Hapstone M2 User manual

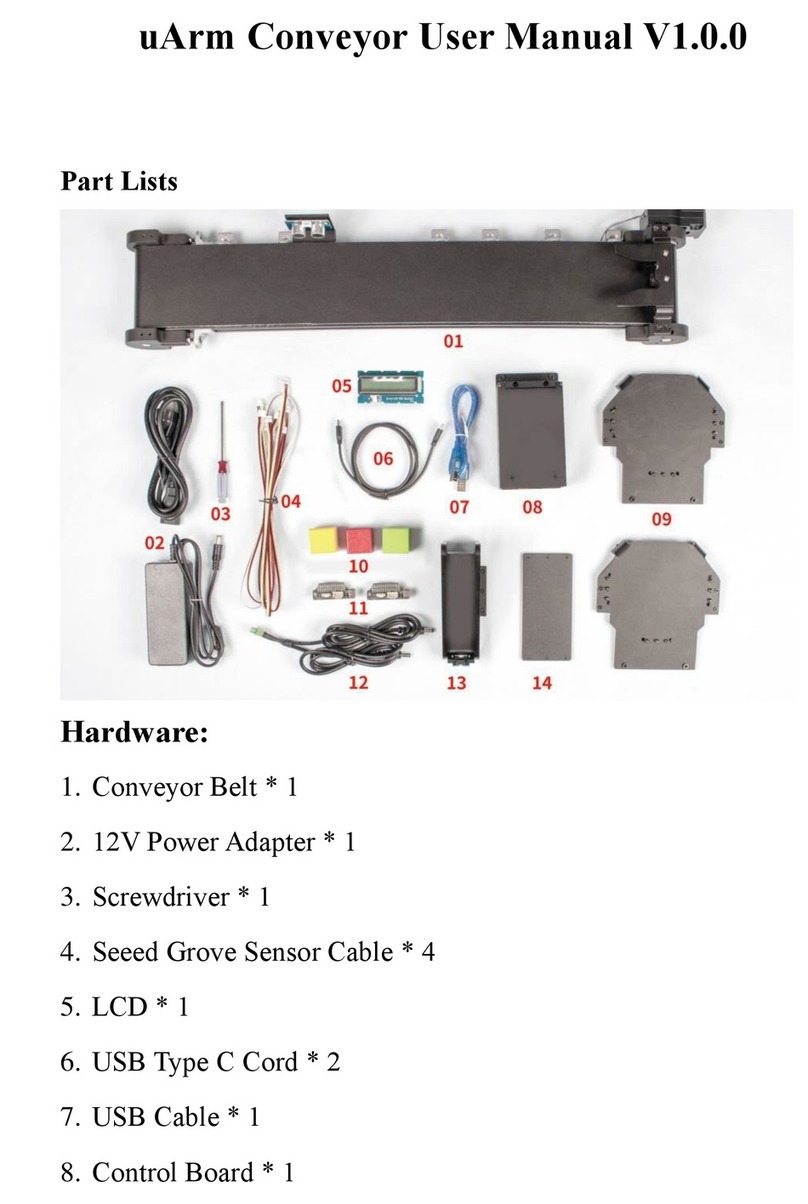

Kit

1. Sharpener base.

2. Vertical rod.

3. Fixing ring.

4. Horizontal rod with pivot unit.

5. Sharpening stones set.

6. Black marker.

7. User Guide.

Technical specs

❖Knife sharpener dimensions (ready to work): 45х13х18.5 cm;

❖Maximum sharpening stone length: 15 cm;

❖Knife sharpener weight: 1.52 kg.

Setup

Assembling

Insert the vertical rod (2) into the sharpener base (1) from the bottom. Put the fixing ring (3) on to the vertical rod on the opposite side of the base.

The fixing ring should touch the base and prevent vertical movement of the vertical rod. Tighten the fixing ring.

The pivot unit is mounted on the horizontal rod (4). Put the pivot unit on to the vertical rod.

Attaching the sharpening stone

The sharpening stone should be fastened on the horizontal shaft in the stone holder. With two fingers, pull the nearest side of the stone holder back

against the spring and and get it as close as you can to the wooden handle. Put the sharpening stone into the stone holder and fasten it with the

thumb screw.

Note: When changingsharpening stones of different thicknesses, be sure to control the angleof sharpening of the knife. It should remain unchanged.

