Congratulations on your purchase of Grex Genesis airbrush; a multi-purpose, reliable and high

performance airbrush designed for the demanding professional. Precision machining and carefully

selected materials are employed in the manufacturing process of each Grex airbrush to insure

consistent high performance and adherence to Grex’s high quality standards. To maintain your

Genesis at its peak performance, proper care and attention must be observed.

Compressors and Air Pressures

Choosing an appropriate air compressor that can supply sufficient pressure for your Genesis

airbrush insures optimal operation and performance. Working pressures vary from 30 to 60 psi,

depending on the type of work being done and what textures are desired. In general, 45 psi or above

is needed to take full advantage of the versatile spray characteristics of the airbrush. Viscosity of the

paint also effects which pressures are ideal. In general, larger volumes and/or thicker paints require

higher pressures.

Assembling Airbrush for Use

Attach an air hose to the compressor and airbrush. Adjust the air pressure according to type of paint

used and desired spray characteristics. Check for any air leaks from the compressor and air hose.

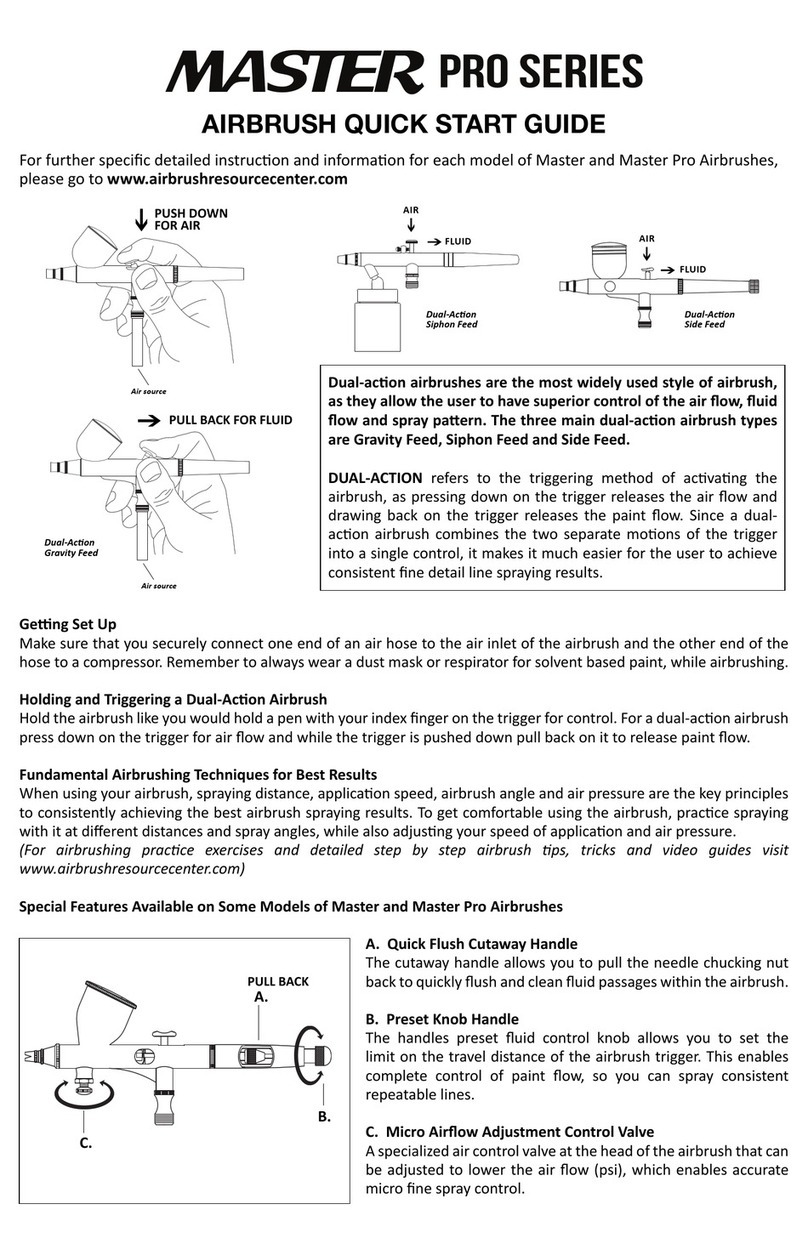

XB, XD, XG, XN, XS - Fill the bottle or color cup with some airbrush cleaner. Pointing the airbrush

away from you, press down on the trigger to allow air flow through the airbrush. Pull back on the

trigger to open the nozzle of the airbrush allowing cleaner to spray out.

