Hanmey Implements AGL Series Guide

Ha

H a n m e y I m p l e m e n t s

1

FLAIL MOWER

AGL AGLB AGLC Series

Operation, Service & Parts Manual

For

AGL Off-set Mulcher

Ha

H a n m e y I m p l e m e n t s

2

TABLE OF CONTENTS

PAGE

General Information......................................................................................4

Introduction.......................................................................................4

Symbols ..............................................................................................4

Safety Labels ...................................................................................................5

Safety Labels ...................................................................................................6

Safety .......................................................................................................... 7--10

Allowed Use....................................................................................................7

Improper Use .................................................................................................7

Safety in the Workplace.................................................................................7

Operator's Requirements...............................................................................7

Safety Clothes ...................................................................................................8

General Safety Rules ......................................................................................8

Prepare the Work...............................................................................................9

.......................................................................................…..10

Set-Up.......................................................................................................11-15

Attachment to the Tractor........................................................……11

............................................................. …12

Ha

H a n m e y I m p l e m e n t s

3

Driveline Attachment…………………………………………13

Working Height Adjustment......................................................... 14

Flail Mower Adjustment ................................................................ 14

Drive Belt Adjustment................................................................... 15

Transport & Storage ................................................................................... 1

…………………………………………………..17

Maintenance..........................................................................................…18-20

General Maintenance ......................................................................... 18

Gearbox........................................................................................... 19

PTO Shaft ....................................................................................... 20

Parts Drawing.........................................................................................21-24

AG200B drawing.......................................................................…..21

Parts list.......................................................................................22-28

Limited Warranty..................................................................................... 29-30

Ha

H a n m e y I m p l e m e n t s

4

GENERAL INFORMATION

INTRODUCTION:

The AG Flails are primarily designed to mow grass, weeds and light brush.

The mowers are assembled for operation with 1000 RPM tractor input only (rated

PTO up to 45 HP), and supplied standard with Cat. I lift pins for tractor attachment.

The mowers can fit Cat. I quick attach hitch, by using suitable bushings to adapt

diameters of lift pins.

SYMBOLS:

This booklet contains three "safety graphic symbols" which highlight the relevant

danger levels or important information:

It draws the operator's attention to

situations which can jeopardize people's

safety.

It draws the attention to situations which

jeopardize the machine efficiency but not

people's safety.

It highlights general information which does

not endanger people's safety or the efficiency

of the parts.

Ha

H a n m e y I m p l e m e n t s

5

SAFETY LABELS

SAFETY LABELS:

The safety labels and the information on the machine, listed in the following table,

must be necessarily read and respected; failure to follow these warnings can cause

death or severe injuries. Make sure that the labels are always present and legible,

should this not be the case, contact your nearest Gear more dealer to replace the

missing or illegible ones.

Ha

H a n m e y I m p l e m e n t s

6

SAFETY LABELS

Ha

H a n m e y I m p l e m e n t s

7

SAFETY

ALLOWED USE:

AG flail mowers, as described in this instruction and maintenance booklet, have been

specifically designed to mow grass, weeds, and light brush up to 1" diameter. Any

other use jeopardizes the operator's safety and the machine integrity.

IMPROTER USE:

The mower was designed to mow grass, weeds, and light brush only. Only operate

this mower on a properly sized and equipped tractor.

When using AG flail mowers, it is particularly forbidden:

-The attachment to tractors of unsuitable power or weight.

-To use other than 1000 R.P.M. PTO speed.

-To work in excessively stony grounds.

-To work on excessive slopes.

-To approach the machine when wearing inappropriate works clothing.

-To get on the machine while it is being used or transported.

Operating this mower in an application for

which it is not designed and/or operating with the wrong size tractor can

cause mower component damage and

equipment failure resulting in possible

serious injury or death.

SAFETY

SAFETY IN THE WORKPLACE:

Most of the accidents which take place while the operator is using the machine or the

equipment or during their maintenance or repair are caused by a lack of compliance

with the basic safety precautions. It is necessary, therefore, to become more and more

conscious of the potential risks of one's action by constantly paying attention to its

effects.

If potentially dangerous situations are known, accidents can be

prevented!

OPERATOR'SREQUIREMENTS:

Physical: good eyesight, coordination and capability of carrying out all functions

required for the machine's use.

Ha

H a n m e y I m p l e m e n t s

8

SAFETY

Mental: Capability of understanding and applying the established rules and safety

precautions. Users must pay attention and be sensible for their own and other people's

safety.

