Harnisch+Rieth D-G 16 S2 User manual

Maschinenbau

Werkzeuge

Laborgeräte

Operating instructions

Machine designation: Automatic blasting unit

Machine type: D-G 16 S2

Machine no.: ...........................

Keep for future reference!

Hausanschrift:

Harnisch+Rieth

GmbH & Co. KG

Küferstr. 14 - 16

D-73650 Winterbach

Telefon

+49 7181 / 96 78-0

Telefax

+49 7181 / 7 31 39

+49 7181 / 96 78-17

E-mail:

info@hr-dental.de

http://www.hr-dental.de

D-G 16 S2 - 18.04.13 / Vers.: 1

1

Dear customer,

Thank you for the confidence you have placed in us by purchasing this

automatic blast-

ing unit

.

Please take time to read these operating instructions carefully, especially before using

the unit for the first time, as this will ensure that the unit will give you good service for

many years to come.

Contents

1

Safety..................................................................................................................... 2

1.1

Correct use ..................................................................................................... 2

1.2

Possible dangers ............................................................................................ 2

1.3

Approved operators ........................................................................................ 2

1.4

Safety measures at site of operation.............................................................. 2

1.5

Marking of safety references contained in these instructions ........................ 3

2

Starting up ............................................................................................................ 3

2.1

Technical data ................................................................................................ 3

2.2

Unpacking the automatic blasting unit............................................................ 3

2.3

Short description of unit and identification of components............................. 4

2.4

Process for putting into operation................................................................... 7

3

Operation .............................................................................................................. 7

3.1

Connect sandblasting device to the compressed air supply .......................... 7

3.2

Filling with blasting agent ............................................................................... 7

3.3

Fill abrasives................................................................................................... 8

3.4

Automatic operational mode........................................................................... 8

3.5

Description of how to set and save the blasting time ..................................... 9

3.6

Manual blasting .............................................................................................. 9

3.7

Automatic cut-out and filter change warning light......................................... 10

4

Cleaning/maintenance ....................................................................................... 10

4.1

Replacing the filter bag................................................................................. 10

4.2

Cleaning (replacing) the super-fine filter ...................................................... 10

4.3

Cleaning the shove-in sieve (embedded material residue) .......................... 11

4.4

Draining of the abrasive............................................................................... 11

4.5

Checking of the injector if blasting performance is reduced......................... 12

4.6

Checking of other components..................................................................... 14

5

Sandblasting area illumination ......................................................................... 14

6

Electrical fuse protection .................................................................................. 14

7

Access to electrical/pneumatic control system.............................................. 14

8

Warranty conditions........................................................................................... 15

9

EC declaration of conformity ............................................................................ 16

2

D-G 16 S2 - 18.04.13 / Vers.: 1

1 Safety

1.1 Correct use

The D-G 16 S2 automatic blasting unit is used in dental laboratories

-

to remove embedded material residue and oxides on cast parts after implanting,

-

for levelling and smoothing cast part surfaces and,

-

for polishing.

Unauthorized modifications and additions are not permitted for safety reasons!

The operating and maintenance conditions specified in these operating instructions must be ad-

hered to.

Caution

The unit is not designed as a medical device!

Use on people is prohibited!

1.2 Possible dangers

-

The sandblasting unit D-G 16 S2 is safe if used properly, but with improper and negligent use

there is a risk of injury from the sandblast emanating from the injector (eye or skin injuries).

-

Before maintenance and cleaning work, the device must be switched off at the main power

switch and the mains connector must be disconnected (pull out the power plug).

-

Before every access to the internal electrical components, the device must be disconnected

from the mains.!

-

If the front lid is open or loose the injector may not be switched on.

-

No cinders may be sucked into the built-in aspirator.

Danger

The unit is not suitable for use in rooms where special conditions exist (e.g. corrosive or poten-

tially explosive atmospheres).

1.3 Approved operators

The operator of the unit should ensure that the operating instructions are accessible to the op-

erating personnel and have been read and fully understood. Only then should the operator

commission the unit.

1.4 Safety measures at site of operation

-

The installation surface must be stable and level enough to support the weight of the automatic

blasting unit.

-

Ensure that no foreign bodies enter the ventilation apertures of the unit.

-

Ensure that the workplace complies with accident prevention regulations at all times through the

enforcement of suitable directions and inspection measures.

D-G 16 S2 - 18.04.13 / Vers.: 1

3

1.5 Marking of safety references contained in these instructions

Note Refers to tips and other particularly helpful information.

Caution

Refers to particular methods of operation or handling, non-adherence to which can lead to mal-

functioning, damage or other problems.

Danger

Refers to dangerous situations which can lead to injuries.

2 Starting up

2.1 Technical data

Machine designation : Automatic blasting unit

Machine type : D-G 16 S2

Unit dimensions : Width 480 mm (with plug for pedal switch),,

Depth 570 mm,

Height 705 mm

Electrical connection : 230 Volt/50 Hz

Overvoltage category : II

Power consumption : max. 460 Watts

Sound pressure level : 58 dB(A) min. air capacity

68 dB(A) max. air capacity

Fine-particle filter quality: : dust class M, DIN EN 60335

Electrical fusing : 2x 5 A/T

Compressed air connection : max. 10 bar

Compressed air consumption : approx. 200 l/min. (per injector)

approx. 400 l/min (with simultaneous operation)

Blasting chamber illumination : E 14 230V / 40 watt incandescent lamp

Weight : Approx. 38 kg

2.2 Unpacking the automatic blasting unit

1. Remove upper crate cover.

Note Position the crate on two squared timbers or a pallet to facilitate removal of the two M8 pack

ing

screws on the underside of the crate.

