HANSCRAFT Evolution 25 Service manual

1. Introduction

2. Specifications

3. Dimension

4. Installation

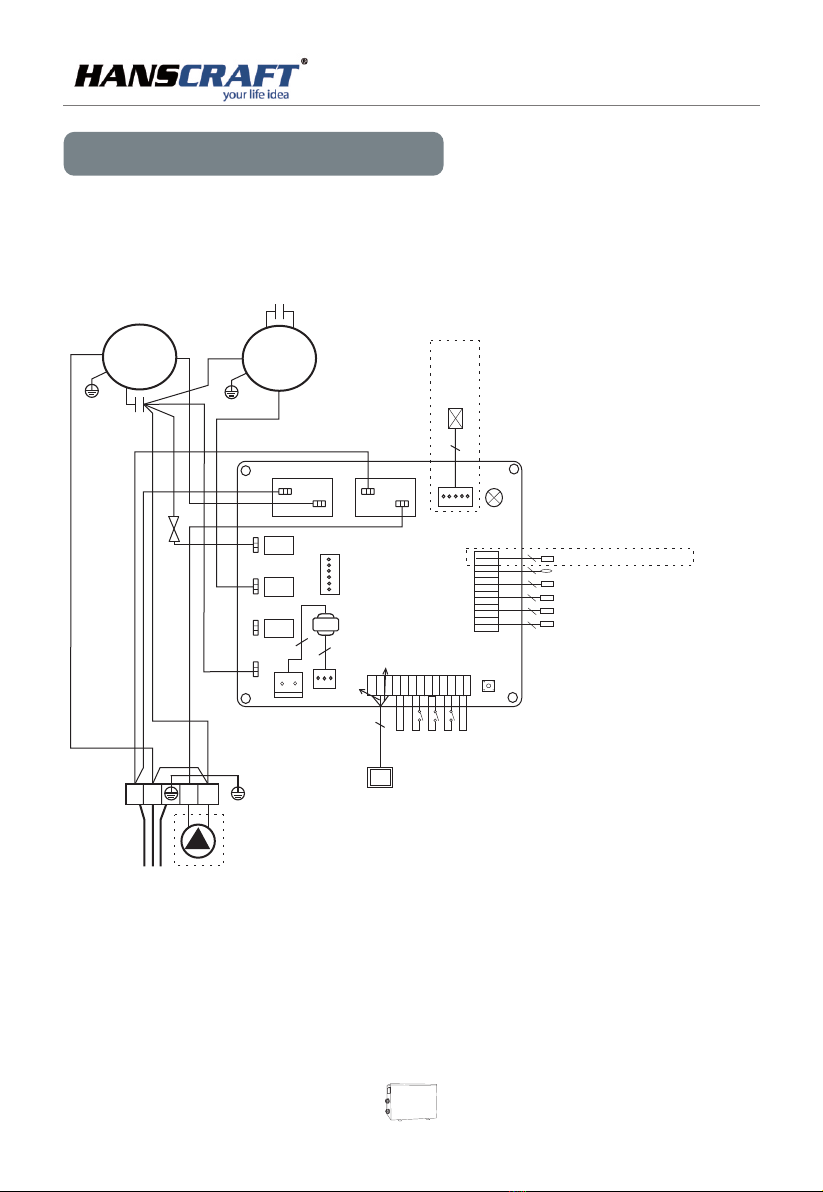

5. Electrical Wiring

6. Initial Startup of the unit

7. Operation

8. Maintenance

9. Troubleshooting

10. Explode diagram

INDEX

PO OL HE A T PUM P

ATTENTION

Thank you for using swimming pool heat pump for your pool heating, it will heat your

pool water and keep the constant temperature when ambient temperature at +7℃ to 40℃

In order to offer qualified, reliable and flexible heat pump unit to our customer, please read

this manual carefully before installing, operating and troubleshooting, then process accordingly.

This manual includes all necessary information

HANSCRAFT

● The heat pump unit must be installed by qualified technicians from after-sales

center or authorized distributor.

● Operating and maintaining according to recommended time and frequency on

the manual.

● Use only standard spare parts.

!

1.Introduction

PO OL H E A T P U M P

01

02

2. Specifications

Above data is subject to modification without notice,

please take the nameplate as standard.

PO OL H E A T P U M P

2.1 Design,R410A,HEATING ONLYHorizontal

Horizontal design, ABS Cabinet

Model Evolution 25 Evolution 40 Evolution 60

* Heating Capacity at Air 27℃, Water 27 , Humidity 80%℃

Heat Output (kW)

Power Consumption (kW)

COP

* Heating Capacity at Air 15℃, Water 26 , Humidity 70%℃

Heat Output (kW)

Power Consumption (kW)

COP

* General data

Voltage

Rated Current (A)

Fuse Current

Advised pool volume

(with pool cover)

Advised water flux

Water Pressure Drop

Condenser

Compressor type

Water pipe in-out

Fan Speed

Noise level(10m)

Noise level(1m)

Refrigerant

* Dimension/ Weight

Net Weight

Gross Weight

Net Dimension

Packing Dimension

6.8 10 13

1.09 1.60 2.07

6.25 6.25 6.25

4.3 6.5 8.2

1.02 1.48 1.86

4.2 4.4 4.4

4.7 7.0 9.0

10A 15A 20A

220-240V/50Hz/1PH

15-25m³ 25-35m³ 30-60m³

2.5~3.7m /h³ 2.8~5.6m /h³ 3.5~7.1m /h³

12KPa 12KPa 15KPa

Titanium in PVC

Rotary/R410a

50mm

830~870RPM

40dB(A) 43dB(A)

47dB(A) 48dB(A)

46dB(A)

40dB(A)

