Grizzly H7509Z User manual

COPYRIGHT © FEBRUARY, 2021 BY GRIZZLY INDUSTRIAL, INC.

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE

OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC.

#CS21711 PRINTED IN TAIWAN V1.02.21

MODEL H7509Z

STAND FOR G0441 DUST COLLECTOR

OWNER'S MANUAL

(For models manufactured since 01/21)

-2- Model H7509Z (Mfd. Since 01/21)

SECTION 1: SETUP

Unpacking

This cyclone dust collector stand was carefully

packaged for safe transport. When unpacking,

separate all enclosed items from packaging mate-

rials and inspect them for shipping damage. If

items are damaged, please call us immedi-

ately at (570) 546-9663.

IMPORTANT: Save all packaging materials until

you are completely satisfied with the stand and

have resolved any issues between Grizzly or the

shipping agent. You MUST have the original pack-

aging to file a freight claim. It is also extremely

helpful if you need to return your stand later.

Anchoring to Floor

Figure 1. Popular method for anchoring

machinery to a concrete floor.

Anchoring to Concrete Floors

Number of Mounting Holes ............................ 4

Diameter of Mounting Hardware................. 1⁄2"

Anchoring machinery to the floor prevents tipping

or shifting and reduces vibration that may occur

during operation, resulting in a machine that runs

slightly quieter and feels more solid.

If the stand and machine will be installed in

a commercial or workplace setting, or if the

machine is permanently connected (hardwired) to

the power supply, local codes may require that it

be anchored to the floor.

If not required by any local codes, fastening the

stand to the floor is an optional step. If you choose

not to do this, we recommend placing your stand

on machine mounts, as these provide an easy

method for leveling and they have vibration-

absorbing pads.

Lag shield anchors with lag screws (see below)

are a popular way to anchor machinery to a con-

crete floor, because the anchors sit flush with the

floor surface, making it easy to unbolt and move

the stand and machine later, if needed. However,

anytime local codes apply, you MUST follow the

anchoring methodology specified by the code.

Stand or Machine Base

Concrete

Lag Screw

Lag Shield Anchor

Flat Washer

Drilled Hole

Needed for Setup

The following items are needed, but not included,

for the setup/assembly of this stand.

Description Qty

• Model G0441 (Mfd. 09.20+). ....................... 1

• Additional People ....................................... 1

• Lifting Equipment ........................................ 1

• Safety Glasses (For Each Person) ............. 1

• Wrench or Socket 1/2" ................................. 2

• 90° Square ................................................. 1

• Scrap Cardboard ........................ As Needed

• Wrench or Socket 9/16" ................................ 2

• Phillips Head Screwdriver #2 ..................... 1

• Wrench or Socket 8mm .............................. 1

• Open-Ended Wrench 30mm ...................... 1

Aside from the information in this manual, all other

content in the Model G0441 owner's manual and

manual update applies and MUST be read and

understood for your own safety. IMPORTANT:

Keep this manual with the G0441 owner's

manual for future reference.