Training: users must have read and studied this manual, its eventual enclosed graphs

and schemes and its identification and danger plates. They must be skilled and trained

on any use or maintenance activities.

WORK CLOTHING:

When working and especially when executing repair or maintenance activities, it is

necessary to wear the following clothing and safety accessories:

-Overalls or other comfortable

clothing, not too loose to prevent

the possibility that parts of them

might be caught in the moving

parts.

-Protective gloves for hands.

-Protective glasses or faceplate to protect eyes and face.

-Protective helmet for the head.

-Safety shoes

Wear only personal safety

accessories in good condition and

complying with the rules in force.

GENERAL SAFETY RULES

ALWAYS CONSIDER THE FEATURES OF THE AREA WHERE WORK IS TAKING PLACE:

-When the equipment is running, it is forbidden to stand within the field

of action of the shredder or of the other accessories of which it is

provided with.

Ha

H a n m e y I m p l e m e n t s

9

PREPARE THE WORK:

-Before and when working, do not drink alcohol, take drugs, or any

other substances which may alter your capability of working with

machine tools.

-Be sure to have sufficient fuel, to prevent a forced stopping of the

machine, maybe during a critical movement.

-Do not use the equipment under unsafe conditions. For instance, it

is forbidden to execute makeshift repair activities just to start

working; it is forbidden to work at night with an insufficiently

illuminated working area.

-NEVER operate implement without all shields in place and in good

operational condition. The operator must be familiar with the mower and

tractor and all associated safety practices before operating the mower and

tractor.

WHEN WORKING OR DURING THE MAINTENANCE ACTIVITIES IT IS NECESSARY TO

REMEMBER:

-The labels and stickers providing instructions and pointing out the

dangers, must not be removed, hidden, or made illegible.

-Do not remove, except in case of maintenance, the shields, guards, and

deflectors equipped on the mower. When it is necessary to remove them,

stop engine, handle with care and reassemble them properly before

restarting the engine and using the equipment. The mower is equipped

with protective deflectors to prevent objects being thrown from the

mower by the blades, however, no shielding is 100% effective. All

shields, guards, and deflectors equipped on the mower must be

maintained in good operational condition.

-It is forbidden to lubricate, clean and adjust the moving parts while they are

running.

-During maintenance or adjustment activities on the equipment it is

forbidden to use hands for executing operations for which there are

specific tools.

-Do not use tools in bad condition or inappropriately, for instance pliers

Ha

H a n m e y I m p l e m e n t s

10

rather than monkey spanners, etc.

-When maintenance or repairs are completed check out that no tools,

wiping rags, or other materials are left inside spaces or guides with

moving parts.

-While using the equipment, it is forbidden to make more than one person

give directions and make signals. The eventual directions and signals

relating to the load handling must be given by one person only.

-Do not unexpectedly call an operator while he is working if not necessary;

it is forbidden as well to frighten or throw objects at the operator, even if

just for fun.

-Watch out for those who are present, especially the children!

-Do not make people get on the machine.

-When the equipment is not needed, stop the vehicle's engine, park it on flat

ground with first speed and parking brake on, with the machine rested on

the ground and PTO disengaged.

-Do not clean, lubricate, repair or adjust with the engine running and the

machine lifted.

-Never use the machine on steep slopes which may jeopardize the

equipment's stability.

The manufacturer declines all responsibility for a lack of compliance with these

instructions.