800g 1100g 1200g

32kg 37kg 61kg

37kg 42kg 68kg

1030*335*560mm 1025*350*620mm

1080*360*610mm 1120*380*665mm

03

3. Dimension

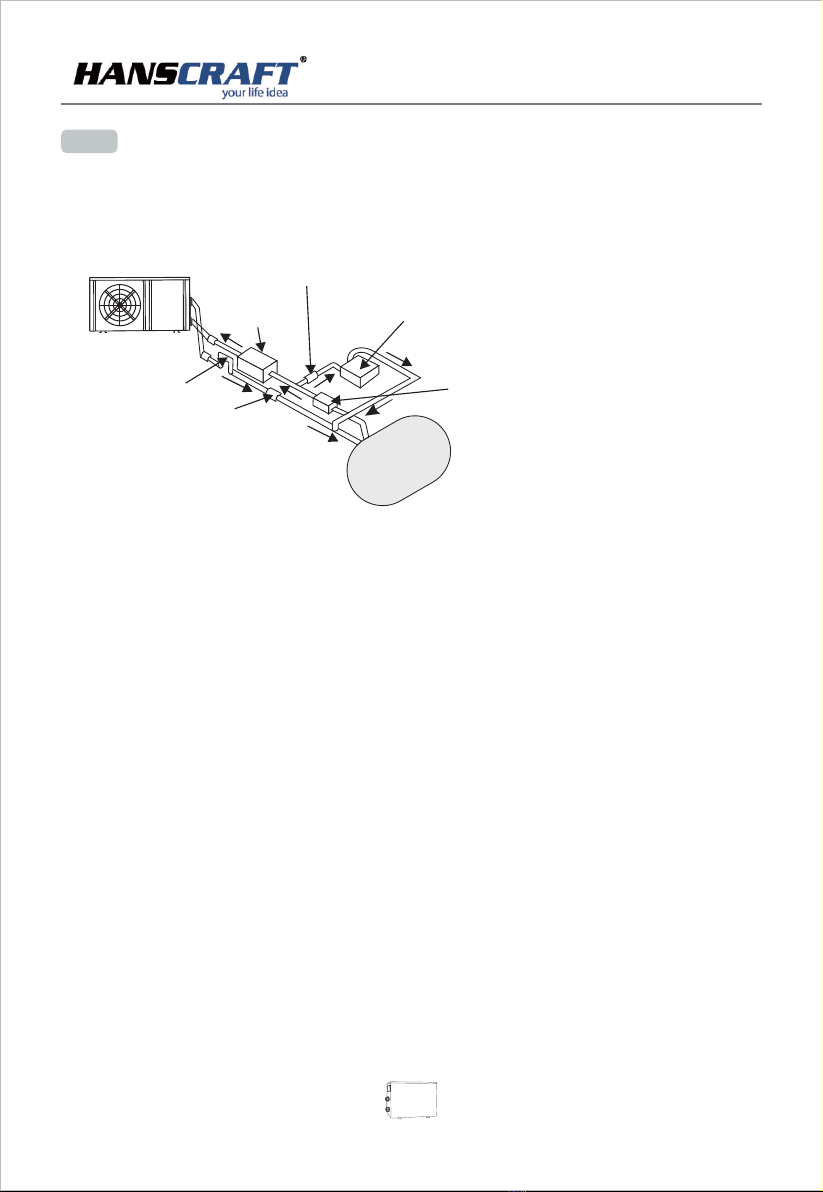

NOTE: The factory only provides the heat pump unit. The other items in the illustration are necessary

spare parts for the water system which are provided by users or installers.

4. Installation

4.1 Installation illustration

PO OL H E A T P U M P

Unit : mm

A

B

C

D

E

F

G

H

I

Models

302

622

288

332

988

230

103

557

98

326

655

306

350

1026

340

108

620

92

EVOLUTION 60

EVOLUTION 25

EVOLUTION 40

ATTENTION:

Please follow these steps when operating the first time :

1.Open valve and charge water

2.Make sure that the pump and the water-in pipe have been filled with water

3.Close the valve and start the unit

4.2 Installation

(1) The heat pump unit must be installed by professional technicians .otherwise unit may be damaged or body injured,

even dead

(2) The unit is designed for outdoor location with good ventilation. Recirculation of cold discharge air back into

evaporator coil will greatly reduce heating capacity and efficiency of the unit, which will void the compressor

warranty.

(3) The unit can be installed almost anywhere in the outdoors.To get a good performance ,it needs to meet the three

factors :

a) Good ventilation

b) Stable and reliable power supply

c) Recycled water system

The difference from gas water heater, it should not bring environmental pollution or have the installing problems

in-windy areas.

(4) The unit should not be installed in a limited air ventilation area ,or placed in a bush where it will block the air inlet .

These location deny the unit of a continuous source of fresh air .When seasons changing ,it may stick leaves on

the evaporator coil ,thereby reducing its efficiency and impact of its service life .

(5) For indoor installation, please consult more instruction from technicians.

(6) When install a bypass, it should be not exceed 30% of nominal flow rate

(7 Must make Water level higher than the circulation pump location.

(8) Below picture show the minimum required distance on each side of pool heat pump unit.

Air inlet

Air outlet

!

PO OL H E A T P U M P

04

05

4.3 's instruction to your system is also critical to the heater's life.The location of chemical

If an automatic chlorinator or brominates is used, it must be located downstream of the heater.