For questions or help, contact our Tech Support

Model H7509Z (Mfd. Since 01/21) -3-

Inventory

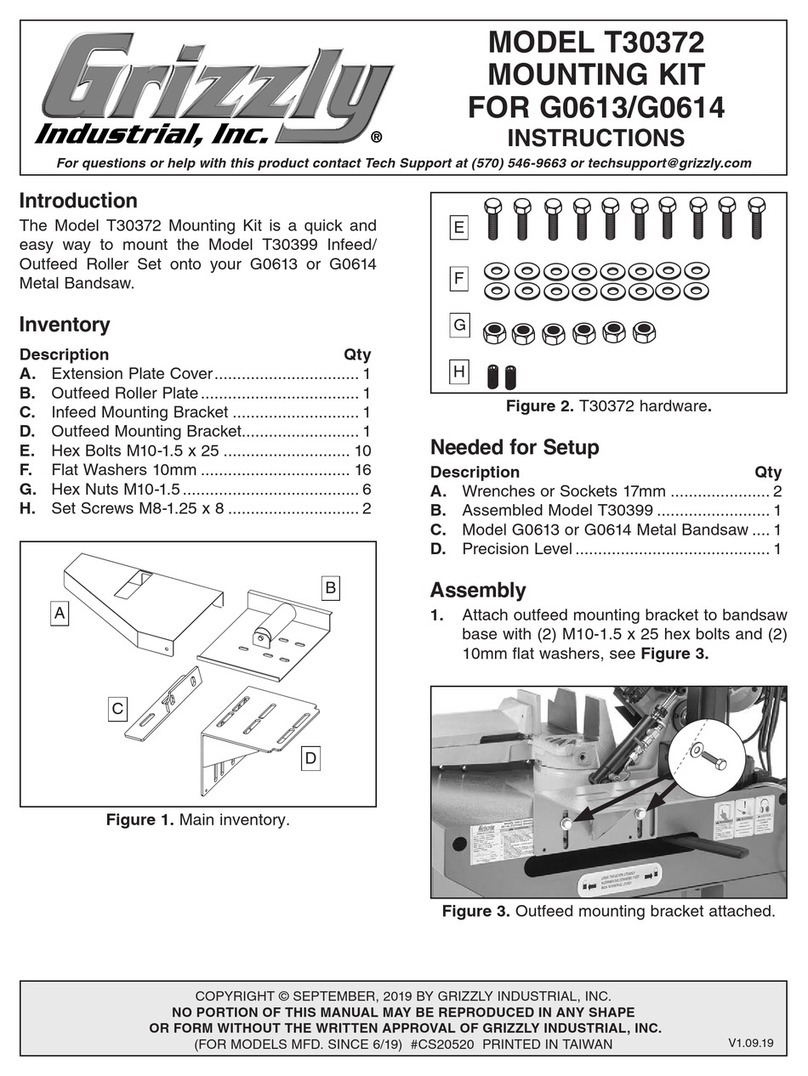

Box Contents (Figure 2) Qty

A. Lower Stand Legs ...................................... 4

B. Upper Stand Legs ...................................... 4

C. Upper Stand Braces ................................... 4

D. Lower Bracket Braces ................................ 4

E. Collector Mounting Brackets ...................... 4

F. Switch Box Base Panel .............................. 1

G. Handle Hook ............................................... 1

H. Handle Hook Base ..................................... 1

I. Hardware (Not Shown)

—Carriage Bolts 5⁄16"-18 x 3⁄4" .................... 56

—Hex Bolts 5⁄16"-18 x 1" .............................. 8

—Hex Bolts 3⁄8"-16 x 3⁄4" .............................. 3

—Hex Bolts 3⁄8"-16 x 1" ............................... 3

—Flat Washers 5⁄16" .................................. 72

—Flat Washers 3⁄8" ................................... 12

—Hex Nuts 5⁄16"-18 .................................... 64

—Hex Nuts 3⁄8"-16 ....................................... 3

—Lock Nuts 3⁄8"-16 ...................................... 3

— Vacuum Hose Clips ................................ 2

NOTICE

If you cannot find an item on this list, care-

fully check around/inside the machine and

packaging materials. Often, these items get

lost in packaging materials while unpack-

ing or they are pre-installed at the factory.

AB

C D

E

F

GH

The following is a list of items shipped with your

stand. Before beginning setup, lay these items out

and inventory them.

If any non-proprietary parts are missing (e.g. a

nut or a washer), we will gladly replace them; or

for the sake of expediency, replacements can be

obtained at your local hardware store.

IMPORTANT: Because the H7509Z stand replac-

es the wall-mount that comes with the Model

G0441 dust collector, you will not use and can set

aside (1) large wall mounting bracket, (1) small

wall mounting bracket, (6) 3⁄8"-16 x 3⁄4" hex bolts,

(12) 3⁄8" flat washers, and (6) 3⁄8"-16 hex nuts.

Figure 2. Model H7509Z inventory.

To reduce your risk of

serious injury, read this

entire manual BEFORE

using machine.