XA - Fill the color cup with some airbrush cleaner. Turn the paint flow adjustment knob on the rear of

the airbrush counter-clockwise to open the nozzle. Pointing the airbrush away from you, press down

on the trigger to allow cleaner to spray out.

XT - Fill the color cup with some airbrush cleaner. Pointing the airbrush away from you, pull back on

the trigger to allow cleaner to spray out.

Caution: The fluid nozzle and needle are very delicate parts. Even the slightest physical damage can

adversely affect the spray pattern.

Paint Preparation

Proper preparation and filtering of paint through a nylon mesh is recommended for best performance.

Paint should always be thinned with its proper solvent. It is best to prepare the paint relatively thin

and make repeated passes across the work to achieve the desired shade. This will also improve the

quality of your work and decrease the cleaning time of your airbrush.

Line Width Adjustments

XB, XD, XG, XN, XS, XT - Line widths produced by the airbrush are controlled by adjusting the

distance the airbrush is held from the work surface and adjusting the amount of paint flow by

positioning of the trigger. As the trigger is pulled further back, the nozzle opens more, releasing more

paint and allowing larger spray widths. To help produce constant line widths, your Genesis airbrush

is designed with a Width Adjustment Knob on the rear of the handle, which controls how far the

trigger can be pulled back. Turning the knob clockwise helps produce finer lines, while turning the

knob counter clockwise helps produce wider lines.