A trap must be installed between the chlorinator and the heater to prevent chlorine return into the

heat pump. (See below pictures)

Pressure-type Chlorinator or Brominator

P-trap

Filter Chlorinator

Check-valve

Water pump

Check-valve

(1) Typically, the pool heat pump unit should be installed aside the pools, less than 7.5 meters distance. If it is

installed farther away, the pipeline system will cause greater heat loss. The most of pipeline are installed under

ground ,although the pipeline system has to do thermal insulation ,but tunnels and the soil around will still occur

heat exchange ,for example,each 30 meters ( 15 meters to and from the pump=30 meters total),unless the ground

is wet or the water table is high.A very rough estimate of heat loss per 30 meters is 0.6KW per hour (2000BTU) for

every 5℃ surrounding the pipe,which translates to about 3% to 5% increase in run time.

(2) To get the best heat exchange of heat pump unit, it should be matched the normal rate of water flow

recommended in specification sheet.

(3) It is required to increase the discharge pipe to prevent freezing in cold season ,to put “T” fitting and ball valve to

facilitate changing the water in winter or emptying the water out of system to prevent freezing when HP stop

operating at the ambient temperature below zero ,otherwise the unit may be damaged .

(4) It is suggested to install the quick adaptor in front of water in-out connection, which could discharge water easily

to prevent water freezing, and be convenient for maintenance and service.

(5) When unit running ,there will be some condensation water discharged from the bottom ,please hold the

drainage nozzle (accessory ) into the hole and clip well ,and then connect a pipe to drain the condensation water out.

(6) If water pressure is over 10 KPA ,or water flow rate is more than 11 cubic meters through heat exchanger ,it is

necessary to install the by-pass pipe in water system.

PO OL H E A T P U M P

wimming pool heat pump wiring diagramS

5. Electrical Wiring

* The dotted line part are only used in some models

RUN/POW

SINGLE-WATER PUMP

LN1

YLW/ G R N

2

Transformer

2

2

POWER 220-240V/50Hz

OUTDOOR MOTOR

RED

OR G

BL K

S BL K

CO M P R ES SO R

CAPACITOR

R WH T WHT

4-WAY VALVE

BL U

BLU

BRN

BRN

BL U

BL K

BLU

C RE D

RED

BLU

RED

5

Ele ctro n ic Exp ansi o n Valv e

LED

OU T2

OUT1

OUT3

OUT4

OUT5

AC-N

CN1

CN2

3

Rem ote sw i tch

Low v olta g e swit ch

Rem ote co n trol ler

Hig h volt a ge swi tch

Pha se seq u ence p rote c tion

CN3

SW1

YLW/ G R N

YLW/GRN

BRN

BLU

YLW

12V

ENT

GND

GND

GN D

GN D

GND

GN D

KYIN

FS

LP

HP

PP

2

2

2

2

2

2

Wat er out l et coi l temp e ratu r e sens or

Wat er inl e t coil t empe r atur e senso r

H coi l temp e ratu re sen s oreat ing

Amb ient emp erat u re t sen sor

Coo ling c o il tem pera t ure se n sor

Ref rige r ant re turn t e mper a ture s enso r

CN4

GN D

GND

GND

GND

GND

GND

T6

T5

T4

T3

T2

T1

COMPRESSOR

Programming

PC Board

FAN CAPACITOR

Wat er f w swi tch

lo

3

4

3

4

Evolution 25 / Evolution 40

PO OL H E A T P U M P

06

07

PO OL H E A T P U M P

Evolution 60

Swimming pool heat pump wiring diagram

RUN/POW

LN1

YLW/ G R N

2

Transformer

2

2

RED

ORG

BLK

S BL K

R WH T

WHT

BL U

BRN

BR N

BL U

RE D

C RE D

BL U

RED

5

El ec tr onic Ex pa ns io n Valve

LE D

OU T 2

OU T 1

OU T 3

OU T 4

OU T 5

AC -N

CN 1

CN 2

YLW/GRN

YLW/GRN

AC CO NT AC TO R

BL U

BRN

4- W A Y V ALV E

3

Remote switch

Lo w vo lt age swi tc h

Re mo te c ontro ll er

Hi gh v ol tage sw it ch

Phase sequence protection

CN 3

SW 1

BR N

BL U

YL W

12V

ENT

GND

GND

GND

GND

GND

GND

KYI N

FS

LP

HP

PP

2

2

2

2

2

2

Wa te r ou tlet co il t em pe ra ture se ns or

Wa te r in let coi l te mp er at ure sen so r

H co il t em perat ur e se ns orea ti ng

Am bi en t em pe ra ture t sen sor

Co ol in g coil te mp er at ur e senso r

Re fr ig erant r et ur n te mp eratu re s en so r

CN 4

GND

GND

GND

GND

GND

GND

T6

T5

T4

T3

T2

T1

SINGLE-WATER PUMP

POWER 208-230V/60Hz

Pr o g r amm i n g

PC Board

BL U

BLU

CO M PRE S SO R

CA P ACI T OR

FA N C APA C IT O R

Water f w switch

lo

3

4

3

4

O U T D O O R M O T O R

C O M P

* The dotted line part are only used in some models

PO OL H E A T P U M P

Note: Please make sure the water pump is running in circulation with adequate rate of water flow.

Startup Procedure after Installation is completed, and please follow these steps:

(1)Turn on your filter pump ,check water leaks and verify flow of swimming pool

(2)Turn on the electrical power supply to the unit, then press the key ON/OFF of wire controller, it should start in several

seconds.

(3)After running a few minutes make sure the air ventilation from the side (top) of the unit is cooler ( Between 5℃ and 10 ℃)

(4)When turn off the filter pump , the unit should also turn off automatically , if not, then adjust the flow switch

(5)Allow the unit and pool pump to run 24 hours per day until the water reaches the desired temperature .When the

temperature reaches the setting value ,the HP unit will shut down ,when the pool temperature drops more than 1℃,please

restart (as long as HP unit is running )

Water Flow Switch:

It is equipped with a flow switch for protecting the HP unit running with adequate water flow rate .It will turn on when the

pool pump runs and shut it off when the pump shuts off. If the pool water level higher than 1 m above or below the heat

pump's automatic adjustment knob, your dealer may need to adjust its initial startup.

