Automatic ATG5000 User manual

405-0234 Page 1 of 26 12/13/11

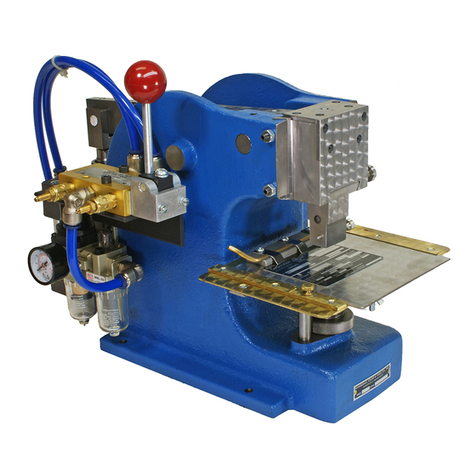

ATG5000 Mill

Owner’s Manual

405-0234 Page 2 of 26 12/13/11

Congratulations! You are now the owner/operator of America’s nest roller mill. Automatic Equipment

Manufacturing Company has pioneered in the development of farm sized roller mills. Now, after

40 years of experience, we offer you the world’s most complete line of mills. You will be joining

thousands of other owners in discovering the value of processing grain the modern way. The

Automatic way.

Take a few minutes to be sure that you understand the maintenance and operation of this roller mill.

Read the Operator’s Manual carefully and you’ll get better results and have fewer problems.

After your roller mill has been in operation for a few hours check for loose bolts; set screws; belts; etc.

All are tight when the roller mill leaves the factory, however, after a break-in period, some items may

require additional tightening.

Like any other equipment, your Automatic roller mill requires proper care and maintenance. Misuse

and neglect will only cause unnecessary expense and dissatisfaction.

BE ALERT - YOUR SAFETY IS INVOLVED

This symbol is used to bring attention to safety precautions and instructions. When you see

this symbol, be alert and pay attention to all instructions.

YOUR PERSONAL SAFETY IS INVOLVED.

!

405-0234 Page 3 of 26 12/13/11

! !

SAFETY PRECAUTIONS

FAILURE TO UNDERSTAND AND PRACTICE

GOOD SAFETY PROCEDURES COULD

RESULT IN BODILY INJURY OR DEATH

All farm machinery is inherently dangerous to children and to persons unfamiliar with its general

operations. Since roller mills contain numerous moving parts which can be extremely hazardous,

steps should be taken to insure the safety of the operator. Automatic Equipment strongly recommends

that no person be permitted to operate this machine without a thorough understanding of how the

machine works and the precautions to be observed.

Safety of the machine operator is a prime consideration of Automatic Equipment. Automatic follows

the guidelines of the OSHA Farm Safety Act in the guarding of its equipment for safe use by our

customers.

The operator of this machine should be a responsible adult, who is familiar with farm machinery

and trained in its operation. REMEMBER your best insurance against accidents is a careful and

responsible operator. A careless operator is a liability to himself and those who work with him.

Prior to operating this equipment, be sure to read and understand the Operator’s Manual. If there is

any portion you do not understand, or any phase of the machine’s operation you do not understand,

be sure to contact your local Automatic Equipment Manufacturing dealer or Automatic Equipment,

Pender, Nebraska.

OTHER SAFETY RECOMMENDATIONS

1. All roller mills are equipped with shielding to protect the operator from injury. These shields can be

easily removed for servicing of the unit; but should ALWAYS be replaced after the unit has been

serviced.

2. DO NOT step over the PTO shaft while it is in motion. Inspect the PTO shield periodically to insure

that it will turn freely.

3. Always keep hands, clothing and loose items clear of moving parts. Do not wear loose-tting

clothing which may catch in moving parts.

4. Always use a safety support and block wheels when working under or around your mill.

5. Keep the machine in good repair. Good maintenance is your responsibility. A poorly maintained

machine is an invitation for trouble. Always use proper tools when servicing machine, making

certain that they are removed from unit when service has been completed.

6. DANGER: Keep hands and feet out of hoppers. NEVER use your hand or foot to dislodge

obstructions from the rolls or to push down grain or snow that may be bridged in hopper.

7. Hydraulic uid can cause serious burns. Hydraulic uid escaping under pressure can have

enough force to penetrate the skin. Hydraulic uid may also infect a minor cut or opening in the

skin. If injured by escaping uid, see a doctor at once. Serious infection or reaction can result if

medical treatment is not given immediately. Make sure all connections are tight and that hoses are

in good condition before disconnecting the lines or performing other work on the hydraulic system.

To nd a lead under pressure, use a small piece of cardboard or wood; never use hands.

8. NEVER adjust or service the unit while in operation.

9. NEVER sit or stand on this machine.

10. ALWAYS disconnect all power sources prior to adjustment or servicing of the unit.

405-0234 Page 4 of 26 12/13/11

WHENEVER ROLLER MILL IS TO BE TRANSPORTED

ON A PUBLIC THOROUGHFARE OBSERVE THESE

INSTRUCTIONS

1. Check clearance carefully before towing the roller mill over bridges and into buildings.

2. Always place the machine in the transport position.

3. For daytime and nighttime, accessory lighting and reective devices should be used for adequate

warning to operators of other vehicles.