-4- Model H7509Z (Mfd. Since 01/21)

Assembly

Before beginning the assembly process, refer to

Needed for Setup in this manual and Inventory

on Page 3 of the Model G0441 Manual Update

and gather all listed items.

IMPORTANT: Use these steps instead of those

listed in the Model G0441 Manual Update to

assemble your dust collector to the H7509Z stand.

HEAVY LIFT!

Straining injury may occur

from improperly lifting

stand/collector parts. To

reduce this risk, get help

from other people and use

lifting equipment rated for

weight of stand/collector.

To assemble dust collector on stand:

1. Connect upper stand legs with lower bracket

braces with (16) 5⁄16"-18 x 3⁄4" carriage bolts,

5⁄16" flat washers, and 5⁄16"-18 hex nuts (see

Figure 3).

Note: Be sure to build frame using bolt holes

indicated in Figures 3–4 and 14. Machine

will not fit correctly on frame if wrong holes

are used and you will need to rebuild frame.

Figure 3. Initial assembly of upper stand legs

connected to lower bracket braces.

Upper

Stand

Leg

Lower Bracket

Brace

x 16

2. Attach upper stand braces to top of assembly

from Step 1, with (16) 5⁄16"-18 x 3⁄4" carriage

bolts, 5⁄16" flat washers, and 5⁄16"-18 hex nuts

(see Figure 4).

3. Square stand, as shown in Figure 5, then

tighten all hardware.

Figure 5. Example of squaring stand assembly

before tightening stand hardware.

Figure 4. Upper braces attached to stand

assembly.

x 16

Upper

Stand

Brace

Note: Only finger tighten hardware in Steps

1–2 for now.

4. Place intake cylinder on floor and apply 3 x

6 x 1800mm foam tape to intake cylinder top

rim, between mounting holes and inside edge

(see Figure 6).

Figure 6. Foam tape applied to intake cylinder

rim.

Foam Tape

Model H7509Z (Mfd. Since 01/21) -5-

We strongly recommend using a general-

purpose silicone sealant on all mating

surfaces during assembly process. For

those components assembled with a rubber

gasket between them, apply sealant evenly

on both sides of gasket before assembly.

5. Place motor/blower housing on a large piece

of cardboard to prevent scratches.

6. Attach intake cylinder to bottom of housing,

as shown in Figure 7, with (4) 5⁄16"-18 x 3⁄4"

hex bolts and 5⁄16" flat washers.

Note: Because this part of dust collector is

not accessible after assembly is complete,

consider using thread locker on bolts that

secure intake cylinder to motor/blower hous-

ing assembly to ensure that fasteners will not

come loose with vibration.

Figure 7. Intake cylinder attached to the bottom

of motor housing.

Motor/Blower

Housing

Intake

Cylinder

x 4

7. Attach cyclone funnel to intake barrel with

barrel gasket between them with (12) 5⁄16"-18

x 1" hex bolts, (24) 5⁄16" flat washers, and (12)

5⁄16"-18 hex nuts (see Figure 8).

Figure 8. Cyclone funnel attached to intake

barrel.

x 12

Barrel

Gasket

Figure 9. Collector mounting brackets and

securing fasteners.

x 8

Note: At places where you see three holes

close together, only use center hole for this

step. The two outside holes will be used in

the next step.

8. Attach (4) Model H7509Z collector mounting

brackets to intake assembly, as shown in

Figure 9, with (8) 5⁄16"-18 x 1" hex bolts, (16)

5⁄16" flat washers, and (8) 5⁄16"-18 hex nuts.

9. Place large piece of cardboard on ground to

prevent scraping parts on bare floor during

next steps.

10. With help of another person, lay stand assem-

bly on its side on cardboard and slide collec-

tor assembly into stand assembly, as shown

in Figure 10.

Cyclone

Funnel

-6- Model H7509Z (Mfd. Since 01/21)

Figure 10. Collector assembly fastened to stand.

x 8

12. Lift assembly upright and rotate it so inlet/

outlet directions are suitable for your shop.

13. Place remaining barrel gasket on top of

intake barrel.