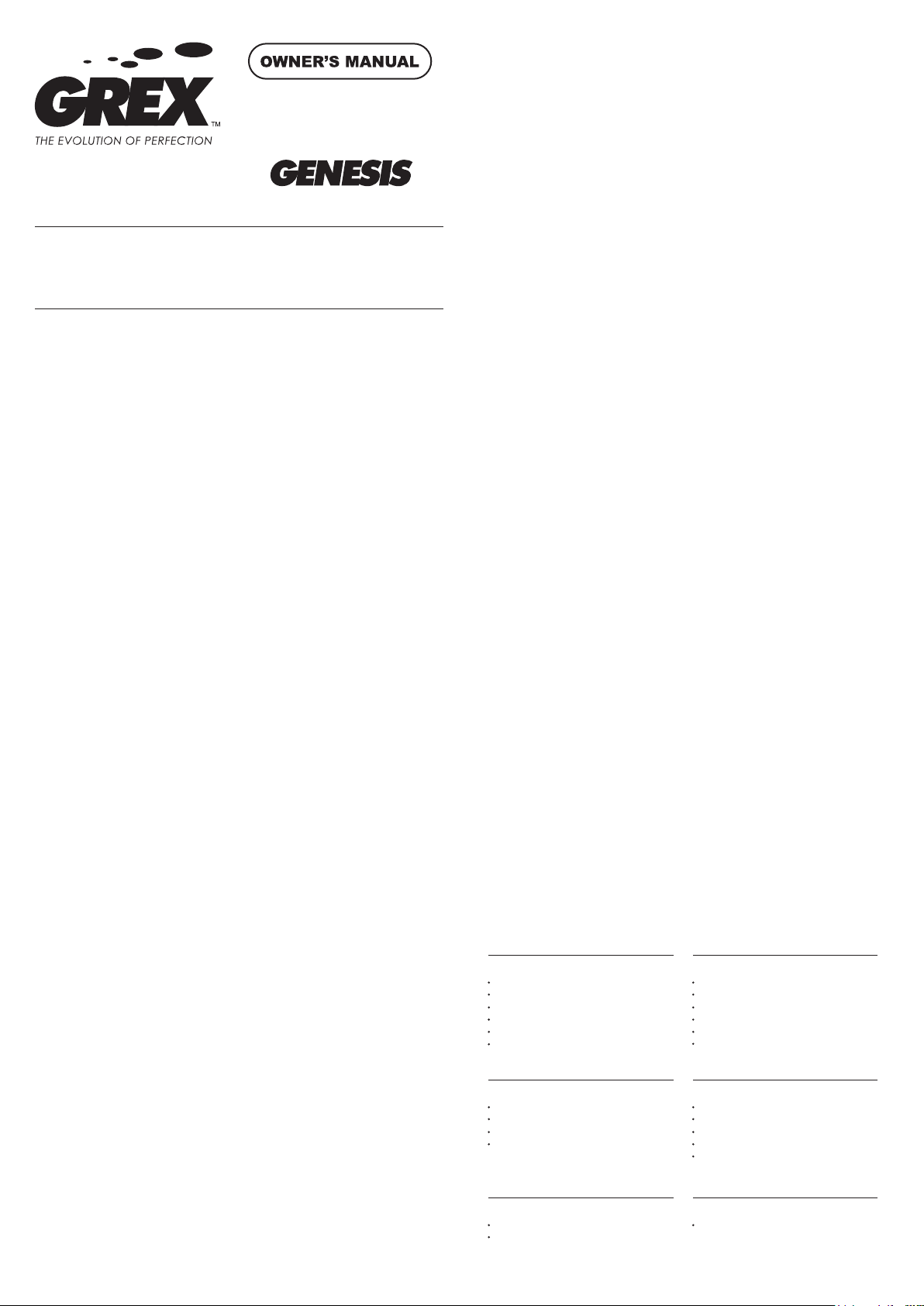

XA – The trigger in this model only controls air flow. So aside from adjusting the distance between

the airbrush and work surface, line widths are controlled by adjusting the Width Adjustment Knob on

the rear of the airbrush.

Fine Line Spraying

XB, XD, XG, XN, XS, XT - To spray a fine line, depress and pull the trigger back slightly while

positioning the airbrush close to the work surface.

XA – Fully turn the Width Adjustment Know clockwise to close off paint flow. Then turn the knob

clockwise slightly to provide a small opening for fine line widths and depress the trigger.

An extremely fine line can be obtained by carefully removing the needle cap and positioning the

airbrush closer to the surface.

Wide Line & Background Spraying

XB, XD, XG, XN, XS, XT - For wider lines and background spraying, depress and pull the trigger

further back to release more paint.

XA – Fully turn the Width Adjustment Know counter-clockwise to release maximum paint flow and

depress the trigger.

Increasing the air pressure and the distance of the airbrush from the surface further increases spray

widths.

Stippling

Stippling is achieved by removing the needle and nozzle cap assembly and adjusting the air pressure

between 5 and 50 psi. Lower air pressure will produce courser stipples whereas higher air pressures

will provide finer stipple effects. Note that paint viscosity will also affect the stippling texture.

GENERAL OPERATION

Cleaning the Airbrush

It is only necessary to clean areas of the airbrush which come in contact with paint namely, the paint

reservoir, around the tip of the needle and the head cap assembly. These areas must be kept clean

for optimum performance of the airbrush.

Before each use

At the beginning of every session, spray water or appropriate paint solvent through the airbrush to

make sure the airbrush is working properly.

Cleaning airbrush between color changes

For the bottle-fed airbrush (XB), changing colors can be accomplished quickly by replacing the color

bottle with a bottle containing the appropriate cleaning solution. Spray the cleaner at a heavy spray

setting into a paper towel or similar material until the airbrush is flushed free of color. Replace the

color bottle and spray with the next color. Repeat the cleaning procedure when finished.

For airbrushes with color cups (XB, XD, XG, XN, XS, XT), empty out remaining paint in the color cup

and spray out any excess paint. Wipe off as much residual paint as possible with a paper towel.