4. Drive at a reasonable speed to maintain complete control of the machine at all times. Twenty (20)

miles per hour is the maximum recommended speed.

5. When transporting on the highway, it is recommended that a safety chain be used with the tractor

and roller mill.

ROLLER MILL MAINTENANCE AND OPERATION

Automatic Grain roller mills are manufactured from the best materials and workmanship available -

each has been tested and properly adjusted at the factory before shipping. Simple adjustments and

minimum maintenance have been emphasized. Reasonable care and operation will assure many

years of trouble-free service.

• BE SURE roller mill is mounted on a rm base. The machine should be level while operating so

the grain will ow evenly across the rolls. This will eliminate unnecessary strain on roll bearings

and shafts, and also do a better job of rolling.

• IT IS IMPORTANT that all units be checked after the rst few hours of service to insure that all

set screws, lock collars, and other hardware has remained secure. This operation should be

performed periodically as part of general maintenance on your roller mill.

• ROLLER TENSION SPRINGS on oating roll are set at the factory to maintain just the right

amount of pressure. NEVER readjust compression spring tension. These springs prevent

stoppage, allowing foreign objects such as nails, bolts, etc. to pass between rolls. On all of our

mills, magnets are available and recommended, as they separate pieces of iron and steel from the

feed. Saving the life of just one animal will pay for several magnet installations.

• HOPPER GATE CONTROL. Your roller mill will not start with grain between rolls. Always start

roller and bring rolls to full RPM before opening feed gate. Make sure feed gate in hopper is

closed before putting grain in hopper. If grain is released to rolls before they are turning, grain will

pile up and it will be necessary to clean out between rolls and run remaining kernels through by

hand before starting.

• FLOW CONTROL ADJUSTMENT. Slowly adjust the valve control lever down to speed up output

and up to slow down output. The valve control lever is upright when in the off position.

• ADJUSTING FEED ROLLS from ne to medium or coarse grind by pulling down on the cam

adjust handle.

Your roller mill is designed to eliminate complicated adjustments. There are only two (2) major points

of adjustment for any small grain or shelled corn - roller spacing and hopper control gate.

1. HOPPER GATE. Open feed gate gradually until you reach the maximum ow of grain that power

will handle. If it becomes necessary to stop the machine at any time before hopper is empty, be

sure to close the feed door before shutting off power.

!!

405-0234 Page 5 of 26 12/13/11

2. ROLLER SPACING. This depends upon the type of grain to be rolled. Different grain varies in

size, shape, toughness and moisture content. This is also true of the same kind of grain from

different localities. For this reason, it is impossible for us to tell you how to set the rolls. Do not

over-roll hard or dry grains, as this will cause dusting. Remember, proper adjustment keeps dust

at a minimum, even when rolling the driest grain.

The closest roll setting is preset at the factory and as a rule and should not require additional

adjustment. However, for certain types or conditions of rolling, some “ne tuning” may be required.

IMPORTANT - Check to make sure the roll teeth do not come in contact with each other by turning

the mill by hand after each adjustment.

DON’T OVERCROWD THE ROLLS - keep a ribbon of grain going between the rolls, and you’ll do a

better job of rolling. This is especially true of oats and barley. It is not necessary to completely atten

the kernel. The grain becomes easy to digest when the hard coat or hull is broken open, exposing the

nutrients to the digestive juices.

ON PTO UNITS - Grade 5 shear bolts should be used at all times in the shear plate of the PTO

assembly.

ALWAYS - ease the PTO in slowly with tractor idling, then increase RPM gradually to full throttle,

900 to 1,000 RPM. Always maintain full tractor throttle and PTO speed while operating mill. NEVER

OPERATE WITH PTO SPEED IN EXCESS OF 1,000 RPM.

TRACTOR HITCH (see illustration below) - The hitch of the roller mill is designed to attach to any

SAE-ASAE standardized tractor draw bar. Adjust the draw bar so that it is 13” - 20” above the

ground. Extend or shorten the tractor draw bar so that the horizontal distance from the end of the

tractor power take-off shaft to the center of the hitch pin hole is 16” for 1,000 RPM. Lock the draw bar

in its crossbar, parallel with the center line of the tractor. Place locking pins on each side of the draw

bar. If the tractor has an offset draw bar, the offset should be down for PTO work.

THE TRACTOR HITCH POINT MUST BE PROPERLY

ADJUSTED. AN IMPROPERLY LOCATED HITCH

POINT MAY CAUSE DAMAGE TO THE POWER

TAKE-OFF WHICH MAY LEAD TO PERSONAL

INJURY.

NEVER ATTEMPT TO LUBRICATE, ADJUST OR OTHERWISE

SERVICE THIS MACHINE UNTIL THE PTO HAS BEEN

DISENGAGED, THE TRACTOR ENGINE HAS BEEN

TURNED OFF AND ALL MOTION HAS BEEN

STOPPED. LISTEN, AS WELL AS LOOK,

FOR MOTION BEFORE PROCEEDING

BEARINGS - All pillow block and cast ange bearings are sealed and as a general rule, require no

lubrication. However, the bearing manufacturer does furnish grease zerks and recommends the

bearings be regreased before one-third (1/3) of the bearings’ calculated life elapses. Usually just a

pump or two of grease per bearing before start up each harvest or after the unit has not been used for

a month or more will be sufcient.