2. Unscrew 2x M8 packing screws.

3. The unit must be lifted out of the crate by two people (approx. 38 kg).

4. Check the accessories:

-

Documentation

-

Mains power supply connection cable ................................................................... No. 35028

-

Pedal switch with cable and plug ........................................................................... No. 67010

-

2 m PVC fabric hose, blue, Ø 8.2 x 6

with plug-in socket for rapid action coupling and coupling ring .............................. No. 72350

-

See delivery docket for any possible further accessories

4

D-G 16 S2 - 18.04.13 / Vers.: 1

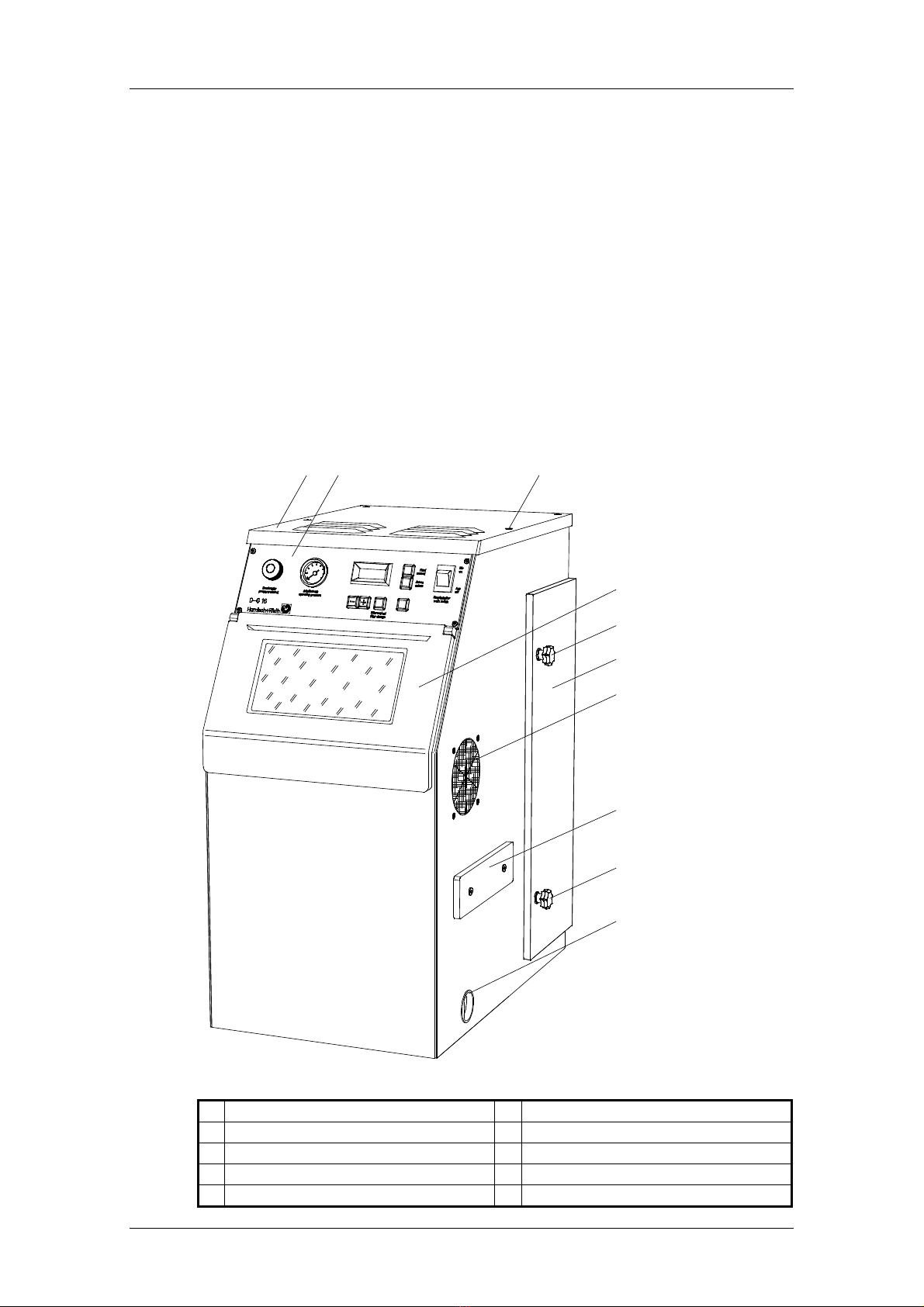

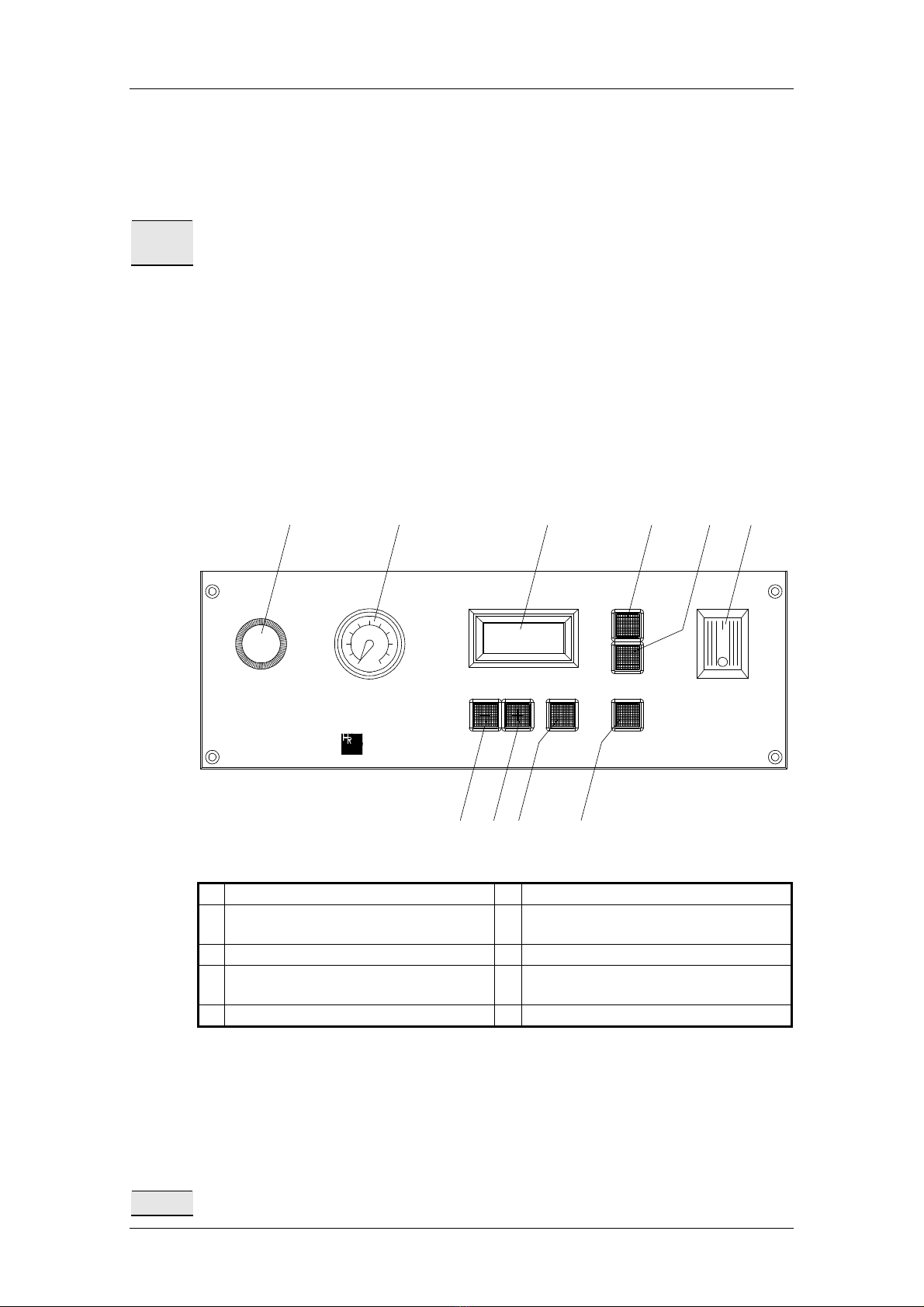

2.3 Short description of unit and identification of components

This device can be used as both an automatic unit or as a manual blasting device. The high-

performance jet with a tetraboric blasting nozzle is simply removed from the holder for manual

blasting operations and guided by hand, the sand blast been activated by a foot-actuated valve.

The spacious blasting chamber is optimally lit by 230 volt illumination and can be observed in

comfort through the broad-surfaced front window. A high-performance, low-noise extractor fan,

combined with an effective filter installation consisting of a large volume filter bag followed by a

super-fine filter, guarantee a dust-free, pleasant working environment. If the dust in the filter bag

reaches the maximum level a filter control lamp illuminates and the unit switches itself off auto-

matically. The filter bag can be replaced easily without generating any dust.

Blasting agent circulation occurs automatically and is kept free of embedded material residue

through the action of a sieve which can be easily removed at the side.

1 2

9

5

8

7

6

5

4

3

Fig. 1: View from the right and the front

1

Device lid 6

Door for filter area

2

Shield 7

Hand through-grip(only on the right side)