14. Using two punches or Phillips screwdrivers,

align mounting holes, as shown in Figure 11,

and lower assembly onto intake barrel.

HEAVY LIFT!

Straining or crushing injury

may occur from improperly

lifting machine or some of

its parts. To reduce this

risk, use a forklift (or other

lifting equipment) rated for

weight of this machine.

Note: In next step, when installing two bolts

above intake port, use duct tape on bottom of

your wrench, as shown in Figure 12, to hold

bolts in place.This will enable you to start the

bolts more easily.

15. Attach assembly to intake barrel, as shown

in Figure 13, with (12) 5⁄16"-18 x 3⁄4" hex bolts

and 5⁄16" flat washers.

Figure 11. Aligning mounting holes.

Barrel Gasket

Here

11. Fasten collector assembly to stand with (8)

5⁄16"-18 x 3⁄4" carriage bolts, 5⁄16" flat washers,

and 5⁄16"-18 hex nuts, as shown in Figure 10.

Figure 13. Securing blower on intake barrel.

x 12

16. Using forklift or assistants, raise assembly

and attach lower stand legs to upper stand

legs, as shown in Figure 14, with (16) 5⁄16"-18

x 3⁄4" carriage bolts, 5⁄16" flat washers, and

5⁄16"-18 hex nuts.

Figure 14. Attaching lower legs to the initial

stand assembly.

x 16

Figure 12. Using tape on wrench in tight spot.

Model H7509Z (Mfd. Since 01/21) -7-

17. Attach outlet port and filter L-braces to blower

housing with outlet gasket between outlet

port and housing, as shown in Figure 15,

using (8) 5⁄16"-18 x 1" hex bolts, (16) 5⁄16" flat

washers, and (8) 5⁄16"-18 hex nuts.

Note: One brace attaches directly to hous-

ing with the following extra hardware:

(2) 5⁄16"-18 x 1" hex bolts, (4) 5⁄16" flat washers,

and (2) 5⁄16"-18 hex nuts.

18. Mount filter to L-braces with brace gaskets

between them, as shown in Figure 16, using

(4) 5⁄16"-18 x 3⁄4" hex bolts and 5⁄16" fender

washers.

Figure 16. Mounting filter to braces.

Brace Gasket Here

Figure 15. Outlet port and filter L-braces

installed.

19. Apply 3 x 15mm foam tape rolls to lips of

outlet port, canister adapter, and both ends

of muffler, as shown in Figure 17.

Figure 17. Foam tape applied to upper

components.

Foam

Tape

Foam

Tape

21. Apply 3 x 6 x 300mm foam tape to mating

surface of cyclone vacuum port.

Figure 18. Muffler properly positioned between

two gray flexible hoses.

Muffler

20. Attach 8" x 5" gray flexible hose between

canister adapter and muffler with (2) 8" hose

clamps, then attach 8" x 20" gray flexible

hose between muffler and outlet port with (2)

8" hose clamps (see Figure 18).

Note: It may be necessary to reposition can-

ister L-braces down one bolt hole or shorten

length of longer piece of flexible hose to

accommodate bend in hose.

x 10

Outlet Port

L-Braces

x 4

Filter

-8- Model H7509Z (Mfd. Since 01/21)

25. Connect upper and lower collection drums

with included metal clamp and provided hex

bolt and nut, as shown in Figure 21.

Figure 21. Installing metal clamp around

collection drum.

22. Attach vacuum tube port to cyclone funnel

with (4) 5⁄16"-18 x 3⁄4" hex bolts and 5⁄16" flat

washers (see Figure 19).

Figure 19. Cyclone vacuum tube and hose

attachment.

Vacuum Port

x 4

23. Attach vacuum hose to cyclone vacuum port

and secure with (1) 1

1⁄4" hose clamp.

24. Attach casters to bottom of lower collection

drum, as shown in Figure 20, with (4) 3⁄8"-16

hex nuts, (8) 3⁄8" flat washers, and (4) 3⁄8" lock

washers included in box with casters.