IMPORTANT - DO NOT OVER GREASE. Over greasing can cause damage to the bearing seal.

WHEEL BEARINGS - Trailer wheel bearings should be cleaned and repacked with grease on a yearly

basis.

PTO Cross bearings should be greased daily. Telescoping sections of the PTO should be greased

yearly.

! !

! !

405-0234 Page 6 of 26 12/13/11

This section is a condensed chart to help you remedy problems if unsatisfactory

operation occurs. If you are unable to determine and correct the trouble, consult your

authorized dealer.

TROUBLE CAUSE REMEDY

Shearing Bolt in PTO 1. Starting mill with grain

between rolls.

Always run mill a short time to clean out mill. Close grain control

gate above rolls before stopping mill.

2. Low RPM. Maintain 900 to 1,000 RPM at all times. PTO will easily shear

under load below this speed.

3. Overload on mills. Running damp, high moisture grain can cause “sticking to the rolls”,

and cause an abnormal power requirement on new mills. There

sometimes can be sticking of dry grain to new rolls, particularly on

oats and barley. This condition should not continue after 2,000 -

3,000 bushels of grain have been run.

4. Opening grain control

gate too fast and too far

open.

Always open gate slowly and open only as far as necessary to keep

rolls “hungry”. Don’t over fee rolls and cause an excess building up

of grain in roll pocket between rolls.

Intake Auger Speed

Control Ineffective

1. Hydraulic hoses reversed

at auger motor and/or

tractor.

Switch hoses.

Intake Auger Runs

Backward

1. Hydraulic hoses reversed

at tractor.

Switch hoses.

Excessive Roll Wear 1. Overfeeding with excess

grain continually sliding

off top of rolls creates

friction and excessive roll

wear.

Keep rolls “hungry”. Adjust control gate to feed in only amount of

grain rolls will take away. Usually overfeeding is not the cause for

roll wear on deep-grooved rollers.

2. Crushing abrasive

materials other than

grain.

Mills are designed to be used only on grain or similar textured

materials.

3. Foreign matter, such as

metal, going between

rolls.

We recommend a magnetic trap to remove steel or iron from the

grain.

4. Gravel in grain. Sand and small gravel is difcult to remove from grain because

of similar sizes as grain. Larger gravel and small rocks can be

removed by screening with wire hardware cloth on frame mounted

in hopper.

Heating of PTO 1. Extreme angle of

operation.

Do not operate over 15° out of line.

2. Failure to grease. Manufacturer recommends greasing.

Excess Vibration 1. Overextended PTO Shorten distance between the mill and tractor.

2. Extreme angle of PTO Do not operate over 15° out of line.

3. Uneven ow of grain into

mill.

Eliminate “surging of grain” into mill as much as possible.

4. Excess RPM Recommend operation 900 to 1,000 RPM.

Whole Grain Coming

Through Mill

1. Improper setting of rolls. Rolls should be set closer together to crimp all grain being

processed.

2. Over feeding. Grain control gate opened so wide rolls will not take all grain and

builds up above rolls. This can cause some whole grain to go over

top and not between rolls.

3. Uneven size kernels. This could be reason for a few small, poorly developed whole

kernels going through mill. It is better to not set mill to crack these

if in doing so you would “over-roll” the majority of the kernels.

405-0234 Page 7 of 26 12/13/11

TROUBLE SHOOTING (Continued)

TROUBLE CAUSE REMEDY

Mill is Hard to Start 1. Grain between rolls. When grain is between rolls, separate rolls to allow grain to fall

through or turn rolls backwards and scoop out grain by hand. The

best remedy is to make a practice of closing gate before stopping

mill so no grain is left between rolls.

Grain too Fine or

Dusting of Grain

1. Over rolling. Open control gate to allow more grain to feed into rollers or readjust

spacing of rolls.

2. Rolling mixed grain. If mixed grains of different sizes are run together, to crack or crimp

the small grain, the rolls “over roll” or pulverize larger kernels

in mixed grain. As a general rule, all grains should be rolled

separately and then mixed after rolling.

3. Failure to reset rolls for

different varieties of grain.

Always reset rolls every time a different grain is to be processed.

4. Very dry grain,

particularly when hard.

Open rolls wider than normal to eliminate over-rolling. On extreme

cases, grain can be tempered by sprinkling a small amount of water

over grain to be rolled and let stand 8 to 12 hours. This is generally

done in small holding bin or wagon. The amount of moisture used

depends on dryness of grain.

Belt Breakage or

Slippage

1. Overloading roller mill. Decrease load on roller mill by reducing intake rate.

2. Belts too loose or too

tight.

Tighten as per recommendation.

3. Using new belts and old

belts together.

Always replace with a complete, new matched set.

When ordering parts for your roller mill, please state your needs with the following information:

1. Complete Model Number (sample: ATG-5000 MillAX4)

2. Serial Number

3. Part Number

4. Complete Description of Part Being Ordered

Repair parts can be ordered through your nearest dealer. If there is no dealer in your area, call

Automatic Equipment Manufacturing at (402) 385-3051.

405-0234 Page 8 of 26 12/13/11

TRAILER FRAME ASSEMBLY

5

4

6

1

8

7

2

3

ITEM NO.

PART NUMBER

DESCRIPTION

QTY.