3

4 x hexagon socket screws 8

Slide-in sieve

4

Front lid 9

Sand drain lid

5

Star handle

D-G 16 S2 - 18.04.13 / Vers.: 1

5

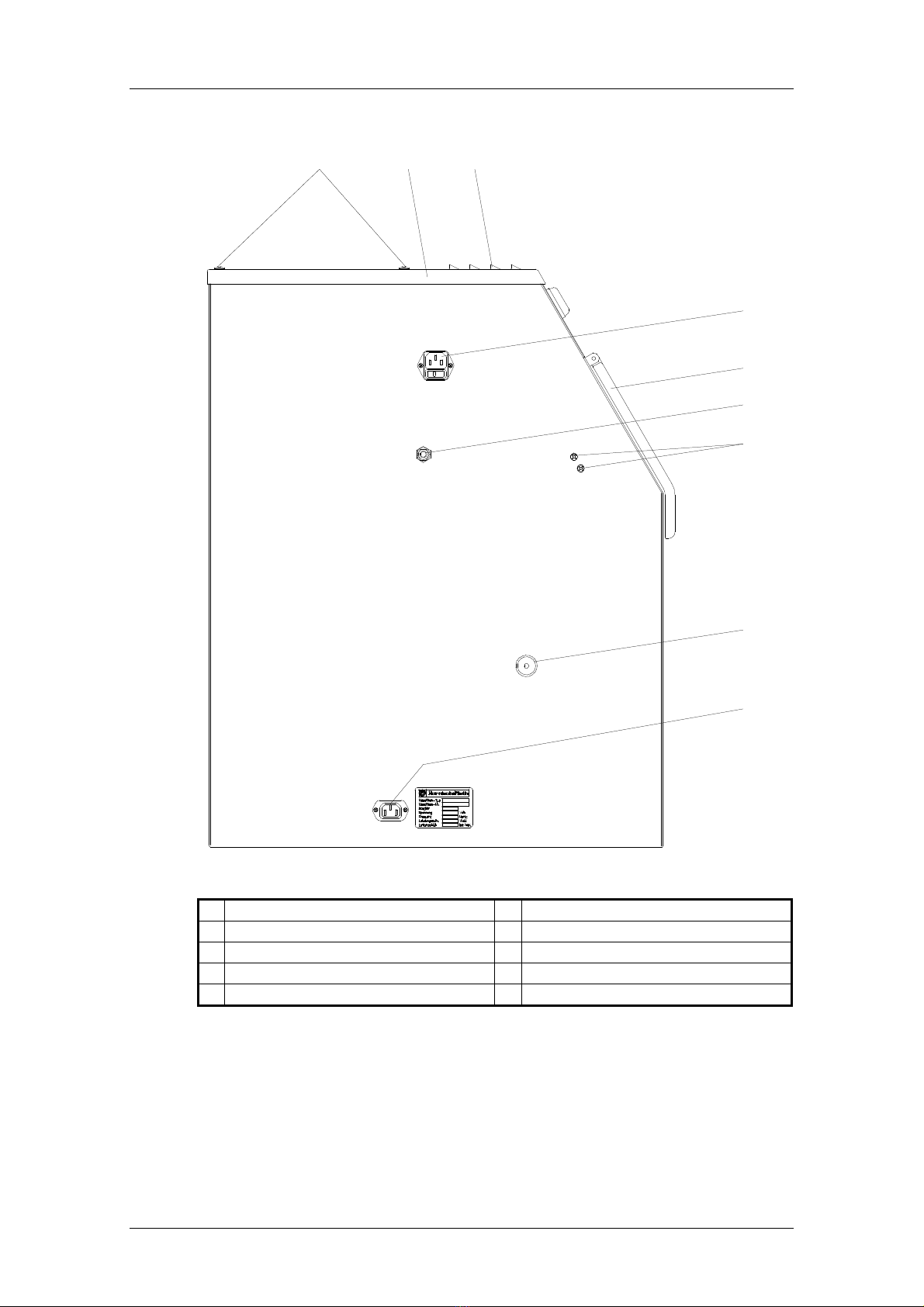

17

16

15

14

4

13

3 1 10

Fig. 2: View from the left

1

Device lid 14

Compressed-air connector

3

4 x M5 hexagonal socket screws 15

Screws for injector mounting

4

Front lid 16

Knurled nut for slide-in sieve

10

Air outlet 17

Socket for foot switches

13

Mains socket (230 V /50 Hz)

6

D-G 16 S2 - 18.04.13 / Vers.: 1

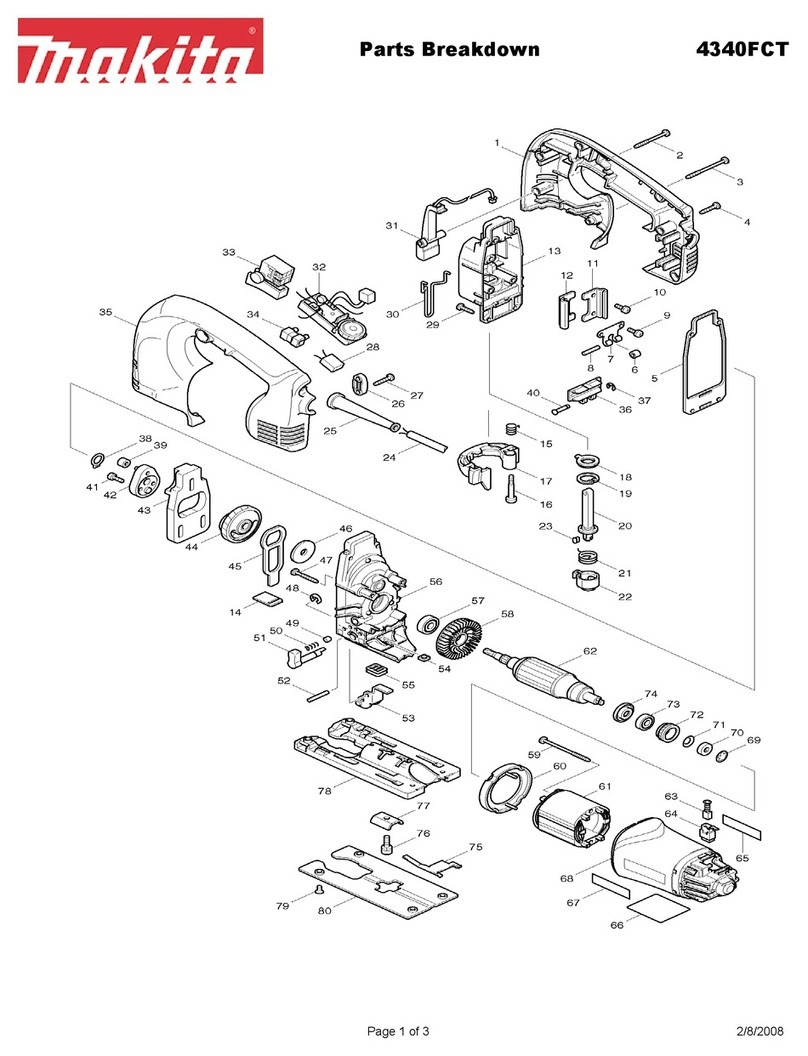

45

42

48

41

31

8

64

63

19

62

27

26

4

10 46 3 29 40 30 47 3

61

50

33

34

18 49

43

1

20

70

28

75

Fig. 3: Device sectioned through the middle and viewed from the right

1

Device lid 40

Support Ø 63 mm

3

4 x M5 hexagonal socket screws 41

Plastic connector for the filter bag

4

Front lid 42

Cover plate for filter bags

8

Slide-in sieve 43

2 x knurled nuts

10

Air outlet 45

Filter bag

18

Sandblasting area light (230V) 46

Aspirator motor

19

Injector mounting 47

Aspiration area

20

Injector 48

Mesh basket

26

Abrasive aspirator hose 49

Sealing surfaces

27

Air hose on the injector (20) 50

Filter area

28

Air hose on the injector (70) 61

Drive motor for sandblasting cage

29

Fine particle filter 62

Fastening binder (securing for transportation)