Time Delay:

HP unit should be equipped with a 3-minute built-in solid-state re-start delay protection. Time delay control is an integral

part of the circuit control, it can eliminate restart cycling and contactor chatter.

The time delay will automatically restart the HP unit approximately 3 minutes after each control circuit interruption .Even a

brief power interruption will activate the solid state 3 minute restart delay and prevent the unit from the starting until the 3

minutes countdown is completed.

6. Initial Startup of the unit

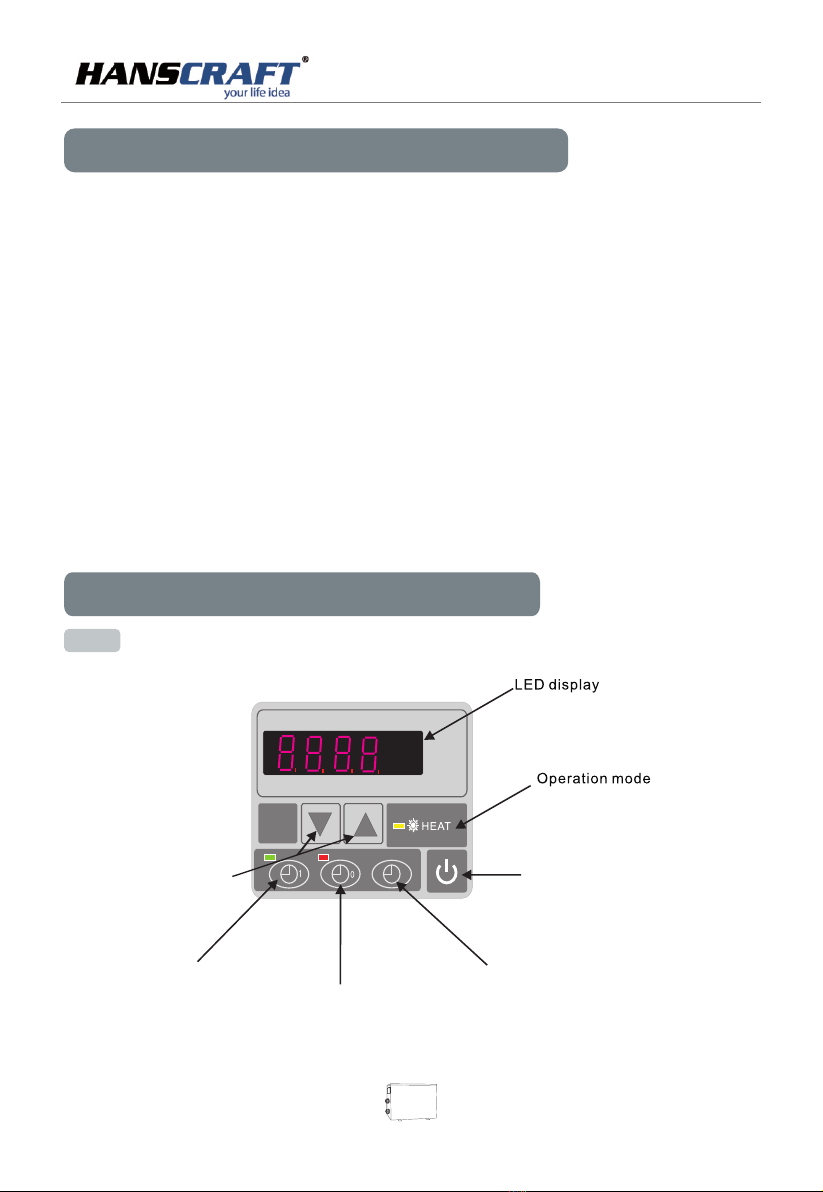

7.1 The functions of LED wire controller

7. Operation Heating Only

ON/OFF

Up and down button

Timer on b utton

Timer off button

Time

button

display

08

09

PO OL H E A T P U M P

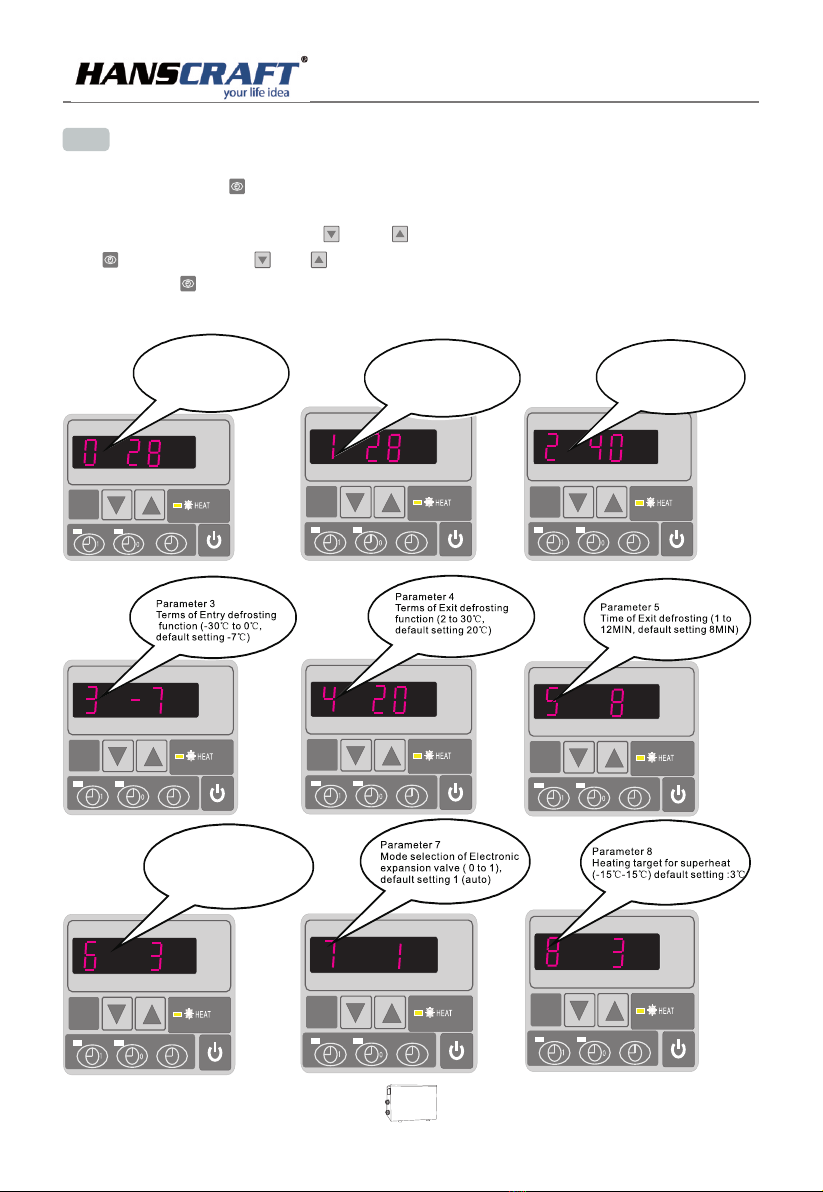

Parameter 2

Total working time of

compressor after frosting

(30-90MIN ,default

setting : 40MIN)

Parameter 0

To set the entering water temp.