1

61-5388

WLDM'T, TRAIL. FRAME

1

2

61-4924

WLD, AXLE, SILAGE MILL

1

3

102-5593

SHIM, AXLE MOUNT, TRAILER

1

4

229-0120

TRAILER JACK, 54 BLR.

1

5

61-6613

WLDM'T, AUGER BASE, 5000 MILL

1

6

61-3913

WELDMENT, YOKE, PTO HOLDER

1

7

62-1524

HUB & SPINDLE ASSY, MILLS, 6 ON 6

2

8

62-1806

ASSY, 11L15 8 PLY TIRE, 6 BOLT WHL

2

Item No. Part No. Description Qty

1................... 61-5388 ...................Trailer Frame .................................................................................. 1

2................... 61-4924 ...................Silage Mill Axle ............................................................................... 1

3................... 102-5593 .................Trailer Axle Mount Shim ................................................................. 1

4................... 229-0120 .................54” Blower Trailer Jack ................................................................... 1

5................... 61-6613 ...................5000 Mill Auger Base...................................................................... 1

6................... 61-3913 ...................PTO Holder Yoke ............................................................................ 1

7................... 62-1524 ...................6 on 6 Hub and Spindle Assembly.................................................. 2

8................... 62-1806 ...................6 Bolt Wheel/11L15 8 Ply Tire Assembly ........................................ 2

405-0234 Page 9 of 26 12/13/11

INTAKE AUGER COMPONENT ASSEMBLY

12

3

4

5

6

7

8

9

10

1112

13

14

15

16

17

18

ITEM NO.

PART NUMBER

DESCRIPTION

EXPLD/QTY.

1

72-0245

ASSY, LOADING AUGER, 14 INCH

1

2

61-5711

WLDM'T, 14 IN SWIVEL

1

3

255-0060

CLAMP BAND SET, 14"

1

4

207-0837

SHAFT, AUGER CARRIER, 14 IN

1

5

229-0057

COTTER PIN, 1/4 x 2

2

6

61-5666

WLDM'T, LOWER PIVOT BRKT

1

7

61-6700

WLDM'T, PIVOT BRKT, 5000 MILL 1

8

61-6701

WLDM'T, AUG SUPP PIVOT, HYD

ASSIST

1

9

61-5754

WLDM'T, AUGER PIVOT PIN, LWR

1

10

61-6698

LINK ARM, LONG, HYD. ASSIST

1

11

207-0931

PIN, HYD. LIFT ASSIST, 5000 MILL

2

12

227-0062

CYLD. 3" BORE X 8" STROKE

1

13

61-6699

LINK ARM, SHORT, HYD. ASSIST

1

14

227-0077

VALVE, DOUBLE SPOOL, OPEN

CENTER

1

15

61-6703

WLD, TRANS LOCK, 14 INT AUGER

1

16

101-7514

MNT BRKT, HYD VALVE CNTRL

1

17

61-6714

WLDM'T, AUGER TRANS. SUPPORT

MNT

1

18

102-7073

CLAMP, HYD HOSE, 5000 MILL

2

Item No. Part No. Description Qty

1................... 72-0245 ...................14” Loading Auger Assembly .......................................................... 1

2................... 61-5711 ...................14” Swivel ....................................................................................... 1

3................... 255-0060 .................14” Clamp Band Set ....................................................................... 1

4................... 207-0837 .................14” Auger Carrier Shaft................................................................... 1

5................... 229-0057 .................1/4” x 2” Cotter Pin ......................................................................... 2

6................... 61-5666 ...................Lower Pivot Bracket ........................................................................ 1

7................... 61-6700 ...................5000 Mill Pivot Bracket ................................................................... 1

8................... 61-6701 ...................Auger Support Pivot Hydraulic Assist ............................................. 1

9................... 61-6754 ...................Lower Auger Pivot Pin .................................................................... 1

10................. 61-6698 ...................Long Hydraulic Assist Link Arm ...................................................... 1

11 ................. 207-0931 .................5000 Mill Hydraulic Lift Assist Pin ................................................... 2

12................. 227-0062 .................3” Bore x 8” Stroke Cylinder ........................................................... 1

13................. 61-6699 ...................Short Hydraulic Assist Link Arm ...................................................... 1

14................. 227-0077 .................Double Spool Open Center Valve ................................................... 1

15................. 61-6703 ...................14” Intake Auger Transmission Lock .............................................. 1

16................. 101-7514 .................Hydraulic Valve Control Mount Bracket .......................................... 1

17................. 61-6714 ...................Auger Transmission Support Mount ............................................... 1

18................. 102-7073 .................5000 Mill Hydraulic Hose Clamp .................................................... 2

405-0234 Page 10 of 26 12/13/11

FRONT SHIELD AND BELT ASSEMBLY

1

2

3

4

7

5

6

ITEM NO.

PART NUMBER

DESCRIPTION

EXP./QTY.

