2/4

DEC ARATION OF COMP IANCE:

GYS certifies that the G spot DRILL is manufactured in compliance with the directive 89/392/CEE, amended

2006/42/CEE.

PRECAUTIONS BEFORE USE

In order to avoid risks of injuries, an person who operates, installs, services or changes accessories, as well as an person

working in the area of this tool, must read and understand the following instructions.

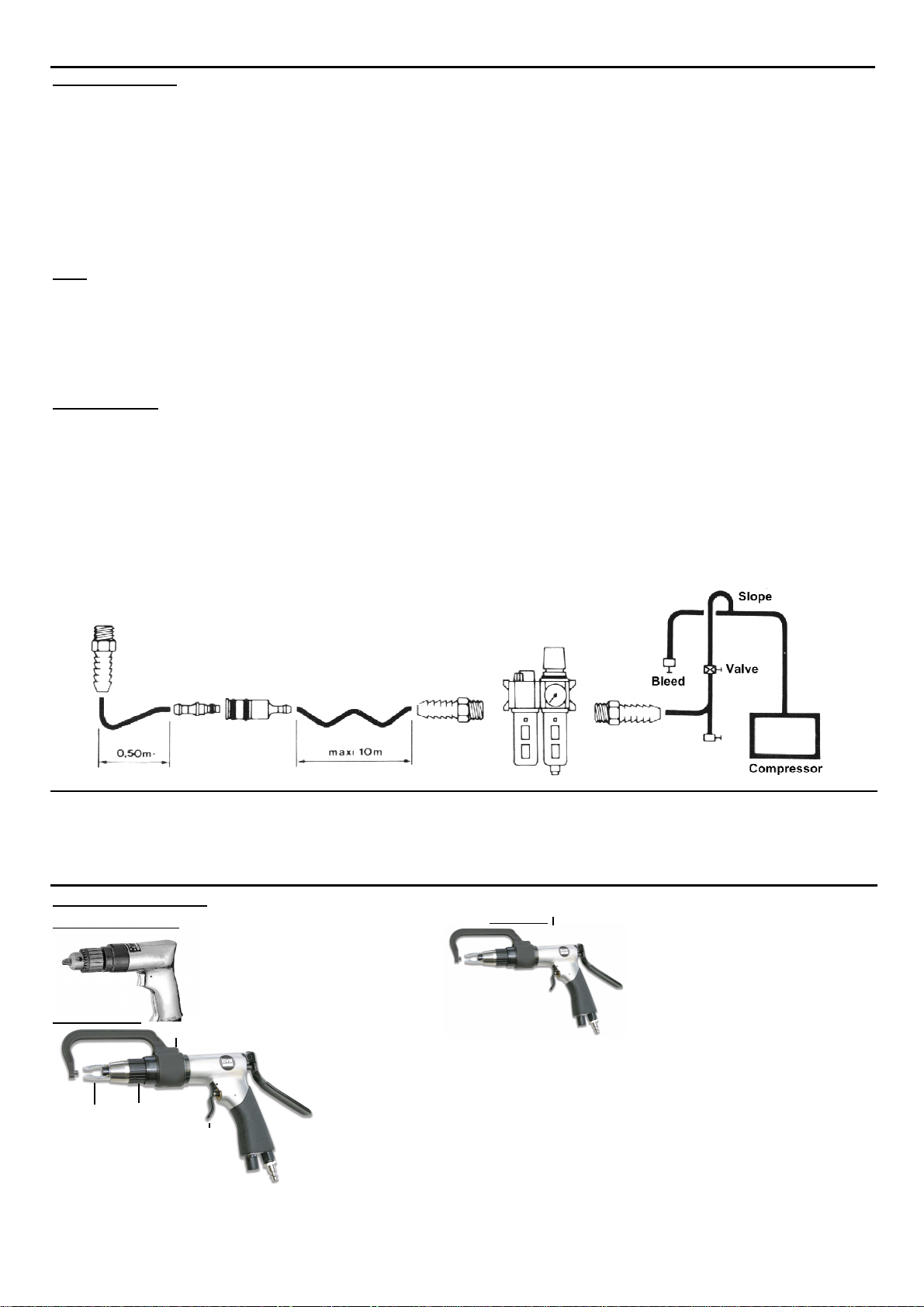

Air supply

• Compressed air can cause serious injuries.

• Alwa s turn off the air suppl and disconnect it before installing, removing or adjusting an accessor on this machine, or

before performing an maintenance on this machine.

• Do not point the jet of compressed air at other people or ourself; keep b standers awa while operating the tool.

• Whiplashing hoses ma cause serious injuries; check carefull the hoses and fittings for leaks and deteriorations.

• Do not fit quick change couplings onto the machine as vibration can cause the coupling to fail.

• Read the instructions for a proper assembl of the tool

• In case swivel connectors are used, secure them with locking pins.

• Operate the tool at the air pressure indicated in order to ensure maximum durabilit of the tool

• Manipulate hoses and fittings carefull . Do not force the hose off the air inlet. Keep air hoses awa from heat sources,

lubricants and sharp materials. Do not use damaged, fra ed or deteriorated air hoses and fittings. Be sure all fittings are

tightl secured.

