HANG KLD-3 User manual

User's Manual

For

Oil Pollution Detector

KLD-3

Please read instruction manual carefully before use!

Kindly Reminder

This operation manual instructs how to safely and correctly operate the KLD-B series oil

contamination detector in detail. Make sure you have understood the content of the

operation manual correctly, and operate the product according to the described procedure.

Please contact your account manager in case of any questions when operating. Operation

should be done under the instruction of the technicians. Do not disassembly the

equipment by yourselves in order to avoid any man-made damage.

Contents

1 Product Introduction..............................................................................4

1.1 Brief introduction.......................................................................... 4

1.2 Technical Data.............................................................................. 4

2 Operation................................................................................................ 6

2.1 Hose Connection..........................................................................6

2.2 Instrument Start............................................................................7

2.3 Measuring interface..................................................................... 7

2.4 Instrument Rinsing.......................................................................8

2.5 Battery Recharging...................................................................... 8

3 Printer...................................................................................................... 9

4 Trouble Shooting....................................................................................9

5 Notes..................................................................................................... 10

6 Packing list............................................................................................11

7 Attached sheet..................................................................................... 11

1 Product Introduction

1.1 Brief introduction

New type hydraulic oil pollution online detector KLD - 3, it is a smart,

lightweight and effective confidential laser oil pollution analysis

instrument. It has many features, can report the condition of

hydraulic and lubrication system, making the maintainers in early

intervention in order to prevent the pollution of hydraulic system

components of wear or damage, which not only reduce the repair

costs to minimum and reduced the total equipment downtime,

improve system security, prolong the service life of equipment.

The equipment adopts color LCD screen visualization in digital and

graphically display the oil pollution condition; Can detect mineral oil,

synthetic oil or fat phosphate, such as hydraulic oil, lubricating oil,

transformer oil, insulating oil, turbine oil, turbine oil, gear oil, engine

oil, aviation kerosene oil. Can be widely used in aerospace, electric

power, petroleum, chemical industry, transportation, port,

metallurgy, machinery, automobile manufacturing and other fields

1.2 Technical Data

Weight:: 3.5 Kg

Dimension: 339 mm * 295 mm * 152 mm (L * W * H)

Electricity source: AC 220 v ±10%, Rechargeable Lithium

Battery

Environmental temperature: 15 ℃to 40 ℃

The oil temperature: 0 ℃~ 55 ℃(24 hour) short-term < 85 ℃

(10 min)

Storage temperature: - 20 ℃~ 60 ℃

Wet degree: relative humidity 20 ~ 85% RH, without

condensation; Store humidity < 90% RH without condensation;

Channels: particle size (including 2µm, 5µm, 15µm, 25 µm,

50µm and 4µm(c),6µm(c),14µm(c)

Pollution level range: ISO 4406 0 ~ 24

NAS 1638 00 ~ 12

Working pressure difference: low voltage 0.7 ~ 3 M Pa

Working pressure: long-term < 4 M Pa (24 hour) short-term <

20 M Pa (30 min)

Working flow: 50 ~ 300 ml/min

Oil viscosity: (10 ~ 100 CST) plus or minus 20%

Sensitivity: 1µm(ISO4402); 4µm(c)(ISO11171)

Repeatability precision: ±0.5 ISO

Calibration period: 1 year

protection grade: IP67 (case closed)