Ha

H a n m e y I m p l e m e n t s

11

SET UP

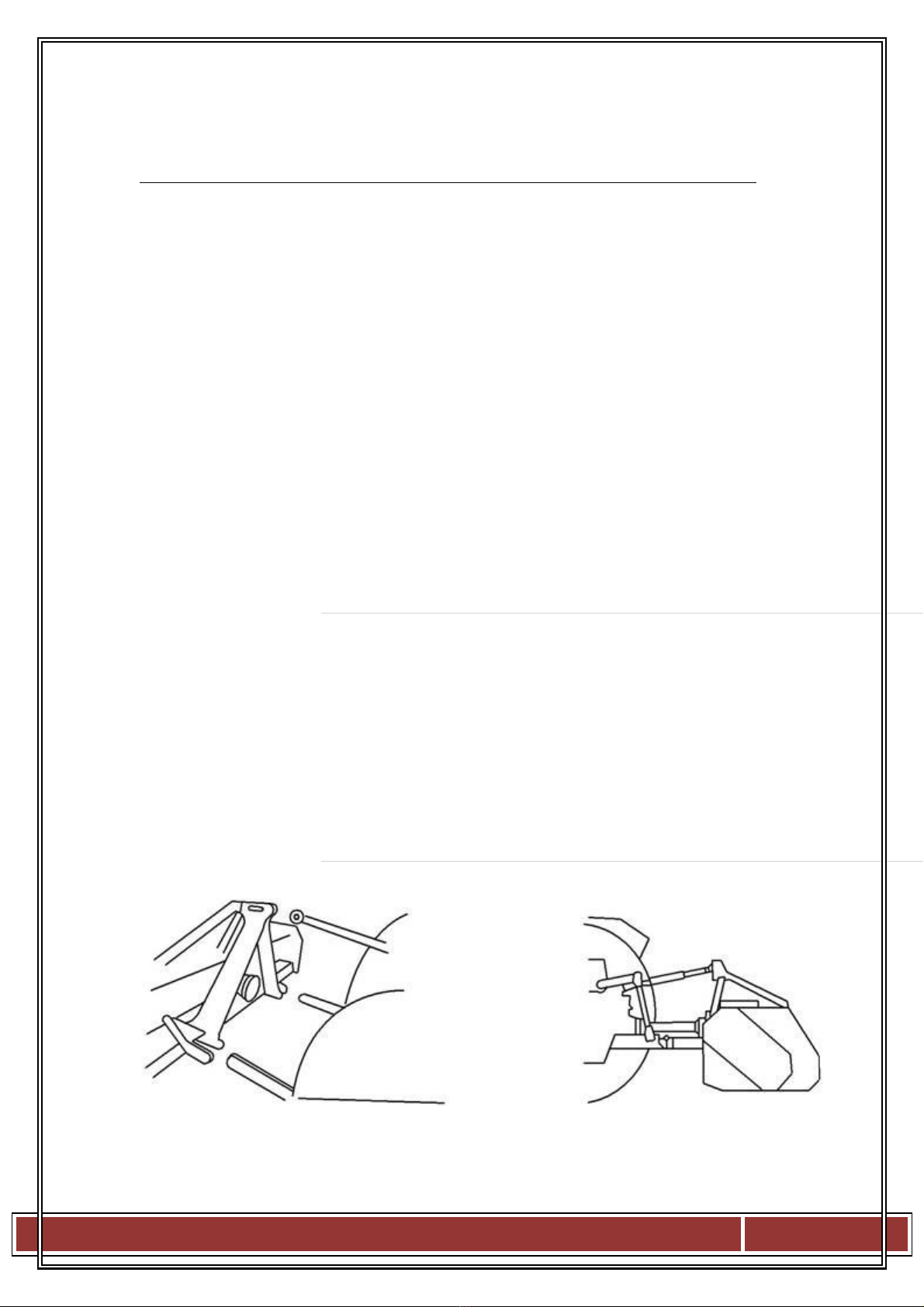

ATTACHMENT TO THE TRACTOR

Before operating the mower, carefully read this Operator's Manual, completely

understand the safety instructions, and know how to operate correctly both the tractor

and the PTO shaft, reading carefully the instruction manuals of the tractor and PTO

shaft manufacturers.

All AG flail mowers have been manufactured to be attached to any tractor provided

with hydraulic and universal 3-point hitch.

The tractor used to operate the mower must have the power, capacity, and required

equipment to safely operate the mower. Operating the mower on improperly sized and

equipped tractors may cause tractor and/ or mower damage and could be a potential

danger to the operator and passers-by.

Before attaching the equipment to the tractor, set both on a flat and smooth ground

and make sure that nobody is standing between

them.

Move slowly the tractor towards the flail mower by aligning the tractor hydraulic lift

arms to the two mower hitches' lateral brackets; stop engine and set parking brake.

Connect first the lower arms by removing the release pins of the brackets placed on the

plates, inserting the lift arms into the arms center and fasteningthem with the relevant

release pins, which had been removed.

Connect, then, the tractor top link to the third upper point by removing the pin located

between the plates, inserting the top link itself and locking it with the pin.

Ha

H a n m e y I m p l e m e n t s

12

SET UP

Adjust the third point so that the upper part of the frame is parallel to the ground.