1

251-0164

BELT, POLYCHAIN, 14MGT-1400-37 1

2

251-0160

BELT, TP3500-14M-115 DS COG

1

3

101-7499

REAR FILLER PLATE, FRONT SHIELD,

5000 MILL

1

4

61-6695

WLDM'T, FRONT SHIELD, 5000 MILL

1

5

61-6704

WLDM'T, DOOR, FRNT SHLD, 5000

MILL

1

6

61-1543

SHIELD, PTO, WELDM'T FR CHAIN DR

1

7

229-0132

LATCH, TENSION

3

Item No. Part No. Description Qty

1................... 251-0164 .................14MGT-1400-37 Polychain Belt...................................................... 1

2................... 251-0160 .................TP3500-14M-115 DS COG Belt ..................................................... 1

3................... 101-7499 .................5000 Mill Front Shield Rear Filler Plate .......................................... 1

4................... 61-6695 ...................5000 Mill Front Shield ..................................................................... 1

5................... 61-6704 ...................5000 Mill Front Shield Door ............................................................ 1

6................... 61-1543 ...................Front Chain Drive PTO Shield ........................................................ 1

7................... 229-0132 .................Tension Latch ................................................................................. 3

405-0234 Page 11 of 26 12/13/11

ASSEMBLY FOR ROLL ADJUSTMENT

1

2

3

4

56

7

8

9

7

10

11

12

13

14

15

ITEM NO.

PART NUMBER

DESCRIPTION

EXPLODED/Q

TY.

1

222-0048

SPRING, COMPRESSION, 3" X 4 7/8"

2

2

107-2457

TUBE, SPRING SPACER

2

3

100-1267

ROCKER, CAM ADJUST

4

4

61-5631

WLDM'T, BRG SUPP PIVOT, BASIC

2

5

62-1494

BRG-ZERK ASSY. 2-15/16 P.B.

4

6

61-4550

WELDMENT, CAM ADJUST ARM

2

7

224-0425

ZERK, STRAIGHT, 1/4-28, SELF-TAP

4

8

101-5351

PLATE, ADJUSTMENT, LEFT

1

9

61-5702

WLDM'T, JOURNAL, CAM ADJ. FRONT

1

10

61-5670

WELDMENT CAM ADJUST

1

11

101-5296

GATE LOCK, HOPPER

2

12

61-4554

WELDMENT, HANDLE CAM ADJUST

2

13

61-5703

WLDM'T, JOURNAL, CAM ADJ. REAR

1

14

101-5350

PLATE, ADJUSTMENT, RIGHT

1

15

202-0081

1-8 HEX NUT, GRADE 8

8

Item No. Part No. Description Qty

1................... 222-0048 .................3” x 4-7/8” Compression Spring...................................................... 2

2................... 107-2457 .................Spring Spacer Tube ........................................................................ 2

3................... 100-1267 .................Cam Adjust Rocker ......................................................................... 2

4................... 61-5631 ...................Basic Bearing Support Pivot ........................................................... 2

5................... 62-1494 ...................2-15/16” PB Bearing-Zerk Assembly .............................................. 4

6................... 61-4550 ...................Cam Adjust Arm .............................................................................. 2

7................... 224-0425 .................1/4”-28 Straight Self Tapping Zerk .................................................. 4

8................... 101-5351 .................Left Adjustment Plate...................................................................... 1

9................... 61-5702 ...................Front Cam Adjust Journal ............................................................... 1

10................. 61-5670 ...................Cam Adjust ..................................................................................... 1

11 ................. 101-5296 .................Hopper Gate Lock .......................................................................... 2

12................. 61-4554 ...................Cam Adjust Handle ......................................................................... 2

13................. 61-5703 ...................Rear Cam Adjust Journal................................................................ 1

14................. 101-5350 .................Right Adjustment Plate ................................................................... 1

15................. 202-0081 .................1”-8 Hex Nut, Grade 8 .................................................................... 8

405-0234 Page 12 of 26 12/13/11

1

2

3

4

5

6

7

8

9

10

111213

14

ITEM NO.

PART NUMBER

DESCRIPTION

EXPLODED./QTY.

1

71-0661

ROLL, ID, 5000, SPL, 2.9375

1

2

71-0656

ROLL, DR, 5000, SPL, 2.9375

1

3

61-5630

WLDM'T, ROLL COVER, BASIC, 5000

2

4

150-0051

BELTING, ROLL BAFFLE

2

5

102-6123

FLAT, BAFFLE SUPPORT

2

6

101-6195

WEAR PLATE, 10 GA. 2

7

62-1494

BRG-ZERK ASSY. 2-15/16 P.B.

4

8

102-6150

FLAT, BRG. STOP

2

9

107-1895 SLEEVE, SHAFT, IDLER

1

10

61-4549

IDLER ARM, PIVOT, BELT DRIVE

1

11

61-5638

WLDM'T, FRAME, BASIC, 5000

1

12

61-6860

WLDM'T, IDLER BRKT, 5000

1

13

61-6862

WLDM'T, SHAFT, IDLER SUPPORT, 5000

1

14

61-6690

WLDM'T, IDLER TIGHTNER MNT

1

ASSEMBLY FOR ROLL ADJUSTMENT

Item No. Part No. Description Qty

1................... 71-0661 ...................5000 Mill Idler Roll .......................................................................... 1

2................... 71-0656 ...................5000 Mill Drive Roll ......................................................................... 1

3................... 61-5630 ...................5000 Mill Basic Roll Cover .............................................................. 2

4................... 150-0051 .................Roll Bafe Belting ........................................................................... 2

5................... 102-6123 .................Bafe Support Flat .......................................................................... 2