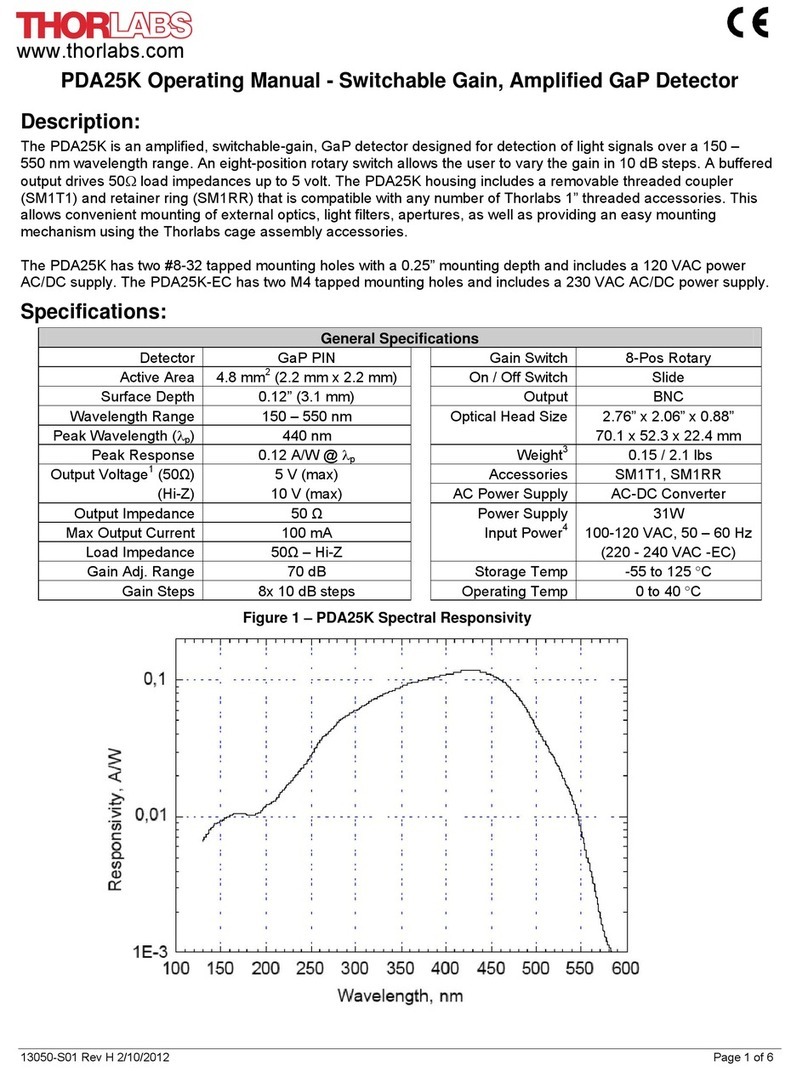

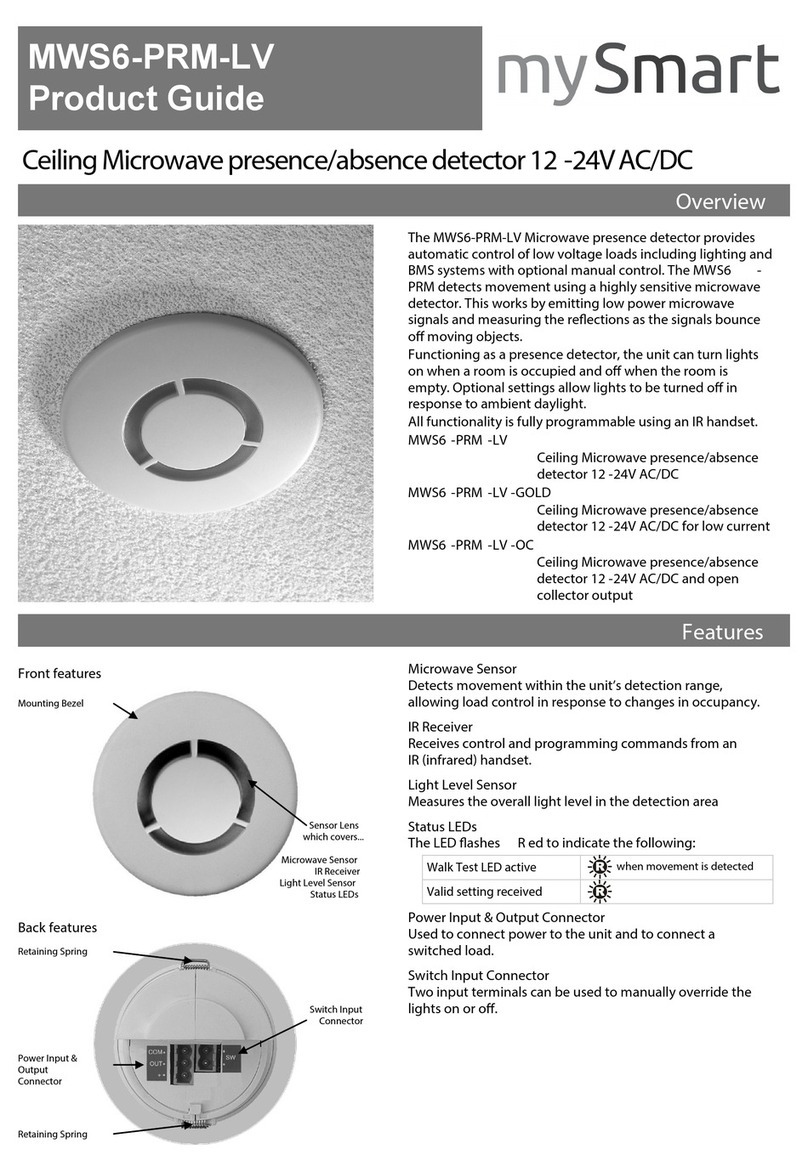

power switch

Owe electric

Pollution shows

oil interface

recharge socket

Press to print

printer

2 Operation

This chapter describes to instruct how to use the KLD-3 to

determine the level of oil contamination, connect hoses, software

operation, hose flushing, etc.

