General Information Grex Tritium Series Owner’s Manual

4

®

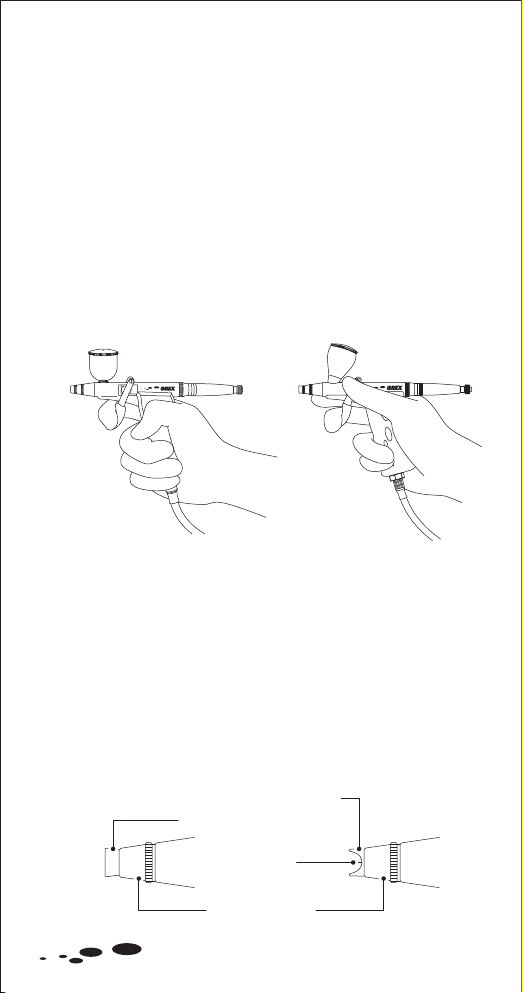

3. GENERAL INFORMATION

3.1 Compressors and Air Pressures

Choosing an appropriate air compressor that supplies sufficient

air flow ensures the ability to take full advantage of the versatile

spray characteristics of your Grex airbrush. Working pressures can

vary from 4 to 80 psi depending on the type of work and what

textures are desired. Paint viscosity and fluid nozzle opening size

can affect optimal working pressures. In general, thicker and higher

viscosity paints require higher pressures. Thick paints may require

45 psi or higher, while thinner paints may only need 18 to 25 psi.

It is strongly recommended that you use air filters, moisture

traps, and pressure regulators as part of your airbrush system.

Having clean, dry air enables optimal performance, provides

hassle-free maintenance, and prolongs the life of your airbrush.

Note: Use of the siphon aachment requires relatively higher

operating pressures than gravity feed cups.

3.2 Paint Preparation

Your Grex airbrush comes standard with Teflon packings which

allows most paints to be used with the airbrush. This includes, but

is not limited to, food dyes, acrylics, textile paints, makeup,

lacquers, and urethanes.

Proper paint preparation is needed for best performance. Paint

must be reduced using the proper solvent (manufacturer

recommended) and mixed thoroughly. Always filter the paint

through a fine nylon mesh to remove clumps and chunks that can

disrupt consistent spray and block the minute passageways in the

airbrush.

Warning: Always wear proper protective gear and clothing (such

as goggles, respirator, dust mask and gloves). Work in a well

ventilated area, especially when using urethane and enamel based

paints. Follow all instructions that come with your paint, and use

the reducers recommended by the paint manufacturer.

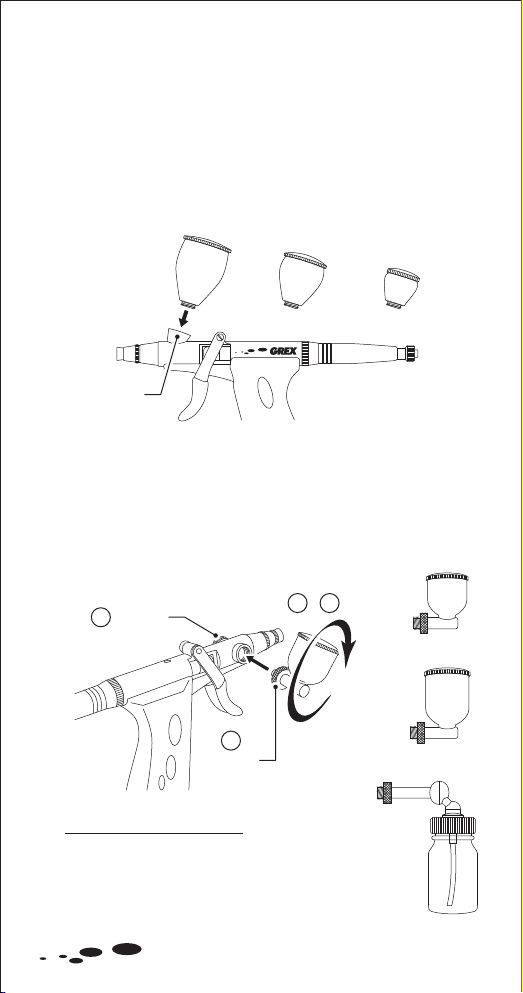

3.3 Airbrush System Setup

Aach any desired accessories, such as moisture traps, filters,

regulators, etc., to your compressor and/or airbrush depending on

your setup. Connect an air hose between the compressor and

airbrush while using the appropriate adapters where necessary.

Refer to Section 8 “Accessories” to learn more about adapters that

may be needed for your system setup. Adjust air pressures

according to paint type and desired spray characteristics. Check for

any air leaks from the compressor and air hose. Then fill the paint

reservoirs or boles with paint when ready to use.