6................... 101-6195 .................Wear Plate ...................................................................................... 2

7................... 62-1494 ...................2-15/16” PB Zerk-Bearing Assembly .............................................. 4

8................... 102-6150 .................Bearing Stop ................................................................................... 2

9................... 107-1895 .................Idler Shaft Sleeve ........................................................................... 1

10................. 61-4549 ...................Belt Drive Idler Arm Pivot ................................................................ 1

11 ................. 61-5638 ...................5000 Mill Basic Frame .................................................................... 1

12................. 61-6860 ...................5000 Mill Idler Bracket .................................................................... 1

13................. 61-6862 ...................5000 Mill Idler Support Shaft .......................................................... 1

14................. 61-6690 ...................Idler Tightener Mount...................................................................... 1

405-0234 Page 13 of 26 12/13/11

COMMON MILL ASSEMBLY

3

2

1

ITEM NO.

PART NUMBER

DESCRIPTION

QTY.

1

62-3698

ASS'Y, TRLR W/ AUGER BASE,

ATG5000

1

2

93-0594

5000 BASIC, 4 CUT

1

3

72-0246 ASSY, HOPPER, 5000

1

Item No. Part No. Description Qty

1................... 62-3698 ...................5000 Mill Trailer with Auger Base ................................................... 1

2................... 93-0594 ...................4 Cut 5000 Mill Basic ...................................................................... 1

3................... 72-0246 ...................5000 Mill Hopper Assembly ............................................................ 1

405-0234 Page 14 of 26 12/13/11

DISCHARGE ASSEMBLY

1

23

4

5

6

78

9

10

11 12

ITEM NO.

PART NUMBER

DESCRIPTION

exploded-1/QTY.

1

61-6719

WLDM'T, A B SCREW, 5000 AUG DISC

1

2

61-6718

WLDM'T, 14" AUGER FLIPPER

2

3

62-3700

14 IN. DISCHARGE AUGER ASSY, 9 FT

1

4

63-3692

DISC. AUG. SPOUT KIT, 14

1

5

102-7048

MNT, AUGER TRANS. SUPPORT

1

6

106-0376

PIPE, DISCH. AUGER RACK SUPPORT

2

7

61-6710

WLDM'T, AUGER TRANS. HOPPER MNT

1

8

61-6706

WLDM'T, AUGER TRANS. SUPPORT

1

9

106-0374

PIPE, SHRT, AUGER TRANS. SUPPORT

1

10

106-0375

PIPE, LNG, AUGER TRANS. SUPPORT

1

11

229-0520

PIN, 1/2 x 2-5/8 EFF.

2

12

62-3213

QUICK- PIN

2

Item No. Part No. Description Qty

1................... 61-6719 ...................5000 Mill Auger Discharge A B Screw ............................................ 1

2................... 61-6718 ...................14” Auger Flipper ............................................................................ 2

3................... 62-3700 ...................9’ Discharge Auger Assembly ......................................................... 1

4................... 63-3692 ...................14” Discharge Auger Spout Kit ....................................................... 1

5................... 102-7048 .................Auger Transmission Support Mount ............................................... 1

6................... 106-0376 .................Discharge Auger Rack Support ...................................................... 2

7................... 61-6710 ...................Hopper Mount Auger Transmission ................................................ 1

8................... 61-6706 ...................Auger Transmission Support .......................................................... 1

9................... 106-0374 .................Short Auger Tranmission Support................................................... 1

10................. 106-0375 .................Long Auger Transmission Support ................................................. 1

11 ................. 229-0520 .................1/2” x 2-5/8” Eff. Pin ........................................................................ 2

12................. 62-3213 ...................Quick Pin ........................................................................................ 2

405-0234 Page 15 of 26 12/13/11

DISCHARGE SUPPORT ASSEMBLY

1 2

3

4

5

6

ITEM NO.

PART NUMBER

DESCRIPTION

exploded./QTY.

1

61-6686

WLDM'T, SHLD, REAR 5000

1

2

101-7463

PLATE, TOP, AUGER BASE TROUGH

EXT.

1

3

61-6677

WLDM'T, RACK SUPPORT, 5000 MILL

1

4

101-7505

SHEET, AUGER SUPPORT BRACE, 5000

MILL

1

5

61-6676

RACK, DISCHARGE AUGER, 5000

MILL

1

6

101-2306

COVER, CLEAN OUT DOOR

2

Item No. Part No. Description Qty

1................... 61-6686 ...................5000 Mill Rear Shield ..................................................................... 1

2................... 101-7463 .................Auger Base Trough Extension Top ................................................. 1

3................... 61-6677 ...................5000 Mill Rack Support .................................................................. 1

4................... 101-7505 .................5000 Mill Auger Support Brace ....................................................... 1

5................... 61-6676 ...................5000 Mill Discharge Auger Rack .................................................... 1

6................... 101-2306 .................Clean Out Door Cover .................................................................... 2

405-0234 Page 16 of 26 12/13/11

9

01

3

8

1

4

7

6

5

71

8

2

11

51

61

41

3121

DISCHARGE SUPPORT ASSEMBLY

Item No. Part No. Description Qty

1................... 61-6666 ...................14” Discharge Tube ........................................................................ 1