Lock all connection parts with the special sway chains or tie rods.

It is always good to make sure that the central gearbox axis is parallel to the ground

thus reducing the stresses on the power takeoff and extending the working life of the

equipment.

Pay attention to the tractor's front wheels grip

when the equipment is set up and lifted; if the

wheels appear to be too lightened, ballast the

tractor front tires or add front weights.

After executing the above-mentioned

activities it is always good to check

that all bolts and nuts of your shredder

are tightened strongly (refer to the

torque specifications in this manual).

Ha

H a n m e y I m p l e m e n t s

13

SET UP

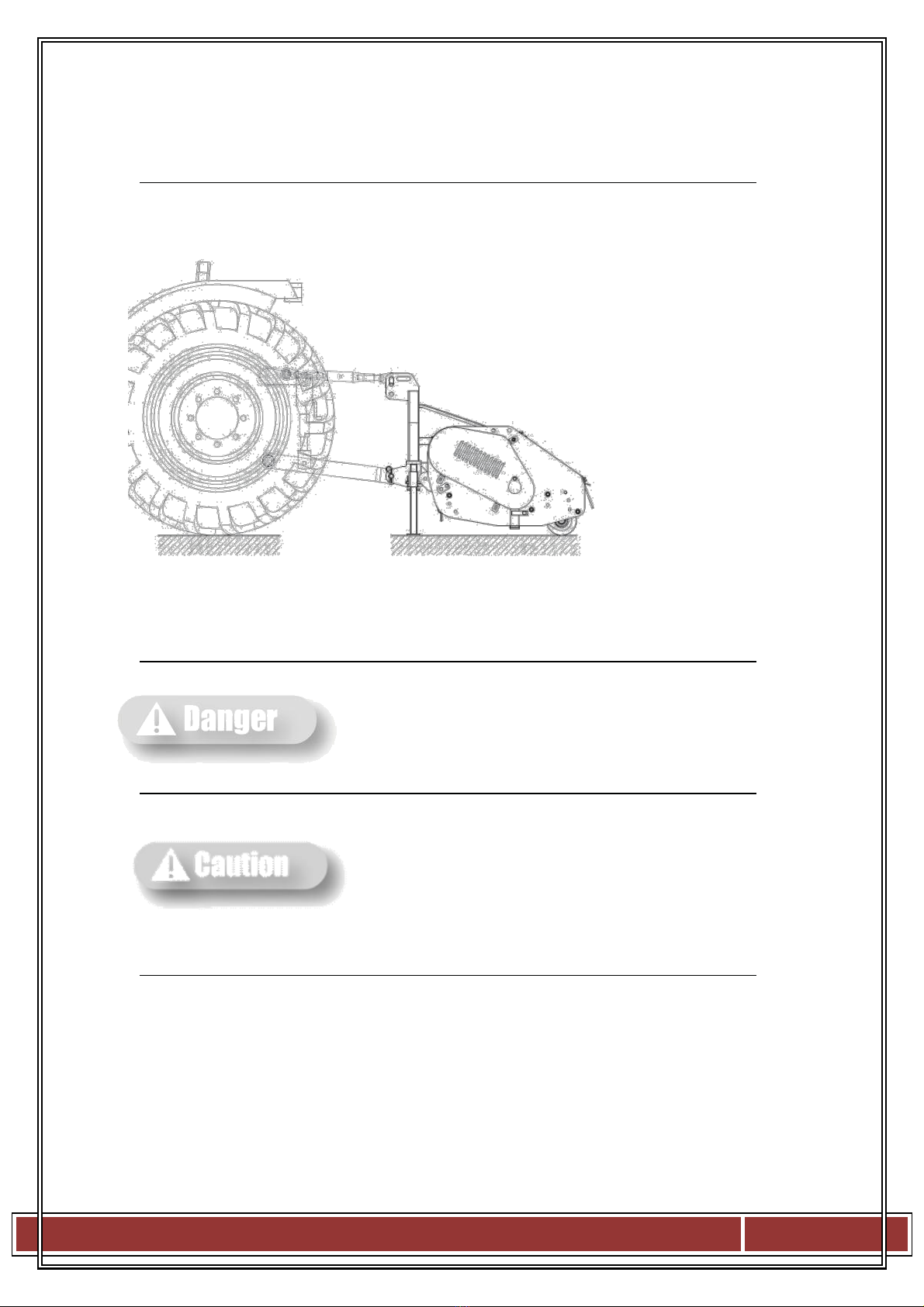

DRIVELINE ATTACHMENT

Before assembling the PTO shaft, check out that its RPM and direction of rotation

match those of the tractor. Moreover, read carefully the instruction manuals of the