Figure 20. Casters attached to lower collection

drum.

x 4

Note: Before attaching hardware in this step,

separate 3⁄8" flat washers into two piles: one

for thin and one for thick. Do not use thin

washers until specified in Step 34.26. Place collection drum vacuum ring on bottom

of collection drum (see Figure 22).

Note: During operation, this ring and vacuum

connection to cyclone funnel will prevent col-

lection bag from collapsing.

Figure 22. Inserting collection drum vacuum

ring.

Model H7509Z (Mfd. Since 01/21) -9-

31. Install drum lid connecting plates with (2) 3⁄8"-

16 x 1" hex bolts, (4) 3⁄8" flat washers, and (2)

3⁄8"-16 lock nuts (see Figure 25).

Figure 24. Installing cyclone funnel adapter.

x 2

Drum Lid

Springs

Cyclone Funnel

Adapter

x 2

Figure 25. Installing drum lid connecting plates

on drum lid.

Connecting Plate

(1 of 2)

27. Attach (2) plastic collection drum handles to

collection drum using (4) 5⁄16"-18 x 3⁄4" Phillips

head screws, 5⁄16" fender washers, and 5⁄16"-18

acorn nuts (see Figure 23).

28. Install larger plastic collection bag into drum.

29. Place collection drum lid seal and lid on top

of collection drum (see Figure 23).

30. Position cyclone funnel adapter and drum lid

together with (2) 3⁄8"-16 x 11" hex bolts, (2)

drum lid springs, and (4) 3⁄8" flat washers, as

shown in Figure 24.

Drum Lid

Collection

Drum

Figure 23. Drum lid and handles installed on

collection drum.

Plastic Collection

Drum Handle

(1 of 2) x 4

Drum Seal

(Hidden by Lid)

32. Attach collection lid handle to cyclone funnel

adapter and drum lid connecting plates with

(4) 3⁄8"-16 x 1" hex bolts, (8) 3⁄8" flat washers,

and (4) 3⁄8"-16 lock nuts (see Figure 26).

Figure 26. Attaching collection lid handle to

connecting plate and adapter.

Drum Lid

Connecting Plate

(1 of 2)

Cyclone

Funnel

Adapter

Handle

x 4

33. While holding assembly in place, move col-

lection drum assembly under cyclone assem-

bly. Press cyclone funnel adapter and springs

down to fit under cyclone funnel.

-10- Model H7509Z (Mfd. Since 01/21)

38. Attach handle hook base to lower stand

brace above handle with (2) 3⁄8"-16 x 1" hex

bolts, (4) 3⁄8" flat washers, and (2) 3⁄8"-16 lock

nuts (see Figure 29).

x 2

Figure 29. Handle hook bracket attached to

lower stand brace.

Handle Hook Bracket

Lower Stand Brace

Figure 28. Cyclone funnel connected to drum lid

with flexible hose (stand removed for clarity).

Cyclone

Funnel

Drum Lid

35. Remove collection drum from under lid, and

secure hex bolts from Step 30 with (2) 3⁄8"-16

lock nuts.

IMPORTANT: DO NOT overtighten. Only

tighten lock nuts until they are flush with bot-

tom of hex bolts.

36. Move collection drum back under lid.

37. Connect bottom of cyclone funnel to collec-

tion drum lid with 9" flexible hose and (2) 9"

hose clamps (see Figure 28).

x 4

Cyclone

Funnel

Figure 27. Cyclone funnel attached to adapter.

Cyclone

Funnel

Adapter

34. Align mounting holes of cyclone funnel and

cyclone funnel adapter then attach with (4)

3⁄8"-16 x 1" hex bolts, (8) 3⁄8" thin flat washers,

and (4) 3⁄8"-16 lock nuts (see Figure 27).

39. Attach handle hook to base with (1) 3⁄8"-16 x

1" hex bolt, (2) 3⁄8" flat washers, and (1) 3⁄8"-16

lock nut (see Figure 30).

Note: Do not tighten nut completely to allow

hook to move.

Figure 30. Handle hook attached to hook

bracket.