2................... 61-6638 ...................12”-14” Discharge Elbow ................................................................ 1

3................... 61-6668 ...................14” Discharge Auger ....................................................................... 1

4................... 61-6673 ...................14” Discharge Auger Screw ............................................................ 1

5................... 61-1890 ...................Capped Driven End Adapter ........................................................... 1

6................... 105-0942 .................Gearbox Support ............................................................................ 1

7................... 225-0041 .................12” Clamp Band Set ....................................................................... 1

8................... 255-0060 .................14” Clamp Band Set ....................................................................... 2

9................... 211-0023 .................1” Flangette Housing ...................................................................... 2

10................. 209-0032 .................1” Flangette Bearing Insert ............................................................. 1

11 ................. 224-0694 .................1/2” NPTF Vent Plug ....................................................................... 1

12................. 224-0316 .................3/8” x 3” Nipple ............................................................................... 1

13................. 224-0570 .................3/8” NPT x 45° Street Elbow ........................................................... 1

14................. 224-0696 .................3/8” NPT x 1/2” Hose Barb ............................................................. 1

15................. 224-0695 .................1/2” x 1/2” Hose Barb ..................................................................... 1

16................. 253-0257 .................11” 1/2” OD Clear Plastic Hose ...................................................... 1

17................. 228-0011 .................Discharge Auger Gearbox .............................................................. 1

405-0234 Page 17 of 26 12/13/11

1

2

3

4

5

6

7

8

9

10

11

12

13

14

12

15

11

ITEM NO.

PART NUMBER

DESCRIPTION exploded.../QTY.

1

227-0116

HYD. MTR, 4 BOLT, PRKR, TB0195FP

1

2

229-0032

SHAFT COUPLER, I BORE

1

3

207-0922

SHAFT, WORM GEAR, 5000 MILL

1

4

204-0200

WORM, DISCH. AUGER, 5000 MILL

1

5

107-3161

TUBE, SPACER, WORM GEAR, 5000

MILL

1

6

209-0083

BEARING INSERT, 3/4 FLANGETTE

2

7

207-0927

BUSHING, END CAP, HYD MTR, 5000 1

8

207-0923

END CAP, HYD. MTR DH, 5000 MILL

1

9

61-6679

WLDM'T, DISCH. AUGER DOG

HOUSE, 5000 MILL

1

10

224-0425

ZERK, STRAIGHT, 1/4-28, SELF-TAP

1

11

229-0220

RETAINING RING, EXTERNAL, 3/4

2

12

207-0925

BUSHING, GEAR SHAFT, DISCH

AUG.,5000

2

13

61-6681

WLDM'T, GEAR SHAFT, 5000 MILL

1

14

100-1294

WORM GEAR, DISCH. AUGER,

MACH.

1

15

207-0926

GEAR SHAFT AXLE, DISCH. AUGER,

5000 1

DISCHARGE AUGER MOTOR ASSEMBLY

Item No. Part No. Description Qty

1................... 227-0116 .................Parker TB0195FP 4 Bolt Hydraulic Motor ...................................... 1

2................... 229-0032 .................1” Bore Shaft Coupler ..................................................................... 1

3................... 207-0922 .................5000 Mill Worm Gear Shaft ............................................................ 1

4................... 204-0200 .................5000 Mill Discharge Auger Worm ................................................... 1

5................... 107-3161 .................5000 Mill Worm Gear Spacer Tube ................................................ 1

6................... 209-0083 .................3/4” Flangette Bearing Insert .......................................................... 2

7................... 207-0927 .................5000 Mill Hydraulic Motor Bushing End Cap .................................. 1

8................... 207-0923 .................5000 Mill Hydraulic Motor Doghouse End Cap............................... 1

9................... 61-6679 ...................Discharge Auger Doghouse............................................................ 1

10................. 224-0425 .................1/4”-28 Self Tapping Straight Zerk .................................................. 1

11 ................. 229-0220 .................3/4” External Retaining Ring........................................................... 2

12................. 207-0925 .................5000 Mill Discharge Auger Gear Shaft Bushing ............................. 2

13................. 61-6681 ...................5000 Mill Gear Shaft ....................................................................... 1

14................. 100-1294 .................Machined Discharge Auger Worm Gear ......................................... 1

15................. 207-0926 .................5000 Mill Discharge Auger Gear Shaft Axle ................................... 1

405-0234 Page 18 of 26 12/13/11

DISCHARGE AUGER ASSEMBLY

1

2

3

4

56

78

ITEM NO.

PART NUMBER

DESCRIPTION

exploded../QTY.

1

101-7472

CLAMP, 14" TUBE

1

2

101-7478

PLATE, DISCH AUGER SUPPORT, 5000

MILL

2

3

61-6678

CLAMP, GUIDE END, 5000 MILL

1

4

206-0169

CHAIN 50X103 PITCH INCL 2 CONN

1

5

209-0083

BEARING INSERT, 3/4 FLANGETTE

4

6

107-3162

TUBE, 1 1/8OD X .781ID X 1 1/2"

2

7

102-1430

BRACKET, CHAIN, RACK, LT.