PTO shaft and the tractor manufacturers. Before starting work, make sure all safety

shields are in place. Check in particular that the safety guards cover the PTO shaft

throughout its extension. When attaching the mower input driveline to the tractor

PTO, be sure that the connecting yoke spring activated locking collar slides freely and

the locking balls are seated securely in the groove on the tractor PTO shaft. A

driveline not attached correctly to the tractor PTO shaft could come loose and result in

personal injury and damage to the implement.

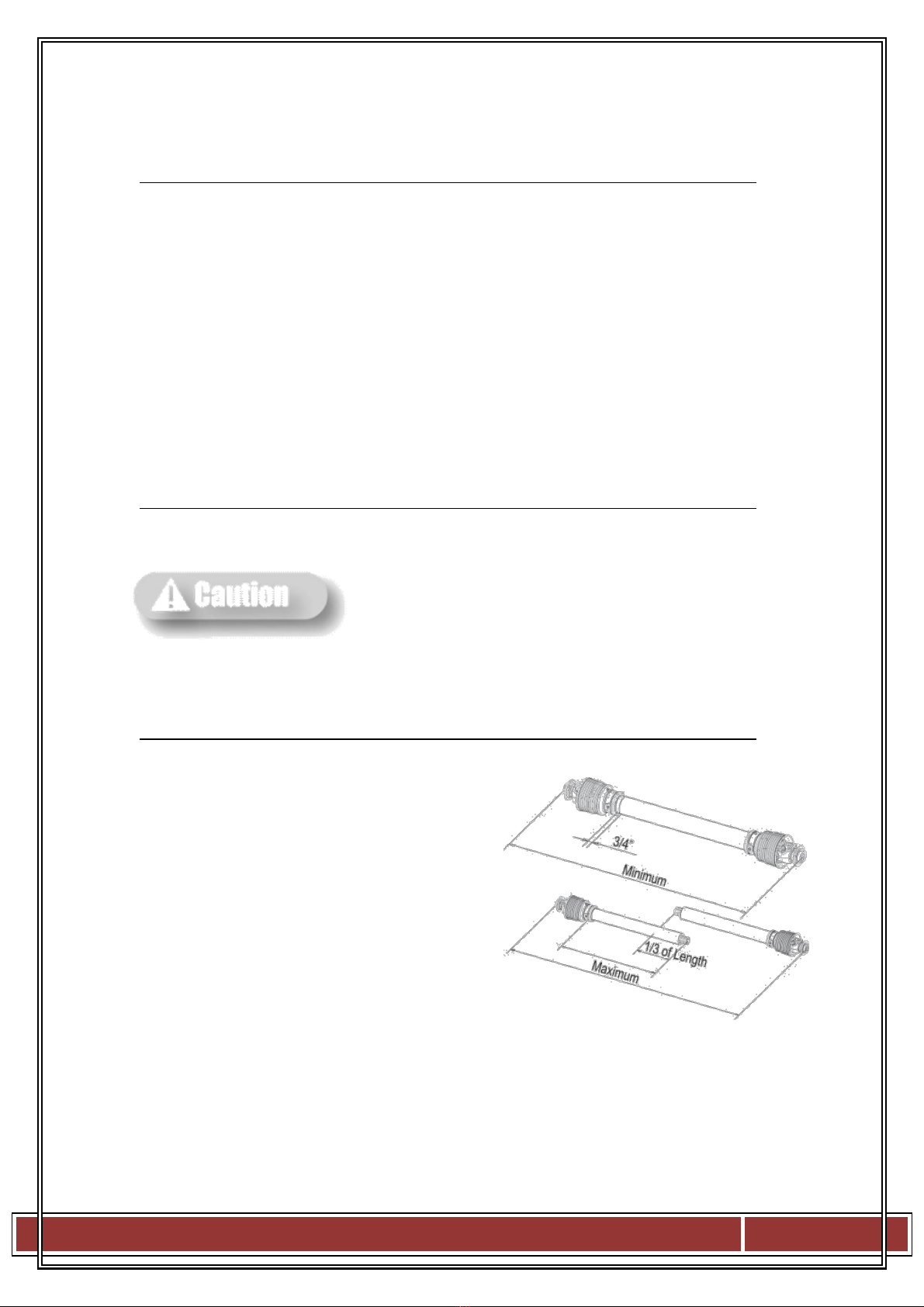

Make sure the driveline will not bottom

out (at its most compressed position

there must be at least a 3/4" clearance

between each profile end and opposite

profile universal joint) or become

disengaged (at its farthest extended

position a minimum profile engagement

of 1/3 of the length must be maintained).