Partially fill the paint reservoir with appropriate cleaning solution and use a bristle paintbrush to

breakdown paint in the reservoir. Spray the cleaner at a heavy spray setting into a paper towel or

similar material. Repeat rinse and spray until airbrush is flushed free of color.

Periodic Cleaning

The cleaning procedures described above are recommended before intermittent breaks during your

work session to prevent paint from drying inside the airbrush’s internal parts. Always empty paint out

if the airbrush is not used for relatively long periods of time and spray appropriate cleaning solution

until the airbrush is flushed free of color. Blockages caused by dried paint are the biggest problem

when using an airbrush. Any time the airbrush becomes clogged, increase the air pressure and spray

appropriate cleaning solution through the airbrush for a short period of time.

After each use

At the end of every session, follow the same cleaning procedures as those described for cleaning

between color changes. Then remove and clean only those parts which come into contact with paint.

Carefully wipe clean the needle, nozzle and needle cap assembly with the appropriate cleaning

solution. It is not necessary to dismantle the entire airbrush. Before replacing the needle, apply a light

coat of lubrication to the needle to facilitate smooth triggering. After the airbrush parts have been

removed and cleaned, they must then be carefully replaced and adjusted in their designated

positions. Failure to align each part correctly will prevent the airbrush from functioning properly. In

many instances, when an airbrush fails to perform correctly, these problems result from improper

cleaning and/or alignment of parts.

Caution: Never soak entire airbrush in any solvent and/or cleaning solution to avoid damaging of o-

rings and airbrush packaging.

Lubrication of Airbrush

Caution: Do not use light machine oil or W-40 for lubrication. Doing so will cause the needle to stick

as it moves through the needle packing.

To insure smooth operation, lubricate the needle and trigger mechanism regularly. Periodically

remove the fluid needle and coat with high quality lubricant. Then wipe the needle with a soft clean

cloth, leaving a light coat of lubricant. Several drops of lube should also be placed in to the trigger

slot of the airbrush body to lube the trigger mechanism and air valve.

Caution: Do not over-lube the needle or the main lever mechanism. Doing so may transfer excess

lube into the nozzle causing severe paint flow problems.