under cooling mode (15-35℃,

default setting:28℃)

Parameter 1

To set the entering water

temp. under heating mode

(15-40℃, default

setting:28℃)

7.2 How to set operation parameter

(LED display wil show real time if HP unit is switched off.)

(1) Press and hold in for 5 seconds to enter operating parameter setting interface.

(2) Under parameter setting, press and to choose parameter below from “0” to “A”, press

again then press or to start setting parameters(see operation parameter table)

and press to confirm; Leave it 8 seconds,,LED will display water in temperature(under

running) or current time(until stops).

Parameter 6

Mode:0 Heat,1 Heat and Cool

Default setting:0

10

PO OL H E A T P U M P

10

HEAT

10

HEAT

Gas return temp. Ambient temp.

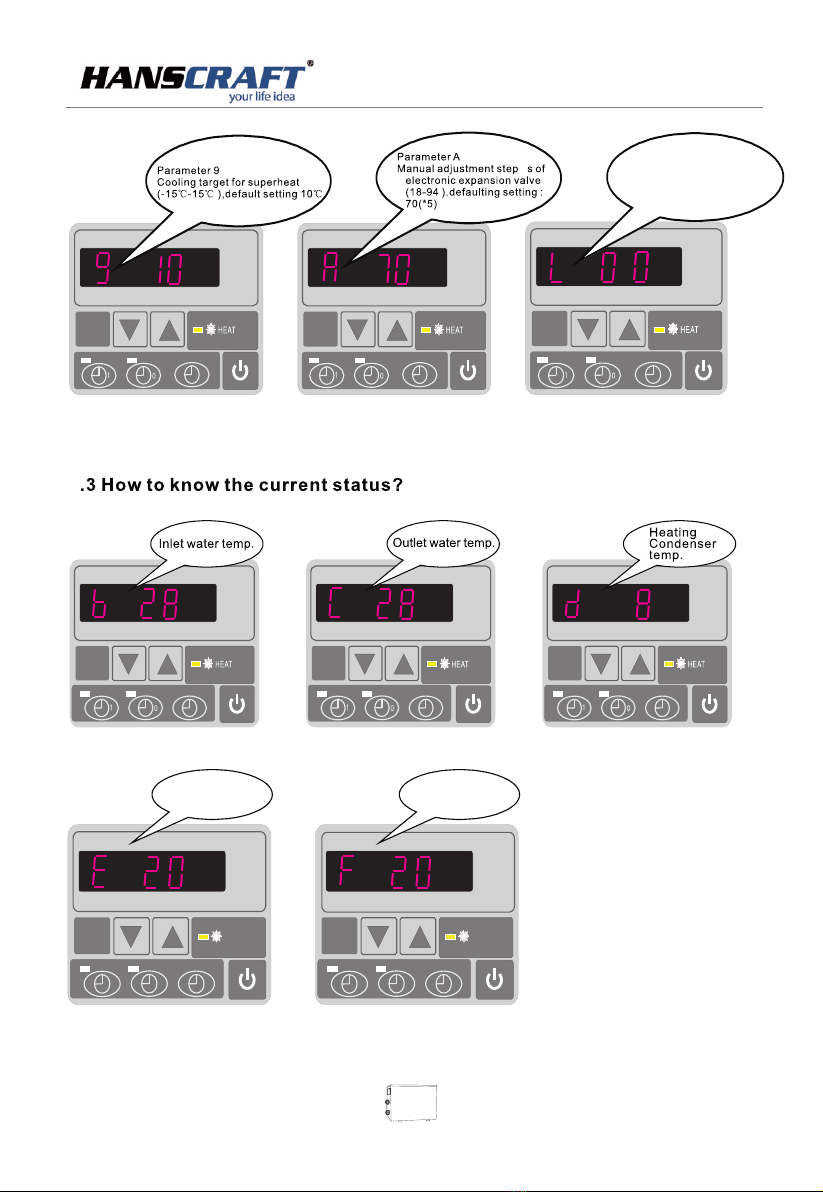

7

Parameter L

Mode:inlet water

temperature correction

Default setting 00

PO OL H E A T P U M P

10

HEAT

10

HEAT

Cooling Condenser

temp.