Check out that the cardan shaft minimum and

maximum length are the ones required by the

machine-tractor coupling. Should problems

arise, contact a skilled repair shop or the

driveshaft retailer. After installation, secure

safety guards both to the tractor and

the machine using the special chains and

make sure that they pivot freely. If the PTO

shaft is equipped with other safety devices,

such as a pair limiter or freewheels, be sure

to install them on the machine side. As for

the PTO use and maintenance refer to the

relevant booklet.

Ha

H a n m e y I m p l e m e n t s

14

SET UP

WORKING HEIGHT ADJUSTMENT

The machine's working height is determined by the position of the rear roller. Lifting

the roller the cutters get close to the soil, whereas lowering it the cutters get far from

it. After a modification of the working height be sure that the cutters skim the ground;

a direct contact with it would cause their wear and this could affect the cutting rotor

balance and may cause objects to be thrown out from under the mower deck.

FLAIL MOWER ADJUSTMENT

- On a flat piece of ground, attach the Flail Mower to the Tractor using the three point

linkage

- Use a solid adjustable top link

- Lower the three point linkage to its lowest position

- With the roller at the rear in contact with the ground, adjust the length of the top link so

that the lower edge at the side of the flail mower is parallel with the ground

- Rotate the blade drum by hand so that a row of blades hang vertically towards the

ground.

- Measure the clearance between the bottom of the extended blades and the ground.

Minimum 50mm

Note in rough or lumpy paddocks the clearance needs to be increased to ensure

that the blades dont impact the ground in operation.

- Adjust the roller height to increase or decrease the blade clearance as required

- Go through steps 4 to 7 until the required clearance is achieved.

When the Flail Mower has been set up with the required tolerances:

Operate the Flail Mower with tractor in low range and the PTO delivering 1000 RPM

Ha

H a n m e y I m p l e m e n t s

15

SET UP

DRIVE BELT ADJUSTMENT

Loosen the Screw A and B that locks the support shaft and loosen the counter nut C.

Loosen the screws that lock the gear box on the mounting plate D.

Adjust the drive belt tension. The correct belt tension is achieved when the belt

can be deflected by the belt thickness about 10mm at the center point between the

pulleys.

Align the gearbox so the drive shaft is parallel with the body.

Use a straight edge to make sure the belt pullies are inline and running true. If

misaligned, call your dealer or service agent for technical support.

Fit the safety covers and tighten the mounting bolts before operation.

Approx.10mm Align with a

Straight Edge

Deflection

Ha

H a n m e y I m p l e m e n t s

16

TRANSPORT & STORAGE

WORKING SPEED

The working speed depends on quality, diameter and height of the material to be cut;

anyway, for efficient mower performance it must be between 2 and 5 MPH. The

power takeoff speed must be 1000 RPM maximum. Operate the mower at its full

rated PTO speed to maintain blade speed for a clean cut.

Do not exceed the rated PTO speed for

the implement. Excessive PTO speeds

can cause driveline or blade failures

resulting in serious injury or death.

ROAD TRANSPORT

Extreme caution should be used when transporting the tractor and implement on

public roadways. The tractor must be equipped with all required safety warning

features including a SMV emblem and flashing warning lights which are clearly

visible from the rear of the unit. Make sure you are in compliance with all local

regulations regarding transporting equipment on public roads and highways. Do not

exceed 20 MPH (32 kph). Reduce speed on rough roads and surfaces. Always use

hazard flashers on the tractor when transporting unless prohibited by law.

STORAGE

If your shredder will not be used for a long period of time, respect the following

suggestions:

1. Wash the machine thoroughly and dry it.

2. Lubricate all bearings with enough grease to eliminate any cavities where

water condensation may occur and cause damage. Refer to "Maintenance

of the Machine" for location of all grease fittings. Be sure the vent on top

of the gearbox is open.