Handle Hook

Bracket

Handle Hook

40. Connect vacuum hose to collection drum

vacuum port with (1) 1

1⁄4" hose clamp (see

Figure 31).

Figure 31. Connecting vacuum hose.

Model H7509Z (Mfd. Since 01/21) -11-

41. Secure vacuum hose inside upper and lower

stand legs with (2) vacuum hose clips (see

Figure 32).

Figure 32. Securing vacuum hose to stand legs.

42. Remove securing Phillips head screw and

open power junction box on Model G0441

switch bracket (see Figure 33).

43. Remove hex nuts, external tooth washers,

and Phillips head screw securing ground wire

to switch bracket (see Figure 34).

44. Remove strain relief shown in Figure 34.

Figure 33. Location of securing screw on power

junction box.

Power

Junction Box

Figure 34. Inside power junction box (shown

with power conduit attached for clarity).

45. Remove (4) Phillips head screws, flat wash-

ers, and hex nuts shown in Figure 34 to

remove junction box from switch bracket.

x 4

Strain Relief

46. Install power junction box to left side of Model

H7509Z switch box base panel as it was

attached to G0441 switch bracket (see Steps

43–45).

47. Close and secure power junction box.

48. Remove securing Phillips head screw and

washer and open magnetic switch box on

Model G0441 switch bracket (see Figure 35).

Figure 35. Location of securing fasteners on

magnetic switch box.

-12- Model H7509Z (Mfd. Since 01/21)

Note: Hand-held remote control uses IR

(infrared) to communicate with control box

receiver port, and must have direct line-of-

sight to switch box face. Locate control box

with this in mind.

Figure 37. Switch mounted to stand.

x 3

53. Slip canister collection bag around opening

under canister filter and secure with metal

bag clamp (see Figure 38).

54. Refer to G0441 Manual for Test Run and

Operation procedures beginning on Page 25.

Note: Remaining 8" hose clamp is for secur-

ing woodworking machine dust hose to inlet

port.

49. Remove (4) Phillips head screws, flat wash-

ers, and hex nuts shown in Figure 36 to

remove magnetic switch from switch bracket.

Figure 36. Inside magnetic switch box.

x 4

50. Install magnetic switch box to right side of

Model H7509Z switch box base panel as it

was attached to G0441 switch bracket (see

Step 49).

51. Close and secure magnetic switch box.

52. Mount switch box base panel on stand, as

shown in Figure 37, with (3) 3⁄8"-16 x 3⁄4" hex

bolts, (6) 3⁄8" flat washers, and (3) 3⁄8"-16 hex

nuts.

Figure 38. Canister collection bag secured to

filter.

Collection Bag

Bag Clamp

Model H7509Z (Mfd. Since 01/21) -13-

BUY PARTS ONLINE AT GRIZZLY.COM!

Scan QR code to visit our Parts Store.

1

2

3

4

5

9

10

11

14

15

18

19

20

21

22

23 24

25

26

27

28

29

6

87

16

17

20

30

12

13

31

3

4

3

Main

SECTION 2: PARTS

We do our best to stock replacement parts when possible, but we cannot guarantee that all parts shown

are available for purchase. Call (800) 523-4777 or visit www.grizzly.com/parts to check for availability.

-14- Model H7509Z (Mfd. Since 01/21)

BUY PARTS ONLINE AT GRIZZLY.COM!

Scan QR code to visit our Parts Store.