Actual steps of

electronic

expansion valve

(1) Press or to check water -in/water-out/heating condenser

/back gas/ambient temperature.

(2) When the unit is switched off, current time is displayed.

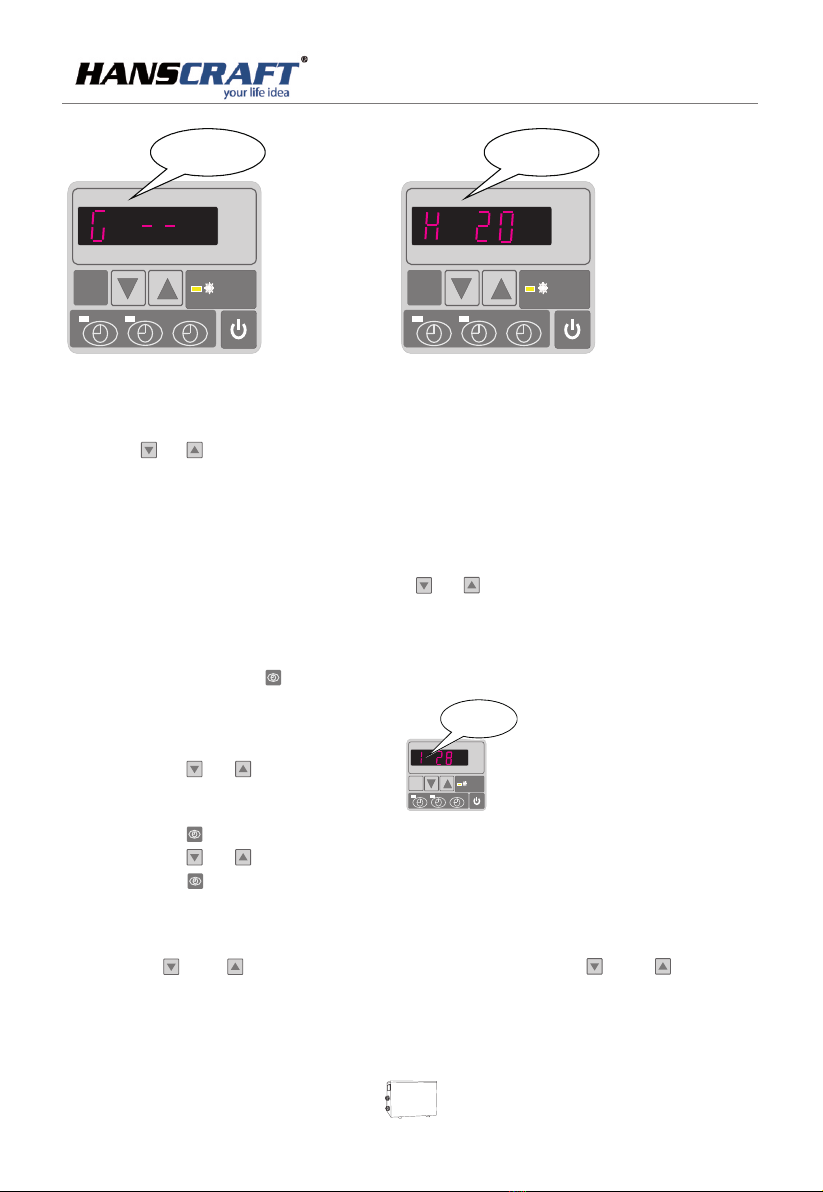

A. Under running status,

(1) Under current heating mode, only press or to adjust heating water temperature.

B. Under standby status,

(1) Press and hold in for 5 seconds until parameters flash to enter operating setting

(2) Press or to reach Parameter 1 ,

(3) Press again.

(4) Press or to set temperature.

(5) Press to confirm and wait for 8 seconds. Machine will reset new temperature.

7.4 Water temperature setting:

10

10

MODE

HEAT

Param et er 1

To set the en te ri ng w at er

temp. u nd er h ea ti ng m ode

(15-3 5℃, de fa ul t

setti ng :2 8℃)

7

5 seconds 5

seconds

.5 Locking setting

Long press and to lock the parameters, Press and for

again to unlock

11

PO OL H E A T P U M P

6

press the again to store the new data.

7

Press to set the time for HP start to run ,and press or to adjust .

again to store the new data.

Press to set the time for HP stop running, press or to adjust .

then, press again to store the new data.

7.

7.

Time setting:

Press to set the time, and press and to adjust the time

Timer on setting

the time

Press the

7.8 Timer off setting

the off time

1

0

1

0

12

7.10 System reset function

Press and at the same time for 10s, parameter from “0” to “L” to be reset to default.

7.9 Cancel Timer Function

Press or first, then press to cancel timer on or timer off setting.