Ha

H a n m e y I m p l e m e n t s

17

3. Loosen the set nut and spindle jack to relieve drive belt tension (NOTE:

Before next season's use, be sure to adjust the drive belt tension.)

4. Coat all exposed surfaces inside the mower with oil or grease to

prevent rusting and pitting during storage.

5. Protect the whole machine with a tarpaulin and put it in a dry place.

PRE-SEASON CHECK

1. Check the oil level in the gearbox and lubricate all bearings. See

"Lubrication".

2. Adjust drive belt tension. See "Belt Drive".

3. Check out all equipment and replace damaged or worn parts.

4. Tighten all bolts and nuts (See "Torque Specifications").

5. Inspect for missing and/or broken blades/knives. Replace as

necessary. See "Knife Replacement".

6. Be sure that the safety guards are in place and secure.

7. Run the Flail Mower at a low RPM checking to make sure that all

driveline parts are moving freely.

Ha

H a n m e y I m p l e m e n t s

18

MAINTENANCE

MAINTENANCE

Maintenance is a fundamental operation to extend life and performances of any

agricultural vehicle; taking care of the machine grants you not only a good work

execution, but also a longer life of the whole equipment and a greater safety on the

workplace.

The operating times indicated in this manual have just an informative character and

are referred to normal conditions of use; they can thus undergo variations according to

the type of service.

Before injecting lubricating grease

into the zerks, clean them

accurately to prevent mud, dust, or

other foreign matters from mixing

up with grease, thus diminishing

the lubrication effect.

- When adding or changing oil,

it is better to use the same oil

type, in order to avoid mixing

oils with different features.

- Before executing maintenance

activities on the machine, stop

engine, disengage power takeoff, set

parking brake and place the

equipment on the ground in

horzontal position.

- After the first working hours, check

that all bolts and nuts are tightened;

remember also to check often all the

machine safety guards.

Ha

H a n m e y I m p l e m e n t s

19

MAINTENANCE

FIRST CHECK

-Check the correct tension of the driving belt

-Check that all bolts and nuts are tightened

-After the first 50 hours of work, change oil in the gearbox

EVERY 8 HOURS OF WORK

-Rotate teardrop shaped plate B and grease the shaft support (driveline side)

through the lubricating nipple A (picture 1)

-Grease the shaft support (external side) through the lubricating zerk A

(picture 2)

-Grease the shaft support (driveline) and the belt tensioner idler pin through

the lubricating zerks A and B (picture 3)

-Grease the stabilizing roller through the lubricating zerkA (picture 4)

EVERY 50 HOURS OF WORK

-Check the correct tension of the driving belt

-Check that all bolts and nuts are tightened

-Check the cutters/hammers for wear

-Check the overgear unit oil level through plug A (picture 5)

EVERY 500 HOURS OF WORK

-Check that all bolts and nuts are tightened

-Change oil in the overgear unit

EVERY 1000 HOURS OF WORK

-Replace the driving belt

-

GEAR BOX MAINTENANCE

-

-The oil should be drained out and replaced after the first 50 hours of operation.

Then the oil should be changed every 250 hours, or at least once a year.

-

-Drain oil from the gearbox thoroughly. Check and clean it. Fill with new gear oil up

to the dedicated oil level.

-

-The draining procedure is as follows: remove the draining bolt under the gear box,

so that the oil drains off. After the oil is drained out, put the plug back and fill with

gear oil up to the dedicated oil

-

-level.