Chart 3.0 Product panel

2.1 Hose Connection

There are two ports labeled inlet and outlet. The connecting

methods are shown in Figure 3-0 below. Ensure that connection of

the nut to the hose is tighten with no oil leakage.

Chart 3.1 Pipeline connection diagram

2.2 Instrument Start

Place the instrument on a dry flat surface. Connect the hoses as

instructed in chapter 3.1. Open the cover, plug in the power cable,

turn on the power switch to start the instrument. Please see below

for details.

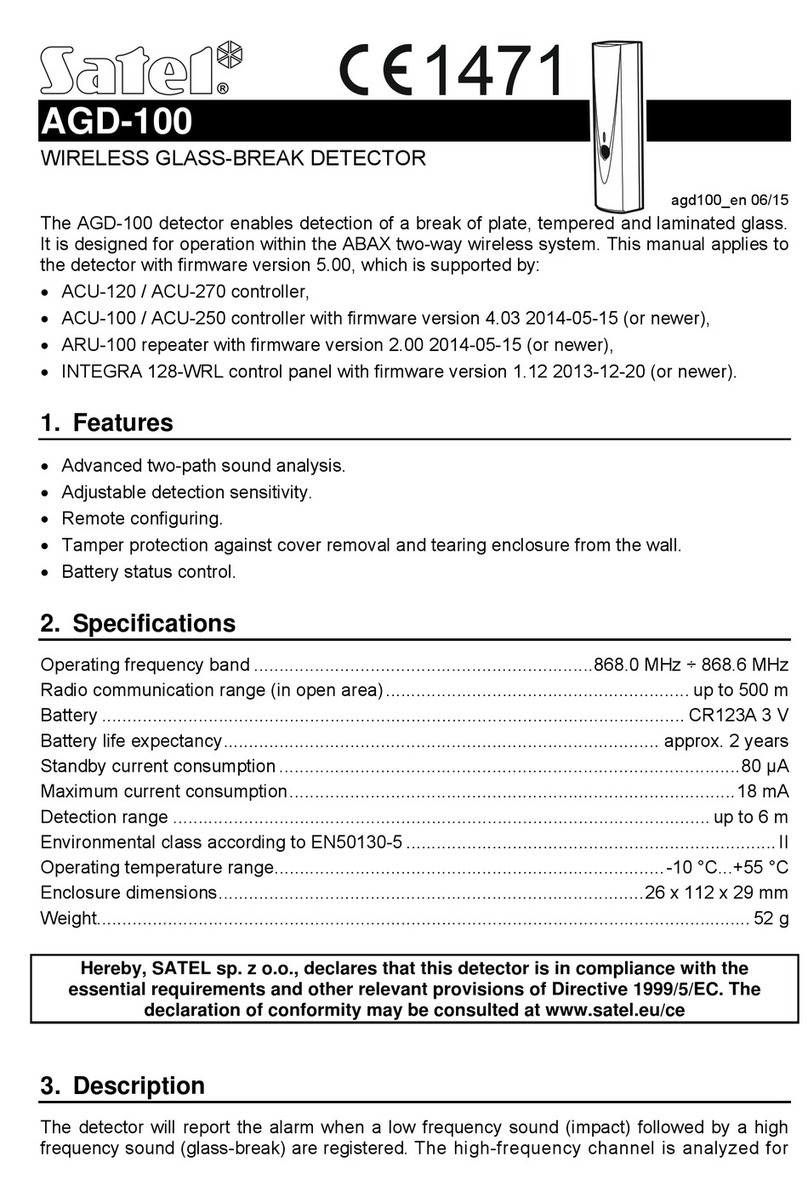

2.3 Measuring interface

The default screen is as follows after the instrument has started.

Sampling period

IOS Level

ISO final grade

The laser current

Receiving voltage

NAS Level

NAS final grade

Chart 3.3 the main measuring interface

In the data display interface, sampling period can be shown as well

as the working circuit temperature, current, voltage, and ISO4406

NAS1638 corresponding standard level. Users can observe the

current different standards according to the need of test information.

Sampling period is 6 seconds (default). The laser parameters such

as current, receiving voltage are sensor diagnostic parameters.

2.4 Instrument Rinsing

Hose flushing is recommended after each operation. Petroleum

ether is the recommended fluid for flushing. Insert the oil-in hose in

flushing fluid and the oil-out hose into a waste container or bottle.

Select the "rinsing" button to start the pump. Keep rinsing liquid

flowing for a minute and then click the "stop" button. Remove the

hoses, let the pump run for a few minutes to eliminate the

remaining rinsing liquid in hoses. Flushing now is completed.

