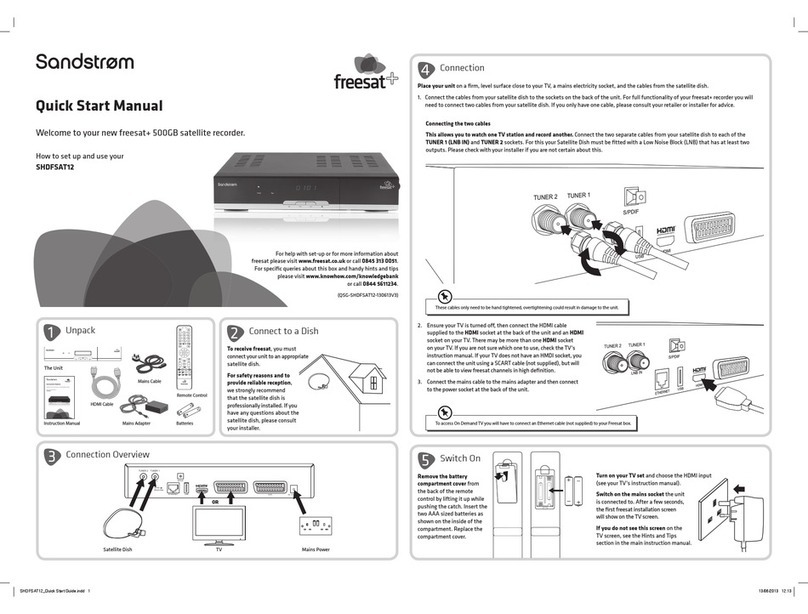

Sandstrom

Sandstrom SHDFSAT12 Quick start manual