3

COMPLETING YOUR SHED

You will need these additional materials:

OPTIONAL MATERIALS

FOUNDATION OR FLOOR MATERIALS

ADDITIONAL MATERIALS NEEDED

BEFORE YOU BEGIN

DRIP EDGE ..................... 20 Feet

#15 ROOFING FELT

To cover 23 Sq. Ft. of roof area.

1" GALVANIZED ROOFING NAILS.........1/4 Lb

For roong felt.

REFER TO THE BACK OF THIS MANUAL AND THE MANUFACTURER’S INSTRUCTIONS

FOR INSTALLATION OF SHINGLES, DRIP EDGE AND FELT.

• This shed kit includes a complete wood oor frame system and oor decking.

• This shed kit does not include ANY leveling materials.

•See the FLOOR LEVELING section on page 6 for recommended methods and suggested materials to properly level your

oor, as this will vary depending on your specic site.

3-TAB SHINGLES ............................ 1 Bundles

PAINT FOR SIDING .......................... 1 Gallon

Use 100% acrylic latex exterior paint. (2) coats recommended.

CAULK ................................................. 1 Tube

Use acrylic latex exterior caulk that is paintable.

1" GALVANIZED ROOFING NAILS.... 1 Lbs

For shingles.

PAINT FOR TRIM .............................1 Quart

Use 100% acrylic latex exterior paint.

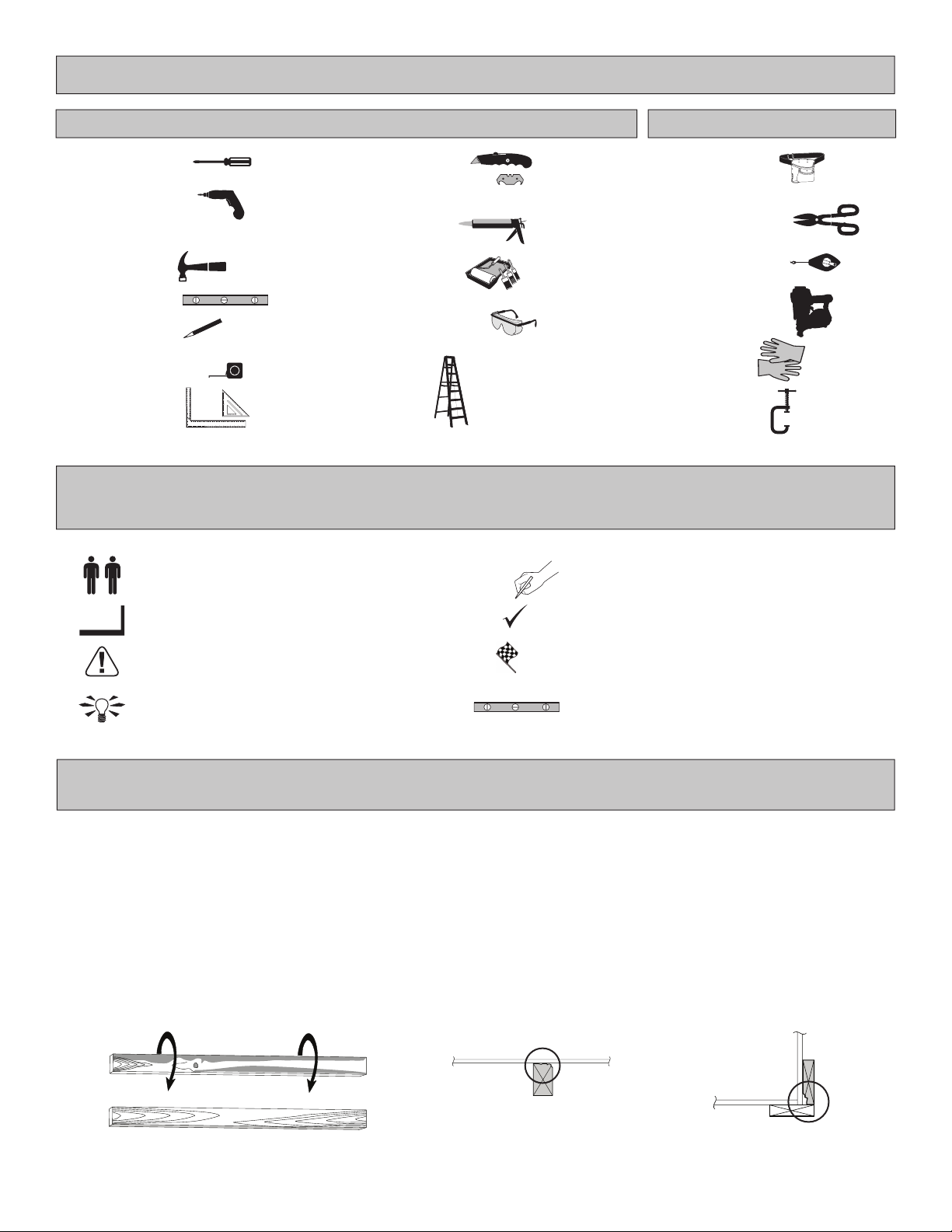

REINFORCED WOOD FLOOR FRAME (OPTIONAL)

IMPORTANT! (The included oor is designed for general use.) Depending on your specic use you may want to construct a heavy

duty oor frame by adding additional oor joists (shown below as shaded). Below is a list of additional materials (not included):

x8

x2 2 x 4 x 8' (5 x 10 x 244 cm) Treated Lumber

Cut lumber to 2 x 4 x 65-1/4" (5 x 10 x 165,7 cm)

3" (7,6 cm) Hot Dipped Galvanized Nails

Optional 9" (322,9 cm)

spacing

Standard 18" (45,7 cm)

spacing

Required to validate warranty