1

8

100-0529

ROD, THREADED, CHAIN SNUGGER

2

Item No. Part No. Description Qty

1................... 101-7472 .................14” Tube Clamp .............................................................................. 1

2................... 101-7478 .................5000 Mill Discharge Auger Support ................................................ 2

3................... 61-6678 ...................5000 Mill Guide End Clamp ............................................................ 1

4................... 206-0169 .................50 x 103 Pitch Chain with 2 Connections ....................................... 1

5................... 209-0083 .................3/4” Flangette Bearing Insert .......................................................... 4

6................... 107-3162 .................1-1/8” OD x .781 ID x 1-1/2” Tube .................................................. 2

7................... 102-1430 .................Left Chain Rack Bracket ................................................................. 1

8................... 100-0529 .................Chain Snugger Threaded Rod ........................................................ 2

405-0234 Page 19 of 26 12/13/11

TIGHTNER ASSEMBLY

1

6

2

3

4

5

ITEM NO.

PART NUMBER

DESCRIPTION

EXP.../QTY.

1

61-1968

SPRING CENTER

1

2

61-5742

WLDM'T, SPRING TIGHTNER BRKT

1

3

61-1863

TAKE UP ROD, IDLER, ROLL DR.

1

4

101-7835

Z BRKT, FRONT SHIELD, 5000 MILL

1

5

101-7834

L BRKT, FRONT SHIELD, 5000 MILL

1

6

222-0078

SPRING, COMP, MILL

1

Item No. Part No. Description Qty

1................... 61-1968 ...................Spring Center ................................................................................. 1

2................... 61-5742 ...................Spring Tightner Bracket .................................................................. 1

3................... 61-1863 ...................Roll Drive Idler Take Up Rod .......................................................... 1

4................... 101-7835 .................5000 Mill Front Shield Z Bracket .................................................... 1

5................... 101-7834 .................5000 Mill Front Shield L Bracket ..................................................... 1

6................... 222-0078 .................4-1/2” - 4-5/8” Compression Spring ................................................ 1

405-0234 Page 20 of 26 12/13/11

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

ITEM NO.

PART NUMBER

DESCRIPTION

QTY.

1

61-5712

WLDM'T, LOADING AUG SCREW, 14"

1

2

101-6265

CLAMP, HOPPER MNT

2

3

61-5713

WLDM'T, LOADING AUGER, 14 IN

1

4

53-0001

1 3/8 FLANGE BEARING

2

5

61-5717

WLDM'T., MTR MNT

1

6

229-0032

SHAFT COUPLER, I BORE

1

7

101-6568

PLATE, SPACER, HYD MOTOR

1

8

227-0099

HYD MTR, LG FRAME,

MO210C01J00A0

1

9

101-6295

FRONT, INTAKE HOPPER, 14 AUGER

1

10

61-5749

WLD, INTAKE ASSIST, 14 AUGER

1

11

101-6292

SIDE, RIGHT, INTAKE HOPPER, 14

AUGER

1

12

101-6294

REAR, INTAKE HOPPER, 14 AUGER

1

13

102-6238

HANDLE, HOPPER LIFT

1

14

225-0008

1/2 EMT SNAP STRAP

4

15

101-6291

SIDE, RIGHT, INTAKE HOPPER, 14

AUGER

1

16

61-5771

GRATE, 14 INTAKE AUGER

1

17

61-5748

WLD, BASE, INTAKE HOPPER, 14

AUGER

1

LOADING AUGER SCREW ASSEMBLY

Item No. Part No. Description Qty

1................... 61-5712 ...................14” Loading Auger Screw ............................................................... 1

2................... 101-6265 .................Hopper Mount Clamp ..................................................................... 2

3................... 61-5713 ...................14” Loading Auger .......................................................................... 1

4................... 53-0001 ...................1-3/8” Flange Bearing ..................................................................... 2

5................... 61-5717 ...................Motor Mount ................................................................................... 1

6................... 229-0032 .................1” Bore Shaft Coupler ..................................................................... 1

7................... 101-6568 .................Hydraulic Motor Spacer Plate ......................................................... 1

8................... 227-0099 .................Large Frame MO210C01J00A0 Hydraulic Motor ........................... 1

9................... 101-6295 .................14” Intake Hopper Front ................................................................. 1

10................. 61-5749 ...................14” Intake Assist ............................................................................. 1

11 ................. 101-6292 .................14” Auger Right Side Intake Hopper ............................................... 1

12................. 101-6294 .................14” Rear Intake Hopper .................................................................. 1

13................. 102-6238 .................Hopper Lift Handle.......................................................................... 1

14................. 225-0008 .................1/2” EMT Snap Strap ...................................................................... 4

15................. 101-6291 .................14” Auger Left Side Intake Hopper ................................................. 1

16................. 61-5771 ...................14” Intake Auger Grate ................................................................... 1

17................. 61-5748 ...................14” Auger Intake Hopper Base ....................................................... 1

Table of contents

Other Automatic Power Tools manuals

Popular Power Tools manuals by other brands

Munsch

Munsch MEK-18-S operating instructions

Gage Bilt

Gage Bilt GB2628 Original instruction

BRADLEY MOWERS

BRADLEY MOWERS S105 Owner's manual and parts list

Numberall

Numberall 136A user manual

Jefferson Professional Tools & Equipment

Jefferson Professional Tools & Equipment JEFPDB0750-12S user manual

Festool

Festool Trion PS-300Q Original operating manual and Spare parts list