Fastening the knife

Position the knife on the rubber mat at the base of the knife sharpener. The edge of a knife with a blade should be directed outwards (towards you).

You will immediately feel the magnet located in the front part of the base. The cutting edge of the knife must slightly overlap the edge of the base

(approximately 1-3 mm). Attach the three-point guide tightly to the knife and secure it with the large thumb screw. The three-point guide allows the

knife to be precisely positioned on the working plate –both before and after being turned over –ensuring a smooth and symmetrical cutting edge.

You need not worry about the safety of your blade, because the guide is made of aluminum. However, for additional protection, you could cover the

blade with protective tape.

Setting the sharpening angle

Before sharpening a knife, it is the necessary to choose the sharpening angle. The sharpening angle chosen depends on the type of knife steel, or

the purpose for which the knife is to be used. The smaller the sharpening angle, the thinner the cutting edge on the knife and, consequently, the

sharper the blade that is obtained. It should be noted that sharp blades are easier to damage, especially if cutting hard surfaces. Thus, you have to

find an optimum angle that makes the knife sharp enough for your needs, but not too easily damaged. Recommendations for the choice of sharpening

angle (in accordance with the type of the knife) are given in the chart below:

Type and purpose of the knife

Sharpening angle

Razors, scalpels

From 10 to 15 degrees

Knives for vegetables, bread, filleting

From 15 to 20 degrees

Professional kitchen knives of different types

From 20 to 25 degrees

Hunting knives and EDC knives

From 25 to 30 degrees

Dagger type knives, axes

From 30 to 40 degrees

Note: When you read about knife sharpening, you may come across the term “full sharpening angle.” This means the sum of the two angles used to

sharpen both sides of a blade (e.g. 15 one side + 15 the other side = 30 full sharpening angle). As a result, when using the Hapstone, you need to

divide the value of the full angle by 2 to get the value of the angle you need to set on the Hapstone.

You can set the sharpening angle using anglemarks on the vertical rod or using a digital angle gauge. Align the top face of the pivot unit to the desired

angle mark.

Note. The actual sharpening angle also depends on the thickness of the knife spine. The thicker the knife spine, the less the actual angle is. For

example, if the knife thickness is 3 mm, the knife sharpening half angle is reduced by about 2 degrees. Keep this in mind when sharpening.

Vertical support

If your knife does not sit tightly on the working surface, lift the knife slightly using the vertical support and tighten the thumb screw.

Sharpening recommendations

Always use the coarsest sharpening stone to begin sharpening a knife. Move the sharpening stone away from you along the blade, and then return it

to the initial position without touching the blade. This is especially important when working with fine sharpening stones.

The whole blade should be worked until you see burrs (fractured stripes of metal along the whole length of the cutting edge). These can be felt by

slowly drawing your nail along the lower part of the edge. After you’ve sharpened the first side, turn the knife over and repeat the procedure for the

second side.

Change the sharpening stones from thecoarsest to the finest and sharpen both sides of the knifeagain. Finer sharpeningstones have less granularity

and will eliminate the burrs.

While changing sharpening stones, remove metal filings from the blade and the knife sharpener to prevent cross contamination of sharpening stones.

Precautions

Hapstone knife sharpener is made of steel and covered with a high-quality coating. It can be used in any conditions. It can be conveniently placed on

any surface and its rubber-tipped legs prevent it from sliding while sharpening.

While sharpening a knife, observe all necessary safety measures. Be careful not to injure your hand on the sharpened blade of your knife.

During the sharpening process, magnetized metal shavings usually accumulate on the blade of the knife. Periodically use a wipe to clean the blade

and remove any accumulated shavings.

Thank you for choosing HAPSTONE. We wish you sharp knives!

© 2017 HAPSTONE

© 2017 Gritomatic

Table of contents

Popular Accessories manuals by other brands

REV Ritter

REV Ritter PRIMALUXE EFRV300USB/1 manual

Niles

Niles MS-360 Installation & operating guide

Becker

Becker P3/30PSF Assembly and operating instructions

Rohde & Schwarz

Rohde & Schwarz R&S NRP-Z Series Getting started

Orion

Orion EQ-1 Equatorial Mount 9011 instruction manual

MyCharge

MyCharge Freedom 1500 owner's manual