30

Fine particle filter bracket 63

Rounded head screw

31

Sand aspirator basket 64

Sandblasting cage

33

Middle floor area 70

Injector for manual blasting

34

4 x screws for floor area 75

Orientation pin

D-G 16 S2 - 18.04.13 / Vers.: 1

7

2.4 Process for putting into operation

(see fig. 2 page 5)

1. Connect unit to compressed air supply (see section “3.1”).

2. Fill blasting agent (see section “3.2”).

3. Check filter system (see section “3.3“).

4. Connect pedal switch to plug socket (1) (in blasting chamber during transportation)

5. Insert mains connection plug (in blasting chamber during transportation) in plug socket (15) and

establish connection to mains supply (230 V/50 Hz).

6. Automatic operating mode (see section “3.4”).

7. Manual blasting (see section “3.6”).

3 Operation

3.1 Connect sandblasting device to the compressed air supply

(see fig. 2 page 5)

1. Connect fabric hose included in delivery to compressed air connection (16).

2. Connect plug-in socket for rapid action coupling with compressed air supply (max. 10 bar).

Caution

Only compressed air free of moisture and oil should be used.

A water separator should be installed directly prior to, or at a max. of 1 m distant from,

the unit

to ensure fault-free operation.

3.2 Filling with blasting agent

(see diag. 1 & 2 page 4 & 5)

The unit is designed by the manufacturer to be used with the following blasting agents:

Type of blasting agent Blasting agent category

Special fused alumina (aluminium oxide) EW 60 (250 µm)

EW 80 (180 µm)

Cat. 60 B (120 µm)

Polishing blasting agent Cat. 150 A (150 µm)

Caution

The unit is designed for use with Harnisch+Rieth blasting agents. Harnisch+Rieth are not liable

for any malfunction or damage resulting from the use of other blasting agents.

1. Open front flap (2)

Note Unscrew knurled nut for shove-in sieve (10) and pull out shove-in sieve (8) to about

3

/

4

of its

length to facilitate inspection of the blasting agent filling level.

2. Fill blasting agent to about 4 cm under the height of the shove-in sieve (8).

Caution

It should be ensured that there are no dirt particles in the blasting agent to avoid malfunctions.

3. Shove in sieve (8) and tighten knurled nut(10) lightly.

8

D-G 16 S2 - 18.04.13 / Vers.: 1

3.3 Fill abrasives

(see fig. 1 and 3, page 4 & 6)

Caution

The D-G 16 S2 automatic blasting unit should only be used with a correctly installed and un-

damaged super-fine filter (7) and filter bag (14).

1. Open door to filter chamber (4) by unscrewing the two star grips (11).

2. Ensure that the super-fine filter (7) is not damaged and correctly pressed onto the sealing sur-

face (49) (i.e., sealed). The two knurled nuts (43) must be tightened firmly and evenly.

3. Ensure that the filter bag (14) is inserted in an undamaged condition in the mesh basket (48).

4. The filter bag plastic connection (41) should sit securely on the connection piece (40).

5. Seal the door to the filter chamber (4) again by gently but firmly tightening the two star grips.

3.4 Automatic operational mode

(see diag. 1 & 3 page 4 & 6)

Aus

off

Autom.

autom.

Hand

manual

start / stop

Ein

on

Arbeitsdruck

operating pressure

D - G 16

Druckregler

pressure control

timer

sec

Harnisch+Rieth Filterwechsel

filter change

60

5

7

5

4

5

3

5

6

5251

0015

55 59 58

Fig. 4: Shield

51

Regulator for operating pressure 56

Filter change LED (red)

52

Pressure gauge for operating pressure 57

"start/stop" button (for automatic opera-

tion)

53

“-" timer pushbutton 58

"Autom./autom." button

54

"+" timer pushbutton 59

"Hand/manual" button (for manual opera-

tion)

55

Display 60

Main power switch

1. Place objects to be blasted in the sandblasting cage (64).

2. The injector (20) must be in the mounting (19) and the rounded head screw (63) must be in its

nut.

3. Close front lid (4).

4. Do not adjust operating pressure at the pressure controller (51) to more than 5bar ! The oper-

ating pressure can be checked at the pressure gauge (52).

Note Upon switching on at the main power switch the device is in an operation ready state.

D-G 16 S2 - 18.04.13 / Vers.: 1

9

5. Turn on device at the main power switch (60).

-

The device is switched immediately to a manual operation mode, the "Hand/manual"

pushbutton lights up green.

6. Press "Autom." pushbutton (58), it lights up green.

7. Set sandblasting time using the pushbuttons "+" and ” -".

Note The sandblasting time set with pushbuttons "+" and “-" is stored automatically after 2 seconds.

The stored sandblasting time also r

emains in effect if the device is switched off or there is a

power failure.

8. Press "start/stop" (57) button

-

Aspiration starts,

-

Sandblasting area light is activated,

-

Sandblasting cage (64) swivels,

-

Injector (20) blasts.

9. After expiry of the set sandblasting time the aspiration is stopped after approx. 7 seconds and

the sandblasting area light is turned off after approx. 20 seconds.

Note

During blasting, blasting can be deactivated using the "start/stop" pushbutton, with the blasting

time being preserved in

the display. By pressing the "start/stop" pushbutton again the blasting

process is reinitiated and the blasting time continues running in the display.