Personal safety

• Operators and service personnel must be able to ph sicall manage the tool and follow the appropriate instructions.

• Keep bod stance balanced and firm. Vibrations, repetitive motions or uncomfortable positions ma be harmful to our

hands. If discomfort, tingling feeling or pain occurs; stop using an machine and seek medical advice.

• Use protective equipment such as glasses, gloves, safet shoes as well as acoustic protection.

• This machine has not been designed to be used in an explosive atmosphere environment. Do not lubricate tools with

flammable or volatile liquids such as kerosene, diesel or petrol.

• Avoid direct contact with the parts in motion when using the tool, to prevent cuts.

• The splitting of a pneumatic tool casing in use ma cause serious injuries. The smallest debris can cause e e injuries and

lead to blindness.

• Alwa s sta at a suitable distance from the cutters, blades, tools in motion, etc…

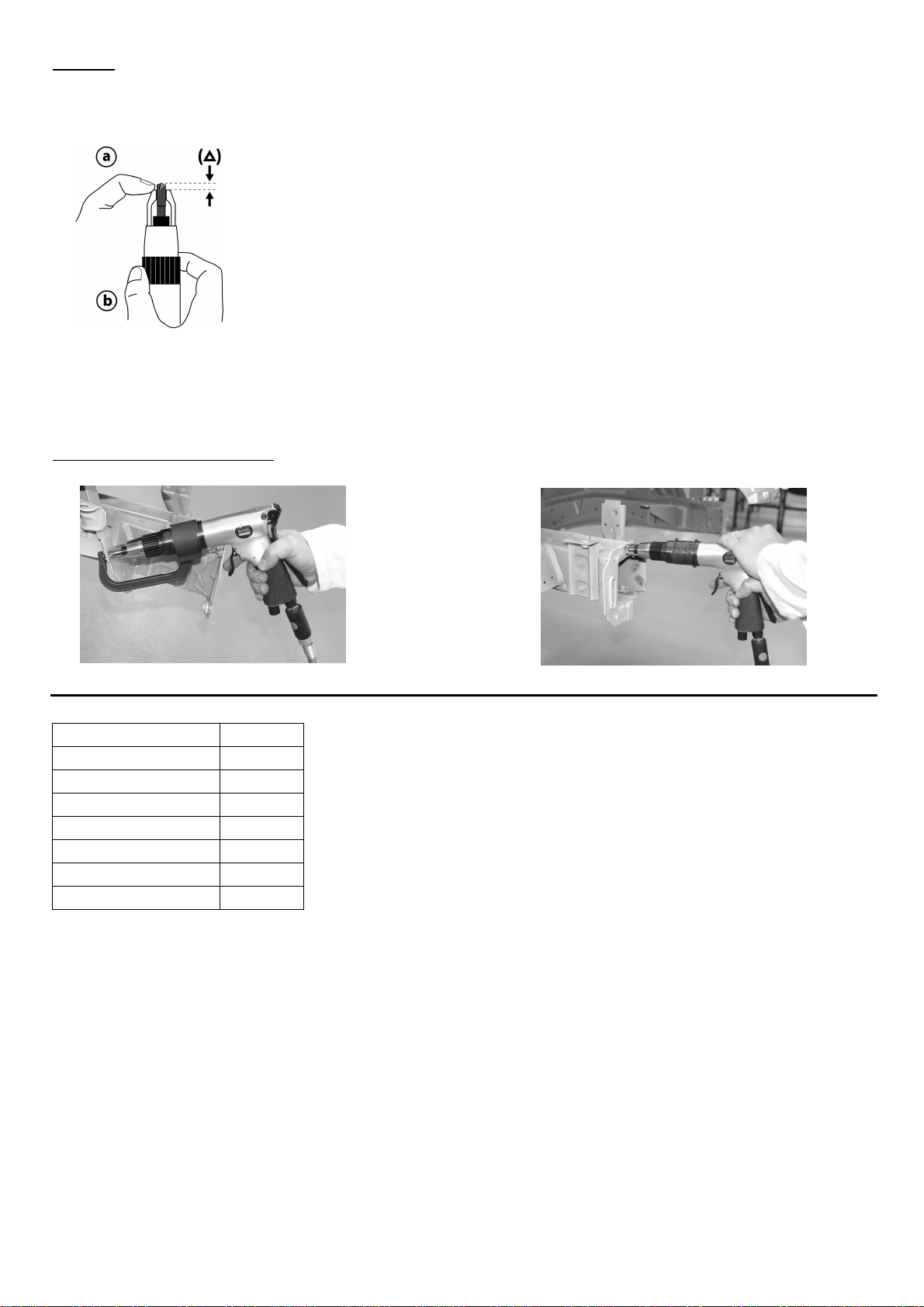

Tool use and care

• Do not carr the machine b the hose

• Do not wear watches, ring bracelets or loose clothing when using the tool, and keep long hair awa from moving parts.

• For safet , top performance and maximum durabilit , operate the tool at the recommended air pressure.

• Cutters heat up while in use. Let them cool down before seizing them. Disconnect air suppl before changing the cutters.

• Operate the G spot DRILL with care to prolong its efficienc in time.

• Do not modif the tool or its accessories