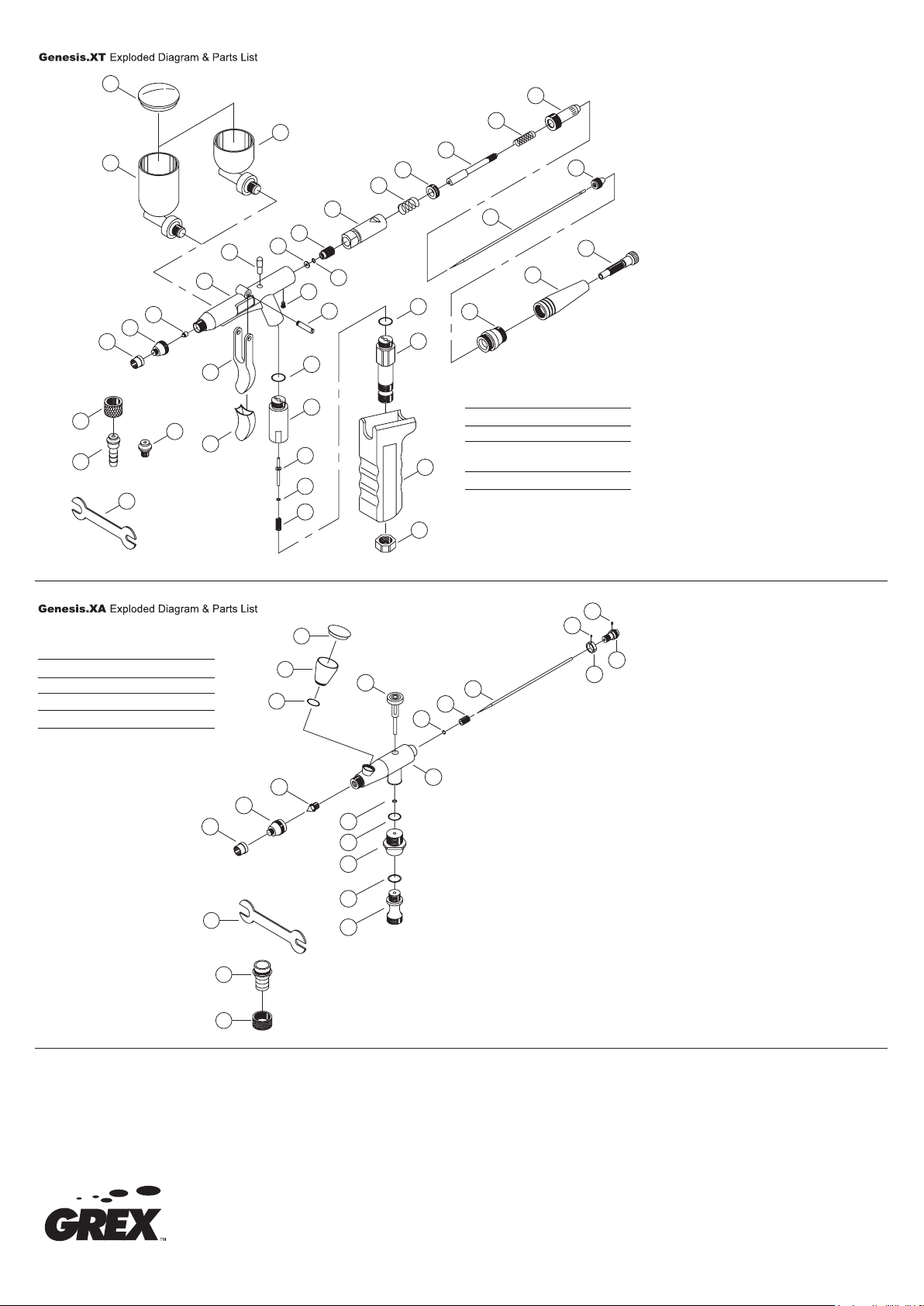

Replacement Parts

Caution: If it is necessary to disassemble the airbrush DO NOT use pliers. In most cases, no tools

are required to disassemble the airbrush except those provided in the kit.

Even though Grex airbrushes are manufactured with precision machining and high quality materials,

several delicate parts require replacement due to normal wear and tear. These include the fluid

nozzle, fluid needle and o-rings.

Fluid Nozzle –Before replacing the fluid nozzle, be sure that the needle is slightly pulled back in the

airbrush. To do this, remove the handle, loosen the needle lock nut and carefully pull the needle back.

In the case of the Genesis.XA, simply turn the width adjust knob counter-clockwise. Remove the

needle cap and nozzle cap then carefully unscrew the nozzle using the wrench supplied with your kit.

Replace with a new nozzle and reassemble the airbrush. Do not over tighten any parts of the

airbrush.

Note: It is recommended to change the fluid needle at the same time to insure even wear.

Fluid Needle – Grex needles are made of precision ground and hardened stainless steel and will

withstand prolonged use. However, because of their fine tip and long taper, they are easily subject to

physical damage. This is a highly delicate part and any small deformations to the needle tip will

compromise the performance of the airbrush. If the tip is severely bent, it must be straightened before

being removed to prevent damage to the fluid nozzle.

Your Genesis airbrush is a durable precision instrument and as with any precision instrument it is

susceptible to damage if handled improperly. It is essential to take care to prevent damaging the

components of this highly sensitive tool in order to assure its peak performance during its lifetime.

Proper maintenance of the Genesis airbrush demands appropriate cleaning and requires correctly

replacing and adjusting the parts. Daily and thorough maintenance of your airbrush will result in

spraying that is smooth, consistent and hassle-free.