Note During automatic operation it is also possible to blast manually using injector (70) by activat

ing

the foot switch.

3.5 Description of how to set and save the blasting time

-

the maximal adjustable blasting time is 60 minutes

-

the minimum adjustable blasting time is 1 minute

-

the blasting time can be adjusted in 1 minute steps

-

by pressing the "+" and “-"pushbuttons, the blasting time is reset and stored after approx. 2 sec-

onds.

Note

If the blasting time is reset during blasting, this blasting time is then stored in the memory. Upon

restarting the device the last time set is indicated on the display.

3.6 Manual blasting

(see fig. 1 and 4, page 4 & 8)

1. Close front lid (4) and turn on device at the main power switch (60).

-

The internal light (18) is switched on,

-

Aspiration is set in motion,

-

The pushbutton "Hand/manual" (59) illuminates.

2. Do not adjust operating pressure at the pressure regulator (51) to more than 5 bar! The operat-

ing pressure can be checked at the pressure gauge (52).

3. The sand blast (from the injector (70) for manual blasting) is released by activating the foot

switch.

10

D-G 16 S2 - 18.04.13 / Vers.: 1

3.7 Automatic cut-out and filter change warning light

(see fig. 1 and 4, page 4 & 8)

Note

As soon as the max. permissible filling of the filter bag (45) is reached, the automatic cut out is

activated via an underpressure sensor and the red warning light "Filter wechseln" (56) lights up.

Blasting is interrupted with the aspiration continuing for about 7 seconds.

-

The filter bag (45) must be changed, see section “4.1”.

Note If the device is deactivated by the automatic cut out, further work can be carried out

for a short

time by turning on and off again and tapping the filter bag (45) without any need to exchange it.

-

For tapping the filter bag (45), open the door for the filter area (6)

Note If after automatic cut-out (filter change display lights up) the

filter bag (14) is only partially filled,

the fine particle filter (29) must be checked and if necessary cleaned, see section “4.2”.

4 Cleaning/maintenance

(see fig. 1 and 4 , page 4 & 8)

Note If the unit is switched off by the automatic switch-

off it is possible to work for some time without

replacing the filter bag by turning the unit off and on again and tapping the filter bag (14).

Open the filter chamber door (4) to tap the filter bag (14).

4.1 Replacing the filter bag

(see diag. 1 & 3 page 4 & 6)

1. Open the filter chamber door (4).

Note The super-fine filter (7) should be inspected and/or cleaned if, after the automatic switch-

off

responds (the filter change indicator illuminates), the filter bag is only slightly filled.

(See section “4.2”)

2. Press the plastic connection (41) away from the connection piece (40) with both hands.

3. Close filter bag (14) with attached plastic cover (42).

4. Carry the filter bag (14) in the mesh basket (48) to the disposal point.

5. Insert new filter bag (14), sealed tightly, and inspect filter installation. (See section “3.3”).

Note

The disposable filter bag should under no circumstances be emptied and reused, as this can

lead to malfunctions, not to mention the fact that this can be detrimental to health.

4.2 Cleaning (replacing) the super-fine filter

(see diag. 1 & 3 page 4 & 6)

Note The super-fine filter (7) should also be removed and dry-

cleaned or replaced after the filter bag

(14) has been changed about ten times! We will gladly take care of the cleaning of your super-

fine filter (7) on an exchange basis. We would be only too pleased to exchange your fine-

particle filters in order to clean them, whereby only type-checked filters compliant with du

st

class M (DIN 60335) are employed.

1. Open door to filter chamber (4) by unscrewing the two star grips (11).

2. Press the plastic connection (41) away from the connection piece (40) with both hands.

D-G 16 S2 - 18.04.13 / Vers.: 1

11

3. Remove filter bag with mesh basket (48).

Danger

Switch off unit at main switch (12)! Pull out mains supply plug!

4. Unscrew 4x hexagonal socket screws (60) and remove cover (66).

5. Unscrew 2x knurled screws (43) in filter chamber (51) and remove the strip (17) upwards.

6. Remove super-fine filter (7) upwards.

Caution

There should be no dust lying on the sealing surfaces (49) or in the suction chamber (47), as

dust could possibly damage the extraction motor (46). The filter chamber (51), suction chamber

(47) and sealing surfaces (49) should be suction cleaned.

7. Insert cleaned or new super-fine filter (7).

8. Insert strip (17) from above.

9. Tighten the 2x knurled screws (43) firmly and evenly again.

10. Replace cover (66) and tighten with 4x hexagonal socket screws (60).

11. Shove in the mesh basket (48) together with the inserted filter bag (14) and press the plastic

connection (41) onto the connecting piece (40) with both hands.

12. Inspect filter installation. (See section “3.3”).

4.3 Cleaning the shove-in sieve (embedded material residue)

(see diag. 1 & 2 page 4 & 5)

1. Unscrew knurled nuts for shove-in sieve (10).

2. Pull out shove-in sieve (8) and clean.

3. Firmly tighten the knurled nuts manually after inserting the shove-in sieve.

4.4 Draining of the abrasive

(see diag. 1 page 4)

1. Position unit with sand drainage outlet on table edge.

2. Drain blasting agent by removing plastic sand outlet cover (13).

Note On this occasion, the shove-in sieve (8) should also be removed and cleaned.