10

13

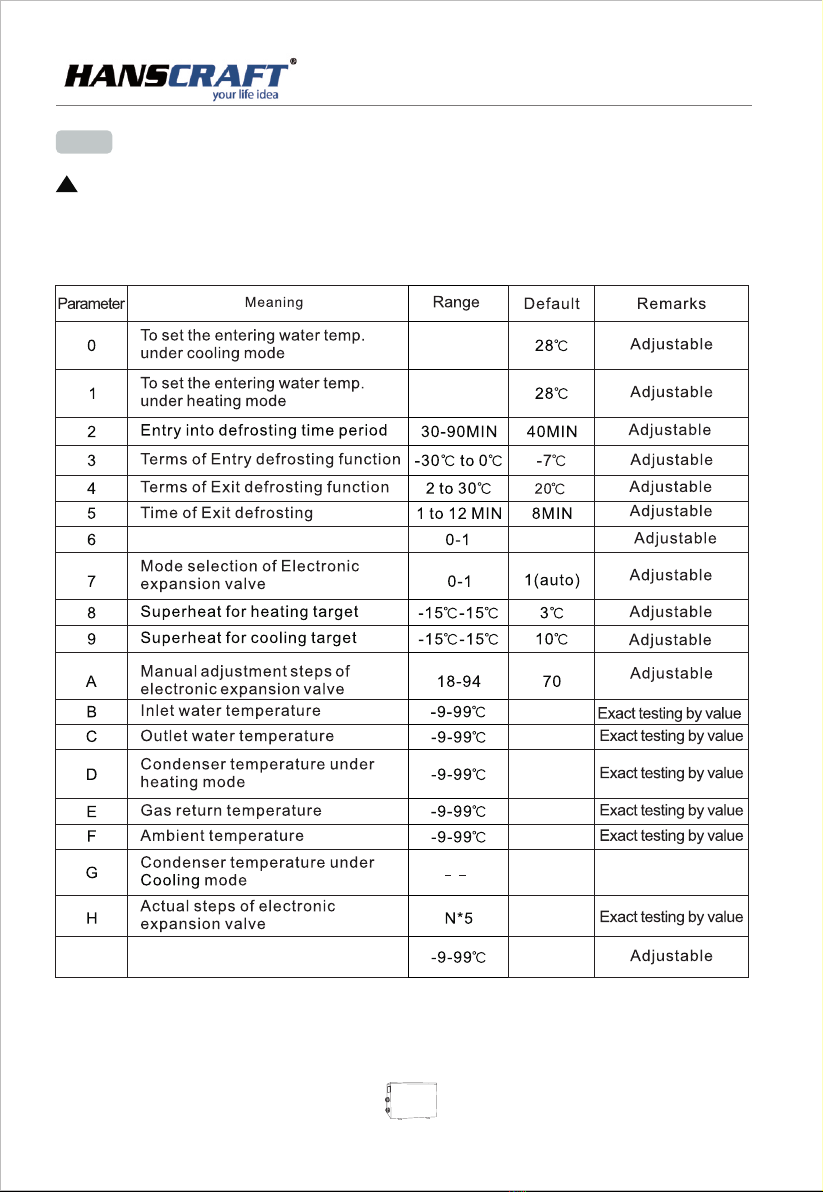

7.4 RUNNING DATA SETTING

Remarks :

(1) LED wire controller can operate the water pump after connected additional cable to the pump device in the position

of “WATER PUMP” terminal accurately .

(2) It is necessary to put an extra 3-phase transfer device for 3 phase water pump.

ATTENTION:

HP running parameters must be checked after installation and before first used.

When the LED on, it will displays water inlet temperature.

When the LED off, it will displays "OFF".

When the LED on, the water temp could be changed.

!

0 ( Heat)

/

15-35℃

15-40℃

PO OL H E A T P U M P

Mode:0 heat,1 heat and cool

LInlet water temperature

correction

(1) You should check the water supply system regularly as to avoid the air entering the system

and occurrence of low water flow, because it would reduce the performance and reliability

of pool heat pump unit.

(2) Clean your spas and filtration system regularly to avoid the damage of the unit as a

result of the dirty of clogged filter.

(3) Keep the HP unit dry, clean, well-ventilated and always clean air side of the heat exchanger,

which can maintain a good heat exchanger and energy saving.

(4) Only a qualified service technician is allowed to operate pressure of the refrigeration system.

(5) Check power cable connection, if heat pump starts to operate abnormally, you should turn

it off and contact with qualified technicians.

(6) You should the water from water pump and other water system, to prevent from the

freezing damage in winter seasons.

(7)

(8)

.

drain

The heat pump and all associated pipe work must be drained down during winter or freezing

conditions.

Always flush with clean water and check thoroughly before recommissioning

the heat pump

WARNING

(1) .

(2) If you are not familiar with your water filtration system and heater

(a) Do not try to adjust, consult the professional dealer.

(b) Before use, please read the Installation and User's Guide.

Note: power supply before

Incorrect installation could result in personal injury.