Note: For hose rinsing, we recommend that high-speed rinsing is

adopted in the beginning, then switch it to low-speed.

2.5 Battery Recharging

Battery is accessories. If you buy the instrument with battery and in

the situation of insufficient power, the display panel owe electric

lights will be on. please recharge in time. Firstly, connect the

external power supply and then turn on the power switch button

charging for 8 to 12 hours. This system standard power supply is

for indoor usage, suggesting that keep the instrument shutting

down when charging. Please remove the charger in time when well

charged.

3 Printer

This system printer is not a self-locking button. Each click of the

print button can make the printer to print out the current test results

(final report generated in NAS1638 standard format). The results

are as shown in the figure below:

Open the cover, install the thermal paper into place. Close the

cover leaving the end of the paper roll outside of the cover.

4 Trouble Shooting

Following is a list of common malfunctions and rectifications that

the operator can perform by themselves. For other problems,

please contact our engineers for further assistance.

5 Notes

Please select the appropriate product model that meets your

actual requirement. Low Pressure model: Not less than 20 psi

(1.3 Bar) of pressure difference. Please make sure there is no

large particles greater than 100µm (visible by naked eyes) or

transparent floccules, as the big particles can clog up at the

sensor.

Please make sure there are no obvious bubbles in the liquid,

otherwise the accuracy of measurement will be affected.

The sample volume should be no less than 100ml.

this product is a precision laser instruments. Strong vibration will

Simple Fault

Resolution for Fault

Unable to start the instrument

Check if the power cable is plugged in and

power turned on.

Unable to print

Check to see if the printer is short of paper.

No oil comes out from the oil-out

Check to see if the oil in hose is connected;

Check to see if pressure is within the required

parameters.

Not less than 20 psi (1.3 Bar) of pressure

difference);

Possible blockage in sensor.(needs to be sent

back to supplier for resolution)

Pop-up window indicating "errors".

Unable particle count.

1.Too many bubbles in oil. Eliminate air by

using ultrasonic bath.

2. Re-enter the measuring interface and try

again.

affect the measurement result. Please don't place the

instrument in a strong mechanical vibration platform or device.

6 Packing list

Product standard packing list

7 Attached sheet

SHEET 1

Standard table of NAS 1638 contamination class

(Unit: particle quantity/100ml)

Contami

nation

class

Range of particle size/μm

5-15

15-25

25-50

50-100

>100

00

125

22

4

1

0

0

250

44

8

2

0

1

500

88

16

3

1

2

1000

178

32

6

1

No.

Item

Specifications

QTY

1

Online oil contamination

detector

ISO4406、NAS1638

1

2

Pressure hose

M16*2 on both sides, 1.5m

2

3

Imported PT type

pressure joint

M16x2 pressure connector

2

4

Electronic instruction

CD

1

5

Paper instruction manual

A4

1

6

Test report

third party test report

(NAS standard, 46 hydraulic oil)

1

7

Certificate

Beijing Hangfeng kewei Quality

inspection

1

8

Power adapter

Charging device

1

9

Printer paper

57*φ33

1

3

2000

356

64

11

2

4

4000

712

128

22

4

5

8000

1425

253

45

8

6

16000

2850

506

90

16

7

32000

5700

1012

180

32

8

64000

11400

2025

360

64

9

12800

0

22800

4050

720

128

10

25600

0

45600

8100

1440

256

11

51200

0

91200

16200

2880

512

12

10240

00

18240

0

32400

5760

1024

13

20480

00

36480

0

64800

11520

2048

14

40960

00

72900

0

12960

0

23040

4096

SHEET 2 Standard table of ISO 4406 contamination class

(Unit: particle quantity/100ml)

Particle quantity per

100ml

Class

code

particle

quantity/100ml

Class

code

Larger

than

Upper

limit

value

Larger

than

Upper

limit

value

1300000

00

2500000

00

28

4000

8000

13

6400000

0

1300000

00

27

2000

4000

12

3200000

0

6400000

0

26

1000

2000

11

1600000

0

3200000

0

25

500

1000

10

8000000

1600000

0

24

250

500

9

4000000

8000000

23

130

250

8

2000000

4000000

22

64

130

7

1000000

2000000

21

32

64

6

500000

1000000

20

16

32

5

250000

500000

19

8

16

4

BEIJING HANG FENG KE WEI EQUIPMENT TECHNOLOGY CO.,LTD.

Tel::+86-10-82866783-8185

Website: www.hangf.com

Email: [email protected]

Fax:+86-10-82600379

Post Code:100141

Address: NO.6 Dacheng Rd, West 4th Ring, Fengtai District, Beijing.

Table of contents