MAINTENANCE

TROUBLESHOOTING

Symptom - Skipping

Dirty Airbrush

Paint too thick

Air pressure to high

Improper nozzle and housing connection

Crack or damaged nozzle

Dried paint on tip of needle

Possible Causes

Symptom - Double Line

Dirty Airbrush

Bent needle

Debris on tip of nozzle or in nozzle cap

Dried paint on tip of needle

Possible Causes

Symptom - Bubbling in Paint Resevoir

Improper nozzle and body seal

Cracked or damaged nozzle

Possible Causes

Symptom - Spattering

Dirty airbrush

Paint buildup in needle cap

Paint too thick

Air pressure too low

Dried paint on tip of needle

Possible Causes

Symptom - No or Restricted Spray

Clogged nozzle

Loose needle lock nut

Improper air pressure

Paint too tick

Cracked or damaged nozzle

Vent hole in bottle lid is plugged

Possible Causes

Symptom - Restricted Trigger Movement

Lubricate area around air valve piston

or trigger chamber

Possible Causes

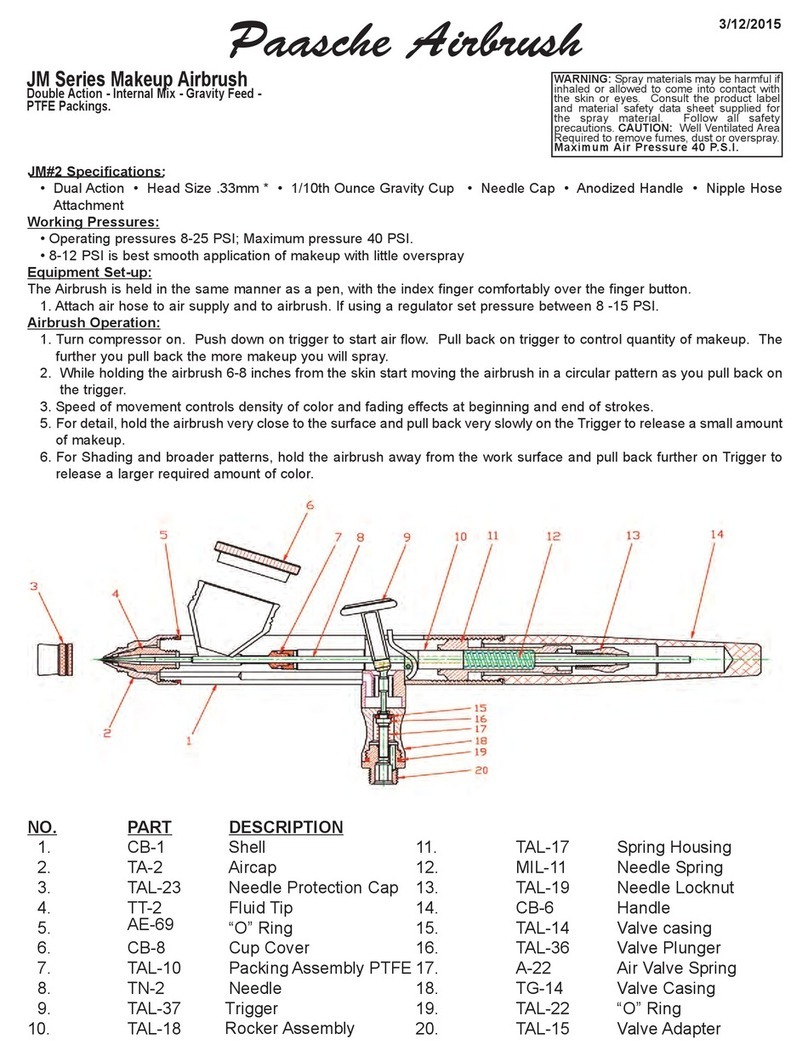

Technical Specifications

Operating Instructions

Maintenance Information

Troubleshooting Guide

Parts Diagrams

Series

The new Genesis series of airbrushes

from Grex. Premium equipment for

creative professionals & hobbyist.

© 2005 Grex Power Tools. All Rights Reserved.