Do not adjust internal control

TURN OFF any maintenance work

8. Maintenance

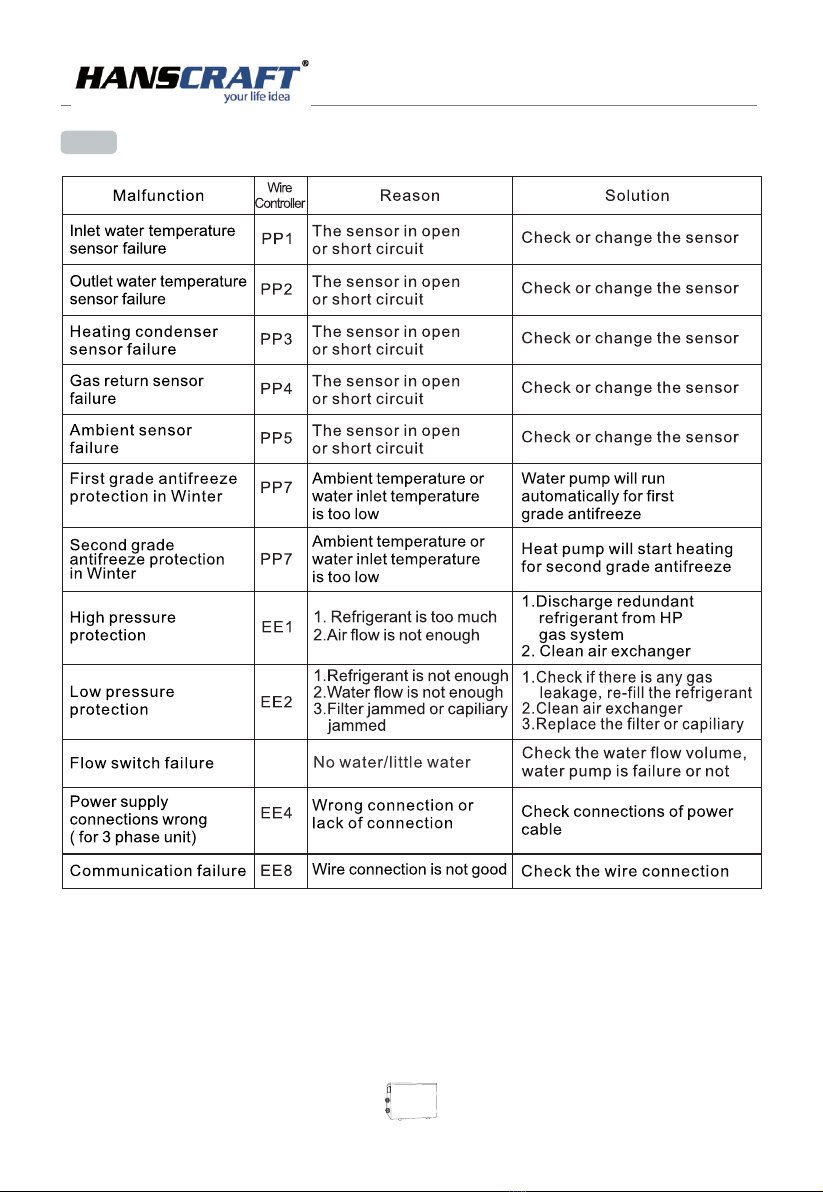

9. Troubleshooting guide

PO OL H E A T P U M P

14

15

Note:1.If the LED display the high and low pressure protection three time in half an hour,

2.If the LED display the "EE4"

Above those matter,you can cut off the power and restart the unit again or take it to maintain

9.1 Error code display on LED wire controller

PO OL H E A T P U M P

ON

Malfunctions Observing Reasons Solution

Heat pump

is not running

LED wire controller

no display No power supply Check cable and circuit breaker

if it is connected.

LED wire controller

displays the

actual time

Heat pump under

standby status

Startup heat pump to run

LED wire controller

displays actual

water temperature

the

1. water temperature is

reaching to setting value

HP under constant

temperature status

2. Heat pump just start to run

3. under defrosting

,

1. verify water temperature setting

2. Startup heat pump after a few minutes

3. LED wire controller should

display “Defrosting”

Water

temperature

is cooling when

HP runs under

heating mode

LED wire controller

displays actual

water temperature

and no Error code

displays

1. choose the wrong mode

2. figures show defects

3. Controller defect

1. adjust the mode to proper running

2. replace the defect LED wire controller,

then check the status after changing the

running mode,verifying the water inlet

and outlet temperature

3. replace defect main controller

Short running LED displays actual

water temperature

no Error

code displays

,

1. fan NO running

2. air ventilation is not

enough

3. refrigerant is not enough

1. Check the cable connections between

the motor and fan if necessary,it

should be replaced.

2. Check the location of heat pump unit,

and eliminate all obstacles to make good

air ventilation

3. Replace or repair the heat pump unit

,

Water stains Water stains on

heat pump unit

1. concreting

2. water leakage

1. No action

2. check the titanium heat exchanger

carefully if it is any defect

Too much ice

on evaporator

Too much ice

on evaporator

1. air ventilation is

not enough

2. refrigerant is not enough

1. check the location of heat pump unit

and eliminate all obstacles to make

good air ventilation

2. replace or repair the heat pump unit

,

9.2 Other Malfunctions and Solutions ( No display on LED wire controller)

PO OL H E A T P U M P

16

In accordance to WEEE Directive (Waste from Electrical and Electronic Equipment Directive)

2002/96/EC this equipment should not be disposed of in the normal waste stream.

10.Exploded Diagram

PO OL H E A T P U M P

17

18

No. No.

Name of parts Name of parts

top cover

back grill

evaporator

Pillar 1

Pillar 2

Left grill

Pillar 3

Upside frame

Fan bracket

Fan motor

Fan blade

Front panel-plastic

Front grill

Controller

Controller box

Fuse box

Electric box

Compressor capacitance

Capacitance clip

PC board

Transformer

Fan capacitance

Scale board

Electric box cover

Compressor

Compressor support

Inlet water temp. sensor clip

Choke plug

Inlet water temp. sensor

Pillar 4

Suction valve

Suction valve cover

Pressure gauge

Terminal block

Wiring clip

Water inlet cover

Retainer ring blue

Water outlet cover

Retainer ring red

Wiring cover

Right panel-plastic

Pillar 5

Back panel-plastic

Ambient temp. sensor

Ambient temp. sensor clip

Low pressure switch

Gas return pipe

Pipe(heat exchanger to 4-way valve)

Separator moudle

Cannula& clip of evaporator temp sensor

Evaporator temp. sensor

Gas collecting pipe

Filter moudle

Base tray

Isolation panel

Heat exchanger

Water flow switch

High pressure switch

Exhaust pipe

4-way valve

Capillary

Pipe(4-way valve to gas collector)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

Parts list

This manual suits for next models

2

Table of contents

Popular Heat Pump manuals by other brands

GE

GE AJHS10DCB Dimension Guide

Trane

Trane TWA075A manual

Maritime Geothermal

Maritime Geothermal ATW-55 Installation and service manual

evoheat

evoheat EVO FLEX 10 Installation & operation manual

Daikin

Daikin Altherma 3 H MT W Installer's reference guide

Glen Dimplex

Glen Dimplex LIH 10TE Installation and operating instruction