REF PART # DESCRIPTION REF PART # DESCRIPTION

1 PH7509Z001 MO UNTI NG BRACKET 17 PH7509Z017 HEX NUT 5/16-18

2 PH7509Z002 CARRIAGE BOLT 5/16-18 X 3/4 18 PH7509Z018 HANDLE HOOK BASE

3 PH7509Z003 FLAT WASHER 5/16 19 PH7509Z019 HEX BOLT 3/8-16 X 1

4 PH7509Z004 HEX NUT 5/16-18 20 PH7509Z020 FLAT WASHER 3/8

5 PH7509Z005 UPPER STAND BRACE 21 PH7509Z021 LOCK NUT 3/8-16

6 PH7509Z006 CARRIAGE BOLT 5/16-18 X 3/4 22 PH7509Z022 HANDLE HOOK

7 PH7509Z007 FLAT WASHER 5/16 23 PH7509Z023 HEX BOLT 3/8-16 X 1

8 PH7509Z008 HEX NUT 5/16-18 24 PH7509Z024 FLAT WASHER 3/8

9 PH7509Z009 UPPER STAND LEG 25 PH7509Z025 LOCK NUT 3/8-16

10 PH7509Z010 LOWER BRACKET BRACE 26 PH7509Z026 VACUUM HOSE CLIP 2-1/2"

11 PH7509Z011 CARRIAGE BOLT 5/16-18 X 3/4 27 PH7509Z027 SWITCH BOX BASE PANEL

12 PH7509Z012 FLAT WASHER 5/16 28 PH7509Z028 HEX BOLT 3/8-16 X 3/4

13 PH7509Z013 HEX NUT 5/16-18 29 PH7509Z029 FLAT WASHER 3/8

14 PH7509Z014 LOWER STAND LEG 30 PH7509Z030 HEX NUT 3/8-16

15 PH7509Z015 CARRIAGE BOLT 5/16-18 X 3/4 31 PH7509Z031 HEX BOLT 5/16-18 X 1

16 PH7509Z016 FLAT WASHER 5/16

Main Parts List

WARRANTY & RETURNS

Grizzly Industrial, Inc. warrants every product it sells for a period of 1 year to the original purchaser from

the date of purchase. This warranty does not apply to defects due directly or indirectly to misuse, abuse,

negligence, accidents, repairs or alterations or lack of maintenance. This is Grizzly’s sole written warranty

and any and all warranties that may be implied by law, including any merchantability or fitness, for any par-

ticular purpose, are hereby limited to the duration of this written warranty. We do not warrant or represent

that the merchandise complies with the provisions of any law or acts unless the manufacturer so warrants.

In no event shall Grizzly’s liability under this warranty exceed the purchase price paid for the product and

any legal actions brought against Grizzly shall be tried in the State of Washington, County of Whatcom.

We shall in no event be liable for death, injuries to persons or property or for incidental, contingent, special,

or consequential damages arising from the use of our products.

The manufacturers reserve the right to change specifications at any time because they constantly strive to

achieve better quality equipment. We make every effort to ensure that our products meet high quality and

durability standards and we hope you never need to use this warranty.

In the event you need to use this warranty, contact us by mail or phone and give us all the details. We will

then issue you a “Return Number,’’ which must be clearly posted on the outside as well as the inside of

the carton. We will not accept any item back without this number. Proof of purchase must accompany the

merchandise.

Please feel free to write or call us if you have any questions about the machine or the manual.

Thank you again for your business and continued support. We hope to serve you again soon.

To

take advantage of this warranty, you must register it at https://www.grizzly.com/forms/warranty, or

you can

scan the QR code below to be automatically directed to our warranty registration page. Enter all

applicable information for

the product.

WARRANTY

Other Grizzly Rack & Stand manuals

Grizzly

Grizzly T28000 User manual

Grizzly

Grizzly T31830 User manual

Grizzly

Grizzly T32468 User manual

Grizzly

Grizzly G0871 User manual

Grizzly

Grizzly T25862 User manual

Grizzly

Grizzly T26979 User manual

Grizzly

Grizzly T30372 User manual

Grizzly

Grizzly T33905 User manual

Grizzly

Grizzly T10117 User manual

Grizzly

Grizzly T33692 User manual

Popular Rack & Stand manuals by other brands

Eastwood

Eastwood 30650 instructions

PSC

PSC Active RF Matrix Rack manual

New Star Computer Products

New Star Computer Products FPMA-C050SILVER instruction manual

The Flying Culinary Circus

The Flying Culinary Circus FCC BBQ instruction manual

CHIEF

CHIEF SL-236 Service manual

Adaptive

Adaptive SBC12-17-CA-30 installation guide