Ha

H a n m e y I m p l e m e n t s

20

MAINTENANCE

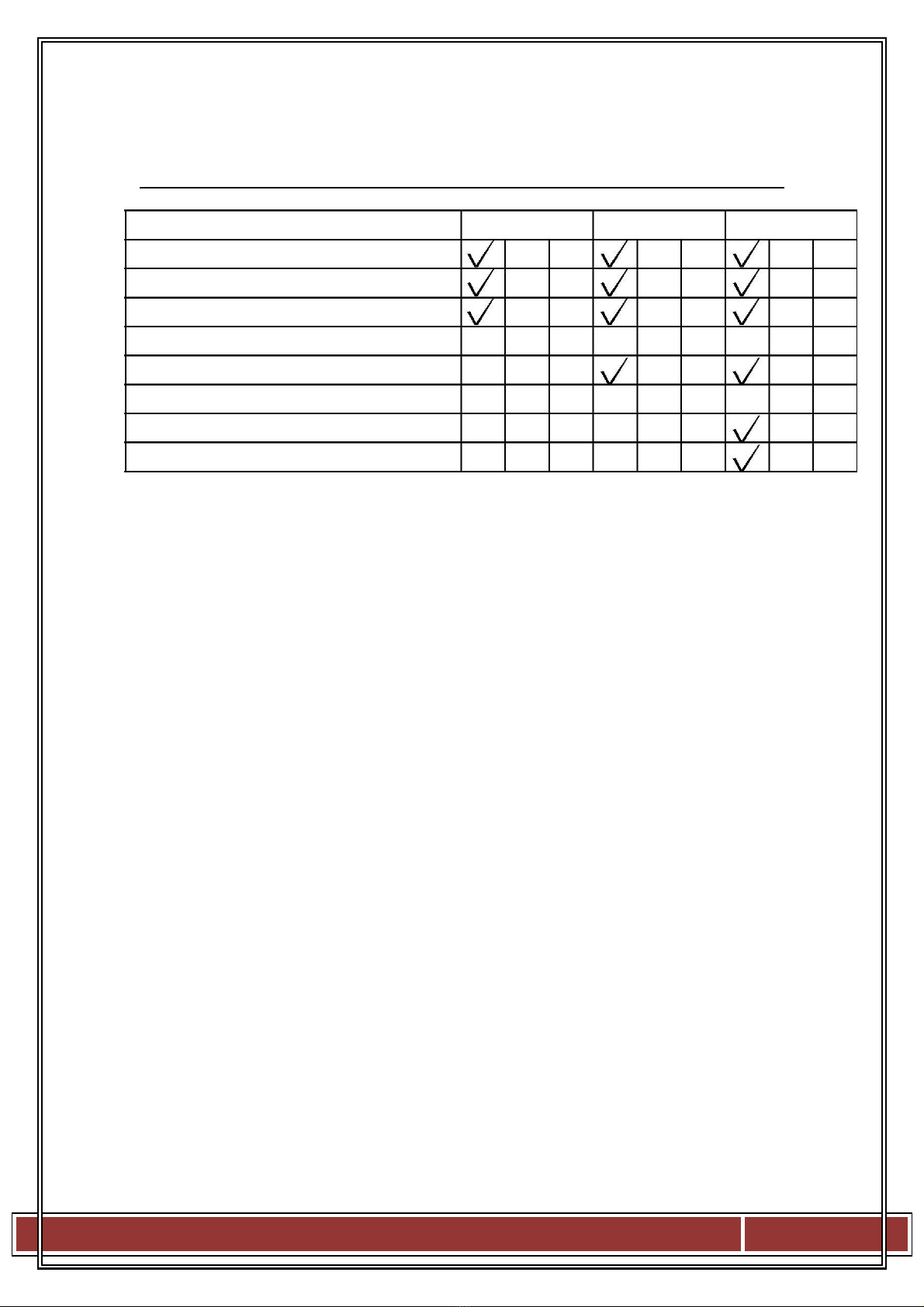

8hrs/ Daily

50hrs/Weekly

Annually

Lubricate PTO Shaft

Lubricate Caster Wheels

Lubricate Blade Spindle

Check Gear Box Oil Level

Clean Machine

Lubricate and Clean PTO Shaft Cover

PTO SHAFT MAINTENANCE

The PTO shaft is designed to telescope to allow for dimensional changes as the machine

goes through its operating range. A tubular guard encloses the driving components and

is designed to turn relative to the driving components. The shaft should telescope easily

and the guard turn freely on the shaft at all times. Annual disassembly, cleaning and

lubrication is recommended to insure that all components function as intended. To

maintain the shaft, follow this procedure:

1. Remove the shaft from the machine.

2. Pull shaft apart.

3. Use a screwdriver to pry the tabs out of the sleeves on each end.

4. Pull the shaft out of the plastic tubular guard.

5. Use a solvent to clean the male and female portions of the telescoping ends.

6. Apply a light coat of grease to each end.

7. Clean the grooves on each end where the tabs are located. Clean each tab also.

8. Apply a light coat of grease to each groove.

9. Insert the shaft into its respective guard and align the slots with the groove.

10. Insert the tabs through the slots and seat in the groove.

11. Check that each guard turns freely on the shaft.

12. Assemble the shaft.

13. Check that the shaft telescopes easily.

14. Replace any components that are damaged or worn.

15. Install the shaft on the machine.

This manual suits for next models

2

Table of contents