(See section “4.3”)

12

D-G 16 S2 - 18.04.13 / Vers.: 1

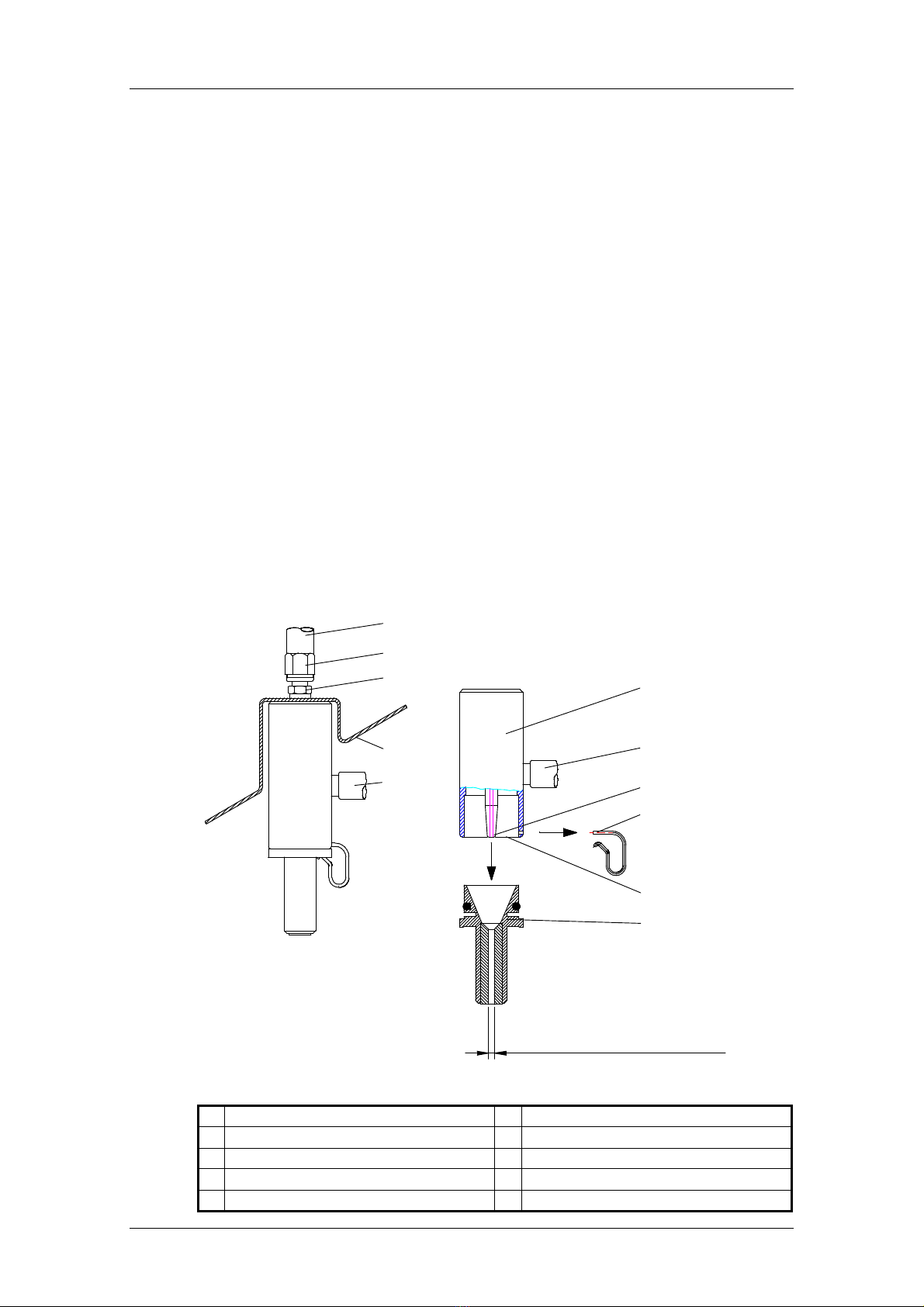

4.5 Checking of the injector if blasting performance is reduced

(see fig. 3 and 4, page 6 & 8)

If there is reduced blasting performance, the injector (20), the jet nozzle (22) and the aspirator

basket (31) must be checked as follows:

1. Disconnect device at the main power switch (60) ! Pull out power plug!

2. Hang up injector (20) after releasing the screw (63) and unscrew injector (70) from its mounting.

3. Pull clip connectors (21) to the side.

4. Pull jet nozzle (22) out by turning and while holding the injector housing (20).

5. Check whether any foreign bodies are present in the nozzle holes, and remove these wherever

appropriate.

6. A severely blasted out nozzle (22) (diameter greater than 4.5 mm) must be replaced.

7. The injector pin (23) must be flush with the surrounding injector ring (24). If the injector pin is

shortened by more than 1.5 mm due to wear, the injector must be replaced.

8. Check the injector pin for any possible external damage.

-

Close off air hoses (27) and (28) and remove injector along with abrasive aspirating hose

(26).

9. Check the aspirator basket (31) in the lower part of the sand reservoir for contamination, and if

necessary clean it. For this purpose see “Draining of the abrasive” section “4.4”.

22

26

24

21

23

70

72

26

29

71

28

Diameter greater than

4.5 mm = exhange jet nozzle

Fig. 5: Dismantling of the injector (70) for manual blasting

21

Clip connector 28

Air hose for injector (70)

22

Jet nozzle 29

Sandblasting area shield

23

Injector pin 70

Injector for manual blasting

24

Injector ring 71

Coupling nut

26

Abrasive aspiration hose 72

Hose fitting

D-G 16 S2 - 18.04.13 / Vers.: 1

13

22

26

24

21

23

20

27

2

7

2

6

2

0

28

19

62

63

Diameter greater than

4.5 mm=exchangejet nozzle

Fig. 6: Dismantling of the injector (20) for automatic blasting

19

Injector mounting 24

Injector ring

20

Injector housing 26

Abrasive aspiration hose

21

Clip connector 27

Air hose

22

Jet nozzle 28

Arrow (Direction for dismantling the injec-

tor)

23

Injector pin 63

Rounded head screw

Caution

If the injector (20) is remounted for automatic blasting the injector must be aligned together with

the jet nozzle using the orientation pin (75) Correction of the orientation of the nozzle is carried

out at the two screws (15). See fig. 2 page 5 and fig. 6 page 13.

Jet nozzle

Injector

Sandblasting

cage

Backwall off

sandblastingarea

Sidewall of housing

Rubberplate

=

=

10

20 mm

Orientationpin

Ø3x163mmlong

Thejet nozzleandthe

orientationpinmustpoint

inthisdirecktion

Thecagesidewalls

must beparallel tothe

housing

Fig. 7: Orientation of the jet nozzle

14

D-G 16 S2 - 18.04.13 / Vers.: 1

4.6 Checking of other components

In order to prevent premature wear and any damage resulting from that, all components ex-

posed to abrasive must be checked at regular intervals. The sandblasting cage as well as its

rubber attachments should receive special attention when checking for wear and be exchanged

wherever appropriate.

5 Sandblasting area illumination

(see fig. 3 page 6)

The blasting chamber illumination (18) requires 230 V/50 Hz.

A defective incandescent lamp is replaced as follows:

1. Switch off unit at main switch (12)! Pull out mains supply plug!

2. Unscrew lamp protection glass (18).

3. Unscrew incandescent lamp.

4. Screw in new E 14 230V / 40 watt incandescent lamp.

5. Screw on lamp protection glass (18) again.

6 Electrical fuse protection

(see diag. 2 page 5)

Two main fuses (5 A/T) are integrated in the mains supply connection socket (13)

7 Access to electrical/pneumatic control system

(see diag. 1 & 2 page 4 & 5)

Danger

Switch off the main switch (12) and pull out the mains supply plug before accessing the electri-

cal/pneumatic control system.

The electrical/pneumatic control system is located under the unit cover (66).

The unit cover is removed by unscrewing the 4x hexagonal socket screws (60).

8 Warranty conditions

This device conforms with current safety regulations and was subjected to extensive testing be-

fore leaving the works.

We grant a 12 months guarantee in which we are obliged to carry out all repairs necessary as a

result of material or production faults free of charge.

Warranty limitations:

1. The guarantee is considered void if repairs are not carried out by specialized dealers or by us.

2. Spare parts deliveries made for reasons covered by the guarantee do not lead to an extension

of the original guaranty period.

3. Incorrect installation (e.g. failure to heed VDE* regulations or written installation instructions).

4. Incorrect operation or stress.

5. External influences (e.g. transportation damage, damage caused by impacting or blows, dam-

age caused by the effects of weather or other natural phenomenae).

6. Repairs and alterations not carried out by authorized third parties.

7. Unit breakdown resulting from adjustment, alteration or any other attempt to adapt the unit is not

considered a material or production fault. This guarantee neither encompasses the costs of

such adjustment, alteration or any other attempt to adapt the unit, nor remedying of the

resulting damage.

8. Normal wear and tear (e.g. spray nozzles, hoses, and including hand-held pieces, union nuts,

glass panes, carbon brushes, illumination agents) or damage resulting from incorrect operation

is not covered by the terms of guarantee.

In order to provide you with a comprehensive service we would like you to fill out the guarantee

return form (enclosed at the beginning of these instructions) and send it to us by fax or letter

(window envelope).

* Verband Deutscher Elektrotechniker (German Electrical Technician Association)

Fax no.: 0 71 81/ 73 13 9

Machine

designation:

Automatic blasting unit

Maschine type:

D-G 16 S2

Maschine no.:

Date of purchase:

Dealer/Store:

From:

Date/signature:

--- ------------------------- ------------------------- --------------------------------------------------- -------------- für Fensterumschlag hier falten-------------- --

Duplicate

Guarantee return form

Harnisch+Rieth GmbH & Co.

Maschinenbau

Postfach 1260

73644 Winterbach

9 EC declaration of conformity

In the meaning of the EC Machine Directive 2006/42/EG

We hereby declare that the design of the machine specified below conforms with basic safety

and health requirements of the listed EC directives.

This certificate is no longer valid in the event of modifications being made to the machine which

are not approved by us.

Name of the manufacturer :Harnisch+Rieth

Address of the manufacturer :Küferstraße 14-16, 73650 Winterbach

Machine designation :Automatic blasting unit

Machine type :D-G 16 S2

The following pertinent EC directives were applied:

EC Machine Directive 2006/42/EG (29.12.2009)

EC Machine Directive 2006/95/EG (29.12.2007)

EMV Directive 2004/108/EC (20.07.2007)

The following harmonizing standards were applied:

T

h

e

following national technical specifications were applied:

DIN EN 60335

: Device for collecting dust which poses a health risk and reintroducing fresh

air into workrooms.

Technical documentation is available.

The operation instructions relating to the machine are also available.

Director of the Quality Control Department

Winterbach, 4 January 2010

DIN EN ISO 12100

Safety of Machinery—Part 1, General Principles of Design (04.2004)

DIN EN ISO 14121-1

Safety of Machinery – Principles of Risk Assessment (12.2007)

DIN EN 61,010-1

Safety regulations for measuring, control, regulating, and laboratory devices

DIN EN 60204-1

Safety of machinery - Electrical equipment of machines (06.2007)

DIN EN 61326-1

Electrical equipment for measurement, control and laboratory use –

EMV Requirements

DIN EN 61000-6-3

Radio-Suppression of Electrical Equipment –

Radio Interference Voltage / Radio Interference

Power (09.2007)

DIN EN 55 014-2

Electromagnetic Compatibility Noise Immunity, ESD, / Burst, / Surge

(10.1997).

Table of contents

Other Harnisch+Rieth Power Tools manuals